Professional Documents

Culture Documents

ASBAS350010069ENR3

Uploaded by

Bruno Alonso PachecoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASBAS350010069ENR3

Uploaded by

Bruno Alonso PachecoCopyright:

Available Formats

ASB No. AS350-01.00.

69

Civil version(s): B1, B2

Military version(s): L1

ALERT SERVICE BULLETIN

SUBJECT: LIMITATIONS - Main Gearbox (MGB) Casings

Limitation and follow-up of casings in torque cycles (TC)

ATA: 63

For the attention of

Revision No. Date of issue

Revision 0 2015-06-02

Revision 1 2015-07-28

Revision 2 2015-12-22

Revision 3 2016-01-07

Summary:

This ALERT SERVICE BULLETIN informs that the Service Life Limit (SLL) follow-up of the MGB sump is now to be

carried out in torque cycles (TC).

Reason for last Revision:

The purpose of Revision 3 of this ALERT SERVICE BULLETIN is to clarify the applicability in paragraph 1.E.2.a.a)

for MGB sumps if the number of torque cycles (TC) logged is known.

Compliance:

Airbus Helicopters renders compliance with this ALERT SERVICE BULLETIN mandatory.

Revision 0 2015-06-02 Page 1/13

Revision 3 2016-01-07 This document is available on the internet: www.airbushelicopters.com/techpub

ASB No. AS350-01.00.69

1. PLANNING INFORMATION

1.A. EFFECTIVITY

NOTE 1

Refer to the Log Cards (FM) to identify the actual

configuration of the helicopter.

1.A.1. Helicopters/installed equipment

Helicopters equipped with a MGB sump with a Part Number indicated in paragraph 4.A.

1.A.2. Non-installed equipment

MGB main modules equipped with a MGB sump with a Part Number indicated in paragraph 4.A.

1.B. ASSOCIATED REQUIREMENTS

Not applicable.

1.C. REASON

Revision 0:

During certification of the AS350 B3"e" helicopter, an optimization of the stress calculation resources for both

MGB main module casings (main casing assembly and MGB sump) revealed critical areas which had not yet

been identified on the previous Ecureuil helicopter versions.

Following these results, Airbus Helicopters has re-substantiated the stress on all existing MGB casings of the

Ecureuil family through the use of these new resources. Consequently, the service life of these casings may

change slightly.

As the MGB casings are mainly stressed in torque cycles (TC), and for harmonization purposes, Airbus

Helicopters has decided to follow-up the main casings and MGB sumps on the Ecureuil helicopter versions

indicated in paragraph 4.A., in torque cycles (TC), although no cracks have been reported on these casings.

The table below indicates the current Service Life Limit (SLL), which is maintained, as well as an additional

limitation from which an inspection of the MGB sumps on AS350 B1, B2 and L1 helicopters is required

through this ASB:

Service Life Limit Limitation before

Designation

(SLL) inspection

MGB Sump 20000 FH 93700 TC

For clarification, the table given in paragraph 4.A. summarizes the SLL values specified in the Master

Servicing Manual (MSM) and the new torque cycle (TC) limitations introduced according to the Ecureuil

family versions, as well as the associated ALERT SERVICE BULLETIN numbers.

Airbus Helicopters renders compliance with this ALERT SERVICE BULLETIN mandatory.

Revision 0 2015-06-02 Page 2/13

Revision 3 2016-01-07 This document is available on the internet: www.airbushelicopters.com/techpub

ASB No. AS350-01.00.69

Revision 1:

Airbus Helicopters has been informed that symbol “XX” has been marked on some MGB sumps, near their

Part Number. This symbol is marked as part of compliance with Letter to Repair Stations (LR) No. 188.

In order to avoid any confusion with this repair and to specify more clearly which casings are concerned by

this ALERT SERVICE BULLETIN, Airbus Helicopters makes compliance with this ALERT SERVICE

BULLETIN Revision 1 mandatory.

Revision 2:

The purpose of revision 2 of this ALERT SERVICE BULLETIN is to modify the time limit for replacing MGB

sumps which are free from cracks, in cases where the number of TCs performed is known (see

paragraph 1.E.2.a. a).

Revision 3:

The purpose of Revision 3 of this ALERT SERVICE BULLETIN is to clarify the applicability in

paragraph 1.E.2.a.a) for MGB sumps if the number of torque cycles (TC) logged is known.

1.D. DESCRIPTION

Revision 0:

This ALERT SERVICE BULLETIN Revision 0 consists in:

- Informing that the follow-up of MGB sumps is now to be carried out in torque cycles (TC) only.

- Calculating the Service Life Limit (SLL) in torque cycles (TC) for casings which have never been

followed-up in torque cycles (TC).

- Implementing a specific inspection to be performed if the new limitation of the MGB sumps as defined in

paragraph 1.E. is exceeded.

Revision 1:

This ALERT SERVICE BULLETIN Revision 1 consists in:

- Marking symbol “V” after the Serial Number (S/N) of MGB sumps for which the number of logged torque

cycles was estimated by converting the number of flying hours, in compliance with this ALERT SERVICE

BULLETIN Revision 0.

