Professional Documents

Culture Documents

Process Flow Diagram

Process Flow Diagram

Uploaded by

Quality VenusOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Flow Diagram

Process Flow Diagram

Uploaded by

Quality VenusCopyright:

Available Formats

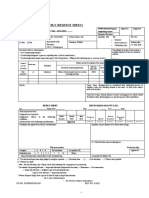

PROCESS FLOW DIAGRAM

VENUS

Part Certification

Family name Date (Orig.) Prepared by

Insert 09-08-2019 Pranav Mehta

Part Number Date (Rev.) Title

2912943-A03 09-29-2023

Part Name Page Phone Number

INSERT TYPE HEX NUT ( M5 x 0.8 ) +918238697871

Cross Functional Team Members Symbol Key:

Pranav Mehta 1 of 2 Manufacturing/Assembly

Jaimin Galani Movement of Materials/Parts

Mahendra Dharaviya Storage of Materials/Parts

Inspection

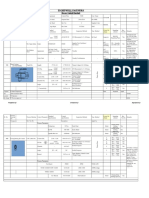

Step # Ope Move Store Insp Operation description Key Product Characteristics Control Characteristics

Raw material inward inspection report /

Brass round bar : 7.70 HEX

1 Raw material size Chemical analysis report /

Material Grade : C3600

Outside laboratory report

2 First five piece inspection report Perfrom first five piece inspection process before starting of mass production First five piece inspection process

Hex size Hex size 7.70 (+/-0.13)

Facing Total Length 9.50 (+/-0.13)

Outer Diameter 6.3 (+/-0.1)

Turning Distance 4.70 (+/-0.13)

3

Step Length 2.70 (+/-0.13)

Counter Sink Counter Sink Counter Sink

Chamfering Chamfer degree 45 degree

Threading Thread M5 x 0.8-6H

Deburring Process Remove outer burrs from outer edges

4

Deburring Process Remove burrs from hole

5 Run SPC As per defined SPC plan SPC Data / Process capability history card

In-process inspection report /

Layer audit report /

Control plan /

First five piece inspection report /

6 Part Cleaning/Washing Process Parts must be free from any contamination

Process route card /

Part cleaning WI-SOP /

Random visual inspection report /

Cleaning timing report

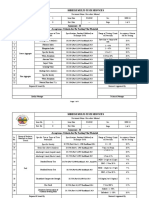

PROCESS FLOW

2 of 2DIAGRAM

VENUS

Part Certification

Family name Date (Orig.) Prepared by

Insert 09-08-2019 Pranav Mehta

Part Number Date (Rev.) Title

2912943-A03 09-29-2023

Part Name Page Phone Number

INSERT TYPE HEX NUT ( M5 x 0.8 ) +918238697871

Cross Functional Team Members Symbol Key:

Pranav Mehta Manufacturing/Assembly

Jaimin Galani Movement of Materials/Parts

Mahendra Dharaviya Storage of Materials/Parts

Inspection

Step # Ope Move Store Insp Operation description Key Product Characteristics Control Characteristics

Visual control /

Visual Inspection OPL

Material should be free from burrs,scratches,marks,source,dents,crack or any

7 other material defects

Perform visual inspection process for 2 times

Random visual inspection report operatorwise random visual inspection report

9.50 (+/-0.13)

Standard machine calibration SOP/SOP to run the sorting machine

8 Optical Sorting 6.3

Perform sorting process for 2 times

Presence of Thread

Check dimension as per customer drawing Final inspection report /

9 Final inspection Inspect material as per control plan Sampling plan /

Do visual checking during final inspection Quality assurance plan

Presence of inspection report,route card,SPC report,Layer audit

10 Dock Audit report,drawing revision level,heat number traceability.Check dimension as Dock audit sheet

per drawing & check defined control plan is followed?

