Professional Documents

Culture Documents

Wilson Air Compressor 3A-450

Uploaded by

elsalseritoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wilson Air Compressor 3A-450

Uploaded by

elsalseritoCopyright:

Available Formats

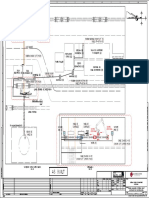

SM-97 SM-97

SPECIFICATIONS

Model no. 3A-450 3A-750 3A-1000

38640-0450 38640-0750 38640-1000

Free Speed (RPM)

450 750 1000

Min. Torque Ft-Lb

3 3 3

Max. Torque Ft-Lb

18 12 10 Torq-Air-Matic

ڤModel 3A-450 (450RPM)

Air Pressure psi ڤModel 3A-750 (750RPM)

90

ڤModel 3A-1000 (1000RPM)

Air Inlet 3/8” NPT

Hose

3/8” I.D.

Air Flow @Free

32 CFM

Speed

Spindle

1/2” Dia. with 2 spots

OPERATING INSTRUCTIONS &

SERVICE MANUAL

TO REDUCE THE RISK OF INJURY, USER MUST READ AND

UNDERSTAND OPERATOR’S MANUAL.

Thomas C. Wilson, Inc. Thomas C. Wilson, Inc.

21-11 44th Avenue, Long Island City, New York 11101 21-11 44th Avenue, Long Island City, New York 11101

Tel: (718)729-3360 Fax: (718)361-2872 http://www.tcwilson.com Tel: (718)729-3360 Fax: (718)361-2872 http://www.tcwilson.com

16 Email: tcwilson@tcwilson.com Email: tcwilson@tcwilson.com

More user manuals on ManualsBase.com

SM-97 SM-97

SAFETY INSTRUCTIONS TROUBLE-SHOOTING (Cont’)

PROBLEM CAUSE & SOLUTION

! WARNING! Torque control will 1. Broken latch release pawl

READ AND UNDERSTAND ALL INSTRUCTIONS not release at torque —Replace–see pg. 8, (Pc. #36, pg. 11).

Failure to follow all instructions listed below, may result setting

in accident, fire and/or personal injury.

2. Broken torque spring

SAVE THESE INSTRUCTIONS —Replace–see pg. 8, (Pc. #5, pg. 11).

3. Broken latch

—Replace–see pg. 8, (Pc. #34, pg. 11).

1. Do not allow corrosive gases or foreign material to enter

4. Broken or excessive wear on tips of all pawls

the unit. Moisture, oil-based contaminants, or other liquids —Replace-see pg8(Pc29,36,40&42, pg.11).

must be filtered out.

5. Broken spring ends or anchor pins of latch

pawls and reverse pawl

2. Eye protection is always required when running motor. —Replace–see pg.8, (Springs & pins, pg. 11).

6. Reaction member seized to int. gear assembly

3. Hearing protection is recommended when in close prox- —Consult factory

imity to all operating air motors. 7. Broken or short roll pin stop on reaction

member. Check for scoring on stop plate sec-

4. Dust mask, non-skid safety shoes, hard hat, gloves and tion of handle connector

other personal safety equipment must be used. —Replace–see pg. 7, (Pc. #32, pg. 11).

8. Ball retainer has broken or lost any balls.

5. Stay alert, watch what you are doing, and use common Check correct assembly of retainers.

sense when operating a power tool. —Replace–see pg. 9, (Pc. #43, pg. 11).

Torque control will 1. Broken latch or latch spring

6. Dress properly. Do not wear loose clothing or jewelry. not relatch in re- —Replace–see pg. 8, (Pc. #28,34, pg. 11).

verse 2. Broken reverse pawls, springs or anchor pin

—Replace–see pg.8 (Pc#39,40,41,42, pg.11).

7. Keep your work area clean and well lit. 3. Slot radii on internal gear oversized/gouged

—Replace internal gear (Pc. #10, pg. 11)

8. Do not operate power tools in explosive atmospheres, such 4. Insufficient torque on drive spindle end

as in the presence of flammable liquids, gases, or dust. —See note on pg.5. Hold spindle end in vise

and manually turn TAM ccw; should relatch.

5. Excessive burrs or wear on internal gears pre-

9. Disconnect the tool from the air supply before installing,

venting free rotation

making any adjustment, changing accessories, servicing or —Debur/replace–see pg. 7,(Pc. #10, pg. 11).

storing tool. Caution: Disassembly or reassembly of torque control unit must be

2 performed by qualified personnel. It is advisable to return torque 15

control units to the factory or consult the factory for necessary repair.

More user manuals on ManualsBase.com

SM-97 SM-97

TROUBLE-SHOOTING GUIDELINES FOR TUBE EXPANSION

PROBLEM CAUSE & REMEDY Improperly rolled joints create additional expense to correct, whether

they are under-rolled and can be corrected merely by rerolling, or

Motor will not run. 1. Inefficient air supply over-rolled and require removal and replacement. The optimal joint is

—Check 90 psi and 32 CFM air supply. one that develops a leak tight joint with adequate strength for the ser-

2. Clogged air inlet screen vice intended with the minimum amount of cold working or reduction

—Replace-see pg.6(pc #75, pg.13). of the tube wall. Experience indicates that joints of this type are ob-

tainable with non-ferrous tubes in surface condensers by expanding

3. Broken or severely worn rotor blades to a wall reduction of 3% to 4% after metal to metal contact of the

—Replace-see pg.6(pc #69, pg.13). tube 0.D. with the tube sheet hole. Steel tubes in heat exchangers

4. Rust due to improper storage of tool may require wall

—Disassemble and clean– Refer to Dis- reductions of 5% to 10%; soft copper and aluminum tubes in heat ex-

assembly procedure. changers also require larger wall reductions in the area of 8% to 12%.

