Professional Documents

Culture Documents

A Review On Modification of Bitumen For Flexible Pavement: March 2018

Uploaded by

isaac MbiawaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Review On Modification of Bitumen For Flexible Pavement: March 2018

Uploaded by

isaac MbiawaCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/325899608

A Review on Modification of Bitumen for Flexible Pavement

Article · March 2018

DOI: 10.22214/ijraset.2018.3582

CITATIONS READS

0 367

1 author:

Mahalakshmi Mannar

Visvesvaraya Technological University

2 PUBLICATIONS 2 CITATIONS

SEE PROFILE

All content following this page was uploaded by Mahalakshmi Mannar on 01 September 2021.

The user has requested enhancement of the downloaded file.

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 6.887

Volume 6 Issue III, March 2018- Available at www.ijraset.com

A Review on Modification of Bitumen for Flexible

Pavement

M. Mahalakshmi1, Dr. K.E. Prakash2, Dr. S. Suresh Babu3

1

Student, Department of Civil Engineering, Visvesvaraya Technological University, Belagavi, Karnataka, India

2

Director, Shree Devi Institute of Technology, Mangalore, Karnataka, India

3

Professor and Head, Department of Civil Engineering, Adhiyamaan College of Engineering, Hosur, Tamil Nadu, India

Abstract: A focus on National and International status review reveals that vast infrastructural development has to be focused

only with the available materials. Since, construction materials are in the stage of extinction, we have to make use of the waste

materials ensuring its suitability to safeguard the environment. Man for all his daily requirements has to travel from one place

to another, mostly by road transport. Bitumen, a road making material is a source from petroleum refineries as a by-product.

Oil is a non renewable resource, thus the bitumen’s availability in the near future is also in the verge of annihilation. Owing to

this, bitumen has to be partially replaced with other possible modifiers. This paper gives an idea of different modifiers that have

been used by researchers and the plausible impact of the modifiers on the strength and durability of the bitumen. Modifiers like

Low Density PolyEthylene(LDPE), High Density Poly Ethylene(HDPE), Nano clay, Rubber, Polypropylene, Nano

Montmorillonite, Nano silica, flyash, Styrene Butadiene Styrene(SBS), Cloisite, Nanofil, Evotherm, Cecabase Rt and Crumb

Rubber are used. Binder percentages used by authors are similar to some extent but modifiers percentages vary extensively.

From the literatures, it is suggested that the optimum percentage of modification only yields better results. Though availability of

the modifiers plays a main role, it must be chosen based on the soil conditions and climatic conditions to meet the specific

requirements of the desired pavement life.

Keywords: Bitumen Modifiers, Nanoclay, Montmorillonite, Polymer, Rubber, Nanosilica, Flyash, Cloisite, Nanofill, CNT

I. INTRODUCTION

Modification of construction materials is the need of the hour. Instead of using all available bitumen source let us focus on

modifying the bitumen partially and analyse modified bitumen’s strength and durability. If strength and durability are enhanced

without affecting the environment then modification of bitumen is preferred. Also, with economic point of view there will be huge

reduction in cost if bitumen is partially replaced with other modifiers for improved performance. Hence, the objective of this paper

is to analyze different modifiers of bitumen.

II. MATERIALS

A. Bitumen

Bitumen is derived as a by-product from distillation of crude oil process and hence may not obtain desired properties in all cases. To

arrive at our required properties, the bitumen is enhanced by carefully selecting the compatible modifiers.

B. Polymer

The polymers are thrown after its usage as waste on the motherland which clogs infiltration of rainwater due to its non

biodegradability. Approximately, 70% of the plastic produced goes as waste very often like one time use example carry bags, etc.,

As per Central Pollution Control Board reports, in India 15342 tonnes/day of waste plastics are generated and it is 5.6 million tonnes

per annum. So, many types of polymer like LDPE, HDPE and Polypropylene are tried in bitumen. This polymer addition

safeguard the bituminous mix and the under layers by preventing the percolation of water.

C. Rubber

Over usage of tyres leads to its malfunctioning hence tyres are thrown out in environment polluting the land because of the stabilizer

and fire retardant contents added in tyres. If burnt they emit methane gases. Globally, per annum 15 million tonnes of waste tyres

are generated out of which India contributes to 1 million tonne. Apart from own generation, reports states that from January to

©IJRASET (UGC Approved Journal): All Rights are Reserved 2594

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 6.887

Volume 6 Issue III, March 2018- Available at www.ijraset.com

March 2016 about 70,000 tonnes of waste tyres have been imported to India. So, we have to technically make use of those tyres for

our needs without affecting the environment.

D. Clay and Nanoclay

Clays are minerals, occurring naturally and subject to variability in constituent materials. Naturally available clay is converted to

nano size to attain high surface area to stick to the bitumen and bind the aggregates together with it. The nano clay modification

yields multifolds of profit even when added in small quantity.

