Professional Documents

Culture Documents

Thyssenkrupp Industrial Solutions (India) Job Safety Analysis

Uploaded by

Nitesh kumar yadavOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thyssenkrupp Industrial Solutions (India) Job Safety Analysis

Uploaded by

Nitesh kumar yadavCopyright:

Available Formats

12-2018

NALCO,Expansion Project Stream-5

Dmanjodi,Odisha (Koraput)

Reference

thyssenkrupp NAL-HSE-MI-JSA-23

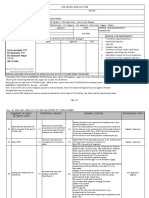

JOB SAFETY ANALYSIS

Industrial Solutions (India)

Job area is considered: Establishment/Project: JSA No.: 23

Project No: 66-6695 1.0MTPA Alumina Refinery

Contractor: tkIS India: Client:

Person participating in 1.Mr.K.Suresh Babu 1. Mr.N.K Singh 1. Mr. Arjun Basu

Job Safety Analysis. 2. Mr. Chaithanya 2. Mr.Atanu roy 2. Mr.Dhawajaraj Samal

3. Mr. Abhinav 3. Mr.Anil singh

4. Mr.Suryakanta Patra

JOB DESCRIPTION: Rubble Masonry/Toe wall Work, Rubble soling/Plinth protection & Gravel filling

Requirement of Working Permit Requirement of adding Personal Protection Requirement of adding special equipment or tool

(Check the relevant box) Equipment.

(Additional list)

Restricted space 1. Helmet 6.Goggles 1.Hammer

Heating job 2. Shoe 7. Cotton hand gloves 2. Roller

Digging 3.Full body harness (if required) 8.Gum boot 3. Earth compacter

Isolation / Energization 4. Lifeline (if required) 9.Fire extinguisher 4. Concrete machine

Other job 5. Ladder/Scaffold 5.Gamala (Pan)

JSA considering procedure Yes No Comment

tkIS India Form: Job Safety Analysis

12-2018

12-2018

NALCO,Expansion Project Stream-5

Dmanjodi,Odisha (Koraput)

Reference

thyssenkrupp NAL-HSE-MI-JSA-23

JOB SAFETY ANALYSIS

Industrial Solutions (India)

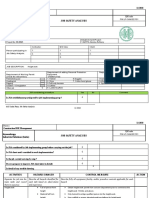

Is JSA establishment participated by job implementing group?

Is JSA considered by Job implementing group before carrying out the job?

Is JSA sheet used/ consulted in work implementation?

Is the job carried out step by step?

Do you propose to improve JSA sheet (give in detail)

Is detail of any trouble showing

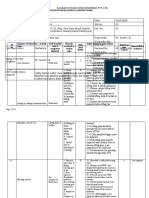

ACTIVITIES HAZARD/ DANGER CONTROL MEASURE ACTION

Separate the job into the Describe all hazards identified for Describe fully all equipment, facility, and/or procedure controls applicable for

main tasks and record them each task based on observations and each hazard.

in sequence. experience.

Rubble Masonry/Toe wall Work

Transportation of stone at 1.Cut/bruise Injury Inspected fit conditioned vehicle should be used. Mr.Chaithanya

site 2.Collision with vehicle to Only authorized person having valid driving licenses should be allowed

vehicle/person to drive the vehicle.

3.Traffic problem Helper/signal man should be with vehicle to guide the operator.

tkIS India Form: Job Safety Analysis

12-2018

12-2018

NALCO,Expansion Project Stream-5

Dmanjodi,Odisha (Koraput)

Reference

thyssenkrupp NAL-HSE-MI-JSA-23

JOB SAFETY ANALYSIS

Industrial Solutions (India)

4.Topple of vehicle While turning/reversing of vehicle, sound the horn to alert the public.

5.Stone fall down from vehicle while Stone should not be over loaded in carriage of transport.

transportation Don’t operate vehicle while the carriage is uplift conditioned.

