Professional Documents

Culture Documents

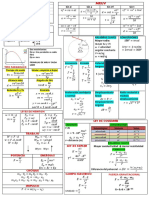

TR - Torque TR (T1-T2) r1 (Larger Pulley) T T1+Tc T TC MV Mass Per Unit Length) T T V M/s T-Max Tension

Uploaded by

adiG48 AtdiG48Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TR - Torque TR (T1-T2) r1 (Larger Pulley) T T1+Tc T TC MV Mass Per Unit Length) T T V M/s T-Max Tension

Uploaded by

adiG48 AtdiG48Copyright:

Available Formats

Formula for flat and V-belt drive:

𝝅𝒅𝟏𝑵𝟏 𝝅𝒅𝟐𝑵𝟐

𝑽𝟏 = ; 𝑽𝟐 = 𝒎/𝒔

𝟔𝟎 𝟔𝟎

Velocity of the belt V1, V2 (Velocity of larger pulley and velocity of smaller pulley)

D1, d2 (Dial larger pulley and smaller pulley)

N1, N2 (Speed of 1 and 2 pulley)

𝑵𝟐 𝒅𝟏

𝒗𝟏 =

Velocity Ratio, 𝑵𝟏 𝒅𝟐

𝒗𝟐

𝑵𝟐 𝒅𝟏 + 𝒕

=

Effect of the belt thickness 𝑵𝟏 𝒅𝟐 + 𝒕

T - thickness

While considering total slip 𝑵𝟐 𝒅𝟏 + 𝒕 𝒔

= (𝟏 − )

𝑵𝟏 𝒅𝟐 + 𝒕 𝟏𝟎𝟎

T – thickness

S-Slip

Effect of creep on belt = x

𝑵𝟐 𝒅𝟏 𝑬+ √𝝈𝟏

𝑵𝟏

𝒅𝟐 𝑬+ √𝝈𝟐

E-Youngs modulus of the belt material

𝝈𝟏 = 𝑺𝒕𝒓𝒆𝒔𝒔 𝒊𝒏 𝒕𝒉𝒆 𝒃𝒆𝒍𝒕 𝒐𝒏 𝒕𝒊𝒈𝒉𝒕 𝒔𝒊𝒅𝒆

𝝈𝟐 = 𝑺𝒕𝒓𝒆𝒔𝒔 𝒊𝒏 𝒕𝒉𝒆 𝒃𝒆𝒍𝒕 𝒐𝒏 𝑺𝒍𝒂𝒄𝒌 𝒔𝒊𝒅𝒆

Open belt drive Cross belt drive

Length of the belt (L) 𝝅 (𝒅𝒎𝒂𝒙−𝒅𝒎𝒊𝒏)𝟐 𝝅 (𝒅𝒎𝒂𝒙+𝒅𝒎𝒊𝒏)𝟐

L= (𝒅𝟏 + 𝒅𝟐) + 𝟐𝒙 + L= (𝒅𝟏 + 𝒅𝟐) + 𝟐𝒙 +

𝟐 𝟒𝒙 𝟐 𝟒𝒙

𝝅 𝝅

Angle of contact of the belt with 𝜽=(𝟏𝟖𝟎° − 𝟐𝜶) , rad 𝜽=(𝟏𝟖𝟎° + 𝟐𝜶) , rad

𝟏𝟖𝟎 𝟏𝟖𝟎

the pulley, (𝜽) 𝜶 = 𝑨𝒏𝒈𝒍𝒆 𝒐𝒇 𝒃𝒆𝒍𝒕𝒊𝒏𝒈 𝜶 = 𝑨𝒏𝒈𝒍𝒆 𝒐𝒇 𝒃𝒆𝒍𝒕𝒊𝒏𝒈

𝜶, 𝑨𝒏𝒈𝒍𝒆 𝒔𝒖𝒃𝒕𝒆𝒏𝒅𝒆𝒅 (𝒓𝟏 − 𝒓𝟐) (𝒓𝟏 + 𝒓𝟐)

