Professional Documents

Culture Documents

Trix 1L Line 2 Liquid

Trix 1L Line 2 Liquid

Uploaded by

Mgr ProdOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trix 1L Line 2 Liquid

Trix 1L Line 2 Liquid

Uploaded by

Mgr ProdCopyright:

Available Formats

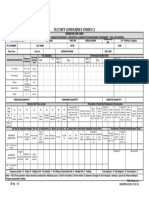

PZ CUSSONS - Line Balancing Worksheet

Date 11-Apr-17

Location Powder

Current Operators

Machine Type/

Production Rate

Thread Color

Process Cycle

EOLR / Day = net

Operations

Combined

Operation

Time Sec.

Seconds

Production Cell Location - Current State avail. Time /

Production rate

Operation Description 42

Totals 13.75 11 4.38

WIP Inventory before first operation

1 Machine Filling Nozzle 7.20 5 1.44 42

2 Manual Insert cap 0.80 1 0.80 75

3 Manual cleaning botol 1.17

4

4 Manual packing 3.64 1.20 50

6 Manual Lakban dan Paleting 0.94 1 0.94 64

Line Balancing Powder IL UK

2

1

1.44

1.20

0.80 0.94

Column I

OUTPUT OUTPUT

(Bottle) (Carton)

Output per menit 42 7

output perjam 2,500 417

output pershift 18,750 3,125

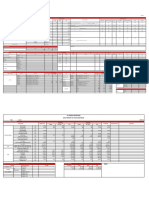

PZ CUSSONS - Line Balancing Worksheet

Date 17-Apr-17

Location Trix 1L X 9 Liquid Line 2

Current Operators

Machine Type/

Production Rate

Thread Color

Process Cycle

EOLR / Day = net

Operations

Combined

Operation

Time Sec.

Seconds

Production Cell Location - Current State avail. Time /

Production rate

Operation Description 12

Totals 19.36 8 14.54

WIP Inventory before first operation

1 Machine Filling Nozzle 9.65 2 4.83 12.4

2 Manual Insert cap 1.90 1 1.90 32

3 Manual Posioning botol 1.17 1 1.17 51

4 Manual Glue button carton 2.14 1 2.14 28

5 Manual packing 2.43 1 2.43 25

6 Manual Glue upper carton 1.65 1 1.65 36

7 Manual Paleting/angkat ke conv end of line 0.42 1 0.42 142

Line Balancing Powder IL UK

6

3

4.83

2

1 2.14 2.43

1.90 1.65

1.17

0 0.42

Column I

OUTPUT OUTPUT

(Bottle) (Carton)

Output per menit 12 2

output perjam 746 124

output pershift 5,596 933

Manpower 8 orang

PZ CUSSONS - Line Balancing Worksheet

Date 17-Apr-17

Location Trix 1L X 9 Liquid Line 2

Current Operators

Machine Type/

Production Rate

Thread Color

Process Cycle

EOLR / Day = net

Operations

Combined

Operation

Time Sec.

Seconds

Production Cell Location - Current State avail. Time /

Production rate

Operation Description 16

Totals 20.69 8 13.37

WIP Inventory before first operation

1 Machine Filling Nozzle 10.98 3 3.66 16.4

2 Manual Insert cap 1.90 1 1.90 32

3 Manual Posioning botol 1.17 1 1.17 51

4 Manual Glue button carton 2.14 1 2.14 28

5 Manual packing 2.43 1 2.43 25

6 Manual Glue upper carton 1.65

1 2.07 29

7 Manual Paleting/angkat ke conv end of line 0.42

Line Balancing Powder IL UK

4

2

3.66

2.14 2.43

1 1.90 2.07

1.17

0

Column I

OUTPUT OUTPUT

(Bottle) (Carton)

Output per menit 16 3

output perjam 984 164

output pershift 7,377 1,230

Manpower 8 orang

PZ CUSSONS - Line Balancing Worksheet

Date 6-Apr-17

Location Powder

Current Operators

Machine Type/

Production Rate

Thread Color

Process Cycle

EOLR / Day = net

Operations

Combined

Operation

Time Sec.