Ensure the vehicle movement surrounding should be cleared from

electrical lines.

Operator should follow the traffic rules.

Stone should not be thrown from the vehicle

The stacking of stone area shall be barricaded.

While parking vehicle wheel choker should provide under the wheel.

1. Joint Fracture Try to avoid manual breaking.

2. Muscle pain Periodic rest should give to manual stone breaking worker.

3. Imparidness/Whiteness of Insist workmen to drink plenty of water.

finger

Correct tools should be usage for breaking of stone.

4. Sprain injury

Job requisite PPE's should be arranged for workmen. Mr.Chaithanya

5. Dehydrate

Don't stack stone access, egress path.

Breaking of stone as 6. Faint/Dizziness

At the time of manually breaking, ensure proper distance to be

required size by 7. Slip/trip

maintained between workmen.

machine(Excavator)/manual 8. Hit to person while stone

hammering Use Goggles to protect eye.

breaking with hammer.

No work to be allowed near the machine movement area.

9. Eye Injury

10. Hit to person /vehicle Experienced and licensed operator only allowed operating the vehicle.

Operator to be checked all safely checks points of vehicle before usage.

tkIS India Form: Job Safety Analysis

12-2018

12-2018

NALCO,Expansion Project Stream-5

Dmanjodi,Odisha (Koraput)

Reference

thyssenkrupp NAL-HSE-MI-JSA-23

JOB SAFETY ANALYSIS

Industrial Solutions (India)

11. Collision to person/vehicle Keep available first aid box near the work area.

12. Topple of vehicle Helper should be with vehicle giving surrounding clearance.

13. Damage to existing structure. Nobody is allowed to work circumstance of machine movement area.

14. Electrocution hazard Over head electrical line should be isolated, if possible reroute the line.

15. Noise/Dust pollution

1.Sprain injury Don't allow to lift over weight of a person’s capacity (refer- BOCW act

2.Body injury of weight lifting).

3.Slip/trip of person Keep the approach tidy for safe movement.

4.Ergonomical injury Pan (gamela) shall be used to carry the stone pieces by manually.

Manual handling stone to 5.Cut injury Follow manual material handling procedure.

Mr.Chaithanya

work spot 6. Snake/Insect/earth worm bite Usage requisite PPE's (Safety shoes,helmet, goggles , hand gloves and

nose mask) during work.

If required pest control the work vicinity.

1.Ergonomical injury to person while Follow the manual material handling procedure. Mr.Chaithanya

carry stone. All personal protective equipment shall be provided i.e. goggles,

2.Cut/bruise Injury

helmet, shoes, safety belt, hand gloves etc.

Masonry work as required 3.Slip/trip injury

Toolbox should be given to the worker prior to start of work

height 4.Rash due to direct contact of

cement on body Approach to be used for access and egress.

5.Fall of person/material Maintain clean and tidy the work area for avoid any earth worm hazard.

6.Collapse of scaffold/elevated

tkIS India Form: Job Safety Analysis

12-2018

12-2018

NALCO,Expansion Project Stream-5

Dmanjodi,Odisha (Koraput)

Reference

thyssenkrupp NAL-HSE-MI-JSA-23

JOB SAFETY ANALYSIS

Industrial Solutions (India)

working platform

7. Noise/Dust pollution

Maintain continuous clean to the working platform to avoid slip/trip. Mr.Chaithanya

Barricade the work area

Proper elevated working platform to be made to do the work safely.

Competent and qualified person shall be deployed on job.

If working height is 1.5mtrs or above height work permit and height fit

workmen only to be engaged on job.

Proper elevated scaffold should erect to do the job safely.

Use full body harness while working at height.

Keep available clean water near the work area for instant cleaning any

cement spillage over body.

Supervisor must be with job all time.

