Professional Documents

Culture Documents

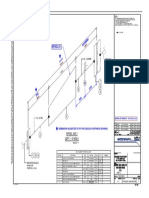

Dosing of Drum Screen

Uploaded by

kapsarcCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dosing of Drum Screen

Uploaded by

kapsarcCopyright:

Available Formats

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO.

NO REPRODUCTION IN FULL, OR IN PART, SHALL BE OBTAINED FROM THIS DRAWING WITHOUT THE WRITTEN CONSENT OF SAUDI ARAMCO.

SAUDI ARABIAN OIL COMPANY

UNTIL CERTIFIED AND DATED

THIS REVISION IS NOT TO BE

USED FOR CONSTRUCTION

1.2.1.2 Drum Screens

One duty and one standby drum screens are provided, each rated for a maximum flow of approximately

180 ML/d of seawater. The flow from the seawater pumps enters a distribution channel upstream of the

ISSUED FOR BID SUBMISSION

screens and is then distributed over inlet weirs into each duty screen. Actuated gates are provided on the

inlet and outlet end of each screen bay to isolate the screens as required. Each screen is slowly rotated

using an electric drive and gearbox and each screen is backwashed by means of a spray bay that

REVISION DESCRIPTION

washes screenings into collection troughs. The screenings then discharge by gravity into drained bins for

disposal off-site. Flow for the wash spray bars is derived from the plant service water system and boosted

to an appropriate pressure using duty and standby screen wash pumps. Adequate spray wash water is

available to allow the simultaneous washing of both screens.

25-00037-0006/01

The number of duty screens is selected automatically by the PCS based on the seawater flow set point.

JOB ORDER/EWO NO.

The appropriate inlet and outlet gates are opened and the screen(s) automatically initiated.

01/20/16

DATE

The operator is able to select either continuous or intermittent rotation of each screen based on operating

experience. In “intermittent” mode the duration of each screen rotation and the rest time between

REV. NO.

rotations can be adjusted.

Washing of the screens is conducted automatically and is initiated either based on an elapsed time (as

OTHER

BY/DATE

entered by the operator) or on “High” upstream level, as measured by a level sensor in the common

screen inlet channel. The drum is automatically rotated during each wash cycle and the duration of the

wash is also adjustable within the control system.

REVIEW FOR KEY DRAWINGS

CONST. AGENCY/DATE OPERATIONS/DATE

REQUIRED (SAUDI ARAMCO)

The PCS will also allow for routine automatic rotation of screen duty/standby mode based on an elapsed

screen run time target that is entered by the operator into the PCS.

1.2.1.3 Pre-treatment Rapid Mixing and Flow Distribution

1.2.1.3.1 Acid Dosing

CERTIFIED/DATE

DESIGN CERTIFICATION

01/20/16

Sulphuric acid will be dosed downstream of the drum screens to adjust ambient pH to the

WB

(DESIGN AGENCY)

optimum level for coagulation with Ferric Chloride.

The acid is stored in bulk in the chemical building and then transferred to day tanks within the

ENGG. DATE

pretreatment complex. It is then dosed using one duty and one standby dosing pumps.

01/2016

RA

The operator will enter the desired adjusted pH within the PCS. Algorithms within the control

system will then derive the estimated acid dose based on the ambient seawater pH and

alkalinity. The acid dose will then be paced to the total seawater flow, as measured by as

AND CERTIFICATION REQUIREMENTS, PER SAEP-334, UNDER

IS COVERED, FOR ALL APPROVAL

measured by summing the flow meters located on the inlets to the pretreatment and then

trimmed to maintain the desired adjusted pH as measured by an analyzer located downstream

DRAWING COMPLETION CERTIFICATE NO:

of the acid addition point. Appropriate alarms will be initiated should the actual pH vary

beyond high and low tolerance levels pre-set into the control system.

Click here to enter text.

REVISION VALIDATION

Each dosing pump is equipped with a discharge flow meter. Should the flow rate on the duty

pump discharge fall below a pre-set value, as calculated by algorithms within the PCS, then

the duty pump will automatically shut down and be replaced by the standby pump. Appropriate

alarms will advise the plant operator that appropriate remedial action is required.