III. REVIEW

A. Polymer

Polymer of both types plastomeric and elastomeric can be used in bitumen. Bitumen has numerous uses as paving, maintaining like

filling, patchwork, recycle and slurry seal. Polymer adapts itself to blend with bitumen for all these uses. Shiva Prasad K et

al.,(2012) suggested that first bitumen has to be heated to 260° to 280°C then the waste plastics must be added to it, if not then the

blend will not be properly mixed. But if so happens the bitumen may catch fire since it reaches its fire point and also loss in weight

of bitumen also may occur. Yazdani et al.,(2012) used polypropylene plastomer, Styrene Butadiene Styrene elastomer and

Nanoclay. Compressive strength and softening point of modified bitumen increased by 55%. Among the various percentages tried,

it was concluded that at PP 5%, SBS 3% and NC 1.5% has given an optimized result in enhancing the properties Avula

Vamshi(2013) found that the stripping value of 10% plastic modified bitumen is nil as compared to virgin bitumen of 0.4%. Also

there is a material cost reduction of 7.99% when plastic waste is used in the road. Modified bitumen decreases the penetration when

compared with the plain bitumen. S. Rajasekaran et al.,(2013) concluded that the thermal analysis using Thermal gravimetric

analysis shows that polymer like Polyethylene, polypropylene and polystyrene softens from 130°C to 140°C without evolution of

gas. It is safe if molten waste plastic is used below 150°C. Also the increasing order of strength is poly styrene, poly ethylene and

poly propylene for the modified bituminous block. Sandhya Dixit et al., (2013) in their paper suggested that maximum 0.6% of

plastic fibre modification only yielded satisfactory results. Marshal stability values increases with binder content of 5.4%. Shweta

N. Rokdey et al., (2015) published that the waste plastics are mixed with hot bitumen at 160°C. Plastic modification of bitumen

increased the melting point of the binder. They used thermosets, elastomers and thermoplastics as modifiers. They also absorbed

that the polymer will not be leached out of bitumen. al., (2015) proved that 9% of LDPE by weight of the bitumen to be an effective

proportion of binder. They achieved 32.5% increase in the stability value comparing with neat bitumen. Voids in mineral

aggregates were 5%. Air voids calculated were up to 66.7% Yash Menaria et al., (2015) in their study found that waste plastic of

8% is the optimum amount to be added to modify the bitumen. They suggested that plastic roads can also be laid with areas having

high tempeature like 50°C. The optimum binder content was found to be 4.5%. Dry process is followed in this work. Amit kumar

Sahu et al., (2016) studied the bitumen modification and suggested that polymer have wonderful adhesion property and hence there

is nil stripping value for about 72 hours againt 5% of stripping in conventional bitumen for 24 hours itself. Moisture absorption of

polymer modified bitumen coated aggregates is found to be 0.12% for 10% of plastics; the value for conventionl bitumen is 4%.

Mehdi Karimi Cheshmehgol et al., (2016), prepared specimens with LDPE from 2 to 14%. They stated that indirect tensile strength

for unconditioned specimens increase by 15.2%, and for conditioned specimens it is 23% increase. Tensile Strength Ratio is 88%

for undified sample and with 10% LDPE modification it is 94%. Minakshi Singhal et al., (2016) calculated that total material cost

when bitumen is modified with waste plastic (6%) is reduced by 7.99% and the marshall stability value achieved is 1161kg. When

plastic content is increased then the ductility and penetration value decreased and softening point value increased.

B. Rubber

Rubber is obtained from waste tires which cannot be used in vehicles. Since we go for waste material utilization our material cost

decreases and also we pave the way for cleaning of environment. Both natural rubber and crumb rubber can be used for

modification. It is used in powder form. Rubber adsorbs bitumen’s aromatic oil and hence gets close each other. Rajesh kumar et

al.,(2014) modified the bitumen with 10% crumb rubber and found that both with unmodified and modified bitumen the optimum

content of HDPE is 8% which yields better stability values in Marshall stability test. It is finalized in their work that 6% is optimum

binder content.

Krishnapriya M. G., (2015) studied the performance of Natural Rubber modified mixes. She found that 5% is the optimum binder

content. Fatigue life increased the resilient modulus at the rest period of 0.9 sec. Natural rubber modified bitumen has excellent

rutting resistance. Yuqiao et al., (2016) viewed that 8% waste poly ethylene modifier is best in penetration compared to the same

©IJRASET (UGC Approved Journal): All Rights are Reserved 2595

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 6.887

Volume 6 Issue III, March 2018- Available at www.ijraset.com

percentage of the compound waste poly ethylene and waste crumb rubber. The softening point at 8% was increased for Waste poly

ethylene but the ductility is less. The waste crumb rubber has low temperature resistance. Prakash Somani et al., (2016) got 6% as

optimum bitumen content since in it they achieved Marshal stability value as 945 kg. Beyond 6% of binder the stability value

decreases. Then the modification of 8% LDPE and 12% Crumb rubber yielded a marshal stability of 1250 kg. The corresponding

flow value is 3.86 mm. Mnjunath. K.R. et al., (2014) added 0.3% and 0.4% of Evotherm and Cecabase RT additive to base bitumen.

Maximum stability is achieved at 130°C temperature and stability values increased upto 24% for Evotherm and 22% for cecabase of

grade 2.

C. Nanoclay

Jeroen Besamusca(2008) analysed two organic Montmorillonite(MMT) Nanoclay. He claimed that ageing characteristics of

bitumen is influenced by the modifiers, which may be due to change in viscous properties because of addition of modifiers.

Viscosity is shear rate dependant and must be taken into account than temperature dependant. Saeed et al.,(2009) with the help of

Nanofill-15 and Cloisite -15A modified the bitumen at 0.2%, 0.4% and 0.7%. Modified bitumen showed superior performance for

dynamic creep than unmodified bitumen. But at low temperature modified bitumen does not show beneficial effect for fatigue test.