𝑺𝒊𝒏𝜶 = 𝑺𝒊𝒏𝜶 =

𝒃𝒆𝒕𝒘𝒆𝒆𝒏 𝒕𝒉𝒆 𝒙 𝒙

𝒔𝒕𝒓𝒂𝒊𝒈𝒉𝒕 𝒑𝒐𝒓𝒕𝒊𝒐𝒏 𝒐𝒇 𝒕𝒉𝒆 𝒃𝒆𝒍𝒕 x = distance between two pulleys

Ratio of driving tension for flat belt 𝑻𝟏

= 𝒆𝝁𝜽 𝝁 =Coefficient of friction; 𝜽=Angle of contact of belt

𝑻𝟐

drive T1=T2= (Tension between tight side and slack side respectively)

𝑻𝟏

= 𝒆𝝁𝜽𝒄𝒐𝒔𝒆𝒄𝜷 -------- For V-belt drive

𝑻𝟐

Power Transmitted 𝟐𝝅𝑵𝑻𝒓

P= (T1-T2) v, N-m/s or watts ; P=

𝟔𝟎

Tr - Torque

Torque on the shaft for larger and Tr =(T1-T2) r1 (Larger pulley)

smaller pulley Tr=(T1-T2) r2 (Smaller pulley)

Strength of the belt (or) Total T = T1+Tc

tension in the belt T = 𝝈𝒃𝒕

Tc = mv2 (mass per unit length)

Initial tension with and without 𝑻𝟏+𝑻𝟐

T0 = 𝟐

considering centrifugal tension 𝑻𝟏+𝑻𝟐+𝟐𝑻𝒄

T0 = 𝟐

Speed of the belt 𝑻

V = √𝟑𝒎 m/s T-Max tension

No of belts (v-belt) 𝑻𝒐𝒕𝒂𝒍 𝒑𝒐𝒘𝒆𝒓 𝒕𝒓𝒂𝒏𝒔𝒎𝒊𝒕𝒕𝒆𝒅

𝑷𝒐𝒘𝒆𝒓 𝒕𝒓𝒂𝒏𝒔𝒎𝒊𝒕𝒕𝒆𝒅 𝒃𝒆𝒓 𝒃𝒆𝒍𝒕

Unit-5

Belt and rope drives:

1) A pulley 350mm in diameter drives another pulley 1400mm in diameter by means of a belt

25mm thick. The driver makes 200 revolutions per minute. Find the speed of the driven pulley

(a) Neglecting the thickness of the belt, (b) Taking the thickness into account, (c) Assuming also

in the latter case

(i) a total slip of 5%,

(ii) a slip of 2% between the driving pulley and the belt and 2% between the belt and the

driven pulley

2) The power is transmitted from a pulley 1m diameter running at 300r.p.m to a pulley 2m diameter

by means of a belt. Find the speed lost by the driven pulley as a result of creep, if the stress on the

tight and slack side of the belt is 1.5MPa and 0.65 MPa respectively. The Young’s modulus for the

material of the belt is 100 MPa.

3) The power is transmitted from a pulley 1m dia running at 200r.p.m to a pulley 2.5m in dia by

means of a belt Find the speed lost by the driven pulley as a result of the creep, the belt is 50cm

wide and 10mm thick and if the tension on the tight and slack sides of the belt are 10N/mm width

and 4N/mm width respectively. Take the young’s modulus for the material of the belt is 100N/

mm2?

4) Find the lengths for both open belts drive and cross belt drive necessary to drive a pulley of

750mm diameter running parallel at a distance of 12 meters from the driving pulley of diameter

4000mm.

5) Two parallel shafts 7 meters apart are connected by crossed belt running over pulleys 50 cm and

70 cm diameters respectively. It is desired to alter the direction of rotation of the driven shaft

without that of the driving shaft. Find by, how much, the length of the belt is to be altered.