THIS REVISION NO. B

REPORT DWG. TYPE PLANT NO. INDEX DRAWING NO. SHT. NO REV. NO.

DSP HIGH LEVEL PLANT CONTROL DOC

6

JEC DESALINATION (RO) PLANT

DSP A VE-933634 OF B

JAZAN SAUDI ARABIA JO / EWO: 25-00037-0006/01 20

Saudi Aramco 2616 ENG. (09/03)

You might also like

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Coagulant Mixing in Sea WaterDocument1 pageCoagulant Mixing in Sea WaterkapsarcNo ratings yet

- Bulk Storage Transfer Equipment PsDocument1 pageBulk Storage Transfer Equipment Psalvaro netoNo ratings yet

- Pulp and Paper PDFDocument12 pagesPulp and Paper PDFVishnu Prakash SinghNo ratings yet

- Stationary Sprinkler: Irrigation SystemDocument21 pagesStationary Sprinkler: Irrigation Systempolanski12345No ratings yet

- Lecture On TWS, TR&CS, SLG - 04.09.2019Document93 pagesLecture On TWS, TR&CS, SLG - 04.09.2019A N MadhavanNo ratings yet

- NPR100 Ratio Controller Model RCWDocument4 pagesNPR100 Ratio Controller Model RCWDaniel Carmona AriasNo ratings yet

- Savi Multirake: Another High Capture Screen From Enviro-CareDocument2 pagesSavi Multirake: Another High Capture Screen From Enviro-CareFelipe BrainNo ratings yet

- 10sismat Multirake Mechanical Screen OTI Brochure A4 SpreadsDocument5 pages10sismat Multirake Mechanical Screen OTI Brochure A4 SpreadsDocu CenterNo ratings yet

- Scotts 2016Document5 pagesScotts 2016Anonymous VNu3ODGavNo ratings yet

- VSM IOM 1 09Document42 pagesVSM IOM 1 09haroldalconzNo ratings yet

- Hansun Water MakerDocument97 pagesHansun Water MakeralexNo ratings yet

- Combi: Packaged Pretreatment System For Sewage and Septage ReceivingDocument2 pagesCombi: Packaged Pretreatment System For Sewage and Septage Receivinglifemillion2847No ratings yet

- Cryostar LNG DispenserDocument4 pagesCryostar LNG Dispenser123habib123fikriNo ratings yet

- Bar Screen BrochureDocument4 pagesBar Screen BrochureCowbeak7959No ratings yet

- Centriquip - 2002 - BrochureDocument5 pagesCentriquip - 2002 - BrochureCentrifugal SeparatorNo ratings yet

- Hull Stress Monitoring System: Electric Sensors' SolutionDocument4 pagesHull Stress Monitoring System: Electric Sensors' SolutionjfcNo ratings yet

- National Foam ManualDocument4 pagesNational Foam ManualRiky AyalaNo ratings yet

- Remote Liquid Level Indicator: Features and BenefitsDocument12 pagesRemote Liquid Level Indicator: Features and BenefitsVishnu PatidarNo ratings yet

- Chapter 4. Shaker Screens: Separation PerformanceDocument10 pagesChapter 4. Shaker Screens: Separation Performancekaleem ullah janNo ratings yet

- Mud Flow Sensor FlyerDocument1 pageMud Flow Sensor FlyerSandesh ChavanNo ratings yet

- Ds Wastewatertreatment Sepcom-Vertical 0318 EngDocument2 pagesDs Wastewatertreatment Sepcom-Vertical 0318 EngCătălina StahurschiNo ratings yet

- AccuMaxFury FusionBrochureDocument9 pagesAccuMaxFury FusionBrochureyanuarNo ratings yet

- Single Accumulator Charging Valve: Description and OperationDocument6 pagesSingle Accumulator Charging Valve: Description and OperationWladimir Franz Rodríguez SaloméNo ratings yet

- BeaverDocument6 pagesBeaverfernando hutnikNo ratings yet

- Pre Treatment of Sea WaterDocument1 pagePre Treatment of Sea WaterkapsarcNo ratings yet

- Automated Decoking Solves Coker Safety ChallengesDocument4 pagesAutomated Decoking Solves Coker Safety ChallengesRobert MontoyaNo ratings yet