Rubble soling/Plinth protection

Inspected fit conditioned vehicle should be used. Mr.Chaithanya

1.Collision of vehicle/person Only authorized person having valid driving licenses should be allowed

Transportation of stone by 2.Traffic problem to drive the vehicle.

tipper to site 3.Topple of vehicle Helper/signal man should be with vehicle to guide the operator.

4.Stone fall down from vehicle while While turning/reversing of vehicle, sound the horn to alert the public.

tkIS India Form: Job Safety Analysis

12-2018

12-2018

NALCO,Expansion Project Stream-5

Dmanjodi,Odisha (Koraput)

Reference

thyssenkrupp NAL-HSE-MI-JSA-23

JOB SAFETY ANALYSIS

Industrial Solutions (India)

transportation Don’t operate vehicle while the carriage is uplift conditioned.

Ensure the vehicle movement surrounding should be cleared from

electrical lines.

Operator should follow the traffic rules.

While parking vehicle wheel choker should provide under the wheel.

Stone should not be over loaded in carriage of transport.

1.Sprain injury Don't allow to lift over weight of a person’s capacity (refer- BOCW act Mr.Chaithanya

2.Body injury of weight lifting).

3.Slip/trip of person Keep the approach tidy for safe movement.

4.Ergonomical injury Pan (gamela) shall be used to carry the stone pieces by manually.

Manual handling stone form 5.Cut injury Follow manual material handling procedure.

site to work spot 6. Snake/Insect/earth worm bite Usage requisite PPE's (Safety shoes,helmet, goggles , hand gloves and

nose mask) during work.

Pest control vicinity of work area.

1. Joint Fracture Periodic rest should give to manual stone breaking worker. Mr.Chaithanya

2. Muscle pain Insist workmen to drink plenty of water.

3. Imparidness/Whiteness of Correct tools should be usage for breaking of stone.

finger

Job requisite PPE's should be arranged for workmen.

4. Sprain injury

Follow manual material handling procedure

Manual Breaking of stone as 5. Dehydrate

Don't stack stone access, egress path.

required 6. Faint/Dizziness

At the time of manually breaking, ensure proper distance to be

7. Slip/trip

maintained between workmen.

tkIS India Form: Job Safety Analysis

12-2018

12-2018

NALCO,Expansion Project Stream-5

Dmanjodi,Odisha (Koraput)

Reference

thyssenkrupp NAL-HSE-MI-JSA-23

JOB SAFETY ANALYSIS

Industrial Solutions (India)

8. Hit to person while stone Use Goggles to protect eye.

breaking with hammer. If required Isolate the electrical lines which is coming under the work

9. Eye Injury area.

10. Personnel injury due to Follow traffic rules and speed limit 20 KMPH.

breaking of hand tools

Keep available first aid box near the work area.

11. Noise/Dust pollution

1.Personel injury Keep restrict both end of road during work over/near the road. Mr.Chaithanya

Compaction by using roller 2.Hit to person/structure Maintain safe distance between structure to person.

or earth compacter/hammer 3. Fire/Explosion Keep clearance surrounding of Vehicle movement.

4.Faint and dizziness Competent and licensed operator only allowed to drive the vehicle.

5.Ergonomical injury Helper should be with operator all time .

6. Noise/Dust pollution

Provide periodic rest to be given to manual work doing workmen.

Follow material handling procedure during handling of material.

Use requisite PPE’s to workmen.

Take care of electrical line during work.

Time to time rest be given to diesel compactor for avoid fire/over

heating.

PCC work

tkIS India Form: Job Safety Analysis

12-2018

12-2018

NALCO,Expansion Project Stream-5

Dmanjodi,Odisha (Koraput)

Reference

thyssenkrupp NAL-HSE-MI-JSA-23

JOB SAFETY ANALYSIS

Industrial Solutions (India)

Concreting 1.Body Rash due to contact with Use rubber gloves, gumboots & goggles to concrete workmen. Mr.Chaithanya

preparation/pouring cement concrete. Keep available cool clean water adjacent of work area for instance

manually/ by Ajax machine clean.

Wash your body & eye after any concrete contact.