Boiler tubes requiring development of optimum joint strength require

5. Broken throttle valve pin or lever wall reductions of 12% to 14%.

—Replace–see pg.6(pc. #78/80, pg. 13). A typical example of the application of this method is indicated for a

Motor will not reach 1. Insufficient air volume 3/4” x 18 ga. tube in a condenser.

RPM. —Check 32 CFM supply.

2. Dirty air inlet screen

Tube Expansion Calculations

—Clean –see pg. 6 (pc.#75, pg.13). Tube Sheet Hole Dia. .760

3. Worn rotor blades - Tube O.D. -.750

—Replace-see pg.6(pc #69, pg.13). = Clearance =.010

4. Air supply hose chocked or too small + Tube I.D. +.652

—See Operating Procedure recom- =I.D. @ Metal to Metal =.662

+4%Reduction (.049x.04x2) +.004

mended hose. =Expanded I.D. =.666

Motor stalls at high 1. Insufficient air pressure

torque —Check 90 psi supply

2. Dirty air inlet screen

—Clean –see pg. 6 (pc.#75, pg.13).

3. Rotor blades worn, chipped or broken

—Replace-see pg.6(pc #69, pg.13). OPERATION

Motor fails to stop 1. Broken throttle valve spring RECOMMENDED OPERATING AIR PRESSURE 90 PSI

—Replace-see pg.6(pc #76, pg.13).

2. Valve ball does not seal 1. Make sure there is an adequate supply of clean air of 90

—Replace or rework valve seat-Refer to psi lubricated with light machine oil of SAE 10 viscosity.

pg. 6 (pc.#77, pg.13) This should be done before all long runs of tube expanding

and after every four hours of continuous use unless an air

line lubricator of ample capacity is used. SEE

’LUBRICATION’ SECTION BELOW.

14 3

More user manuals on ManualsBase.com

SM-97 PARTS LIST (Cont’) SM-97

OPERATION (Cont’)

2. Loosen the four hexagon socket set screws at rear of con-

trol housing 1/2 to 3/4 turn and rotate index mark on housing

to desired torque. Tighten all four screws. See paragraph enti-

tled “Calculating the Expansion Required”.

To avoid the possibility of over-rolling, it is best to make

the trial setting low and work up to the desired setting, a re-

cord of which should be kept for future use.

3. The clamp-on handle (Part No. 24305) can be swiveled to the

position most convenient for the operator. Its use is optional

but recommended for any job requiring more than three foot-

pounds torque.

4. Always blow out air hose thoroughly before attaching it to

throttle valve cap which takes the 3/8” pipe coupling of 3/8”

hose assembly supplied (No. 50007). Always use a 3/8” I.D. or

larger air line when maximum power is desired and be sure that

air pressure at the tool is at least 90 psi gauge.

5. The exhaust deflector can be rotated to deflect exhaust air

in the most convenient direction.

6. Select required snap-on mandrel drive and attach it to tool

spindle nose. Be sure to align detents within it with drilled

spots on spindle nose. (Instructions for releasing detents are

stamped on mandrel drive sleeves.)

7. Adjust Thrust Collar on expander and attach mandrel to

snap-on mandrel drive by engag-ing detent and circular groove

on mandrel’s square shank.

4 13

More user manuals on ManualsBase.com

SM-97 SM-97

PARTS LIST (Cont’) OPERATION (Cont’)

Key Description 3A- 3A- 3A- Key Description 3A- 3A- 3A- 8. Insert expander in tube as required.

1000 750 450 1000 0750 0450

Motor & Spindle As- 38649 38649 38649 77 Valve Ball 2629 2629 2629 9. Completely depress throttle valve trigger lever to find

sembly -1000 -0750 -0450 forward speed. When preset torque has been reached, drive will

78 Valve Pin 51540 51540 51540

Intermed Spindle Ass’y 51143 51142 51141

dis-engage and mandrel will stop rotating; release throttle

(Keys 55 thru 61) 79 Lever Pin 28215 28215 28215 valve lever when this occurs.

55 Intermediate Spindle 51123 51122 51121 80 Throttle Valve Lever 53501 53501 53501

10.Fully squeeze reverse valve trigger into reverse position

56 Planet Pin (2) 24512 24512 24512 82 Trigger Pin 28215 28215 28215

(depressed). Valve locks in this position and only releases when

57 Planet Gear (2) 51102 24321 51105 84 Throttle Valve trigger 51563 51563 51563 throttle valve trigger lever is released. Depress throttle valve

85 Reversing Valve 51544 51544 51544

trigger lever to reverse drive and back expander out of tube.