Seconds

Production Cell Location - Current State avail. Time /

Production rate

Operation Description 15

Totals 28.41 12 14.16

WIP Inventory before first operation

1 Machine Filling Nozzle 7.20 3 2.40 25

2 Manual Insert cap 0.80 1 0.80 75

3 Manual Kencang cap & cleaning botol 4.07 2 2.04 29

4 Manual cleaning botol 6.96 2 3.48 17

5 Manual packing 7.87 2 3.94 15

6 Manual Prepare Carton 0.76 1 0.76 79

7 Manual Paleting 0.75 1 0.75 80

Line Balancing Powder IL UK

5

2 3.94

3.48

1 2.40 2.04

0.80 0.76 0.75

0

Column I

OUTPUT OUTPUT

(Bottle) (Carton)

Output per menit 15 3

output perjam 900 150

output pershift 6,750 1,125

PZ CUSSONS - Line Balancing Worksheet

Date 6-Apr-17

Location Powder

Current Operators

Machine Type/

Production Rate

Thread Color

Process Cycle

EOLR / Day = net

Operations

Combined

Operation

Time Sec.

Seconds

Production Cell Location - Recomendation avail. Time /

Production rate

Operation Description 22

Totals 28.16 12 8.24

WIP Inventory before first operation

1 Machine Filling Nozzle 7.20 3 2.40 25

2 Manual Insert cap 0.80 1 0.80 75

3 Manual Kencang cap & cleanning botol 4.07

4 2.76 22

4 Manual cleaning botol 6.96

5 Manual packing 7.87

6 Manual Prepare Carton 0.76 4 2.28 26

7 Manual Paleting 0.50

Line Balancing Powder IL UK

2.76

2.40 2.28

1

0.80

0

Column I

OUTPUT OUTPUT

(Bottle) (Carton)

Output per menit 22 4

output perjam 1,320 220

output pershift 9,900 1,650

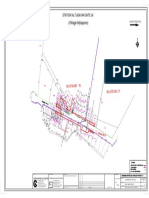

Layout :

Note : Process kencang cap dan cleaning botol pindah didepan dirotari table

Proses prepare carton diconbine dengan packing dan paleting

You might also like

- Safety and Reference: Owner'S ManualDocument84 pagesSafety and Reference: Owner'S ManualjpmcorpNo ratings yet

- LIZ Fashion Industry Limited Sewing Line Balanching (Initial)Document2 pagesLIZ Fashion Industry Limited Sewing Line Balanching (Initial)Nitta MallikNo ratings yet

- Imperial Bolts Nuts & WashersDocument7 pagesImperial Bolts Nuts & WashersstugwynneNo ratings yet

- Without Punch Part Mix: Customer/Supplier / in Plant Quality Problem Analysis and Countermeasure Sheet (5 - Rule)Document13 pagesWithout Punch Part Mix: Customer/Supplier / in Plant Quality Problem Analysis and Countermeasure Sheet (5 - Rule)Rohtash fastnerNo ratings yet

- Chapter 12 (WTA) - Horizontal Well Test Analysis (D. Tiab)Document158 pagesChapter 12 (WTA) - Horizontal Well Test Analysis (D. Tiab)qwertyNo ratings yet

- Production Study Sheet: Effective Non Effective ActivitiesDocument3 pagesProduction Study Sheet: Effective Non Effective Activitieslodestar ieNo ratings yet

- Job Schedule Sheet: Machine Component Job Description Planned by Wo NoDocument8 pagesJob Schedule Sheet: Machine Component Job Description Planned by Wo NoYudha RafiNo ratings yet

- Obstructive Sleep ApnoeaDocument43 pagesObstructive Sleep Apnoeachunshienwc6833100% (3)

- INGFRT-11 Run at RateDocument3 pagesINGFRT-11 Run at RateMarisol RubioNo ratings yet

- Production Report Shift WiseDocument5 pagesProduction Report Shift WiseOBSC PerfectionNo ratings yet