- Adding details concerning the casings listed in paragraph 4.A.

Revisions 2 and 3:

Clarification of the applicability in paragraph 1.E.2.a.a) for MGB sumps if the number of torque cycles (TC)

logged is known.

1.E. COMPLIANCE

1.E.1. Compliance at the works

Not applicable.

Revision 0 2015-06-02 Page 3/13

Revision 3 2016-01-07 This document is available on the internet: www.airbushelicopters.com/techpub

ASB No. AS350-01.00.69

1.E.2. Compliance in service

CAUTION

AFTER EACH INSPECTION, REPORT THE RESULTS

OBTAINED TO THE AIRBUS HELICOPTERS TECHNICAL

SUPPORT DEPARTMENT BY SENDING AN E-MAIL TO:

support.technical-dyncomp.ah@airbus.com

Helicopters/installed equipment

1.E.2.a. For helicopters on which Revision 0 of this ALERT SERVICE BULLETIN has not been complied with:

Within 165 flying hours and no later than within 6 months following receipt of this ALERT SERVICE

BULLETIN Revision 0, issued on June 02, 2015, record the number of flying hours and, if possible, the

number of torque cycles logged by the MGB sump:

NOTE 2

For casings installed on MGBs which have not yet

undergone Complete Overhaul (RG), it is possible to

determine the number of torque cycles through the cycle

follow-up carried out for other MGB components.

a) If the number of torque cycles (TC) logged is known:

. If the MGB sump has logged less than 92700 TC on the date of first compliance with this ALERT

SERVICE BULLETIN:

- No additional action is required until 92700 TC are reached.

- When 92700 TC are reached, check within 1000 TC that there are no cracks at each of the

attachment lugs (Area A, Figure 1) of the casing as per paragraph 3.B.2.:

Interpretation of the results:

- If there is a crack, replace the casing before resuming flights.

- If there are no cracks:

. Replace the casing during the next Repair (RE) or Complete Overhaul (RG) of the MGB main

module no later than within 27000 TC following the check, without exceeding 120000 TC.

. If the MGB sump has logged 92700 or more TC on the date of first compliance with this ALERT

SERVICE BULLETIN:

- Check that there are no cracks at each of the attachment lugs (Area A, Figure 1) of the casing within

1000 TC and as per paragraph 3.B.2.:

Interpretation of the results:

- If there is a crack, replace the casing before resuming flights.

- If there are no cracks:

. Replace the casing during the next Repair (RE) or Complete Overhaul (RG) of the MGB main

module no later than within 27000 TC following the check, without exceeding 120000 TC.

Revision 0 2015-06-02 Page 4/13

Revision 3 2016-01-07 This document is available on the internet: www.airbushelicopters.com/techpub

ASB No. AS350-01.00.69

b) If the number of torque cycles (TC) logged is unknown:

. Convert the flying hours into torque cycles:

- Number of torque cycles = number of flying hours x 6

. Update the Log Card (FM) by specifying the calculated number of torque cycles (TC).

. Mark a "V" after the Serial Number (S/N) of the MGB sump:

- on the casing as per MTC Work Card 20.08.05.103,

- on the MGB Log Card.

NOTE 3

The "V" symbol marked after the S/N of the casing means

that the number of torque cycles has been estimated by

converting the number of flying hours logged by this casing

into torque cycles.

. Check that there are no cracks at each of the attachment lugs (Area A, Figure 1) within

1000 TC following first compliance with this ALERT SERVICE BULLETIN, as per paragraph 3.B.2.:

then,

. every 27000 TC.

Interpretation of the results:

. If there is a crack, replace the casing before resuming flights.

. If there are no cracks:

- Replace the casing during the next Repair (RE) or Complete Overhaul (RG) of the MGB main module

after having reached 93700 TC, without exceeding 120000 TC.

NOTE 4

The MGB casings can only be replaced by a D-level

maintenance center.

1.E.2.b. For helicopters on which Revision 0 of this ALERT SERVICE BULLETIN has been complied with:

a) If the number of torque cycles (TC) logged by the MGB sump has been estimated by converting

the number of flying hours logged by the MGB sump into torque cycles:

No later than within 3 months following receipt of this ALERT SERVICE BULLETIN Revision 1, issued

on July 28, 2015:

- Mark a “V” after the Serial Number (S/N) of the MGB sump:

. on the MGB sump, as per MTC Work Card 20.08.05.103.

. on the MGB Log Card.

NOTE 5

Symbol “V” marked after the S/N of the MGB sump means

that the number of torque cycles has been estimated by

converting the number of flying hours logged by the MGB

sump into torque cycles.

Revision 0 2015-06-02 Page 5/13

Revision 3 2016-01-07 This document is available on the internet: www.airbushelicopters.com/techpub

ASB No. AS350-01.00.69

- Delete symbol “X” marked as part of compliance with ALERT SERVICE BULLETIN Revision 0:

. from the MGB sump.

. from the MGB Log Card.

- If symbol “XX” is marked near the Part Number of the MGB sump, leave the symbol as is.

NOTE 6

Symbol “XX” is marked on casings on which LR No. 188 was

complied with.

b) In other cases:

- No additional action is required.