58 Needle Roller (2 Sets) 24354 24354 24354

Trigger

59 Roller retainer (2 Sets) 24355 24355 24355 Note: There must be a positive resistance to turning on the tool

86 Trigger Spring 52635 52635 52635

60 Retainer Washer 51118 51118 51118 spindle of 5-6 inch— pounds in the reverse direction before

87 Drive Screw (2) 6896 6896 6896 drive will reengage and set latching pawls for rotation in the

61 Rear Drive Ball Bearing 24525 24525 24525 forward direction.

88 Nameplate 38635 38635 38635

Air Motor Assembly 53581 53581 53581

89 Retaining Ring 53560 53560 53560

(Keys 62 thru 69) -0001 -0002 -0003 11. Measure tube’s actual inside diameter. If the amount of ex-

90 Gasket 51229 51229 51229

62 Rotor 51133 51132 51131 pansion is not sufficient, adjust torque control to a slightly

91 Rear Plug 21994 21994 21994 higher value and roll the next tube.

63 Adapter Ring 52497 52497 52497

92 Rear Motor Bearing 21944 21944 21944

64 Bearing Separator 51191 51191 51191 12. When desired expansion has been attained, maintain the set-

93 Rear End Plate 51532 51532 51532 ting and roll the entire lot. Reroll all trial tubes which were

65 Front Motor Bearing 51361 51361 51361

94 Roll Pin 51474 51474 51474 not completely expanded.

66 Front Plate 50809 50809 50809

95 Seal Ring 28187 28187 28187

67 Front Bearing Spacer 51135 51135 51135 13. Always record settings used and tube data such as tube 0.D.

96 Exhaust Muffler Assy 53840 53840 53840 and gauge with tube sheet thickness for future reference.

68 Cylinder 51225 51225 51225

Dead Handle 24305

69 Rotor Blade (Set of 4) 51139 51139 51139

Hex. Key 5/16 52147

Motor Housing Ass’y 53579 53579 53579

Key70thru86,90,93&94 Hex. Key 1/8 52144

70 Motor Housing 53580 53580 53580 Hex. Key 3/16 51254

LUBRICATION

Amount of oil used will vary with tool usage but daily filling

74 Throttle Valve Cap 42872 42872 42872 of handle oil reservoir should normally be adequate. Check that

75 Air Screen 51179 51179 51179 a fine mist of oil is always present in the air which passes

out through exhaust deflector holes. For continuous and heavy

76 Throttle Valve Spring 51541 51541 51541 tool usage, it is preferable to use an automatic air line lu-

bri-cator. For this purpose, the Wilson Air Filter-Lubricator

Unit (Cat. #8596 for 3/8” lines) is recommended. This unit com-

bines an automatic lubricator with an efficient air filter.

Caution: To inhibit rust during tool storage be sure a liberal

amount of oil has been introduced into valve and air motor.

Also be sure operat-ing air moisture content is kept at a mini-

mum. Compressor after coolers, air line traps, water separators

and use of rust-inhibiting lubricat-ing oil all help. Thor-

oughly clean or replace any rusted parts found during service

checks.

12 5

More user manuals on ManualsBase.com

SM-97 SM-97

MAINTENANCE & SERVICING PARTS LIST (Cont’)

Air Tools should be handled with reasonable care when servic-

ing. It is important that the correct tools and fixtures are used

when servicing this Air Tool. Order replacement parts by part

number, model and serial number of tool. To maintain Torq-Air-

Matic efficiency, periodic checks should be made of the follow-

ing:

Rotor Blades - Generally these are the only parts requiring

replacement after long service. Always replace the rotor blades

in a set of 4 only, whenever they are broken or cylinder edge is

gouged, worn uneven or worn down 1/16". This would cause the

blade edges to be 1/16" below top of its slot in rotor drum.

Cylinder and Rear End Plate - Replacement is required only if

part is broken or rubbing surfaces are gouged.

Ball Bearing - normally these ball bearings should not require

additional lubrication during tool life. However, whenever tube

roller is disassembled for servicing, the motor ball bearings

should be lubricated with light oil (SAE #10) while the drive

ball bearings should receive a small amount of bearing grease.

All ball bearings should turn smoothly and freely with no notice-

able looseness. There should be a snub fit with no shake both in 50

their housings and on their shafts. However, the front motor ball

bearing is a mild press fit on its rotor shaft.

Note: Dirty or gummed up ball bearings should be cleaned in

kerosene and flushed with clean light oil (SAE No. 10). DO NOT

USE AN AIR BLAST. After flushing, re-lubricate as specified. Be

sure both plastic seals are properly replaced on front drive ball

bearing.

Intermediate Spindle Assembly and Drive Spindle Assembly - Do

not disassemble planet gears from their spindles unless the gears

do not move freely about their planet pins. Be careful not to

lose any one of the nine needle rollers assembled within each

planet gear. Lubricate planet gear and needle rollers with a good

bearing grease only.

Caution: Note position of planet pin milled step in relation to

steel retaining ring or turned step on drive spindle on assembly

drawing before reassembling either spindle.