11 Packing Packing as per customer requirement Visual packing condition / Packing list / Label

You might also like

- Quality Control PlanDocument1 pageQuality Control PlanJoki PenangNo ratings yet

- Vishwas Electroplaters: Control Plan For Acid Zinc Barrel Plating & Hexavalent PassivationDocument13 pagesVishwas Electroplaters: Control Plan For Acid Zinc Barrel Plating & Hexavalent PassivationAnonymous YptJ5iDNo ratings yet

- Quality Control Process Chart (Machining)Document7 pagesQuality Control Process Chart (Machining)mani317No ratings yet

- Control Plan: 3 1/4" Bore A-Series Side-Lug CapsDocument4 pagesControl Plan: 3 1/4" Bore A-Series Side-Lug CapsRavichandran D100% (1)

- CP20200804-A Model Control Plan - FoundationsDocument6 pagesCP20200804-A Model Control Plan - Foundationsmanno200No ratings yet

- SMT Generic Control PlanDocument2 pagesSMT Generic Control Plansmtdrkd81% (21)

- Machining Control PlannDocument18 pagesMachining Control PlannSuraj Rawat0% (1)

- GM Machining CP REV 03Document17 pagesGM Machining CP REV 03Suraj RawatNo ratings yet

- Casting CPDocument2 pagesCasting CPSuraj RawatNo ratings yet

- Efwe 2 e 4 GF 1 W 3Document1 pageEfwe 2 e 4 GF 1 W 3BALACHANDAR SNo ratings yet

- Control Plan For Zinc Flake CoatingDocument3 pagesControl Plan For Zinc Flake Coatingx y100% (1)

- Without Punch Part Mix: Customer/Supplier / in Plant Quality Problem Analysis and Countermeasure Sheet (5 - Rule)Document13 pagesWithout Punch Part Mix: Customer/Supplier / in Plant Quality Problem Analysis and Countermeasure Sheet (5 - Rule)Rohtash fastnerNo ratings yet

- D10414410a Fmea CastingDocument7 pagesD10414410a Fmea CastingSuraj RawatNo ratings yet

- D10414410a Fmea MachiningDocument13 pagesD10414410a Fmea MachiningSuraj RawatNo ratings yet

- Microwave Transmission OverviewDocument12 pagesMicrowave Transmission OverviewJunaid MuidynNo ratings yet

- Standard Operating Procedure / Work Instructions / Visual AidsDocument3 pagesStandard Operating Procedure / Work Instructions / Visual AidsSwapnil BachhavNo ratings yet

- D10414410A CP Rev 00Document21 pagesD10414410A CP Rev 00Suraj RawatNo ratings yet

- CAPA Thread OutDocument80 pagesCAPA Thread OutRohtash fastnerNo ratings yet

- PFD Control Plan and FMEA FormatsDocument12 pagesPFD Control Plan and FMEA FormatsDINESH SHARMA100% (1)

- Control Plan: Process InformationDocument20 pagesControl Plan: Process InformationGeovanni calderonNo ratings yet

- CP-SS BLK-01Document5 pagesCP-SS BLK-01yogesh WakchaureNo ratings yet

- HIRARCDocument106 pagesHIRARCMohdNajib Mahmud75% (4)

- Control Plan Template 2011 PDFDocument1 pageControl Plan Template 2011 PDFSenthil_KNo ratings yet

- 07 Control PlanDocument5 pages07 Control PlanManoharar RNo ratings yet

- Annex 2 Process Audit PDFDocument15 pagesAnnex 2 Process Audit PDFAngie GuerreroNo ratings yet

- DC System DesignDocument6 pagesDC System DesignTukaram Pawar100% (1)

- Chapter 3Document6 pagesChapter 3Ores Legazpi100% (4)

- Control Plan-StampingDocument2 pagesControl Plan-StampingVipin Jangra100% (1)

- Chapter DBMS ArchitectureDocument37 pagesChapter DBMS Architecturejuhi naikNo ratings yet

- WoodwardDocument104 pagesWoodwardwachuwachuNo ratings yet

- Installation Manual-A: TK 50555-2-IM (Rev. 8, 02/06)Document60 pagesInstallation Manual-A: TK 50555-2-IM (Rev. 8, 02/06)معمر حميد100% (1)

- HART Vs Foundation Fieldbus - ComparisonDocument10 pagesHART Vs Foundation Fieldbus - ComparisonrajkumarpandeyNo ratings yet

- Control Plan: FG 260 As Per IS 210: 2009Document24 pagesControl Plan: FG 260 As Per IS 210: 2009Suraj RawatNo ratings yet

- GM Casting CPDocument3 pagesGM Casting CPSuraj RawatNo ratings yet

- Waiver Request Format Rev 3Document2 pagesWaiver Request Format Rev 3manjunatha gNo ratings yet

- Isir - (00003)Document1 pageIsir - (00003)ducthangspktNo ratings yet

- Cntlplan 5Document4 pagesCntlplan 5sumeetsaini88No ratings yet

- BEL/CP/78670517/C04 78670517 - C04 Bracket FMD, FLR, WildbarDocument3 pagesBEL/CP/78670517/C04 78670517 - C04 Bracket FMD, FLR, WildbarashishNo ratings yet