Non-installed equipment:

Before installation of a MGB on the helicopter, comply with paragraph 1.E.2.

1.F. APPROVAL

Approval of modifications:

Not applicable.

Approval of this document:

The technical information contained in this ALERT SERVICE BULLETIN Revision 0 was approved

on June 01, 2015 under the authority of EASA Design Organization Approval No. 21J.056 for helicopters of

civil versions subject to an Airworthiness Certificate.

The technical information contained in this ALERT SERVICE BULLETIN Revision 0 was approved

on June 01, 2015 under the prerogatives of the recognition of design capability FRA21J-002-DGA for French

Government helicopters.

The technical information contained in this ALERT SERVICE BULLETIN Revision 0 was approved

on June 01, 2015 by the Airbus Helicopters Airworthiness Department for export military versions.

The technical information contained in this ALERT SERVICE BULLETIN Revision 1 was approved

on July 27, 2015 under the authority of EASA Design Organization Approval No. 21J.056 for helicopters of

civil versions subject to an Airworthiness Certificate.

The technical information contained in this ALERT SERVICE BULLETIN Revision 1 was approved

on July 27, 2015 under the prerogatives of the recognition of design capability FRA21J-002-DGA for French

Government helicopters.

The technical information contained in this ALERT SERVICE BULLETIN Revision 1 was approved

on July 27, 2015 by the Airbus Helicopters Airworthiness Department for export military versions.

Revision 0 2015-06-02 Page 6/13

Revision 3 2016-01-07 This document is available on the internet: www.airbushelicopters.com/techpub

ASB No. AS350-01.00.69

The technical information contained in this ALERT SERVICE BULLETIN Revision 2 was approved

on December 21, 2015 under the authority of EASA Design Organization Approval No. 21J.056 for

helicopters of civil versions subject to an Airworthiness Certificate.

The technical information contained in this ALERT SERVICE BULLETIN Revision 2 was approved

on December 21, 2015 under the prerogatives of the recognition of design capability FRA21J-002-DGA for

French Government helicopters.

The technical information contained in this ALERT SERVICE BULLETIN Revision 2 was approved

on December 21, 2015 by the Airbus Helicopters Airworthiness Department for export military versions.

The technical information contained in this ALERT SERVICE BULLETIN Revision 3 was approved

on January 07, 2016 under the authority of EASA Design Organization Approval No. 21J.056 for helicopters

of civil versions subject to an Airworthiness Certificate.

The technical information contained in this ALERT SERVICE BULLETIN Revision 3 was approved

on January 07, 2016 under the prerogatives of the recognition of design capability FRA21J-002-DGA for

French Government helicopters.

The technical information contained in this ALERT SERVICE BULLETIN Revision 3 was approved

on January 07, 2016 by the Airbus Helicopters Airworthiness Department for export military versions.

1.G. MANPOWER

For compliance with this ALERT SERVICE BULLETIN, Airbus Helicopters recommends the following

personnel qualifications:

Qualification: 1 Technician.

The time for the operations is given for information purposes, for a standard configuration.

Time for the operations: approximately 2 hours.

1.H. WEIGHT AND BALANCE

Not applicable.

1.I. EFFECT ON ELECTRICAL LOADS

Not applicable.

1.J. SOFTWARE MODIFICATION EMBODIMENT RECORD

Not applicable.

Revision 0 2015-06-02 Page 7/13

Revision 3 2016-01-07 This document is available on the internet: www.airbushelicopters.com/techpub

ASB No. AS350-01.00.69

1.K. REFERENCES

The documents required for compliance with this ALERT SERVICE BULLETIN are as follows:

For AS350 helicopters, version B2:

AMM: 63-00-00, 4-1: Main rotor drive - Removal/Installation - MGB/MRH Assembly

For AS350 helicopters, versions B1 and L1:

MET: 63.00.00.402: Main rotor drive: MGB - Bidirectional suspension: Removal-Installation

For AS350 helicopters, all versions:

MTC: 20.02.09.101: Crack detection - Crack detection through dye-penetrant inspection: General

MTC: 20.02.09.601: Crack detection - Checking structural parts/components using the dye penetrant

procedure

MTC: 20.04.02.401: Stripping: Chemical stripping of organic surface finishes

MTC: 20.04.05.101: Paint and primer application procedure - General information about painting means

and paint touch-ups

MTC: 20.08.05.101: General rules applicable to aircraft - Drafting and updating the log card (F.M.) for

equipment follow-up

MTC: 20.08.05.103: General rules applicable to aircraft - Monitoring of parts in operation - marking -

service life customization

1.L. DOCUMENTS AFFECTED

Not applicable.

1.M. INTERCHANGEABILITY OR MIXABILITY OF PARTS

Not applicable.

Revision 0 2015-06-02 Page 8/13

Revision 3 2016-01-07 This document is available on the internet: www.airbushelicopters.com/techpub

ASB No. AS350-01.00.69

2. MATERIAL INFORMATION

2.A. MATERIAL: PRICE - AVAILABILITY - PROCUREMENT

Not applicable.