Air Screen - Throttle valve air screen assembly should be

cleaned by reverse flushing when necessary. Before reassembly

note on drawing that air screen cylinder is assembled within the

throttle valve cap. Also when reassembling be sure small end of

conical throttle valve spring rests against the 3/8" diameter

hardened steel ball. Be sure air screen flange comes to rest cor-

rectly within its counter-bore in steel seat insert.

6 11

More user manuals on ManualsBase.com

SM-97 SM-97

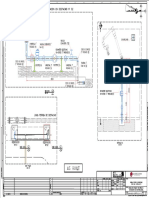

PARTS LIST DISASSEMBLY

Key Description 3A- 3A- 3A- Key Description 3A- 3A- 3A-

The following instructions should be studied carefully before

1000 750 450 1000 0750 0450

attempting disassembly of Model ‘3A’ Torq-Air—Matic. In most

Torque Control Ass’y 38641 38641 38641 26 Reaction Member 24907 cases, the major difficulty encountered has been caused by im-

-1000 -0750 -0450 proper disassembly and reassembly procedures.

27 Retainer 28096

1 Retainer (2) 24317

28 Latch Spring 24913

2 Spirolox Ring 34262

Torque control disassembly procedure

29 Latch Return Pawl 24911 If air motor has been operating properly, do not remove it from

3 Front Bearing 28069 torque control section at this time, but proceed as outlined. The

30 Return Pawl Spring 24912

steps to be followed have been grouped. Steps within a group may

4 Control Housing Ass’y 40024 40024 40024

-1000 -0750 -0450 31 Latch Pin 24333 be performed in any sequence. The groups, however, cannot and

must not be per-formed out of sequence. All steps within a group

5 Main Spring 24307 32 Roll Pin (2) 25177

must be completed before proceeding to the following group. Refer

6 Main Spring Anchor 24318 33 Roll Pin 24908 to assembly drawing on Page 11.

7 Button Head Screw (2) 24319 34 Latch 24910

Group no.1

8 Lock Washer (2) 28106 35 Latch Release Spring 24331 (A) Unscrew and remove both spring anchor button head screws. Use

36 Latch Release Pawl 24323 3/16” hexagon key supplied.

9 Main Spring Pin 24313

(B) (B) Unscrew all four torque setting set screws halfway out at

10 Internal Gear 38658 38657 38658 37 Latch Release Pin (2) 24330 rear of control housing. Use 1/8” hexagon key supplied.

38 Dowel Pin 24298 (C) Remove outside bearing shaft retainer ring (Piece No.1).

11 Drive Spindle 38664 38664 38661

12 Planet Gear (3) 24504 24364 24321 39 Reverse Pawl Pin 24328 Group no. 2

40 Tongued ReversePawl 38665 38665 38665 (A) Grasp unit by torque control housing with the 1/2” diameter

13 Needle Roller (3 Sets) 24354

output spindle uppermost and vertical. Hold it with the motor

14 Roller Retainer (3Sets) 24355 41 Reverse Pawl Spring 24914

handle 1/2’ to 1” above the work surface.

15 Planet Pin (3) 24314 42 Grooved ReversePawl 24909 (B) With a soft faced hammer, tap the output spindle gently. The entire internal mech-anism

will fall free as soon as the reduced diameter portion of

16 Snubber Shim (0-3) 40561 43 Retainer 28067-0001

output spindle has pass-ed through front ball bearing.

17 O-Ring 28100 44 Set Screw (4) 20480 NOTE: Avoid hitting this bearing or housing.

18 Quad-Ring 28102 45 Index Plate 38653 40014 38652

Group no.3

19 O-Ring 28101 46 Screw (2) 24320

(A) Remove inside bearing shaft retainer ring (Pc #1).

20 Quad-Ring 28103 47 Rear Bearing 51194 (B) Lift out front ball bearing (Pc #25).

(C) Lift off front brake shoe (Pc #21 ).

21 Brake Shoe 38643 48 Handle Connector 38651

(D) Remove 3 brake rolls (Pc #23).

22 Brake Rolls Retainer 24311 49 Internal Gear 38654 38653 38655 (E) Lift off brake roll retaining ring (Pc #22 ).

23 Brake Roll (3) 24324 50 Balls (13) 21941

Group no.4

24 Bearing Race Brake- 38644 (A) The subassembly consisting of reaction member assembly with

Cam latch and various pawls, mainspring with its pin and anchor

25 Front Ball Retainer 28088 and brake cam may then be lifted up off motor drive spindle

assembly.

(B) When failure is due to a malfunction of torque control unit,

the failing parts, usually, can be found easily by observing

operations of the various pawis and latch. This can be done

by holding subassembly in the hand and applying torque or

turning force to internal gear (Pc #10) within reaction mem-

ber (Pc #26). See Trouble Shooting Chart.