If any Power connection required, it must be gone through RCCB not

by- pass.

No naked cable permitted around the work area.

2. Machine/vehicle hit to person or All power cable should be insulated well and overhead.

object.

A signaling person should deploy for communication. If required bell or

siren to be usage.

3.Cut /bruise injury due to Fall/hit of

If chute used , Tie the it properly.

person.

Only skilled workers to be deployed for concreting work.

Use proper access.

Barricade the concreting work area.

Ensure Proper supervision to the job.

4.slip/trip of person. Give PEP talk to workmen prior before start the job.

5.Sprain/pain injury All debris must be removed after concreting.

Gravel filling

Inspected fit conditioned vehicle should be used. Mr.Chaithanya

tkIS India Form: Job Safety Analysis

12-2018

12-2018

NALCO,Expansion Project Stream-5

Dmanjodi,Odisha (Koraput)

Reference

thyssenkrupp NAL-HSE-MI-JSA-23

JOB SAFETY ANALYSIS

Industrial Solutions (India)

1.Collision of vehicle/person Only authorized person having valid driving licenses should be allowed

Transportation of stone/sand 2.Traffic problem to drive the vehicle.

by vehicle to site 3.Topple of vehicle Helper/signal man should be with vehicle to guide the operator.

4.Stone/sand fall down from vehicle While turning/reversing of vehicle, sound the horn to alert the public.

while transportation Don’t operate vehicle while the carriage is uplift conditioned.

Ensure the vehicle movement surrounding should be cleared from

electrical lines.

Operator should follow the traffic rules.

While parking vehicle wheel choker should provide under the wheel.

Stone should not be over loaded in carriage of transport.

Sand filled vehicle should have proper cover avoid of any spillage

during operation.

1.Sprain injury Don't allow to lift over weight of a person’s capacity (refer- BOCW act Mr.Chaithanya

2.Body injury of weight lifting).

3.Slip/trip of person Keep the approach tidy for safe movement.

4.Ergonomical injury Pan (gamela) shall be used to carry the stone/sand pieces by manually.

Manual handling & 5.Cut injury Follow manual material handling procedure.

spreading of stone/sand to 6. Snake/Insect/earth worm bite Usage requisite PPE's (Safety shoes,helmet, goggles , hand gloves and

work spot 7.Eye injury nose mask) during work.

Pest control vicinity of work area.

1. Joint Fracture Periodic rest should give to manual stone breaking worker. Mr.Chaithanya

2. Muscle pain Insist workmen to drink plenty of water.

tkIS India Form: Job Safety Analysis

12-2018

12-2018

NALCO,Expansion Project Stream-5

Dmanjodi,Odisha (Koraput)

Reference

thyssenkrupp NAL-HSE-MI-JSA-23

JOB SAFETY ANALYSIS

Industrial Solutions (India)

3. Imparidness/Whiteness of Correct tools should be usage for breaking of stone.

finger Job requisite PPE's should be arranged for workmen.

4. Sprain injury Follow manual material handling procedure

Manual Breaking of stone as 5. Dehydrate

Don't stack stone access, egress path.

required 6. Faint/Dizziness

At the time of manually breaking, ensure proper distance to be

7. Slip/trip maintained between workmen.

8. Hit to person while stone

Use Goggles to protect eye.

breaking with hammer.

If required Isolate the electrical lines which is coming under the work

9. Eye Injury

area.

10. Personnel injury due to

Follow traffic rules and speed limit 20 KMPH.

breaking of hand tools

Keep available first aid box near the work area.