Cloisite increases the stability by 15% but Nanofill only by 6%. Among the two MMT cloisite-15A performed well compared to

Nanofill-15A in resilient modulus test, dynamic creep test, indirect tensile strength test and Fatigue resistance test. Jahromi et

al.,(2009) tested specimens at 5 °, 25° and 40° C at loading frequency of 0.5 Hz. Pulse period was 500 ms and recovery time was

1500 ms. 2% to 7% of Nano clay is used to modify. Depending on test temperature and Nanoclay content, for Cloisite-15A

stiffness varied from 8% to 40% and Nanofill-15 from 3% to 18%. Creep test at 40° C and 60° C show high pulse for modified

mixtures. Van de Ven et al.,(2009) checked the influence of Nano clay modifiers on fresh and aged bitumen with Dynamic Shear

Rheometer, penetration and softening point Cloisite Nanoclay increased rutting resistnce, Indirect tensile strength, stiffness for

40/60 penetration bitumen.

Nanofill modifier increased ageing resistance of 70/100 bitumen both in short and long term ageing. S Ghaffarpour(2011) expressed

that fatigue resisting parameter improved 1.2 to 1.4 times in unaged condition by adding Cloisite in 7% when comparing with

unmodified bitumen. Nanofill modification decreases fatigue life but ageing, exihibits same fatigue life. He also concluded like

enhancement of bitumen properties depends on Nanoclay type, clay pretreatment and selection of polymer.

You et al.,(2011) used 2% and 4% by weight of bitumen. Rotational viscosity increased on an average by 41% and 112%.

Dynamic shear complex modulus increased by 66% when 2% Nanoclay A is added and by 125% when 4% Nano clay A is added.

Similarly, 184% and 196% of dynamic shear modulus is increased with Nanoclay B. Use of both Nano clay(NC) reduced the strain

failure rate in tensile strength test.

Ezio et al., (2012) noticed in unaged stage 0.5% blend exihibiting higher Complex shear modulus for any phase angle value with

respect to binder of 1% CNT. After Rolling Thin Film Oven Test(RTFO), differences were minimum between unaged and aged but

after Pressure ageing vessel the condition reversed like 1% blend was stiffer than 0.5% .

Jun yang et al.,(2013) found that sodium MMT and organophilic MMT can increase ageing resistance and in low temperature,

where snow susceptibility is there, these modifications have a higher hand in terms of quality of bitumen.

Lamya et al.,(2013) added 3%,7% and 9% of organic MMT NC(N3 and N4) with bitumen. N3 is having X-Ray diffraction

properties equal to 2.28 and N4 equal to 3.8.

In DSR, Complex Shear Modulus increased and phase angle decreased for modified binders compared to unmodified ones. Hence,

modified binders have increased resistance to shear deformation.

Ali Jamshidi et al.,(2015) identified that there is a visible difference in the rate of change in rheology of asphalt modified with

numerous types and contents of nano materials (2% and 4%). The critical temperature is found to be 64°C for NI44 P2 binder from

rutting factor gradient analysis.

Saad Issa Sarsam(2013) tested with silica fumes and Flyash for penetration, softening point, ductility and rheologicl characteristics.

Silica is best known for adhesion and nano silica material with high surface area and stiffness modulus decreases the temperature

susceptibility. Silica fumes increases viscosity and softening point whereas flyash decreases viscosity and increases softening point.

Farhad Zafari et al.,(2014) seen through their investigation that after addition of 6% Nano silica penetration decreased, softening

point increased and ductility decreased. It might be because of high surface area absorbing more binder. Among various

percentages 2%, 4% and 6%, it was the 6% Nanosilica that lead the bitumen not to age soon.

©IJRASET (UGC Approved Journal): All Rights are Reserved 2596

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 6.887

Volume 6 Issue III, March 2018- Available at www.ijraset.com

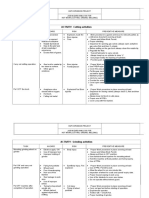

Table – I

Percentage of modifiers by different authors

Author Percentage of Modifiers Type of Modifier

Zhanping You 2, 4 Nano montmorillonite

Saeed Ghaffarpour 2,4,7 Montmorillonite

Jahromi

Van de ven 3,6 Cloisite

6 Nanofil

Lamya 3,7,9 Organic MMT

Ghaffarpour 2,4,7 Cloisite-15A

2,4,7 Nanofil-15

Ezio Santagata 0.1,0.5,1 Carbon Nano Tubes

Farhad zafari 2,4,6 Nano silica

Ali Jamshidi 2,4 Polymer

4,6 Nanosilica

Sandhya Dixit 0.1,0.2,0.3,0.4,0.5,0.6,0.7,0.8,0.9 Plastic bag Fibres

Yuqiao Yang 1,2,3,4,5,6,7,8,9 Waste poly ethylene, Waste Crumb Rubber

Saad Issa sarsam 3,6,9,12 Flyash

1,2,3,4 Silica Fumes

Avula Vamshi 10 Plastic waste

Mehdi Karimi 2,4,6,8,10,12,14 LDPE

Cheshmehgol

Prakash somani 4,6,8 LDPE

2,4,6 Crumb Rubber

Minakshi Shingal 1,2,3,5,10 Waste Plastic

S.Ghaffarpour Jahromi 7 Nanofil-15

Cloisite-15A

Shiva Prasad 2,4,6,8,10,12 Poly Ethylene Terapthalate,LDPE, HDPE

S Rajasekaran 5,10,20,25 Polyethylene(PE), PolyPropylene(PP),

Polystyrene(PS)