10 7

More user manuals on ManualsBase.com

DISASSEMBLY(Cont’) SM-97 SM-97

REASSEMBLY

NOTE: As machine is being driven in forward direction, a coun- To reassemble TORQUE CONTROL or AIR MOTOR follow disassembly

terclockwise torque is applied to the internal gear, when look- steps in reverse.

ing at the open end. This gear is prevented from turning in

reaction member by the latch (Pc. #34), which can be released by

tripping release pawl (Pc #36) while applying a counterclock- • Torque control special note

wise torque to internal gear, which is then free to continue On reassembly of ball retainers, small ball retainer (Pc #25)

rotation in that direction. When tool is reversed, a clockwise must be assembled with solid part of ball cage facing steel

torque is applied to internal gear which makes one turn only to front bearing housing (Pc #4) in aluminum control housing.

reengage the main latch (Pc #34). Large ball retainer (Pc #43) must be assembled with solid part

of ball cage facing steel handle connector (Pc #48).

Group no. 5

If investigation shows that malfunction is due to a broken • Air motor special note

latch, pawl or spring, they can be replaced in the following Be sure rotor blades are well oiled before replacing them in

manner: their rotor slots. Also check that rotor turns very freely af-

(A) Grasp brake cam (Pc #24) and punch reaction member from it. ter air motor is reassembled and adapter ring is tightened

NOTE: When replacing this brake cam for reassembly, be sure it down. Observe extreme care in mesh-ing the rotor pinion and

is seated squarely and firmly against the shoulder on the reac- intermediate spindle pinion with their planet gears when reas-

tion member. sembling gear housing assembly to air motor.

Group no.6 • Complete torq-air-matic reassembly sequence

Assemble air motor into motor housing, then assemble intermedi-

(A) Mainspring (Pc #5) with its anchor (Piece No.6 ) and main-

spring pin (Pc #9)can then be removed. ate spindle assembly to air motor assembly. Next screw interme-

diate internal gear with attached torque control assembly onto

adapter ring. Tighten air motor assembly to torque control as-

Group no.7 sembly. See method of disassembly above. Assure that gears mesh

(A) Removal of retaining ring (Pc #27) will permit removal of properly before tightening; do not force. Torque unit will

various pins on which the latch and pawls are pivoted. screw onto motor assembly easily with proper gear mesh.

consisting of reaction with latch and various pawls, its pin

and anchor and brake lifted up off motor drive

Air motor disassembly procedure

Maintenance and Repair tools

4 Oz. Ball Pein Hammer

(A) Hold Torq-Air-Matic fixed with offset handle upwards.

4 Oz. Soft Faced Hammer (Brass and Plastic Tip)

(B) Prevent rotation with wrench locked on 2” hexagon located Set of Screwdrivers:1/8” w. x 4” 1g. blade

against torque calibrated index plate. 1/4” w. x 4” 1g. blade

(C) Tap motor handle with a soft-faced mallet in a counter- 9” Smooth Jaw Adjustable Wrench (With 2” Minimum Opening)

clockwise direction when viewed from offset handle end. 8” Pressure Lock Wrench (vise grip)

(D) Unscrew and remove air motor and offset housing assembly Set of Allen Hex. Wrenches (5/64, 3/32, 1/8, 5/32 and 3/16)

complete. 9-1/2” Channel Lock Pliers

(E) Remove intermediate spindle assembly from air motor assem- Long Needle Nose Pliers

bly or from within internal gear.

Set of Retaining Ring Pliers Waldes No. 2 & No. 4

(F) Unscrew adapter ring (Pc #63 ) out of cast aluminum motor Set of Machinists long nose punches

housing. (1/16, 3/32, 1/8, 5/32, 3/16 and 1/4)

(G) Rotor with 4 rotor blades, front plate spacer, ball bearing 6-1/2” Half Round Needle File for Deburring

and separator can now be lifted out. Small Hand Scraper for Deburring

Note: Leave cylinder and assembled rear end plate within mo- Sheets fine emery cloth for polishing

tor housing. Refer to assembly drawing on page xx.

8 9

You might also like

- Series 909 Righ Angle Tube Roller: SpecificationsDocument12 pagesSeries 909 Righ Angle Tube Roller: SpecificationsAlex NavedaNo ratings yet

- SM 133Document8 pagesSM 133gabriel90ccNo ratings yet

- I TFC 280 Instruction ManualDocument6 pagesI TFC 280 Instruction Manualsharri_myidtr11No ratings yet

- SM-281A Tube Roller Specifications and Operating InstructionsDocument4 pagesSM-281A Tube Roller Specifications and Operating InstructionsesmaeelNo ratings yet

- Street Series: CBR-1000RRDocument3 pagesStreet Series: CBR-1000RR김재치No ratings yet

- TY-L Series Sprinklers Technical Data SheetDocument6 pagesTY-L Series Sprinklers Technical Data SheetJimenez FerchoNo ratings yet

- Kysor On/Off Rear Air Fan Drive: Installation - ServiceDocument12 pagesKysor On/Off Rear Air Fan Drive: Installation - ServiceeloyabnerNo ratings yet

- High Speed Drill System: Instructions For UseDocument32 pagesHigh Speed Drill System: Instructions For UseAbdiaziz WalhadNo ratings yet

- COMBI 350 Sawing Machine Operating ManualDocument9 pagesCOMBI 350 Sawing Machine Operating ManualDein MasterNo ratings yet

- Tyco Water Motor AlarmDocument6 pagesTyco Water Motor AlarmhendrobamaNo ratings yet

- Product Information: Air Impact WrenchDocument12 pagesProduct Information: Air Impact WrenchPham Thien TruongNo ratings yet