11. Noise/Dust pollution

Prepared by Reviewed by Approved by

(Contractor -Mythri) (tkIS-Department Lead) (tkIS-Site Manager/HSE manager)

Name: Name: Name:

Designation: Designation: Designation:

Signature: Signature: Signature:

Date: Date: Date:

tkIS India Form: Job Safety Analysis

12-2018

12-2018

NALCO,Expansion Project Stream-5

Dmanjodi,Odisha (Koraput)

Reference

thyssenkrupp NAL-HSE-MI-JSA-23

JOB SAFETY ANALYSIS

Industrial Solutions (India)

tkIS India Form: Job Safety Analysis

12-2018

You might also like

- Research and Design of Snow Hydrology Sensors and Instrumentation: Selected Research PapersFrom EverandResearch and Design of Snow Hydrology Sensors and Instrumentation: Selected Research PapersNo ratings yet

- Fabrication and welding works safetyDocument3 pagesFabrication and welding works safetyMohamedSaidNo ratings yet

- Jsa PDFDocument5 pagesJsa PDFVAMSINo ratings yet

- 3 SPS Sop RCC FullDocument14 pages3 SPS Sop RCC FullDwitikrushna RoutNo ratings yet

- Jsa Ducting Rev 00Document1 pageJsa Ducting Rev 00SRR HSE Department, Sandvik Project,No ratings yet

- Job Hazard AnalysisDocument3 pagesJob Hazard AnalysisBrain Dee Tech LtdNo ratings yet

- SWMS-Pipe Instalation Work at Utility 25.01.21Document10 pagesSWMS-Pipe Instalation Work at Utility 25.01.21Ansari FaisalNo ratings yet

- Job Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectDocument5 pagesJob Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectShilpiengg SafetyNo ratings yet

- MS Working at HeightsDocument15 pagesMS Working at HeightsNauval FadliNo ratings yet

- Arc Welding - JSADocument6 pagesArc Welding - JSAdroffilcz27No ratings yet

- 07 Method Sytatement For Drilling MachineDocument5 pages07 Method Sytatement For Drilling MachineNishar Balkavade100% (1)

- Air Compressor Operation SafetyDocument10 pagesAir Compressor Operation SafetyKelvin TanNo ratings yet

- 11.pneumatic Pressure Testing.Document7 pages11.pneumatic Pressure Testing.Mohammad Fazal KhanNo ratings yet

- Hot Works: Risk Assesment Form For Rolling ShutterDocument1 pageHot Works: Risk Assesment Form For Rolling Shutterchandanprakash30No ratings yet

- PipingDocument9 pagesPipingshamierrul shahliNo ratings yet

- Updated JSA For SAPMTofficeDocument30 pagesUpdated JSA For SAPMTofficeShaikh Abu bakarNo ratings yet

- JSA - LOAD TEST PILE No. 1Document6 pagesJSA - LOAD TEST PILE No. 1Sanjeet SinghNo ratings yet

- Risk Assessment for Civil WorksDocument8 pagesRisk Assessment for Civil WorkssufiyanNo ratings yet

- Sealcoating /crack Repair Parking Lots: Job Safety AnalysisDocument3 pagesSealcoating /crack Repair Parking Lots: Job Safety AnalysisRetselisitsoe0% (1)

- Ratna Infrastructure JSA ListDocument113 pagesRatna Infrastructure JSA ListAmit BhattNo ratings yet

- Lifting OperationDocument8 pagesLifting OperationFILE 1131No ratings yet

- NASDA WIND POWER SUB-STATION EXCAVATION SAFETYDocument2 pagesNASDA WIND POWER SUB-STATION EXCAVATION SAFETYRaza Muhammad SoomroNo ratings yet

- Safety Signs On Construction SiteDocument1 pageSafety Signs On Construction SiteBëBå Wossen AssefaNo ratings yet

- JHA For Installation 2 Inch Nozzle..Document6 pagesJHA For Installation 2 Inch Nozzle..arnolhari100% (1)

- 02 Heavy Vehicle Movement, Loading Unloading & Shifting SOPDocument8 pages02 Heavy Vehicle Movement, Loading Unloading & Shifting SOPB&R HSE BALCO SEP SiteNo ratings yet

- ExcavationDocument3 pagesExcavationprasanna ok100% (1)