- 5S ImplementationDocument35 pages5S ImplementationPrateek Gupta100% (1)

- Vishwas Electroplaters: Control Plan For Acid Zinc Barrel Plating & Hexavalent PassivationDocument13 pagesVishwas Electroplaters: Control Plan For Acid Zinc Barrel Plating & Hexavalent PassivationAnonymous YptJ5iDNo ratings yet

- Advanced Practice On Word Formation PDFDocument0 pagesAdvanced Practice On Word Formation PDFKhiem Vuong100% (1)

- Unit 2 Lab ManualDocument19 pagesUnit 2 Lab Manualkari1995No ratings yet

- 000 ZA E 09411 Punch List ProcedureDocument17 pages000 ZA E 09411 Punch List Procedurealinor_tn100% (1)

- Cataumet BoatsDocument10 pagesCataumet BoatsChiranth Erappa100% (1)

- Arc Flash Issues in Transmission andDocument462 pagesArc Flash Issues in Transmission andLaurence MichaelNo ratings yet

- Mechanical Completion Procedure PDFDocument69 pagesMechanical Completion Procedure PDFDoctorOberman100% (3)

- 5E Lesson Plan-PolygonsDocument3 pages5E Lesson Plan-PolygonsNoli Asuro50% (4)

- Standard Work SheetsDocument6 pagesStandard Work SheetsThanh NguyenNo ratings yet

- Arthropods of Public Health Importance Key To Common Classes and OrdersDocument14 pagesArthropods of Public Health Importance Key To Common Classes and OrdersEmil GonzalezNo ratings yet

- Daily Prod Report SGB 04 - 07 - 2022Document2 pagesDaily Prod Report SGB 04 - 07 - 2022Said PrayogiNo ratings yet

- Delta Calculations LTSW Module 2 EXERCISEDocument20 pagesDelta Calculations LTSW Module 2 EXERCISEdraganNo ratings yet

- MTP132-Daily Report 15 April 2023Document3 pagesMTP132-Daily Report 15 April 2023Bambang ArdiansyahNo ratings yet

- Unit ReinforcementDocument1 pageUnit ReinforcementMaulidNo ratings yet

- Work Content Evaluation & Line BalancingDocument21 pagesWork Content Evaluation & Line BalancingPrajkta RanpiseNo ratings yet

- Mounting Face TappingDocument1 pageMounting Face TappingChiller PartyNo ratings yet

- Side FacingDocument1 pageSide FacingChiller PartyNo ratings yet

- Print Work Definition Report - 300000133439714Document11 pagesPrint Work Definition Report - 300000133439714Fayez Al-ahmadiNo ratings yet

- Bush CostingPebhaDocument1 pageBush CostingPebhaEr Raj VeerNo ratings yet

- Process Flow DiagramDocument2 pagesProcess Flow DiagramQuality VenusNo ratings yet

- Flange FacingDocument1 pageFlange FacingChiller PartyNo ratings yet

- 6-RLT9VZ10S16D5 Low - Pressure - FiltersDocument1 page6-RLT9VZ10S16D5 Low - Pressure - FiltersNibin OdukkathilNo ratings yet

- FB6066 UA Product Brochure - 1Document4 pagesFB6066 UA Product Brochure - 1charithaNo ratings yet

- Line Balancing - Amila WickramasearaDocument18 pagesLine Balancing - Amila WickramasearaamilanuwanwNo ratings yet

- Daily Prod Report SGB 05 - 07 - 2022Document2 pagesDaily Prod Report SGB 05 - 07 - 2022Said PrayogiNo ratings yet

- Daily Prod Report SGB 03 - 07 - 2022Document2 pagesDaily Prod Report SGB 03 - 07 - 2022Said PrayogiNo ratings yet

- MTP132-Daily Report 16 July 2023Document9 pagesMTP132-Daily Report 16 July 2023Bambang ArdiansyahNo ratings yet