- 40 90 Mechanical Seal Kits SWIDocument2 pages40 90 Mechanical Seal Kits SWIWong DaNo ratings yet

- Engg 2Document8 pagesEngg 2ganesan 0011No ratings yet

- 2761 252 00Document8 pages2761 252 00joravicaNo ratings yet

- Water Ace R33SU Submersible PumpDocument16 pagesWater Ace R33SU Submersible PumpatereñoneNo ratings yet

- YoshimuraDocument7 pagesYoshimuraNguon MadolyNo ratings yet

- Weir Minerals Multiflo Electro-Magnetic (Robatic) Clutch Disassembly AND Assembly ProcedureDocument10 pagesWeir Minerals Multiflo Electro-Magnetic (Robatic) Clutch Disassembly AND Assembly ProcedurePutra JawaNo ratings yet

- TFP 3153Document6 pagesTFP 3153Diego PinedaNo ratings yet

- R230 Manual Macfarlane GeneratorsDocument7 pagesR230 Manual Macfarlane Generatorsshutter1001No ratings yet

- ASB 412-00-106 - Tail Rotor (T - R) Blade 212-010-750-009 - 011 - 105 - 107 Tip Block Retention Modification Rev. D - 18-Mar-2005Document9 pagesASB 412-00-106 - Tail Rotor (T - R) Blade 212-010-750-009 - 011 - 105 - 107 Tip Block Retention Modification Rev. D - 18-Mar-2005yu gangNo ratings yet

- B TY LDocument4 pagesB TY Lcvproyectos.01No ratings yet

- ROBA-stop - M: Your Reliable PartnerDocument28 pagesROBA-stop - M: Your Reliable PartneruripssNo ratings yet

- UVPL-CAT-Dia Act-UA-11 & 12 - 04 - 2018Document12 pagesUVPL-CAT-Dia Act-UA-11 & 12 - 04 - 2018Subhash NarayananNo ratings yet

- SB-912-037 R1 - SB-914-023 R1 - Installation of An Electric Starter With Enhanced Power For Rotax Motor Type 912 Und 914 (Serie)Document4 pagesSB-912-037 R1 - SB-914-023 R1 - Installation of An Electric Starter With Enhanced Power For Rotax Motor Type 912 Und 914 (Serie)hugoumpire198No ratings yet

- SB-912-037 R1 - SB-914-023 R1 - Installation of An Electric Starter With Enhanced Power For Rotax Motor Type 912 Und 914 (Serie)Document4 pagesSB-912-037 R1 - SB-914-023 R1 - Installation of An Electric Starter With Enhanced Power For Rotax Motor Type 912 Und 914 (Serie)AO BeltranNo ratings yet

- Nordic 5900Document4 pagesNordic 5900adalberto vegaNo ratings yet

- I TFC 280 Instruction ManualDocument6 pagesI TFC 280 Instruction Manualsharri_myidtr11No ratings yet

- Installation and Operating Instructions: Hayward High-Performance PumpsDocument4 pagesInstallation and Operating Instructions: Hayward High-Performance Pumpsa siongNo ratings yet

- Roba - Stop - M: Your Reliable PartnerDocument20 pagesRoba - Stop - M: Your Reliable PartnerCaio DiasNo ratings yet

- Injection Pump Specification Model: Vest +3Oos-RDocument3 pagesInjection Pump Specification Model: Vest +3Oos-RVentas R11No ratings yet

- Campana WMA-1 TYCODocument4 pagesCampana WMA-1 TYCOsnonumNo ratings yet

- Maintenance Best Practices For Hand-Held Plasma Cutting Systems - Victor Technologies TrainingDocument2 pagesMaintenance Best Practices For Hand-Held Plasma Cutting Systems - Victor Technologies TrainingcarlosNo ratings yet

- Scotch Yoke or Rack-and-Pinion: Choosing the Best Pneumatic ActuatorDocument2 pagesScotch Yoke or Rack-and-Pinion: Choosing the Best Pneumatic ActuatorAhmed KhairiNo ratings yet

- TFP110 08 2018Document6 pagesTFP110 08 2018SamiYousifNo ratings yet

- Desenhos Dimensoes - 1sdh004745a1001 - B - 4 PDFDocument16 pagesDesenhos Dimensoes - 1sdh004745a1001 - B - 4 PDFFernando DelvanNo ratings yet

- 73 53HP SMDocument95 pages73 53HP SMpellboyzpowersportsNo ratings yet

- Rociador Ty LDocument8 pagesRociador Ty LOscar Fernandez SanchezNo ratings yet

- Data Shett FP Valiant MachineDocument47 pagesData Shett FP Valiant MachineRICARDONo ratings yet

- Operation Manual For The RX 29 ShakerDocument19 pagesOperation Manual For The RX 29 ShakerCarlos Esaú López GómezNo ratings yet

- Drive ShaftDocument9 pagesDrive ShaftSteven AmadorNo ratings yet

- Titan ManualDocument16 pagesTitan ManualpedropcNo ratings yet

- Manual de Operacion XQ 140Document55 pagesManual de Operacion XQ 140Diana RosasNo ratings yet