- Risk Assessment for Corian at Mozoon Towers ProjectDocument12 pagesRisk Assessment for Corian at Mozoon Towers Projectadeoye AdeyemiNo ratings yet

- Kursus Sijil Kompeten Penyelia Keselamatan Tapak Bina: Site Safety Supervisor Competency Course CertificateDocument163 pagesKursus Sijil Kompeten Penyelia Keselamatan Tapak Bina: Site Safety Supervisor Competency Course CertificateDurga SreetharanNo ratings yet

- DOD-MST-AKG-2-E-012 (Rev-A) Installation of TransformerDocument4 pagesDOD-MST-AKG-2-E-012 (Rev-A) Installation of TransformerProfessional TrustNo ratings yet

- SWP 5 Excavations Shoring and Trenches PDFDocument4 pagesSWP 5 Excavations Shoring and Trenches PDFThanesh ManogaranNo ratings yet

- Job Safety Analysis for PCC WorkDocument6 pagesJob Safety Analysis for PCC WorkCICON EngineersNo ratings yet

- Asian Paints - Prem Gloss EnamelDocument1 pageAsian Paints - Prem Gloss EnamelwilliumstNo ratings yet

- 19.hydro Pressure Testing.Document8 pages19.hydro Pressure Testing.Mohammad Fazal KhanNo ratings yet

- DemolitionDocument2 pagesDemolitionGanga Daran100% (1)

- Nitoproof 230Document2 pagesNitoproof 230Balasubramanian Ananth50% (2)

- Job Safety Analysis WorksheetDocument7 pagesJob Safety Analysis WorksheetMohamedSaidNo ratings yet

- Tbam: Dikkowita Fisheries HarbourDocument8 pagesTbam: Dikkowita Fisheries HarbourkskahatadeniyaNo ratings yet

- 0 JsaDocument54 pages0 JsaRavi AmarlapudiNo ratings yet

- JSA - Crane Setuppdf PDFDocument12 pagesJSA - Crane Setuppdf PDFChoko ChokriNo ratings yet

- SWP Brick LayingDocument3 pagesSWP Brick LayingHanis MuhamadNo ratings yet

- ISC-JSA Grouting Works For Shared FenceDocument4 pagesISC-JSA Grouting Works For Shared FenceSameer AlmahboubNo ratings yet

- Risk Assessment-Maintance of Tanks, VesselsDocument5 pagesRisk Assessment-Maintance of Tanks, VesselsKono Nor AtanNo ratings yet

- Sarawak JSA for Concrete CuttingDocument4 pagesSarawak JSA for Concrete CuttingMohammad Irfan Kiki IsmailNo ratings yet

- PT-03 JSA Dismantling of Slip Form (22-05-09)Document10 pagesPT-03 JSA Dismantling of Slip Form (22-05-09)M Waqas HabibNo ratings yet

- Job Safety Analysis: S.No Activities Hazard Risk Control MeasuresDocument2 pagesJob Safety Analysis: S.No Activities Hazard Risk Control Measureskhaja asifuddinNo ratings yet

- JSA Formet New Blasting & PaintingDocument5 pagesJSA Formet New Blasting & Paintingsakthi venkatNo ratings yet

- Job Hazard Analysis: Task Excavation and Laying of Cable From A8 To A9Document4 pagesJob Hazard Analysis: Task Excavation and Laying of Cable From A8 To A9OGBONNAYA MARTINSNo ratings yet

- JSA For Scaffolding Erection Removal Around AT-911Document1 pageJSA For Scaffolding Erection Removal Around AT-911Equipment Materials100% (1)

- Retail Permit to Work System - Job Hazard AnalysisDocument4 pagesRetail Permit to Work System - Job Hazard Analysismyn maliQue0% (1)

- JOB SAFETY ANALYSIS FOR HOT SPLICING BELT REPLACEMENTDocument8 pagesJOB SAFETY ANALYSIS FOR HOT SPLICING BELT REPLACEMENTPed KapedNo ratings yet