2.B. INFORMATION CONCERNING INDUSTRIAL SUPPORT

Not applicable.

2.C. MATERIAL REQUIRED FOR EACH HELICOPTER/COMPONENT

Not applicable.

2.D. MATERIAL TO BE RETURNED

Not applicable.

Revision 0 2015-06-02 Page 9/13

Revision 3 2016-01-07 This document is available on the internet: www.airbushelicopters.com/techpub

ASB No. AS350-01.00.69

3. ACCOMPLISHMENT INSTRUCTIONS

3.A. GENERAL

Read and comply with the General information about painting means and paint touch-ups as per MTC Work

Card 20.04.05.101.

3.B. OPERATIONAL PROCEDURE

3.B.1. Preliminary steps

Install the access equipment.

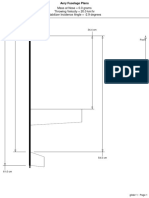

3.B.2. Check for cracks on each of the attachment lugs (Figure 1)

- Visually check that there are no cracks at each of the attachment lugs (Area A, Figure 1).

- If in doubt about the absence of cracks:

. Remove the MGB as per AMM Task 63-00-00, 4-1 or MET Work Card 63.00.00.402.

. Strip each of the attachment lugs in area A (Figure 1) as per MTC Work Card 20.04.02.401.

. Perform a non-destructive inspection (e.g. dye-penetrant inspection as per MTC Work

Cards 20.02.09.101 and 20.02.09.601).

. Check that there are no cracks.

- Interpret the results as per paragraph 1.E.2.

- If previously removed, install a MGB as per AMM Task 63-00-00, 4-1 or MET Work Card 63.00.00.402.

3.B.3. Final steps

Remove the access equipment.

3.C. IDENTIFICATION

Identification of this document:

Record compliance with this document, with the revision number, in the helicopter documents.

Record compliance with this document, with the revision number, on the MGB Log Card (FM) as per MTC

Work Card 20.08.05.101.

3.D. OPERATING AND MAINTENANCE INSTRUCTIONS

Not applicable.

Revision 0 2015-06-02 Page 10/13

Revision 3 2016-01-07 This document is available on the internet: www.airbushelicopters.com/techpub

ASB No. AS350-01.00.69

Area A

Figure 1

Revision 0 2015-06-02 Page 11/13

Revision 3 2016-01-07 This document is available on the internet: www.airbushelicopters.com/techpub

ASB No. AS350-01.00.69

4. APPENDIX

4.A. Table of casings which are concerned by the introduction of the torque cycle limitations

ALERT

New limitation

Casing Part Service life SERVICE

Helicopter Version(s) Casing before

Numbers limit BULLETIN

inspection

No.

350A32-3119-03

B1, B2, L1 MGB sump 350A32-3119-05 20000 FH 93700 TC 01.00.69

350A32-3156-21

Fitted on assembly

350A32-3156-01

AS350 350A32-3156-22 20000 FH

Main Casing 89800 TC

B3 Fitted on assembly // 120000 TC 01.00.68

350A32-3156-02

350A32-3121-04

350A32-3121-06

MGB sump 350A32-3119-05 20000 FH 78100 TC

E, F, F1, 350A32-3119-03

MGB sump 350A32-3119-05 20000 FH 93700 TC 01.00.56

F2, N

AS355 Main Casing

350A32-3121-07 10900 FH 65400 TC

assembly

NP 01.00.55

350A32-3119-03

MGB sump 12800 FH 76800 TC

350A32-3119-05

350A32-3119-03

A2, C2, U2 MGB sump 20000 FH 93700 TC 01.00.28

350A32-3119-05

350A32-3156-21

Fitted on assembly

350A32-3156-01

AS550 350A32-3156-22 20000 FH

Main Casing 89800 TC

C3 Fitted on assembly // 120000 TC 01.00.27

350A32-3156-02

350A32-3121-04

350A32-3121-06

MGB sump 350A32-3119-05 20000 FH 78100 TC

AF, AN, SN, 350A32-3119-03

AS555 MGB sump 350A32-3119-05 20000 FH 93700 TC 01.00.25

UF, UN

Revision 0 2015-06-02 Page 12/13

Revision 3 2016-01-07 This document is available on the internet: www.airbushelicopters.com/techpub

ASB No. AS350-01.00.69

Table of casings which are concerned by the introduction of the torque cycle limitations

(cont’d).

ALERT

New limitation

Casing Service life SERVICE

Helicopter Version(s) Casing before

Part Numbers limit BULLETIN

inspection

No.