6) Two pulleys, one 450mm diameter and the other 200mm diameter are on parallel shafts 1.95m

apart and are connected by a open belt. Find the length of the belt required and the angle of contact

between the belt and each pulley.

What power can be transmitted by the belt when the larger pulley rotates at 200rpm, if the

maximum permissible tension in the belt is 1000N, and the coefficient of friction between the belt

and pulley is 0.25?

7) Find the width of the belt necessary to transmit 75kW to a pulley 300mm diameter, if the pulley

makes 1600rpm and the coefficient of friction between the belt and the pulley is 0.22. Assume the

angle of contact as 2100 and the maximum tension in the belt is not to exceed 8N/mm width.

8) A flat belt is required to transmit 35kW from a pulley of 1.5m effective diameter running at

300rpm. The angle of lap is 1650 and µ=0.3. Determine, taking centrifugal tension into account,

width of the belt required. It is given that the belt thickness is 9.5mm, density of its material is 1.1

Mg/mm3 and the related permissible working stress is 2.5MPa.

9) A belt drive is required to transmit 12kW from a motor running at 720rpm. The belt is 12mm thick

and has a mass density of 0.001 gm/mm3. Shaft stress in the belt not to exceed 2.5N/mm2.

Diameter of driving pulley is 250mm whereas the speed of the driven pulley is 240rpm. The two

shafts are 1.25m apart. Coefficient of friction is 0.25. Determine the width of the belt.

10) A leather belt 125mm and 6mm thick, transmits power from a pulley with the angle of lap 1500

and µ=0.3. If the mass of 1 m3 of leather is 1 Mg and the stress in the belt is not to exceed 2.75 MPa,

find the maximum power that can be transmitted and the corresponding speed of the belt.

11) An open belt drive connects two pulleys 1.2m and 0.5m diameter on parallel shafts 3.6m apart.

The belt has a mass of 1kg/m length and maximum tension in it is not to exceed 2KN. The 1.2m

pulley, which is the driver, runs at 200rpm. Due to the belt slip on one of the pulleys, the velocity of

the driven shafts is only 450rpm. If µ=0.3, find

(i)Torque on each of the two shafts,

(ii)Power transmitted,

(iii)Power lost in friction, and

(iv)Efficiency of the drive.

12) In a belt drive, the tension ratio is 2.6. The mass of the belt is 1Kg/m length. It runs at a speed of

5m/s and at this speed, power transmitted is 8kW. What should be the initial tension in the belt and

what should be the strength of the belt?

13) A 100 mm wide and 10 mm thick belt transmits 5 kW between two parallel shafts. The distance

between the shaft centers is 1.5 m and the diameter of the smaller pulley is 440 mm. The driving

and the driven shafts rotate at 60rpm and 150 rpm respectively. Find the stress in the belt if the two

pulleys are connected by

(i) An open belt and

(ii) A cross belt

The coefficient of friction is 0.22.

14) The initial tension in a flat belt drive is 1800N. The angle of lap on the smaller pulley is 170 0.

µ=0.25. The pulley has a diameter of 0.9m and it runs at 450 rpm. Determine the power that can be

transmitted at the above speed. Neglect the centrifugal tension.

You might also like

- Solid Mechanics ME 212 - Week 1 PDFDocument39 pagesSolid Mechanics ME 212 - Week 1 PDFAlpha WolfNo ratings yet

- STRESSES SHAFTINGS KEYS and SPLINES COUPLINGS Feb2023 Rev0Document15 pagesSTRESSES SHAFTINGS KEYS and SPLINES COUPLINGS Feb2023 Rev0loureniel de jesusNo ratings yet

- Dynamics FULL Equation SheetDocument2 pagesDynamics FULL Equation SheetZachNo ratings yet

- Belts Drives: Flexible Drives Used To Transmit Power Between ShaftsDocument2 pagesBelts Drives: Flexible Drives Used To Transmit Power Between ShaftsDaniel FloresNo ratings yet

- CT Sizing - CT Over Dimensioning FactorDocument19 pagesCT Sizing - CT Over Dimensioning FactorEngr Fahimuddin QureshiNo ratings yet