Yash Menaria 6,8,10,12,14, PE,PP,PS

Rao 5,7,9,11 PE

Shwetha Rokdey 10,20,30,40 Waste Plastic

Amit kumar Sahu 1,2,3,5,10 Crumb Rubber

Rajeshkumar 6,8,10 HDPE

Manjunath 0.3, 0.4 Evotherm

0.3, 0.4 Cecabase Rt

Krishnapriya 2 Natural Rubber

Jeroen Besamusca 3,6 Organic MMT

IV. CONCLUSION

A. From The Literatures On Modification Of Bitumen Using Waste Polymer And Rubber The Following Conclusions Were Drawn

1) Modifiers enhance the water proof quality of bitumen.

2) The objective is that at working condition of the pavement bitumen should be less temperature susceptible and at construction

condition workability must be maintained and modifiers does this magically.

3) Cost of modified binder is reduced when compared with conventional binder

4) Modified binders possess increased stability and durability compared to neat binders.

©IJRASET (UGC Approved Journal): All Rights are Reserved 2597

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 6.887

Volume 6 Issue III, March 2018- Available at www.ijraset.com

5) Modifiers improve the thermal stability From the literatures on modification of bitumen, using materials like clay the following

conclusions were drawn

6) Bitumen is an organic material it undergoes ageing when it comes in contact with UV light and oxygen but ageing resistance is

achieved by modifying with Nano clay

7) The prediction of permanent deformation based on complex shear modulus and phase angle shows improvement for Cloisite

properties but not much difference using Nanofill.

B. From these total Literatures on Modification of Bitumen The Following Conclusions Were Drawn

1) Mixing of the additives in particular speed for certain time period plays a significant role in quality achievement.

2) Many researchers have concentrated on Penetration, softening point, viscosity test and marshal stability test before and after

modification which yields a fast result about the properties.

3) Rutting in short term, Fatigue in long term and water susceptibility during all period are areas to be concentrated and hence

advanced research is carried out in this only by few researchers, it needs to be still more focussed.

4) Also, modification in the field has to be checked even after all lab tests have been done. Since live traffic and environment

conditions for at least a minimum width and length poses the real time challenges.

5) The percentage of modifiers addition must not be too high since it decreases the quality.

6) Proper selection of modifiers with required quantity based on neat bitumen revolutionizes the road pavement with increased

strength, durability and reduced cost.

V. List of symbols and Abbreviations

LDPE – Low Density Poly Ethylene LDPE

HDPE – High Density Poly Ethylene

SBS – Styrene Butadiene Styrene

MMT – Montmorillonite

CNT – Carbon Nano Tubes

PS – Polystyrene

UV – Ultra Violet

RTFO – Rolling Thin Film Oven

DSR – Dynamic Shear Rheometer

PP – Poly Propylene

PE – Poly Ethylene

NC – Nano Clay

REFERENCES

[1] Minakshi Singhal, Yudhvir Yadav and Ranadip Mandal, 2016 “Use of Modified Bitumen in Highway Construction”, International Journal for Innovative

Research in Science and Technology, vol. 2,Isssue 12, pp. 376-382.

[2] Yuqiao Yang and Youliang Cheng, 2016 “Preparation and Performance of Asphalt Compound Modified with Waste Crumb Rubber and Waste Polyethylene”,

Advances in Materials Science and Engineering, Volume 2016, Article ID 5803709, 6 pages.

[3] Prakash Somani, Vikash Maharaniya, Banwarilal kumawat and Rahul dev rangera, 2016, “Strengthen of Flexible Pavement by using Waste Plastic and

Rubber”, SSRG International Journal of Civl Engineering – Volume 3 Issue 5, pp. 246-250.

[4] Shweta N. Rokdey, P.L. Naktode and M.R. Nikhar, 2015 “Use of Plastic Waste in Road Construction”, International Journal of Computer applications,

ICQUEST, pp. 27-29.

[5] Sukaina Kazmi and Dubasi Govardhana Rao, 2015, “Utilization of Waste Plastic Materials as Bitumen-Blends for Road Construction in Oman”, Scholars

Journal of Engineering and Technology , 3(1A) pp. 9-13

[6] Yash Menaria and Rupal Sankhla, 2015, “Use of Waste Plastic in Flexible Pavements – Green Roads”, Open Journal of Civil Engineering, pp. 299-311.

[7] Krishnapriya M. G., 2015 “Performance Evaluation of Natural Rubber Modified Bituminous Mixes”, Trans Stellar Journal Publications Volume 5, Issue 1,

Feb 2015, pp 1-12.

[8] Ali Jamshidi, Mohd Rosli Mohd Hasan, Hui Yao, Zhanping You, Meor Othman Hamzah, 2015, “Characterization of the rate of change of rheological

properties of nano-modified asphalt”, Construction and Building Materials, Elsevier, 98, pp. 437 -446.