- Control Plan - 608 2RS C3Document28 pagesControl Plan - 608 2RS C3trandangbkNo ratings yet

- Machining Control PlanDocument1 pageMachining Control PlanGARIMA CASTINGS, JAIPURNo ratings yet

- Control Plan: Process / Operation DescriptionDocument3 pagesControl Plan: Process / Operation DescriptionsharanNo ratings yet

- Pt. Prestasi Inti Rubber: Control PlanDocument1 pagePt. Prestasi Inti Rubber: Control PlanHardjonoNo ratings yet

- Cantrol Plan Shaft TM Rev 76M00 RevisedDocument10 pagesCantrol Plan Shaft TM Rev 76M00 RevisednishantNo ratings yet

- Work Permit - Load Testing Spiderframe PPR RoomDocument5 pagesWork Permit - Load Testing Spiderframe PPR RoomReynold AndikaNo ratings yet

- Control Plan - 23768162 - P01Document7 pagesControl Plan - 23768162 - P01ashishNo ratings yet

- Control Plan - 22887306 - P03Document3 pagesControl Plan - 22887306 - P03ashishNo ratings yet

- Pro-Quality Associates Control PlanDocument1 pagePro-Quality Associates Control PlanDeepak kumarNo ratings yet

- Pro-Quality Associates Control PlanDocument1 pagePro-Quality Associates Control PlanDeepak kumarNo ratings yet

- 1.PFD 561-89-86933Document8 pages1.PFD 561-89-86933Balaji AnbazaganNo ratings yet

- Spacer PFDDocument1 pageSpacer PFDShoaib AkhtarNo ratings yet

- Control Plan: Prototype Pre-Launch XDocument1 pageControl Plan: Prototype Pre-Launch XkishortilekarNo ratings yet

- Six Sigma Project ReportDocument39 pagesSix Sigma Project Reportsumeetsaini88No ratings yet

- NEW FORMATE Cover CPDocument47 pagesNEW FORMATE Cover CPVeera Mani KNo ratings yet

- Control PlanDocument26 pagesControl PlanashishNo ratings yet

- Control Plan TWIN ANCHORDocument5 pagesControl Plan TWIN ANCHORMURALIDHRANo ratings yet

- Plan de Surveillance Pièce PlastiqueDocument2 pagesPlan de Surveillance Pièce PlastiqueFida GhanmiNo ratings yet

- CP For Assembly PartsDocument1 pageCP For Assembly Partssantosh kumarNo ratings yet

- Alloy Wheel H-2000-3805-01 MC PDFDocument6 pagesAlloy Wheel H-2000-3805-01 MC PDFAliya RaheelNo ratings yet

- KWPG2-EN-FRM-009 REV C FMEA-Bracket KUDocument8 pagesKWPG2-EN-FRM-009 REV C FMEA-Bracket KUMyst ToganNo ratings yet

- Control Plan-06Document2 pagesControl Plan-06PARI VALLALNo ratings yet

- Ac Extraction Permanent Works FormDocument2 pagesAc Extraction Permanent Works Formbest essaysNo ratings yet

- CNC MachiningDocument1 pageCNC MachiningChiller PartyNo ratings yet

- Control Plan: Cervantes Chavez, Sanchez Hernandez, Espinoza Rodriguez, Torres MuñizDocument8 pagesControl Plan: Cervantes Chavez, Sanchez Hernandez, Espinoza Rodriguez, Torres MuñizLuis Guillermo Cervantes ChávezNo ratings yet

- Shreeji Multi-Tech ServicesDocument4 pagesShreeji Multi-Tech ServicesSHREEJI MULTIT-ECHNo ratings yet

- CP YwdDocument5 pagesCP YwdRaj BistNo ratings yet

- Certificate of Conformance: VenusDocument1 pageCertificate of Conformance: VenusQuality VenusNo ratings yet

- Job CardDocument1 pageJob CardQuality VenusNo ratings yet

- Dryer Verification ProcedureDocument2 pagesDryer Verification ProcedureQuality VenusNo ratings yet

- Caliper Calibration ProcedureDocument3 pagesCaliper Calibration ProcedureQuality VenusNo ratings yet

- Shutdown-Start-Up ProcedureDocument2 pagesShutdown-Start-Up ProcedureQuality VenusNo ratings yet