350A32-3156-21

Fitted on assembly

350A32-3156-01

20000 FH

Main Casing 89800 TC

// 120000 TC

EC130 B4 350A32-3156-22 04A005

Fitted on assembly

350A32-3156-02

20000 FH

MGB sump 350A32-3119-05 78100 TC

// 120000 TC

Revision 0 2015-06-02 Page 13/13

Revision 3 2016-01-07 This document is available on the internet: www.airbushelicopters.com/techpub

You might also like

- FAA Approved 2022 Parts Price List for Honeywell B737 BrakesDocument1 pageFAA Approved 2022 Parts Price List for Honeywell B737 BrakesPhillip FriedmanNo ratings yet

- 2 Light PSU VEGDocument3 pages2 Light PSU VEGRuss HoweNo ratings yet

- DGO9 InstallDocument23 pagesDGO9 InstallairmasterNo ratings yet

- G500/G600 PFD/MFD System ICA InstructionsDocument15 pagesG500/G600 PFD/MFD System ICA InstructionsBrunoNo ratings yet

- Service Letter: Pilatus Aircraft Ltd. Ch-6371 Stans, SwitzerlandDocument54 pagesService Letter: Pilatus Aircraft Ltd. Ch-6371 Stans, SwitzerlandDiego CabreraNo ratings yet

- Database - Download - Instructions COLLINSDocument19 pagesDatabase - Download - Instructions COLLINSVladimir Quintero Y Claudia OrozcoNo ratings yet

- 600-00719-000 Entegra EXP5000 PFD Release 6 Install Quick Ref Guide Rev CDocument4 pages600-00719-000 Entegra EXP5000 PFD Release 6 Install Quick Ref Guide Rev CBrad GrangerNo ratings yet

- Airbus Approved Suppliers ListDocument382 pagesAirbus Approved Suppliers ListHarith AnehNo ratings yet

- Chapter 6 Dimensions and AreasDocument21 pagesChapter 6 Dimensions and AreasHrishikesh NarasimhanNo ratings yet

- Peregrine AML STC KT74Document184 pagesPeregrine AML STC KT74AeromechanixNo ratings yet

- Amm At01Document726 pagesAmm At01AlejandroNo ratings yet

- Part 145 Airworthiness Approved OrganisationsDocument145 pagesPart 145 Airworthiness Approved Organisationsflorin constantinNo ratings yet

- Title: Landing Gear - Nose Gear - Define New Nose Gear Line Replaceable Unit BreakdownDocument182 pagesTitle: Landing Gear - Nose Gear - Define New Nose Gear Line Replaceable Unit BreakdownKevin John PangilinanNo ratings yet

- s12 AiraileDocument35 pagess12 AiraileabdulkissNo ratings yet

- Dynon Skyview Installation GuideDocument292 pagesDynon Skyview Installation GuideLUCAS ANTONIO PRIETONo ratings yet

- PC 761-678Document480 pagesPC 761-678Victor RamirezNo ratings yet

- Honeywell KRA 405BDocument4 pagesHoneywell KRA 405BPravesh Kumar ThakurNo ratings yet

- Cessna Citation X+ 2019 (Xplus - BrochureDocument9 pagesCessna Citation X+ 2019 (Xplus - Brochuremark7f2001No ratings yet

- BRA-EDIT 01-75PAA-6 (I) - 1 Preflight/Turnaround/Postflight Checklist Isochronal Scheduled Inspection System Model P-3 Series AircraftDocument62 pagesBRA-EDIT 01-75PAA-6 (I) - 1 Preflight/Turnaround/Postflight Checklist Isochronal Scheduled Inspection System Model P-3 Series AircraftsabatrumpetNo ratings yet

- Air Data Attitude Heading Reference System: FeaturesDocument2 pagesAir Data Attitude Heading Reference System: FeaturesIventNo ratings yet

- Component Maintenance Manual With Illustrated Parts ListDocument141 pagesComponent Maintenance Manual With Illustrated Parts ListDouglas de OliveiraNo ratings yet

- SN4500 82009 0133 D Component Maintenance ManualDocument12 pagesSN4500 82009 0133 D Component Maintenance ManualAka MonuNo ratings yet

- Stinson SR-10 1941 Description & Maintenance Manual (445-601)Document16 pagesStinson SR-10 1941 Description & Maintenance Manual (445-601)wellingtonNo ratings yet

- AS4000 Installation Manual 925600Document142 pagesAS4000 Installation Manual 925600Brandon100% (1)

- Fault Code MPC ListDocument176 pagesFault Code MPC ListederlucianoribeiroNo ratings yet

- Support Documents For Genesys Aerosystems Avionics ComponentsDocument7 pagesSupport Documents For Genesys Aerosystems Avionics ComponentsNickNo ratings yet

- Rockwell Collins Bsi Training Document 20181001Document75 pagesRockwell Collins Bsi Training Document 20181001Nora NaitoNo ratings yet

- @ A318/A319/A320/A321: Duct Repair ManualDocument116 pages@ A318/A319/A320/A321: Duct Repair ManualErichCastrejónRodriguezNo ratings yet

- WJ5 Turboprop EngineDocument4 pagesWJ5 Turboprop EngineCarlosNo ratings yet

- Anexo 3.1. Balsas RFD 50 PersonasDocument226 pagesAnexo 3.1. Balsas RFD 50 PersonasdimasjosesmithNo ratings yet

- Premier 1A CAMP ReportDocument100 pagesPremier 1A CAMP ReportT/ROX0% (1)

- A318/A319/A320/A321: Service BulletinDocument208 pagesA318/A319/A320/A321: Service BulletinMarin MatevNo ratings yet