[9] Manjunath.K.R., Dheeraj Kumar N and Thippeswamy G S, 2014, “Performance and Evaluation on Marshall Stability Properties of Warm mix Asphalt using

Evotherm and Cecabase Rt – A Chemical Additive”, International Journal of Engineering Trends and Technology, Vol.12 No. 8, pp. 406-410

[10] K. Rajesh kumar and Dr. N. Mahendran, 2014, ”Experimental studies on Modified Bituminous mixes using waste HDPE and Crumb Rubber”, International

Journal of Emerging Technology and Advanced Engineering, Vol. 4, Issue 4, pp. 587- 597

©IJRASET (UGC Approved Journal): All Rights are Reserved 2598

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 6.887

Volume 6 Issue III, March 2018- Available at www.ijraset.com

[11] Farhad Zafari Mohaammad Rhi, Nazanin Moshtagh, Hosein Nazockdast, 2014, “The Improvement of Bituemen Properties by Adding Nano silica”, Study of

Civil Engineering and Architecture, Volume 3

[12] Avula Vamshi, 2013, “Use of waste plastic in construction of Bituminous road”, Journal of Engineering, Volume 2, No. 3, pp. 123-128

[13] S. Rajasekaran, Dr.R. Vasudevan, and Dr. Samuvel Paulraj, 2013, “Reuse of Waste Plastics Coated Aggregates – Bitumen Mix composite for Road Application

– Green Method”, American Journal of Engineering Research”, Vol.2, Issue 11, pp. 01-13

[14] Saad Issa Sarsam, 2013, “Effect of Nano Materials on Asphalt Cement Properties”, International Journal of Scientific Research in Knowledge 1(10), pp. 422-

426

[15] Lamya M.J. Mahdi, Ratnasamy Muniandy, Robiah Bt.Yunus, Salihudin Hsham, Elther Aburkaba, 2013, “Effect of Short Term Aging on Organic

Montmorilloite Nanoclay Modified Asphalt”, Indian Journal of Science and Technology, Vol 6(11), pp. 5434-5442,

[16] Sandhya Dixit and Deepak Rastogi, 2013, “Studies on the Improvement of Characteristics of Bitumen with Use of waste Plastic”, International Journal of

Emerging Technology and Advanced Engineering, Volume 3, Issue 3, pp. 895-900

[17] Shiva Prasad K, Manjunath K. R, K. V R Prasad, 2012 “Study on Marshall Stability Properties of BC Mix Used in Road Construction by Adding waste plastic

bottles”, IOSR Journal of Mechanical and Civil Engineering, Vol. 2, Issue 2, pp. 12 – 23.

[18] S Ghaffarpour Jahromi, N.A. Ahmadi, .M. Mortazvi and . Vosough, 2011, “Rutting and Fatigue Behavior of Nanoclay modified Bitumen”, The Islamic

Republic of Iran, IJST, Transactions of Civil Engineering, Vol.35, No C2, pp. 277-281.

[19] Zhanping You, Julian Mills-Bele, Justin M.Foley, Samit Roy, Gregory M. Odegard, Qingli Dai, shu Wei Goh, 2011, “Nanoclay – modified asphalt materials:

Preparation and Characterization”, Construction and Building Materials 25, pp. 1072-1078

[20] Saeed Ghaffarpour Jahromi, Behrooz Andalibizade and Shahram Vossough, 2009, “Engineering properties of Nanoclay modified asphalt concrete mixtures”,

The Arabian Journal for Science and Engineering, Volume 35, Number 1B pp. 89-103

[21] Saeed Ghffarpour Jahromi and Ali Khodaii, 2009, “Identification Effect of Nanoclay on Engineering Properties of Asphalt Mixtures”, AUT journal of

Modeling and Simulation, MISC, Vol. 41, No.1,pp. 49-57

[22] M.F.C. Van de Ven & A.A.A.Molenaar, Jeroen Besamusca, 2009, “Nanoclay for binder modification of aphalt mixtures”, Advanced Testing and

Characterization of Bituminous Materials –Loizos Part II, Scarpas & Al-Qadi(eds) Taylor & Francis Group, London, pp. 133-142.

[23] Jeroen Besamusca, Martin F.C. Van de Ven, Andre A.A. Molenaar, Jeroen Noordergraaf, 2008, “Nanotechnology for Binder of Asphalt Mixtures” 4th

Eurasphalt & Eurobitume Congress, Copenhagen.

[24] Amit kumar Sahu and R K Singh, 2016, “Application of Waste Plastic Materials in Road Construction”, 2nd International Seminar on “Utilization of Non-

Conventional Energy Sources for Sustainable Development of Rural Areas

[25] Mehdi Karimi Cheshmehgol, Dr. Malik Shoeb Ahmad, 2016 “Construction of Bituminous Macadam using Plastic waste”,12th Transportation Planning and

Implementation Methodologies for developing Countries

[26] Ezio Santagata, Orazio Baglieri, Lucia Tsantilis, Davide Dalmazzo, 2012 “Rheological Characterization of Bituminous Binders Modified with Carbon

Nanotubes”, SIIV – 5th International Congress – Sustainability of Road Infrastructures, Sciverse Science Direct, Procedia – Social and Behavioural Sciences 53

pp. 546-555

[27] Abolghasem Yazdani, Sara Pourjafar, 2012, “Optimization of Asphalt Binder Modified with PP/SBS/Nanoclay Nanocomposite using Taguchi Method”, World