- Laminar or Viscous Flow 6Document26 pagesLaminar or Viscous Flow 6Sunil BagadeNo ratings yet

- N1 - Equations of Motion For Viscous Incompressible FluidDocument17 pagesN1 - Equations of Motion For Viscous Incompressible FluidAnirban SarkarNo ratings yet

- SpringsDocument5 pagesSpringsAhmad AbdNo ratings yet

- FormulasDocument2 pagesFormulasRyan MamawagNo ratings yet

- First Order Circuits - RC and RLDocument22 pagesFirst Order Circuits - RC and RLTyspoNo ratings yet

- Md1-Notes-Curved BeamsDocument12 pagesMd1-Notes-Curved Beamsmeeth504No ratings yet

- Reynolds Transport TheoremDocument2 pagesReynolds Transport TheoremNati FernandezNo ratings yet

- 01 Time Domain SpecificationDocument26 pages01 Time Domain SpecificationShadowツNo ratings yet

- + + So Integrating Factor Will Be So × × + / +Document4 pages+ + So Integrating Factor Will Be So × × + / +Jaya ChaubeyNo ratings yet

- 11 FM Lecture-Online - (EE-CpE-ICT)Document8 pages11 FM Lecture-Online - (EE-CpE-ICT)AsdffghhklNo ratings yet

- Machine Element Design CheatsheetDocument25 pagesMachine Element Design CheatsheetDarien ChiaNo ratings yet

- L07 - Charge Carrier Density - 1 PDFDocument17 pagesL07 - Charge Carrier Density - 1 PDFakshat mishraNo ratings yet

- Dynamic Analysis of Op-AmpDocument5 pagesDynamic Analysis of Op-AmpSayemNo ratings yet

- Analysis of Transients in The Circuit 3Document5 pagesAnalysis of Transients in The Circuit 3Lil bro tamiNo ratings yet

- Constantes Código de Colores: Lateral Base 2 Total Lateral Base 1 3 2Document1 pageConstantes Código de Colores: Lateral Base 2 Total Lateral Base 1 3 2ConnyBarriosNo ratings yet

- V-Belt HelperDocument3 pagesV-Belt Helpermohamed yehiaNo ratings yet

- Ch 6 - waves (PHY 001) Solution of Probems.pdf · إصدار ١Document5 pagesCh 6 - waves (PHY 001) Solution of Probems.pdf · إصدار ١make handNo ratings yet

- Formulario FisicaDocument1 pageFormulario Fisicanayely merchanNo ratings yet

- Lecture String and Bar VibrationsDocument21 pagesLecture String and Bar Vibrationsanand maniNo ratings yet

- 10 Waveguides GeneralApproach PDFDocument28 pages10 Waveguides GeneralApproach PDFKOTTI NIKHITHANo ratings yet

- 10 Waveguides GeneralApproachDocument28 pages10 Waveguides GeneralApproachRounak MandalNo ratings yet

- AC Fundementals - Part IIDocument20 pagesAC Fundementals - Part IIwhitehatesmNo ratings yet

- Physics 141 Equation Sheet-Knight 4 EdDocument1 pagePhysics 141 Equation Sheet-Knight 4 EdSimon SituNo ratings yet

- Hagen Poisuille EquationDocument4 pagesHagen Poisuille EquationRochakNo ratings yet

- Formula Sheet FE - W21Document3 pagesFormula Sheet FE - W21debbyNo ratings yet

- Formula Sheet 082021Document3 pagesFormula Sheet 082021pang mmNo ratings yet

- Instruments and Measurements Formula SheetDocument2 pagesInstruments and Measurements Formula SheetSoha Ayaz MehmoodNo ratings yet

- UntitledDocument58 pagesUntitledchandrakanth maheshNo ratings yet

- Lecture 4 - Fluid Dynamics - Linear Momentum ConservationDocument5 pagesLecture 4 - Fluid Dynamics - Linear Momentum ConservationApdo MustafaNo ratings yet