- EQ-011 Multielement WavemakerDocument4 pagesEQ-011 Multielement WavemakerFahmy ArdhiansyahNo ratings yet

- DS WasteWaterTreatment SEPCOM 0318 ENGDocument2 pagesDS WasteWaterTreatment SEPCOM 0318 ENGandreasNo ratings yet

- Condenser Level Protection - Functional DescriptionDocument2 pagesCondenser Level Protection - Functional DescriptiondnbinhNo ratings yet

- PICVs Valves Datasheetvp223r - vp224r - Picv - Specification - SheetDocument12 pagesPICVs Valves Datasheetvp223r - vp224r - Picv - Specification - SheetMuhammad Usman IqbalNo ratings yet

- Rotary Screen Rs Rc2Document3 pagesRotary Screen Rs Rc2MariusCapraNo ratings yet

- NDJ Drip Eng 160914Document48 pagesNDJ Drip Eng 160914CARLOS EDUARDONo ratings yet

- Alfa Laval DecanterDocument16 pagesAlfa Laval DecanterAKSHAY BHATKARNo ratings yet

- Cyclone Separators Flyer A4Document2 pagesCyclone Separators Flyer A4Ifnu SetyadiNo ratings yet

- Linear Shale-Shaker KemtronDocument19 pagesLinear Shale-Shaker KemtronWilliamNo ratings yet

- 1000-OCD CM 1Ph 220VAC 02 PDFDocument48 pages1000-OCD CM 1Ph 220VAC 02 PDFMiguel100% (1)

- NPR080 Ratio Controller Model RCTDocument4 pagesNPR080 Ratio Controller Model RCTJorge VelasquezNo ratings yet

- 2.14-1-OM ProC EMDocument36 pages2.14-1-OM ProC EMsemohamed2025No ratings yet

- STW 6500 Egg Tray WasherwebDocument2 pagesSTW 6500 Egg Tray WasherwebAlex SharkNo ratings yet

- Hydroelectric Generator Maintenance: Using The ZonicbookDocument2 pagesHydroelectric Generator Maintenance: Using The ZonicbookPrasanna DharmapriyaNo ratings yet

- C1802Document16 pagesC1802GOKUL PRASADNo ratings yet

- Alfa Laval Decanter PDFDocument16 pagesAlfa Laval Decanter PDFdaniel adamNo ratings yet

- 20mu14 PDFDocument24 pages20mu14 PDFOmar Cuellar BNo ratings yet

- Control ChokesDocument16 pagesControl Chokessolo devonNo ratings yet

- Geofabrics Flo Vault Product Brochure Jan23Document4 pagesGeofabrics Flo Vault Product Brochure Jan23Scott McCallumNo ratings yet

- A Review of Lime Slakers and Their Advantages and DisadvantagesDocument21 pagesA Review of Lime Slakers and Their Advantages and DisadvantagesThang NguyenNo ratings yet

- ASME Paper 82-PET-12Document4 pagesASME Paper 82-PET-12Hadi VeyseNo ratings yet

- (Part 4) RTPC 102 FsaDocument82 pages(Part 4) RTPC 102 FsaCarlos Joshua OreoNo ratings yet

- MahagencoDocument16 pagesMahagencokeen2seeuNo ratings yet

- WJ Wiper and Washer Systems 8K - 1Document26 pagesWJ Wiper and Washer Systems 8K - 1thomas rulduNo ratings yet

- System Integrated Water Softener: On-Demand Steam SolutionsDocument4 pagesSystem Integrated Water Softener: On-Demand Steam SolutionsvgdbrifNo ratings yet

- Eimco Brackettband MLDocument8 pagesEimco Brackettband MLManiyarasan DeivasigamaniNo ratings yet

- Installation Instructions and In-Span Positioning Tables: ClientDocument15 pagesInstallation Instructions and In-Span Positioning Tables: ClientGuido Garrido SalgadoNo ratings yet

- Ariel-Er-105 1 1Document9 pagesAriel-Er-105 1 1gustavofx21No ratings yet

- Emotron DCM Product Brochure 01 4613 01 ENDocument8 pagesEmotron DCM Product Brochure 01 4613 01 ENerickzaoNo ratings yet