Academy of Science, Engineering and Technology

[28] Jun yang and Susan Tighe, 2013 “A review of advance of Nanotechnology in asphalt mixtures”, 13th COTA Internationl Conference of Transportation

Professionals, Procedia – Social and Behavioral Sciences 96, pp. 1269-1276

©IJRASET (UGC Approved Journal): All Rights are Reserved 2599

View publication stats

You might also like

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsFrom EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsNo ratings yet

- Use of Plastic Waste in Road Construction For SustDocument5 pagesUse of Plastic Waste in Road Construction For SustVenkateswarlu GajulaNo ratings yet

- 321 ArticleText 520 1 10 201904251Document13 pages321 ArticleText 520 1 10 201904251Ebenezer EffisahNo ratings yet

- Use of Plastic Waste in Bituminous Pavement: International Journal of Chemtech Research January 2017Document9 pagesUse of Plastic Waste in Bituminous Pavement: International Journal of Chemtech Research January 2017sulemanNo ratings yet

- Agro WasteDocument25 pagesAgro WastehemanthreddyNo ratings yet

- Paper On Plastic To RoadDocument6 pagesPaper On Plastic To RoadSumskrutha Kosgi ShroffNo ratings yet

- Performance Evaluation of Environmentally Sustainable Waste Polythene Fiber Reinforced Bituminous Mix For RoadsDocument6 pagesPerformance Evaluation of Environmentally Sustainable Waste Polythene Fiber Reinforced Bituminous Mix For RoadsEditor IJTSRDNo ratings yet

- A Discussion On Additives Used in Asphalt Concrete For The Enhancement of PropertiesDocument7 pagesA Discussion On Additives Used in Asphalt Concrete For The Enhancement of PropertiesIJRASETPublicationsNo ratings yet

- Utilizationof Waste Plasticin ConcreteDocument7 pagesUtilizationof Waste Plasticin ConcreteSangramNo ratings yet

- 804 811V10N8CTDocument9 pages804 811V10N8CTDIVIN KURUPNo ratings yet

- Civil Engineering: Khammam Institute of Technology and SciencesDocument31 pagesCivil Engineering: Khammam Institute of Technology and Sciencesramesh ankathiNo ratings yet

- Crumb Rubber Modified Bitumen and Quarry Dust in Flexible PavementsDocument7 pagesCrumb Rubber Modified Bitumen and Quarry Dust in Flexible PavementsaiplNo ratings yet

- Use of Waste Plastic in Construction of Bituminous RoadDocument5 pagesUse of Waste Plastic in Construction of Bituminous RoadTanmay SethiNo ratings yet

- Effectiveness of Waste Polythene Bags Modified Bitumen Mixes and Their Comparative Economical AnalysisDocument8 pagesEffectiveness of Waste Polythene Bags Modified Bitumen Mixes and Their Comparative Economical AnalysisFajuyigbeNo ratings yet

- Evaluation of Design Mix Bituminous Concrete Using Plastic Waste in Road PavementDocument3 pagesEvaluation of Design Mix Bituminous Concrete Using Plastic Waste in Road PavementEditor IJTSRDNo ratings yet

- 321-Article Text-520-1-10-20190425Document12 pages321-Article Text-520-1-10-20190425Ahmed khushalNo ratings yet

- Experimental Study On Use of Hypo Sludge and Nylon Fibre in Paver BlockDocument6 pagesExperimental Study On Use of Hypo Sludge and Nylon Fibre in Paver BlockIJRASETPublicationsNo ratings yet

- J0704047981 PDFDocument3 pagesJ0704047981 PDFShuddhashil GhoshNo ratings yet

- Resources 12 00010Document29 pagesResources 12 00010d TjonasanNo ratings yet

- Utilization of Waste Plastic in ConcreteDocument7 pagesUtilization of Waste Plastic in ConcreteTanika EdwardsNo ratings yet

- Thesis ProposalDocument7 pagesThesis ProposalMEHIDE HASANNo ratings yet

- Irjet V6i4297 PDFDocument7 pagesIrjet V6i4297 PDFRana Talal RaziNo ratings yet

- COconut Shell PaperDocument10 pagesCOconut Shell PaperPeer MohamedNo ratings yet

- Irjet V6i4297 PDFDocument7 pagesIrjet V6i4297 PDFRana Talal RaziNo ratings yet

- Effects of Waste Plastic in Concrete: March 2019Document7 pagesEffects of Waste Plastic in Concrete: March 2019taramalik07No ratings yet

- Utilization of Waste Polythene As Low Cost and Eco-Friendly Material in PPC ConcreteDocument5 pagesUtilization of Waste Polythene As Low Cost and Eco-Friendly Material in PPC ConcreteEditor IJTSRDNo ratings yet

- Irjet V5i1240Document8 pagesIrjet V5i1240Aman raj singhNo ratings yet

- Use of Modified Bitumen in Highway Construction: Minakshi Singhal Yudhvir YadavDocument7 pagesUse of Modified Bitumen in Highway Construction: Minakshi Singhal Yudhvir Yadavnswain76No ratings yet

- ENT182306Document6 pagesENT182306NM2104TE06 PRATHURI SUMANTHNo ratings yet

- Hypo Sludge and Steel Fiber As Partially Replacement of CementDocument6 pagesHypo Sludge and Steel Fiber As Partially Replacement of CementIJRASETPublicationsNo ratings yet