- Master Minimum Equipment List (MMEL) : U.S. Department of Transportation Federal Aviation AdministrationDocument64 pagesMaster Minimum Equipment List (MMEL) : U.S. Department of Transportation Federal Aviation AdministrationYaron KalinaNo ratings yet

- Helicopter Vendor ListDocument16 pagesHelicopter Vendor ListGinanjar PranathaNo ratings yet

- Crew Seat Manual with Parts ListDocument76 pagesCrew Seat Manual with Parts Listhin wongyaiNo ratings yet

- Ftdx10 Manual-English CompressedDocument123 pagesFtdx10 Manual-English CompressedJose antonio Santana gilNo ratings yet

- Alert SB BK117-D2-42-005-Rev3-ENDocument9 pagesAlert SB BK117-D2-42-005-Rev3-ENHermawan WawanNo ratings yet

- L3 Troubleshooting - Guide - XT16xx - v1.0 PDFDocument208 pagesL3 Troubleshooting - Guide - XT16xx - v1.0 PDFmigsayalNo ratings yet

- Avtek Transutama Capability ListDocument34 pagesAvtek Transutama Capability ListAlphard DarmawanNo ratings yet

- Coatings Non-ITAR Product and Specification GuideDocument16 pagesCoatings Non-ITAR Product and Specification GuideCarlos Alberto Rozo R.No ratings yet

- ARINC 429 to Synchro Converter Model 44SM7Document3 pagesARINC 429 to Synchro Converter Model 44SM7ekinox_es100% (1)

- Master Minimum Equipment List (MMEL) : U.S. Department of Transportation Federal Aviation AdministrationDocument47 pagesMaster Minimum Equipment List (MMEL) : U.S. Department of Transportation Federal Aviation AdministrationEmmanuelNo ratings yet

- Helicopter 3 02 2015 Complete CatalogDocument114 pagesHelicopter 3 02 2015 Complete CatalogJacksonNo ratings yet

- Afm Emb-145Document10 pagesAfm Emb-145Jimmy SteepNo ratings yet

- TM 11-1520-217-34P-2 24-Oct-77 USAPADocument88 pagesTM 11-1520-217-34P-2 24-Oct-77 USAPAruiNo ratings yet

- 42 CfeDocument108 pages42 CfeWilfredo Díaz Gonzalez100% (1)

- RG Series Main Aircraft Battery Component Maintenance ManualDocument3 pagesRG Series Main Aircraft Battery Component Maintenance ManualJudy LopezNo ratings yet

- Airbus - SPARESDocument1 pageAirbus - SPARESomar omranNo ratings yet

- SP09 Australian 10 Years GregDocument30 pagesSP09 Australian 10 Years GregMasuda AkterNo ratings yet

- Binder - All Sources ForDocument42 pagesBinder - All Sources Forjose matosNo ratings yet

- FAA 2018 0855 0002 - Attachment - 2Document15 pagesFAA 2018 0855 0002 - Attachment - 2Andrew OlsonNo ratings yet

- MODEL 150 SERIES (1969 - 1976) : Supplemental Inspection Number: 55-11-02 1. TitleDocument3 pagesMODEL 150 SERIES (1969 - 1976) : Supplemental Inspection Number: 55-11-02 1. TitleRebeca SerranoNo ratings yet

- 06-117751 - Aircraft Maintenance Manual (EA500) - 1Document7,296 pages06-117751 - Aircraft Maintenance Manual (EA500) - 1Miguel VieroNo ratings yet

- Hosking PDFDocument10 pagesHosking PDFDimitra Eirini DiamantidouNo ratings yet

- SB 27-3459r2 Gust Lock InspectionDocument12 pagesSB 27-3459r2 Gust Lock InspectionGarrett ReeveNo ratings yet

- Century 21 With NSD 360A HSIDocument1 pageCentury 21 With NSD 360A HSIalex castroNo ratings yet

- 5.-Cap Sist. CombustibleDocument25 pages5.-Cap Sist. CombustibleRicardo RubioNo ratings yet

- DLC50 Control PanelDocument2 pagesDLC50 Control PanelameraldaherNo ratings yet

- AS550C3e EQUATEUR Páginas EliminadasDocument395 pagesAS550C3e EQUATEUR Páginas EliminadasdaryelNo ratings yet

- Service Bulletin: SB MBB-BK117 C-2-65-004Document7 pagesService Bulletin: SB MBB-BK117 C-2-65-004Samantha Carrascal SilvaNo ratings yet

- Skidtube Installation: Instructions For Continued AirworthinessDocument47 pagesSkidtube Installation: Instructions For Continued AirworthinessBruno Alonso PachecoNo ratings yet

- Master AS350B3 PMVR EASA RN13 22-05 EngDocument36 pagesMaster AS350B3 PMVR EASA RN13 22-05 EngBruno Alonso PachecoNo ratings yet

- Apostila Bell 505 - CompressedDocument440 pagesApostila Bell 505 - CompressedBruno Alonso Pacheco100% (1)

- Aerospatiale A350Document8 pagesAerospatiale A350Bruno Alonso PachecoNo ratings yet