- CH06Document50 pagesCH06inxs_the_bestNo ratings yet

- Instructiuni Instalare MOSDORFERDocument15 pagesInstructiuni Instalare MOSDORFERLiciu CiprianNo ratings yet

- Guidelines For Welding Stainless Alloy Piping Part 1Document4 pagesGuidelines For Welding Stainless Alloy Piping Part 1kapsarcNo ratings yet

- PN 16 Flange EN1092Document2 pagesPN 16 Flange EN1092kapsarcNo ratings yet

- Guidelines For Welding Stainless Alloy Piping Part 2Document4 pagesGuidelines For Welding Stainless Alloy Piping Part 2kapsarcNo ratings yet

- WQT - Aws D1.1Document3 pagesWQT - Aws D1.1kapsarc100% (1)

- Viking Material SpecsDocument12 pagesViking Material SpecskapsarcNo ratings yet

- One Week Look A Head PlanDocument1 pageOne Week Look A Head PlankapsarcNo ratings yet

- Piping IsoDocument1 pagePiping IsokapsarcNo ratings yet

- Slurry PumpDocument1 pageSlurry PumpkapsarcNo ratings yet

- Horizontal Slurry PumpDocument1 pageHorizontal Slurry PumpkapsarcNo ratings yet

- Pre Qualified WPSDocument1 pagePre Qualified WPSkapsarcNo ratings yet

- Boehler 2507 P100 Rutile E2594 16 Covered ElectrodeDocument1 pageBoehler 2507 P100 Rutile E2594 16 Covered ElectrodekapsarcNo ratings yet

- Pump Back Pressure RegulatorDocument1 pagePump Back Pressure RegulatorkapsarcNo ratings yet

- Forces On BoltsDocument1 pageForces On BoltskapsarcNo ratings yet

- Vertical Dry Pit PumpDocument1 pageVertical Dry Pit PumpkapsarcNo ratings yet

- Construction Progress Report - 2Document2 pagesConstruction Progress Report - 2kapsarcNo ratings yet

- Drive Unit For PumpDocument1 pageDrive Unit For PumpkapsarcNo ratings yet

- Construction Progress Report - 1Document2 pagesConstruction Progress Report - 1kapsarcNo ratings yet

- Chemical Compositiopn of FCAW ElectrodesDocument1 pageChemical Compositiopn of FCAW ElectrodeskapsarcNo ratings yet

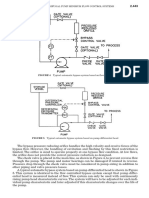

- Instrumentation Control For Pumps - 1Document1 pageInstrumentation Control For Pumps - 1kapsarcNo ratings yet

- Double Suction ImpellerDocument1 pageDouble Suction ImpellerkapsarcNo ratings yet

- Integral Flange FactorDocument1 pageIntegral Flange FactorkapsarcNo ratings yet

- Delta Ferrite ContentDocument1 pageDelta Ferrite ContentkapsarcNo ratings yet

- RT Acceptance Criteria For Pressure VesselDocument1 pageRT Acceptance Criteria For Pressure VesselkapsarcNo ratings yet

- Hot Tapping ArrangmentDocument1 pageHot Tapping ArrangmentkapsarcNo ratings yet

- Weld Joint Location in Pressure VesselDocument1 pageWeld Joint Location in Pressure VesselkapsarcNo ratings yet

- Pump Alarm ControlDocument1 pagePump Alarm ControlkapsarcNo ratings yet

- Flange ImperfectionDocument1 pageFlange ImperfectionkapsarcNo ratings yet

- Piping DrawingDocument1 pagePiping DrawingkapsarcNo ratings yet

- Inspection For TanksDocument1 pageInspection For TankskapsarcNo ratings yet

- Piping DWGDocument1 pagePiping DWGkapsarcNo ratings yet

- Lecture 25Document4 pagesLecture 25216435964No ratings yet

- 2013 Tuli Kivi CatalogDocument34 pages2013 Tuli Kivi Catalogمحمدحنيدق محمد غنيمNo ratings yet