- Waste Plastic GoooodDocument12 pagesWaste Plastic GoooodAngel AngelNo ratings yet

- A Research On Study The Behaviour of Concrete Using Waste Tires ChipsDocument5 pagesA Research On Study The Behaviour of Concrete Using Waste Tires ChipsEditor IJTSRDNo ratings yet

- Study of Effective Utilization of Waste P.E.T (Plastic) and Steel Slag To Enhance The Performance of Bitumen Based PavementDocument8 pagesStudy of Effective Utilization of Waste P.E.T (Plastic) and Steel Slag To Enhance The Performance of Bitumen Based PavementIJRASETPublicationsNo ratings yet

- Final Report Print PDFDocument40 pagesFinal Report Print PDFShriramNo ratings yet

- Partial Repacement of Plastic in BitumenDocument5 pagesPartial Repacement of Plastic in BitumenSri HariNo ratings yet

- Utilization of Rubber Waste in Construction of Flexible PavementDocument8 pagesUtilization of Rubber Waste in Construction of Flexible Pavementathirah mfNo ratings yet

- 45kp RLP Jrpicriset201717th 19thfebruary2017Document6 pages45kp RLP Jrpicriset201717th 19thfebruary2017tony ynca berrospiNo ratings yet

- Journal Printabs 4haug14esrDocument11 pagesJournal Printabs 4haug14esrBruno CarleteNo ratings yet

- Tapas Singh1Document4 pagesTapas Singh1Nabin PoudyalNo ratings yet

- Use of Waste Plastic in Construction ofDocument10 pagesUse of Waste Plastic in Construction ofAnjali chilakalaNo ratings yet

- An Overview of Use of Waste Plastic in Road Construction: April 2018Document4 pagesAn Overview of Use of Waste Plastic in Road Construction: April 2018Manohar SimhadriNo ratings yet

- Minor Project Synopsis Civil FinalDocument9 pagesMinor Project Synopsis Civil FinalAceNo ratings yet

- Experimental Investigation On Reinforced Concrete With Plastic FiberDocument6 pagesExperimental Investigation On Reinforced Concrete With Plastic FiberIJRASETPublicationsNo ratings yet

- New Proposal - 21-6-2018Document14 pagesNew Proposal - 21-6-2018Shivkumar HosamaniNo ratings yet

- Irjet V7i4845Document9 pagesIrjet V7i4845N SanthoshNo ratings yet

- Use of Plastic Waste in Bituminous Road ConstructionDocument5 pagesUse of Plastic Waste in Bituminous Road ConstructionIJSTE100% (1)

- Plastic RoadsDocument30 pagesPlastic RoadsNigam Meher100% (14)

- A Study On Influence of Ldpe On Properties of Bitumen Pavement Under Submergence Condition IJERTV8IS060459Document6 pagesA Study On Influence of Ldpe On Properties of Bitumen Pavement Under Submergence Condition IJERTV8IS060459SyedBaqirNo ratings yet

- Bitumen Modification With Waste Plastic and Crumb Rubber: Athira R Prasad, DR Sowmya N JDocument6 pagesBitumen Modification With Waste Plastic and Crumb Rubber: Athira R Prasad, DR Sowmya N JDejan MilosavljevicNo ratings yet

- Strength of Concrete by Replacement of Coarse Aggregates With Waste Rubber and Demolished Waste MaterialsDocument10 pagesStrength of Concrete by Replacement of Coarse Aggregates With Waste Rubber and Demolished Waste MaterialsInder KumarNo ratings yet

- Review On Partial Replacement of Cement in ConcretDocument6 pagesReview On Partial Replacement of Cement in ConcretElmeerajh JudavarNo ratings yet

- Minor Project Plastic WasteDocument24 pagesMinor Project Plastic Wastearjun kumar0% (1)

- Manufacturing of Interlocking Brick With Cement-Lime Mortar and HyposludgeDocument8 pagesManufacturing of Interlocking Brick With Cement-Lime Mortar and Hyposludgeadvitya.constructionsNo ratings yet

- SL No. Chapters Pg. No.: Use of Waste Plastic For Road ConstructionDocument11 pagesSL No. Chapters Pg. No.: Use of Waste Plastic For Road Constructionvinay kumar h sNo ratings yet

- Effect of Granite Dust & M-Sand On Strength Properties of Conventional ConcreteDocument11 pagesEffect of Granite Dust & M-Sand On Strength Properties of Conventional ConcreteDulguunkherlen BudkhandNo ratings yet

- 61dea99ecba586 55037266Document7 pages61dea99ecba586 55037266Romil SharmaNo ratings yet

- Use of Waste Plastic in Flexible PavementDocument4 pagesUse of Waste Plastic in Flexible PavementEttaMahenderNo ratings yet

- Impact of Partial Substitution of Cement With Cow Dung Ash and Rice Husk Ash On Performance of ConcreteDocument8 pagesImpact of Partial Substitution of Cement With Cow Dung Ash and Rice Husk Ash On Performance of ConcreteIJRASETPublicationsNo ratings yet