- Me 362 - 4Document21 pagesMe 362 - 4ElormeNo ratings yet

- General Physics Summary of FormulasDocument8 pagesGeneral Physics Summary of FormulasJemimah FVNo ratings yet

- Formula Sheet For ICT - 3Document2 pagesFormula Sheet For ICT - 3kazeemsodikisola1991No ratings yet

- Hafizh Renanto Akhmad - PR 2 KindinDocument14 pagesHafizh Renanto Akhmad - PR 2 KindinHafizh Renanto AkhmadNo ratings yet

- Topic 3 - Kinematics CurveDocument30 pagesTopic 3 - Kinematics CurveBoodjieh So ImbaNo ratings yet

- Solution Methodology: FLUENT That Has Been Used in The Study. Details About The Computational ApproachDocument9 pagesSolution Methodology: FLUENT That Has Been Used in The Study. Details About The Computational ApproachSouvik BanerjeeNo ratings yet

- IM BrakingDocument10 pagesIM BrakingABCNo ratings yet

- Physics 1301 Equation SheetDocument2 pagesPhysics 1301 Equation Sheeth.krijestoracNo ratings yet

- Torsion Sample Problem 2Document9 pagesTorsion Sample Problem 2Richiel Pasilan LañohanNo ratings yet

- Laplace and Z-TransformsDocument23 pagesLaplace and Z-TransformsHussam AliraqiNo ratings yet

- Part 4: Force, Pressure and Torque Measurement: Strain GaugesDocument3 pagesPart 4: Force, Pressure and Torque Measurement: Strain Gauges123andybNo ratings yet

- Fuente: Malmivuo, Jaakko Plonsey, Robert Bioelectromagnetism, Principles and Applications of Bioelectric andDocument1 pageFuente: Malmivuo, Jaakko Plonsey, Robert Bioelectromagnetism, Principles and Applications of Bioelectric andJuan David CastañoNo ratings yet

- Lecture 3Document6 pagesLecture 3Milind BhatiaNo ratings yet

- Shunt Voltage RegulatorDocument4 pagesShunt Voltage RegulatorSamuel mutindaNo ratings yet

- AERO213 MockExam2022Document9 pagesAERO213 MockExam2022JordanNo ratings yet

- AERO213: Aeroengines: AERO213 School of Engineering DR David JC DennisDocument9 pagesAERO213: Aeroengines: AERO213 School of Engineering DR David JC DennisAhmed ElgamalNo ratings yet

- Dynamics - Lesson 11& 12Document11 pagesDynamics - Lesson 11& 12Vimukthi LakshanNo ratings yet

- Bearings and ClutchesDocument4 pagesBearings and ClutchesCarl Vincent TapilNo ratings yet

- Lightning Protection AssignmentDocument4 pagesLightning Protection AssignmentsameeraNo ratings yet

- Unit 2 NotesDocument27 pagesUnit 2 Notes19058nithishNo ratings yet

- The Spectral Theory of Toeplitz Operators. (AM-99), Volume 99From EverandThe Spectral Theory of Toeplitz Operators. (AM-99), Volume 99No ratings yet

- A-level Maths Revision: Cheeky Revision ShortcutsFrom EverandA-level Maths Revision: Cheeky Revision ShortcutsRating: 3.5 out of 5 stars3.5/5 (8)

- Green's Function Estimates for Lattice Schrödinger Operators and Applications. (AM-158)From EverandGreen's Function Estimates for Lattice Schrödinger Operators and Applications. (AM-158)No ratings yet

- One Page Resume of An Experienced CandidateDocument3 pagesOne Page Resume of An Experienced CandidateadiG48 AtdiG48No ratings yet

- Output Camd LabDocument6 pagesOutput Camd LabadiG48 AtdiG48No ratings yet

- CV Checklist: S.No. Items To Be Checked Yes No 1 Does Your CV Have The Following Important Sections?Document1 pageCV Checklist: S.No. Items To Be Checked Yes No 1 Does Your CV Have The Following Important Sections?adiG48 AtdiG48No ratings yet