- Ots GRSH 250 00Document6 pagesOts GRSH 250 00ABC - Angela GomezNo ratings yet

- Cutter Instructions Booklet 2015Document16 pagesCutter Instructions Booklet 2015Mahmoud AliNo ratings yet

- Street Series: Yamaha R3 Yamaha MT-03Document5 pagesStreet Series: Yamaha R3 Yamaha MT-03Alex PlevakoNo ratings yet

- 50cc Sky LinkDocument20 pages50cc Sky LinkHezron Bryian ManurungNo ratings yet

- Operations Manual 2011Document18 pagesOperations Manual 2011Esteban VásquezNo ratings yet

- Hfe Denon Dra-F107 F107dab Service enDocument83 pagesHfe Denon Dra-F107 F107dab Service enDavid NicolasNo ratings yet

- 52788-L330 Lantec Winch Carrier WinchDocument52 pages52788-L330 Lantec Winch Carrier WinchDaniel Rincón100% (3)

- A600L Twin Hose ReelDocument19 pagesA600L Twin Hose ReelSusantoNo ratings yet

- 6" 6" 6" 6" WRDP WRDP WRDP WRDP - 2MP 2MP 2MP 2MP - NS Safety Valve NS Safety Valve NS Safety Valve NS Safety ValveDocument20 pages6" 6" 6" 6" WRDP WRDP WRDP WRDP - 2MP 2MP 2MP 2MP - NS Safety Valve NS Safety Valve NS Safety Valve NS Safety ValvePilar HernandezNo ratings yet

- Rociador TY3131Document10 pagesRociador TY3131Pavel RamirezNo ratings yet

- Protect Sprinklers from DamageDocument4 pagesProtect Sprinklers from DamageAchraf BoudayaNo ratings yet

- Preparatory Steps for Engine OverhaulDocument13 pagesPreparatory Steps for Engine OverhaulSebastian Nicușor PărăoanuNo ratings yet

- PB Owner's ManualDocument20 pagesPB Owner's ManualJorge RicaurteNo ratings yet

- Hitachi R-Z570ARU7 Service ManualDocument11 pagesHitachi R-Z570ARU7 Service ManualFuadNo ratings yet

- 4f50n CompleteDocument58 pages4f50n CompleteCarlos Treviño100% (1)

- Parts List For 1-056-000 Series (Rev. A & B) Manual Adjust BrakesDocument4 pagesParts List For 1-056-000 Series (Rev. A & B) Manual Adjust BrakesAnonymous QxmwZz4No ratings yet

- Rev A Durospeed GuideDocument15 pagesRev A Durospeed GuideCamilo Arroyave JNo ratings yet

- Foxboro 871 PHDocument16 pagesFoxboro 871 PHelsalseritoNo ratings yet

- Iscc GRFPTS 2 013Document1 pageIscc GRFPTS 2 013elsalseritoNo ratings yet

- Iscc GRFPTS 2 010Document1 pageIscc GRFPTS 2 010elsalseritoNo ratings yet

- Iscc GRFPTS 2 008Document1 pageIscc GRFPTS 2 008elsalseritoNo ratings yet

- Parts List: January 2010Document14 pagesParts List: January 2010elsalseritoNo ratings yet

- Transmisor de PH - Modelo 875PHDocument24 pagesTransmisor de PH - Modelo 875PHelsalseritoNo ratings yet

- Iscc GRFPTS 2 011Document1 pageIscc GRFPTS 2 011elsalseritoNo ratings yet

- Iscc GRFPTS 2 012Document1 pageIscc GRFPTS 2 012elsalseritoNo ratings yet

- 27R-03 .72Document10 pages27R-03 .72Jesus IzaguirreNo ratings yet

- 27R-03 .72Document10 pages27R-03 .72Jesus IzaguirreNo ratings yet

- 47R 11Document17 pages47R 11Guillermo Kelly100% (4)

- RSC ConduitDocument3 pagesRSC ConduitelsalseritoNo ratings yet

- 27R-03 .72Document10 pages27R-03 .72Jesus IzaguirreNo ratings yet

- Conexión Del Trasmisor Remoto Al Tubo de CaudalDocument1 pageConexión Del Trasmisor Remoto Al Tubo de CaudalelsalseritoNo ratings yet

- Electric Actuators for Industrial Valve AutomationDocument88 pagesElectric Actuators for Industrial Valve AutomationelsalseritoNo ratings yet

- Cooling System ElectricalDocument3 pagesCooling System ElectricalelsalseritoNo ratings yet

- Mini BallDocument11 pagesMini Ballelsalserito100% (1)

- PMK TrimetDocument1 pagePMK TrimetelsalseritoNo ratings yet

- Conc Surf PrepDocument6 pagesConc Surf PrepelsalseritoNo ratings yet

- Mini BallDocument11 pagesMini Ballelsalserito100% (1)

- Kit 2Document20 pagesKit 2elsalseritoNo ratings yet

- Effect of Non-Newtonian Fluids On The Performance of Plate Type Heat ExchangerDocument4 pagesEffect of Non-Newtonian Fluids On The Performance of Plate Type Heat Exchangerdeepika snehiNo ratings yet