- Use of Plastic Waste in Flexible Pavements: Volume 2, Issue 4, April 2013Document13 pagesUse of Plastic Waste in Flexible Pavements: Volume 2, Issue 4, April 2013International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- 5 Grammatical Hybridity in Camfranglais?: Roland KießlingDocument26 pages5 Grammatical Hybridity in Camfranglais?: Roland Kießlingisaac MbiawaNo ratings yet

- Applied Clay Science: Research PaperDocument13 pagesApplied Clay Science: Research Paperisaac MbiawaNo ratings yet

- Novel Green Plants Extract As Corrosion Inhibiting Coating For Steel Embedded in ConcreteDocument14 pagesNovel Green Plants Extract As Corrosion Inhibiting Coating For Steel Embedded in Concreteisaac MbiawaNo ratings yet

- Journal Pre-Proof: Journal of Building EngineeringDocument31 pagesJournal Pre-Proof: Journal of Building Engineeringisaac MbiawaNo ratings yet

- Mechanical and Microstructural Properties of Cameroonian CPJ NC CEM II/B-P 42.5R Cement Substitution by Glass Powder in The Cement Paste and MortarDocument13 pagesMechanical and Microstructural Properties of Cameroonian CPJ NC CEM II/B-P 42.5R Cement Substitution by Glass Powder in The Cement Paste and Mortarisaac MbiawaNo ratings yet

- HIC 412C - Data Sheet (CT Vacuum Pump & Evaporator) PDFDocument3 pagesHIC 412C - Data Sheet (CT Vacuum Pump & Evaporator) PDFsuyono4131No ratings yet

- Lampiran 4Document24 pagesLampiran 4csecNo ratings yet

- The Role and Significance of Magnesium in Modern Day Research A Review - 2021Document61 pagesThe Role and Significance of Magnesium in Modern Day Research A Review - 2021Mingying QinNo ratings yet

- Open Ended Laboratory ProjectDocument2 pagesOpen Ended Laboratory ProjectAnonymous rpcAOpNo ratings yet

- Chitosan - A Versatile Semi-Synthetic Polymer in BiomedicalDocument34 pagesChitosan - A Versatile Semi-Synthetic Polymer in BiomedicalBianca Ionela DraganNo ratings yet

- Green EnergyDocument4 pagesGreen EnergyAlexandru AndreiNo ratings yet

- SA 516 Gr. 70Document3 pagesSA 516 Gr. 70GANESHNo ratings yet

- Burnside ParkDocument8 pagesBurnside ParkAhmadinijadNo ratings yet

- Ict-Narrative ReportDocument22 pagesIct-Narrative ReportEthan James EscañoNo ratings yet

- Spring Mock Test IIDocument11 pagesSpring Mock Test IIdiegoNo ratings yet

- Ams200 PDFDocument4 pagesAms200 PDFJair Jesús Cazares Rojas100% (2)

- HANSA Organizational Structure V2Document26 pagesHANSA Organizational Structure V2HANSA blogNo ratings yet

- MVHRDocument4 pagesMVHRtexas_peteNo ratings yet

- FM-4-12 (Foam Water Sprinkler System)Document56 pagesFM-4-12 (Foam Water Sprinkler System)Yashodhan RajwadeNo ratings yet

- Proposal Report For CentrifugeDocument3 pagesProposal Report For CentrifugeDinesh KatochNo ratings yet

- P Malan AIAA2009 Gamma Re ThetaDocument14 pagesP Malan AIAA2009 Gamma Re ThetaMohammed BarahmehNo ratings yet

- List of All BAPIsDocument38 pagesList of All BAPIsSritam MohantyNo ratings yet

- Paint ReportDocument31 pagesPaint ReportMark Vincent Esmeralda MamigoNo ratings yet

- EF132 BEE Lecture 2 & 3Document49 pagesEF132 BEE Lecture 2 & 3Anonymous gdLjDzNo ratings yet

- Ortho IsometricDocument33 pagesOrtho IsometricFaaz Al Wahab100% (1)

- Temperature CH 10 8thDocument12 pagesTemperature CH 10 8ththegedusNo ratings yet

- Physics Presentation Class 10Document16 pagesPhysics Presentation Class 10Akash SehrawatNo ratings yet

- Neutral Conductor Sizing: Angelo Baggini - Angelo - Baggini@unibg - It Franco Bua - Franco - Bua@ecd - ItDocument16 pagesNeutral Conductor Sizing: Angelo Baggini - Angelo - Baggini@unibg - It Franco Bua - Franco - Bua@ecd - Itdheyab farajNo ratings yet

- BN-20 Master Guide R3Document112 pagesBN-20 Master Guide R3Serge MaciaNo ratings yet

- Polyurethane DispersionsDocument10 pagesPolyurethane DispersionsalpersakirmetinNo ratings yet

- Design of Engineering Materials: Stress-Strain DiagramDocument32 pagesDesign of Engineering Materials: Stress-Strain DiagramTRNADEWNo ratings yet

- JW Marriott CaseDocument11 pagesJW Marriott Casegogana93No ratings yet

- Biochar Effects On Soil Compaction in Two Contrasting Soils: Universität Bremen University of AveiroDocument2 pagesBiochar Effects On Soil Compaction in Two Contrasting Soils: Universität Bremen University of AveiroLiv CBNo ratings yet

- Tie in Hot Work JHADocument4 pagesTie in Hot Work JHAmalik jahan100% (2)

- Bag House CollectionDocument12 pagesBag House Collection113314No ratings yet