- Relavop Ecureuil Single Engine Family - Final VersionDocument34 pagesRelavop Ecureuil Single Engine Family - Final VersionBruno Alonso PachecoNo ratings yet

- Installation Instructions Airbus Helicopters As350 Cable Cutters Kit P/N 646.4001, 646.4002, 646.4003, 646.4004, 646.4005, 646.4006Document32 pagesInstallation Instructions Airbus Helicopters As350 Cable Cutters Kit P/N 646.4001, 646.4002, 646.4003, 646.4004, 646.4005, 646.4006Bruno Alonso PachecoNo ratings yet

- Arriel 1D1 TBO TableDocument8 pagesArriel 1D1 TBO TableBruno Alonso PachecoNo ratings yet

- Skidtube Installation: Instructions For Continued AirworthinessDocument47 pagesSkidtube Installation: Instructions For Continued AirworthinessBruno Alonso PachecoNo ratings yet

- EASA OEB Final Report Eurocopter AS350 Family (B3e) 04 06082012Document41 pagesEASA OEB Final Report Eurocopter AS350 Family (B3e) 04 06082012Bruno Alonso PachecoNo ratings yet

- Skidtube Installations: Installation InstructionsDocument35 pagesSkidtube Installations: Installation InstructionsBruno Alonso PachecoNo ratings yet

- Curso - TURMA 1 - AVIATION ENGLISH LEVEL 3 FOR CIVIL AVIATION PROFESSIONALS - MISTO - EAD - DE 28 DE ABRIL A 27 DE MAIO - INSCRIÇÕES ENCERRADASDocument3 pagesCurso - TURMA 1 - AVIATION ENGLISH LEVEL 3 FOR CIVIL AVIATION PROFESSIONALS - MISTO - EAD - DE 28 DE ABRIL A 27 DE MAIO - INSCRIÇÕES ENCERRADASBruno Alonso PachecoNo ratings yet

- Iigps-1 NCDocument8 pagesIigps-1 NCBruno Alonso PachecoNo ratings yet

- 3561 S 64 Rev 0 ENDocument2 pages3561 S 64 Rev 0 ENBruno Alonso PachecoNo ratings yet

- Program of The CourseDocument1 pageProgram of The CourseBruno Alonso PachecoNo ratings yet

- 80 45 Minutes 1 Hour: Attempt Quiz Now Attempt Quis NowDocument2 pages80 45 Minutes 1 Hour: Attempt Quiz Now Attempt Quis NowBruno Alonso PachecoNo ratings yet

- Safety Information Notice: Subject: Tail Rotor Reminder of The Dedicated Maintenance For The Tail Rotor Trailing Edge TabDocument2 pagesSafety Information Notice: Subject: Tail Rotor Reminder of The Dedicated Maintenance For The Tail Rotor Trailing Edge TabBruno Alonso PachecoNo ratings yet

- Easa Withdrawal Statement Pad 14-078Document1 pageEasa Withdrawal Statement Pad 14-078Bruno Alonso PachecoNo ratings yet

- ATIS - Basic Level - EXERCISEDocument3 pagesATIS - Basic Level - EXERCISEBruno Alonso PachecoNo ratings yet

- Notification of A Proposal To Issue An Airworthiness DirectiveDocument4 pagesNotification of A Proposal To Issue An Airworthiness DirectiveBruno Alonso PachecoNo ratings yet

- Information Notice: Subject: Tail Rotor Slippage of Self-Adhesive Polyurethane Sand-Erosion Protective StripsDocument2 pagesInformation Notice: Subject: Tail Rotor Slippage of Self-Adhesive Polyurethane Sand-Erosion Protective StripsBruno Alonso PachecoNo ratings yet

- Alert Service Bulletin: EmergencyDocument13 pagesAlert Service Bulletin: EmergencyBruno Alonso PachecoNo ratings yet

- Easa Emergency Airworthiness Directive: AD No.: 2011-0128-EDocument3 pagesEasa Emergency Airworthiness Directive: AD No.: 2011-0128-EBruno Alonso PachecoNo ratings yet

- ASBAS350630009ENR2ERRDocument14 pagesASBAS350630009ENR2ERRBruno Alonso PachecoNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document5 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)TusharRoyNo ratings yet

- D350 607 3 RevFDocument25 pagesD350 607 3 RevFBruno Alonso PachecoNo ratings yet

- Easa Airworthiness Directive: AD No.: 2009-0246Document2 pagesEasa Airworthiness Directive: AD No.: 2009-0246Bruno Alonso PachecoNo ratings yet

- Alert Service Bulletin: EmergencyDocument12 pagesAlert Service Bulletin: EmergencyBruno Alonso PachecoNo ratings yet

- D350 607 2 RevDDocument20 pagesD350 607 2 RevDBruno Alonso PachecoNo ratings yet

- Pt12 AFCSDocument109 pagesPt12 AFCSBruno Alonso PachecoNo ratings yet

- DCS DH Mosquito FB - VI Flight Manual enDocument146 pagesDCS DH Mosquito FB - VI Flight Manual enMiles DeiNo ratings yet

- FAA 8083 30 - Ch04 PDFDocument34 pagesFAA 8083 30 - Ch04 PDFDaniel Barbosa MotaNo ratings yet