- Ffu 0000767 01Document4 pagesFfu 0000767 01Omar ScaniaNo ratings yet

- Dfa TabbelDocument6 pagesDfa Tabbelapi-330012159No ratings yet

- Odyssey Craft (PVT.) LTD.: Buyer - PDS - PEPE Product - Trouser Style No - Lilen Trouser Style Details Lilen TrouserDocument4 pagesOdyssey Craft (PVT.) LTD.: Buyer - PDS - PEPE Product - Trouser Style No - Lilen Trouser Style Details Lilen TrouserFORHAD HOSSAINNo ratings yet

- Reconciliation On Cost March 2018-Manday - ManishDocument4 pagesReconciliation On Cost March 2018-Manday - ManishDeepum HalloomanNo ratings yet

- Updated Gantt ChartDocument2 pagesUpdated Gantt ChartRonald ModestoNo ratings yet

- Daily Prod Report SGB 01 - 07 - 2022Document2 pagesDaily Prod Report SGB 01 - 07 - 2022Said PrayogiNo ratings yet

- #2 Report of Supermarket Improvement TeamDocument26 pages#2 Report of Supermarket Improvement TeamMatthew AlvinNo ratings yet

- Production Daily Report - Umum 1Document3 pagesProduction Daily Report - Umum 1ayu agustinaNo ratings yet

- Airend Engine AsslyDocument2 pagesAirend Engine AsslyabhijitNo ratings yet

- Attn: Akebono Braxe Astra VietnamDocument5 pagesAttn: Akebono Braxe Astra VietnamanhthoNo ratings yet

- Daily Report 8 April 2023 PDFDocument2 pagesDaily Report 8 April 2023 PDFBambang ArdiansyahNo ratings yet

- Daily Drilling Fluid Report (041A) - 01 April 16-1Document1 pageDaily Drilling Fluid Report (041A) - 01 April 16-1Lenin FontanaNo ratings yet

- Lidl 348543 B2Document1 pageLidl 348543 B2Sazzadahmed. TeNo ratings yet

- Daily Report 7 April 2023 Sent PDFDocument2 pagesDaily Report 7 April 2023 Sent PDFBambang ArdiansyahNo ratings yet

- Daily Report: Embasy Renovation ProjectDocument3 pagesDaily Report: Embasy Renovation ProjectQuốc Hùng VũNo ratings yet

- 15MVAR ReactorDocument2 pages15MVAR ReactorBarry79xNo ratings yet

- Value Stream MappingDocument14 pagesValue Stream MappingGerardo Raamiireez FüğėėnNo ratings yet

- Daily Progress Drumshell 03.01.23Document3 pagesDaily Progress Drumshell 03.01.23kehlmathias07No ratings yet

- Gage R&R (ANOVA) Report For .21 - 0681 / - 0668 XDDocument3 pagesGage R&R (ANOVA) Report For .21 - 0681 / - 0668 XDAKIN KAYODENo ratings yet

- NEW Peta Okupasi KKNI Otomotif JUNI 01-1Document1 pageNEW Peta Okupasi KKNI Otomotif JUNI 01-1Maulana Ali RamadhanNo ratings yet

- Macy's 100194220TG Operation Breakdown - Fower Fleece Set BottomDocument2 pagesMacy's 100194220TG Operation Breakdown - Fower Fleece Set BottomSaefi IsmailNo ratings yet

- Program of Works Hand Washing FJMSDocument2 pagesProgram of Works Hand Washing FJMSMakRo DaxNo ratings yet

- Potential Failure Mode and Effects Analysis (Pfmea)Document3 pagesPotential Failure Mode and Effects Analysis (Pfmea)aslamNo ratings yet

- 1145 Manpower AttendanceDocument19 pages1145 Manpower AttendanceveerlloydNo ratings yet

- Line Balance 059Document39 pagesLine Balance 059smitaNo ratings yet

- Spacer PFDDocument1 pageSpacer PFDShoaib AkhtarNo ratings yet

- 01/10/2012 Ultrasonic Examination Certificate: in Salah Gas Sout Fields Developments ProjectDocument2 pages01/10/2012 Ultrasonic Examination Certificate: in Salah Gas Sout Fields Developments ProjectdaemsalNo ratings yet