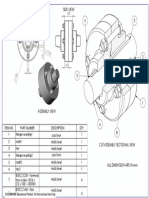

- Flange Coupling PDFDocument1 pageFlange Coupling PDFadiG48 AtdiG48No ratings yet

- Bushed Bearing PDFDocument1 pageBushed Bearing PDFadiG48 AtdiG48No ratings yet

- Fuzzy Logic ControlDocument9 pagesFuzzy Logic ControladiG48 AtdiG48No ratings yet

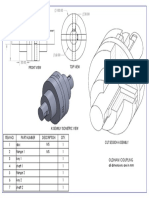

- Oldham Coupling DrawingDocument1 pageOldham Coupling DrawingadiG48 AtdiG48No ratings yet

- Screw Jack PDFDocument1 pageScrew Jack PDFadiG48 AtdiG48No ratings yet

- Issues On Unepmloyment in IndiaDocument1 pageIssues On Unepmloyment in IndiaadiG48 AtdiG48No ratings yet

- Sample of A Statement of Purpose (Sop)Document2 pagesSample of A Statement of Purpose (Sop)adiG48 AtdiG48No ratings yet

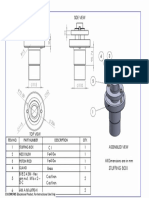

- Stuffing Box PDFDocument1 pageStuffing Box PDFadiG48 AtdiG48No ratings yet

- Rearrange The Following Jumbled Sentences in A Logical Order Q No.1Document2 pagesRearrange The Following Jumbled Sentences in A Logical Order Q No.1adiG48 AtdiG48No ratings yet

- HS8461 Report WritingDocument10 pagesHS8461 Report WritingadiG48 AtdiG48No ratings yet

- Reading Comprehension Passage 2 Read The Passage Carefully and Answer The Following QuestionsDocument2 pagesReading Comprehension Passage 2 Read The Passage Carefully and Answer The Following QuestionsadiG48 AtdiG48No ratings yet

- HS8461-Flow Chart-Recycling Waste PaperDocument1 pageHS8461-Flow Chart-Recycling Waste PaperadiG48 AtdiG48No ratings yet

- HS8461 - Lab Record-Cover PageDocument1 pageHS8461 - Lab Record-Cover PageadiG48 AtdiG48No ratings yet

- Reading Comprehension Passage 1 Read The Passage Below and Answer The Questions That FollowDocument3 pagesReading Comprehension Passage 1 Read The Passage Below and Answer The Questions That FollowadiG48 AtdiG48No ratings yet

- Reading Comprehension Passage-3 Read The Passage Carefully and Answer The FollowingDocument2 pagesReading Comprehension Passage-3 Read The Passage Carefully and Answer The FollowingadiG48 AtdiG48No ratings yet

- Argumentative Essay On TechnologyDocument2 pagesArgumentative Essay On TechnologyadiG48 AtdiG48No ratings yet

- Resume 1Document1 pageResume 1adiG48 AtdiG48No ratings yet

- Universal Coupling DrawingDocument1 pageUniversal Coupling DrawingadiG48 AtdiG48No ratings yet

- HS8461 Lab Record IndexDocument1 pageHS8461 Lab Record IndexadiG48 AtdiG48No ratings yet

- HS8461 Flow Chart Cement ManufactureDocument1 pageHS8461 Flow Chart Cement ManufactureadiG48 AtdiG48No ratings yet

- DOM MCQ (1-6) - RevisedDocument112 pagesDOM MCQ (1-6) - RevisedSAURAV KOULNo ratings yet

- Code AsterDocument12 pagesCode Asterfabvn01_125620890No ratings yet

- Handout No. 10 in Physical Science: MelcDocument11 pagesHandout No. 10 in Physical Science: MelcDulce J. LuatonNo ratings yet