- S.8 Calcutta: A Stunning Scratchbuild by Megas TsonosDocument68 pagesS.8 Calcutta: A Stunning Scratchbuild by Megas Tsonos钟志毅100% (3)

- AC 25-7A CH1 Flight Test GuideDocument116 pagesAC 25-7A CH1 Flight Test GuideriversgardenNo ratings yet

- Ats Team Moe Issue 3 Revision 1 - 12.07.2013Document235 pagesAts Team Moe Issue 3 Revision 1 - 12.07.2013MikeNo ratings yet

- 72.61.00.045 26-MAR-2020 08-DEC-2021 Closed A319-100N, A320-200N, A321-200N, A321-200NX, A321-200NY 72-61 Iae LLC Pratt & Whitney TFU UpdateDocument9 pages72.61.00.045 26-MAR-2020 08-DEC-2021 Closed A319-100N, A320-200N, A321-200N, A321-200NX, A321-200NY 72-61 Iae LLC Pratt & Whitney TFU UpdatejivomirNo ratings yet

- MNL SIN: Tuesday May 3Document4 pagesMNL SIN: Tuesday May 3Isabel Paralejas イザベルNo ratings yet

- The Zephyr Song (Red Hot Chilli Peppers) The Zephyr Song (Red Hot Chilli Peppers)Document1 pageThe Zephyr Song (Red Hot Chilli Peppers) The Zephyr Song (Red Hot Chilli Peppers)DanielleOkNo ratings yet

- SD-1 Minisport: SpacekDocument4 pagesSD-1 Minisport: SpacekAnderson PerosaNo ratings yet

- Aerospace 08 00169 v2Document27 pagesAerospace 08 00169 v2kirancallsNo ratings yet

- Science & TechnologyDocument65 pagesScience & TechnologyAbhishek BoraNo ratings yet

- Incompressible Flow over Finite Wings AnalysisDocument39 pagesIncompressible Flow over Finite Wings AnalysisBasil DubeNo ratings yet

- Avionics Circuit Breaker Panel - 17280001 Thru 17280003 REF Nomenclature Effectivity DES Number 1 2 3 4 5 6 7 From TO Units PER AssyDocument2 pagesAvionics Circuit Breaker Panel - 17280001 Thru 17280003 REF Nomenclature Effectivity DES Number 1 2 3 4 5 6 7 From TO Units PER AssybnolascoNo ratings yet

- User Manual: IncludedDocument12 pagesUser Manual: IncludedBert BaradasNo ratings yet

- Submersible Unmanned Flying Boat: Design and ExperimentDocument6 pagesSubmersible Unmanned Flying Boat: Design and ExperimentVigneshRamakrishnanNo ratings yet

- Endurance Test Procedure Rev 1.0Document12 pagesEndurance Test Procedure Rev 1.0ANSHAD MECHANICALNo ratings yet

- UK Composites Strategy - 0Document33 pagesUK Composites Strategy - 0pallenNo ratings yet

- 3 Exact Numerical ValuesDocument23 pages3 Exact Numerical ValuesNagamani ArumugamNo ratings yet

- Monitoring Landing Gear SystemDocument17 pagesMonitoring Landing Gear SystemAhmedBassyouniNo ratings yet

- Agard CP 467Document430 pagesAgard CP 467iama nubertNo ratings yet

- Unsettled Topics in Unmanned Aerial Vehicle Icing: Richard Hann Tor Arne JohansenDocument32 pagesUnsettled Topics in Unmanned Aerial Vehicle Icing: Richard Hann Tor Arne Johansens rNo ratings yet

- Aircraft Maintenance BasicsDocument5 pagesAircraft Maintenance Basicseric1961lkNo ratings yet

- Mass at Nose 0.0 Grams Throwing Velocity 20.0 KM/HR Stabilizer Incidence Angle - 2.9 DegreesDocument4 pagesMass at Nose 0.0 Grams Throwing Velocity 20.0 KM/HR Stabilizer Incidence Angle - 2.9 DegreesQuinn LynchNo ratings yet

- PA28R-180 Maneuvers Manual Revised 5/14/2012 Arrow IDocument24 pagesPA28R-180 Maneuvers Manual Revised 5/14/2012 Arrow IArturo PiñolNo ratings yet

- EASA TCDS E.007 (IM) General Electric CF6 80E1 Series Engines 02 25102011Document9 pagesEASA TCDS E.007 (IM) General Electric CF6 80E1 Series Engines 02 25102011Graham WaterfieldNo ratings yet

- 139 HumsDocument116 pages139 HumsAlaa Mortada100% (3)

- Be Winter 2022Document1 pageBe Winter 2022AADITYA SHAHNo ratings yet

- 15 - Landing GearDocument2 pages15 - Landing Gear郝帅No ratings yet

- APGuide 2006Document16 pagesAPGuide 2006Biblioteca Brasil AviationNo ratings yet

- 1 - HND QCF Propulsion Assignment 3 2011.2012Document6 pages1 - HND QCF Propulsion Assignment 3 2011.2012Muhammad HussainNo ratings yet