- Bop FebDocument5 pagesBop FebVarga TrigustaraNo ratings yet

- Repport UT CS - 7Document1 pageRepport UT CS - 7daemsalNo ratings yet

- How To Install OpenStack On CentOS 8 With PackstackDocument15 pagesHow To Install OpenStack On CentOS 8 With PackstackLoubna QueenNo ratings yet

- Ws c2960l 16ps LL DatasheetDocument5 pagesWs c2960l 16ps LL DatasheetjuanNo ratings yet

- Spectrophotometric Determination of Equilibrium Constant of A ReactionDocument9 pagesSpectrophotometric Determination of Equilibrium Constant of A ReactionRic Michael De VeraNo ratings yet

- 2.3 Monitor Unit: - MU-201CR (20 Inch LCD) - MU-231CR (23 Inch LCD)Document3 pages2.3 Monitor Unit: - MU-201CR (20 Inch LCD) - MU-231CR (23 Inch LCD)PhuocTranThienNo ratings yet

- Adyar Gate Junction PDFDocument1 pageAdyar Gate Junction PDFAnwar ShaikNo ratings yet

- Dywidag Systems International - Mechanical Anchors and Rebar Rock Bolts (DSI, 2013)Document16 pagesDywidag Systems International - Mechanical Anchors and Rebar Rock Bolts (DSI, 2013)sandycastleNo ratings yet

- 2x16 BOGIE SPARE PARTSDocument7 pages2x16 BOGIE SPARE PARTSVignesh PrabhuNo ratings yet

- Samsung Horticulture Technical Brochure 190627Document16 pagesSamsung Horticulture Technical Brochure 190627Stiven AndrewNo ratings yet

- Livelihood Due To Establishment of Sitakunda Eco ParkDocument10 pagesLivelihood Due To Establishment of Sitakunda Eco ParkDr. Mohammad Shamsuddoha100% (1)

- (Computing 14) A. Aguilera, D. Ayala (Auth.), Professor Dr. Guido Brunnett, Dr. Hanspeter Bieri, Professor Dr. Gerald Farin (Eds.) - Geometric Modelling-Springer-Verlag Wien (2001)Document356 pages(Computing 14) A. Aguilera, D. Ayala (Auth.), Professor Dr. Guido Brunnett, Dr. Hanspeter Bieri, Professor Dr. Gerald Farin (Eds.) - Geometric Modelling-Springer-Verlag Wien (2001)ANDRES Fernando Mosquera DIAZNo ratings yet

- 10 Support Vector MachineDocument130 pages10 Support Vector MachineAnurag LahkarNo ratings yet

- L6 U3 SNC1D NotesDocument6 pagesL6 U3 SNC1D NotesabhieNo ratings yet

- Applied MathsDocument8 pagesApplied MathsVinay MishraNo ratings yet

- Extended Essay 4Document20 pagesExtended Essay 4thatoNo ratings yet

- Data Coll Action of ResortDocument62 pagesData Coll Action of ResortLakshmiRaviChanduKolusu0% (1)

- Bloomfield Microbial ContaminationDocument2 pagesBloomfield Microbial ContaminationKruperTrooperNo ratings yet

- The Social Determinants of Mental HealthDocument8 pagesThe Social Determinants of Mental Healthmelicruz14No ratings yet

- Jhajjar Master PlanDocument1 pageJhajjar Master PlanMayank AhujaNo ratings yet

- Corrosion Short Courses, Corrosion Training Courses and Corrosion Courses For In-House Training, Online and Distance LearningDocument3 pagesCorrosion Short Courses, Corrosion Training Courses and Corrosion Courses For In-House Training, Online and Distance LearningAsyrafNo ratings yet

- Expansion Processes of A Perfect Gas - : TH Series: ThermodynamicsDocument3 pagesExpansion Processes of A Perfect Gas - : TH Series: ThermodynamicsSyamim AsyrafNo ratings yet

- Chap 05 MagnetismandmatterxiiphysicsncertsolDocument26 pagesChap 05 MagnetismandmatterxiiphysicsncertsolANMOLNo ratings yet