- Work Method StatementDocument10 pagesWork Method StatementMdNasruddin shaikhNo ratings yet

- Charge Air System of Alco LocosDocument44 pagesCharge Air System of Alco LocosmajjisatNo ratings yet

- ME 503 DomDocument9 pagesME 503 Domsuneel kumar rathoreNo ratings yet

- Your Guide To Hydraulic FracturingDocument1 pageYour Guide To Hydraulic FracturingMartin GriffinNo ratings yet

- Reiki Book PDFDocument108 pagesReiki Book PDFGurpreet Singh Sohal100% (1)

- Roto-Glide: Heavy-Duty Bearing Grease For Electric MotorsDocument1 pageRoto-Glide: Heavy-Duty Bearing Grease For Electric MotorsJoao Botas50% (2)

- 10 - Chapter 3Document46 pages10 - Chapter 3Varsha ViswanathNo ratings yet

- Analysis of Commercial Proanthocyanidins. Part 1 The Chemical Composition of Quebracho (Schinopsis Lorentzii and Schinopsis Balansae) Heartwood Extract 2012 Phytochemistry 1Document11 pagesAnalysis of Commercial Proanthocyanidins. Part 1 The Chemical Composition of Quebracho (Schinopsis Lorentzii and Schinopsis Balansae) Heartwood Extract 2012 Phytochemistry 1Eric FernandoNo ratings yet

- Energies 14 04876 v2Document15 pagesEnergies 14 04876 v2FlogamagNo ratings yet

- ISO-50001-JK-WhiteDocument24 pagesISO-50001-JK-WhiteAgustinusDwiSusantoNo ratings yet

- Optoelectronic Devices: John Carlo S. TigueDocument4 pagesOptoelectronic Devices: John Carlo S. TigueJohnCarloTigueNo ratings yet

- E-10 Storage Batteries - 1465729800 - E-10Document10 pagesE-10 Storage Batteries - 1465729800 - E-10nicolas.travailNo ratings yet

- DLC CoatingDocument2 pagesDLC CoatingFernando Tapia GibsonNo ratings yet

- Training Manual Operations: July 1999-Rev.0Document110 pagesTraining Manual Operations: July 1999-Rev.0FharishPutraNo ratings yet

- SteamTurbineGenerator Datasheet 500MWDocument8 pagesSteamTurbineGenerator Datasheet 500MWParantap RahaNo ratings yet

- Lessons Learnt From HIAD 2.0-FinalDocument38 pagesLessons Learnt From HIAD 2.0-FinalMathis ThollotNo ratings yet

- LUMS Daily Student The H' WordDocument16 pagesLUMS Daily Student The H' WordKhawaja DaudNo ratings yet

- 16V4000 - T1637K33 Rated Power 2700 BHP at 1900 R-MinDocument9 pages16V4000 - T1637K33 Rated Power 2700 BHP at 1900 R-MinJuan PujolNo ratings yet

- Load Dispatch Centre: By-Siddharth KumarDocument16 pagesLoad Dispatch Centre: By-Siddharth KumarSIDDHARTHNo ratings yet

- Sprinter P12V1575 - BatterieDocument1 pageSprinter P12V1575 - BatterieblufanNo ratings yet

- Retigo Vision CatalogueDocument32 pagesRetigo Vision Cataloguesuonodimusica0% (1)

- Study of Power System Security in Indian Utility 62 Bus SystemDocument10 pagesStudy of Power System Security in Indian Utility 62 Bus SystempjNo ratings yet

- Simbologia PDFDocument1 pageSimbologia PDFMartin Abraham Perez UriasNo ratings yet

- Welding ElectrodesDocument13 pagesWelding ElectrodesArimoro Cyril ObuseNo ratings yet

- Ramakant Sir Physics Tutorials: (Magnetism) DURATION: 45mins MARKS: 50Document5 pagesRamakant Sir Physics Tutorials: (Magnetism) DURATION: 45mins MARKS: 50Kshitij BichaveNo ratings yet

- Hidraulika FESTO 2019 PDFDocument232 pagesHidraulika FESTO 2019 PDFKresimir Coric100% (1)

- Automation Control ProductsDocument112 pagesAutomation Control Productsnavin jollyNo ratings yet