- Microscope Calibration ProcedureDocument4 pagesMicroscope Calibration ProcedureQuality VenusNo ratings yet

- Training Schedule 2018Document2 pagesTraining Schedule 2018Quality VenusNo ratings yet

- Training EffectivenessDocument1 pageTraining EffectivenessQuality VenusNo ratings yet

- Training Evaluation FormDocument2 pagesTraining Evaluation FormQuality VenusNo ratings yet

- Quality Assurance PlanDocument4 pagesQuality Assurance PlanQuality VenusNo ratings yet

- MAT P 014 Counterfeit Parts Avoidance ProcedureDocument5 pagesMAT P 014 Counterfeit Parts Avoidance ProcedureQuality VenusNo ratings yet

- Product Audit 4813Document1 pageProduct Audit 4813Quality VenusNo ratings yet

- Rmi CMRT6-10Document176 pagesRmi CMRT6-10Quality VenusNo ratings yet

- Safety CalenderDocument1 pageSafety CalenderQuality VenusNo ratings yet

- First & Last PieceDocument3 pagesFirst & Last PieceQuality VenusNo ratings yet

- Attribute R&RDocument3 pagesAttribute R&RQuality VenusNo ratings yet

- Certificate of ConformanceDocument1 pageCertificate of ConformanceQuality VenusNo ratings yet

- Valvula Solenoide Norgren SxeDocument2 pagesValvula Solenoide Norgren SxeBase SistemasNo ratings yet

- Are Mobiles Taking Over Our LivesDocument5 pagesAre Mobiles Taking Over Our LivesSalma BazziNo ratings yet

- MosfetDocument13 pagesMosfetapi-26783388100% (1)

- Amm 592-594 1015-1Document1 pageAmm 592-594 1015-123dr0207No ratings yet

- Code CoverageDocument14 pagesCode CoveragevijayanreddyNo ratings yet

- Google People Operations - The Secrets of The World's Most Scientific Human Resources DepartmentDocument3 pagesGoogle People Operations - The Secrets of The World's Most Scientific Human Resources DepartmentAtul KohliNo ratings yet

- Catálogo de Peças Jivo 245Document199 pagesCatálogo de Peças Jivo 245posvendasdf5No ratings yet

- CN & cx200 Operators 50072 PDFDocument72 pagesCN & cx200 Operators 50072 PDFMohamed HarbNo ratings yet

- Donaldson Pf-Eg Filter Housing. Process FluidDocument3 pagesDonaldson Pf-Eg Filter Housing. Process FluidluisNo ratings yet

- ANSI Test Weight (282 LBS) For WebDocument2 pagesANSI Test Weight (282 LBS) For WebOscar Ivan Gonzalez SalasNo ratings yet

- RS401L LuguangElectronicDocument2 pagesRS401L LuguangElectronicvvvvzzzzzNo ratings yet

- Elmex Price List 2018 FinalDocument36 pagesElmex Price List 2018 Finalpranay prakashNo ratings yet

- 53rd Annual Report 2013-2014Document127 pages53rd Annual Report 2013-2014sriramrangaNo ratings yet

- Case Study-S.MDocument3 pagesCase Study-S.Mjaveria_nabihaNo ratings yet

- 2023.01.15 Intervention Report Lance Cooling ValveDocument1 page2023.01.15 Intervention Report Lance Cooling ValveRamy Hassan EmaraNo ratings yet

- Whats FairDocument12 pagesWhats FairfactorialthreeNo ratings yet

- Noah Arroyo - Resume 4 2f25 2f18Document1 pageNoah Arroyo - Resume 4 2f25 2f18api-404072302No ratings yet

- R.Ashwin Chakravarthy: Avc Polytechnic College, MayiladuthuraiDocument2 pagesR.Ashwin Chakravarthy: Avc Polytechnic College, MayiladuthuraiMaster RajaNo ratings yet

- Khan Shatyr Centre Structural Engineering Article 2009Document5 pagesKhan Shatyr Centre Structural Engineering Article 2009Hasan GüleryüzNo ratings yet

- Certificates - ZOV DOC - ENDocument1 pageCertificates - ZOV DOC - ENaleksa.savicNo ratings yet

- Ieee STDDocument22 pagesIeee STDBalaji SpNo ratings yet

- Compiler Construction ToolsDocument2 pagesCompiler Construction Toolsbijay khadka100% (1)