- Tutorial Sheet 4Document2 pagesTutorial Sheet 4Syed YousufuddinNo ratings yet

- University of Health Sciences Lahore: Affiliated Private Sector Medical/Dental Colleges' Application FormDocument5 pagesUniversity of Health Sciences Lahore: Affiliated Private Sector Medical/Dental Colleges' Application FormkhnNo ratings yet

- Corticosteroid: Saut Samuel Simamora Department Ophthalmology Diponegoro University-Kariadi HospitalDocument21 pagesCorticosteroid: Saut Samuel Simamora Department Ophthalmology Diponegoro University-Kariadi HospitalSania NadianisaNo ratings yet

- Rational Choice TheoryDocument6 pagesRational Choice TheoryMaria Theresa HerbolingoNo ratings yet

- 3M Bio-Acoustic Simulator User Manual (053-012 Rev D)Document21 pages3M Bio-Acoustic Simulator User Manual (053-012 Rev D)rodrigocornejo81No ratings yet

- The Taste of Tradition: Submitted byDocument14 pagesThe Taste of Tradition: Submitted byvijay malikNo ratings yet

- PackageCare Maintenance ChecklistDocument1 pagePackageCare Maintenance ChecklistBùi ViệtNo ratings yet

- 6-Step Guide to Crushing Imposter SyndromeDocument10 pages6-Step Guide to Crushing Imposter SyndromeMark KestNo ratings yet

- May 4-22 Culinary 1 Lesson Plans PDFDocument4 pagesMay 4-22 Culinary 1 Lesson Plans PDFesefsdfsfNo ratings yet

- Impact of Excessive Mobile Phone Usage On Human JCSB 1000235Document5 pagesImpact of Excessive Mobile Phone Usage On Human JCSB 1000235nidNo ratings yet

- Zollinger-Ellison Syndrome (Gastrinoma)Document15 pagesZollinger-Ellison Syndrome (Gastrinoma)Huy QuangNo ratings yet

- Will The Real SMART Goals Please Stand Up?: Robert S. Rubin Saint Louis UniversityDocument2 pagesWill The Real SMART Goals Please Stand Up?: Robert S. Rubin Saint Louis UniversityKyoko TakayanagiNo ratings yet

- Megawin: Numerical Over Current & Earth Fault RelayDocument16 pagesMegawin: Numerical Over Current & Earth Fault Relaynaran19794735100% (5)

- Detailed Lesson Plan in Household Services Adiel RavaneraDocument8 pagesDetailed Lesson Plan in Household Services Adiel RavaneraAdielNo ratings yet

- Project 3 - Gas Turbine Tutorial - ChemCad Draft - 01 15 2020Document58 pagesProject 3 - Gas Turbine Tutorial - ChemCad Draft - 01 15 2020Daniel Andres Canro CalderónNo ratings yet

- Pensions Reforms at NSSFDocument4 pagesPensions Reforms at NSSFcliffmogere2348No ratings yet

- SordariaDocument31 pagesSordariaapi-251288828No ratings yet

- WorkbookEdition 12 A Theory of HumorismDocument4 pagesWorkbookEdition 12 A Theory of HumorismMabel Ferr50% (2)

- Science Activity Sheet Quarter 4 - MELC 2 Week 2: Uses of WaterDocument13 pagesScience Activity Sheet Quarter 4 - MELC 2 Week 2: Uses of WaterShareinne TeamkNo ratings yet

- 2002 - Comparison of The Absorption of Micronized (Daflon 500 MG) and Nonmicronized 14c-Diosmin TabletsDocument9 pages2002 - Comparison of The Absorption of Micronized (Daflon 500 MG) and Nonmicronized 14c-Diosmin TabletsMai HuynhNo ratings yet

- Torsion of Circular Shaft: Torque or Turning Moment or Twisting MomentDocument13 pagesTorsion of Circular Shaft: Torque or Turning Moment or Twisting Momentmahmudul adilNo ratings yet

- (IJCST-V11I6P5) :A.E.E. El-Alfi, M. E. A. Awad, F. A. A. KhalilDocument9 pages(IJCST-V11I6P5) :A.E.E. El-Alfi, M. E. A. Awad, F. A. A. KhalilEighthSenseGroupNo ratings yet

- REBA Employee Assessment Worksheet: A. Neck, Trunk and Leg AnalysisDocument1 pageREBA Employee Assessment Worksheet: A. Neck, Trunk and Leg AnalysisAgni JayantiNo ratings yet

- Text StructureDocument25 pagesText Structureapi-245317957No ratings yet

- Mbenson hw410 1602c - Unit-9-AssignmentDocument46 pagesMbenson hw410 1602c - Unit-9-Assignmentapi-355858071No ratings yet

- CHAPTER 3: Toxic Effects of Drugs: Pharmacology Page 1Document1 pageCHAPTER 3: Toxic Effects of Drugs: Pharmacology Page 1Gabriel GonzagaNo ratings yet

- Laughter Yoga Benefits Workplace ProductivityDocument2 pagesLaughter Yoga Benefits Workplace ProductivityJose Manuel Araujo OrregoNo ratings yet

- 02 - Purulent Inflammatory DiseaseDocument60 pages02 - Purulent Inflammatory Diseaseshekhawatyuvraj051No ratings yet