- Bulk and Surface Acoustic Waves - Fundamentals, Devices, and Applications (Guigen Zhang) (Z-Library)Document361 pagesBulk and Surface Acoustic Waves - Fundamentals, Devices, and Applications (Guigen Zhang) (Z-Library)ostomaconsultingNo ratings yet

- Theory of The Faraday and Kerr Effects in FerromagneticsDocument12 pagesTheory of The Faraday and Kerr Effects in FerromagneticsPeter RichterNo ratings yet

- MacSTARS 2000 Reference Manual (Eng)Document23 pagesMacSTARS 2000 Reference Manual (Eng)Jefferson Alves Freitas100% (1)

- Solidworks Simulation - Theoretical Manual PDFDocument115 pagesSolidworks Simulation - Theoretical Manual PDFUsama AbudawudNo ratings yet

- Turbulent Flow and Friction Factor in Porous MediaDocument39 pagesTurbulent Flow and Friction Factor in Porous MediaAminNo ratings yet

- Isat 2010 Set - BDocument12 pagesIsat 2010 Set - BpremsempireNo ratings yet

- Structural Masangkay Quiz 2Document6 pagesStructural Masangkay Quiz 2Sharmaine FalcisNo ratings yet

- Almanac Data For IRNSSDocument2 pagesAlmanac Data For IRNSSBaka NuduNo ratings yet

- PD 6698-2009Document30 pagesPD 6698-2009Dennoh Mbuthia100% (4)

- Design of Linear Motion SystemsDocument9 pagesDesign of Linear Motion SystemsSander VossNo ratings yet

- Moment Curvative Relationships For Partially Prestressed Concrete BeamsDocument12 pagesMoment Curvative Relationships For Partially Prestressed Concrete BeamsFreefirekannadigaNo ratings yet

- VASP Tutorial DielectricsRPA PDFDocument51 pagesVASP Tutorial DielectricsRPA PDFndsramNo ratings yet

- LAB MANUAL. EXPERIMENT 1. Viscosity of Fluids (Ball Drop Method)Document6 pagesLAB MANUAL. EXPERIMENT 1. Viscosity of Fluids (Ball Drop Method)james Principe0% (2)

- Mitsuboshi Products ARPMDocument102 pagesMitsuboshi Products ARPMRizal Agus FiantoNo ratings yet

- Clutch and BrakeDocument32 pagesClutch and BrakeAbel TayeNo ratings yet

- Open Quantum Systems An IntroductionDocument100 pagesOpen Quantum Systems An IntroductionRachel Baltazar VitancolNo ratings yet

- Properties of Liquid SimpleDocument3 pagesProperties of Liquid SimpleOsadreuasa100% (3)

- 1st Paper Chapter 8 MCQDocument2 pages1st Paper Chapter 8 MCQAzmain Rashid Raiyan 200011101No ratings yet

- CAPE Unit 1 Paper 2 2010 (PHYSICS)Document22 pagesCAPE Unit 1 Paper 2 2010 (PHYSICS)Christopher McCarthy100% (1)

- Satellite Sub SystemDocument25 pagesSatellite Sub SystemDr-Gurpreet Kumar100% (1)

- Rotational MotionDocument63 pagesRotational MotionyouNo ratings yet

- Momentum Equation.Document8 pagesMomentum Equation.Ayub Ali WehelieNo ratings yet

- Eme Heat Transfer-1Document5 pagesEme Heat Transfer-1Syed AnsarNo ratings yet

- Deterministic Chaos: An IntroductionDocument10 pagesDeterministic Chaos: An IntroductionRika Indah LestariNo ratings yet

- B.Tech 2nd Yr CEDocument16 pagesB.Tech 2nd Yr CEvkmstp2005No ratings yet

- Reverse Engineering Gear Demo (PDFDrive)Document120 pagesReverse Engineering Gear Demo (PDFDrive)Javkhlantugs GankhuyagNo ratings yet

- 7th Grade - Work and Simple MachinesDocument24 pages7th Grade - Work and Simple Machinesleojohn2No ratings yet