- JSA-03 Shed DismantlingDocument3 pagesJSA-03 Shed DismantlingSwaroop Cherry0% (1)

- Breaker Machine Safety ChecklistDocument1 pageBreaker Machine Safety ChecklistNair R RakeshNo ratings yet

- Shifting of Material & Equipment.: Job Safety Analysis JobDocument6 pagesShifting of Material & Equipment.: Job Safety Analysis JobPrabir PujariNo ratings yet

- JSA For The Conveyor BeltDocument1 pageJSA For The Conveyor BeltSaklain MustakNo ratings yet

- Stringing, Welding and Coating Process.Document3 pagesStringing, Welding and Coating Process.Beyar. ShNo ratings yet

- Jsa Ground Grid MocksvilleDocument2 pagesJsa Ground Grid MocksvilleChristopher NewbyNo ratings yet

- Scaffold TowerDocument20 pagesScaffold TowerAndhika HerdiawanNo ratings yet

- Backfilling Work SafetyDocument5 pagesBackfilling Work SafetyNitesh KumarNo ratings yet

- JSA FOR BLASTINGDocument7 pagesJSA FOR BLASTINGMOHD SUHAILNo ratings yet

- Height Work Safety AnalysisDocument4 pagesHeight Work Safety AnalysisNitesh KumarNo ratings yet

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 6Document6 pagesThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 6Nitesh kumar yadavNo ratings yet

- 5.JSA of Batching Plant InstallationDocument4 pages5.JSA of Batching Plant InstallationNitesh kumar yadavNo ratings yet

- 5.JSA of Batching Plant InstallationDocument4 pages5.JSA of Batching Plant InstallationNitesh kumar yadavNo ratings yet

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 6Document6 pagesThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 6Nitesh kumar yadavNo ratings yet

- Risk Assessment Cover Sheet: Wayame 150kV ProjectDocument42 pagesRisk Assessment Cover Sheet: Wayame 150kV ProjectBaso Firdaus PannecceNo ratings yet

- Induction Training For Visitors - MaonaDocument31 pagesInduction Training For Visitors - MaonaMaona power plant Plant100% (1)

- Asphalt - MC 250 (Superior) - Superior Refining Company, LLC (Husky Energy)Document11 pagesAsphalt - MC 250 (Superior) - Superior Refining Company, LLC (Husky Energy)Lindsey BondNo ratings yet

- Msds Nano PolishDocument5 pagesMsds Nano PolishGan LordNo ratings yet

- Catalogue Welding Accessories PPEDocument107 pagesCatalogue Welding Accessories PPEVijo JoseNo ratings yet

- Hyundai R160LC-7ADocument499 pagesHyundai R160LC-7AГригорий Григорян88% (8)

- Kappler CatalogDocument8 pagesKappler CatalogGersonDarioOrtizReyesNo ratings yet

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument14 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingKamil AYDINNo ratings yet

- Leak Tightness TestingDocument2 pagesLeak Tightness TestingSamantha HarveyNo ratings yet

- Accident Investigation FormDocument4 pagesAccident Investigation FormRameish Rao Subarmaniyan100% (1)

- SDS Rust Veto As EuDocument11 pagesSDS Rust Veto As EuaaronNo ratings yet

- Control Measures of Chemical Hazard.. Gondaleeya DevangDocument17 pagesControl Measures of Chemical Hazard.. Gondaleeya DevangDevang GondaliyaNo ratings yet

- Risk Assessment & Damage ControlDocument29 pagesRisk Assessment & Damage ControlRa muNo ratings yet

- MDSD FludarabinDocument10 pagesMDSD FludarabinImanda EsaNo ratings yet

- Ral 3020Document6 pagesRal 3020spazzbgtNo ratings yet

- Tender Form C Work Execution PlanDocument87 pagesTender Form C Work Execution Plannuvie ohwoefeNo ratings yet

- MSDS ErgotamineDocument9 pagesMSDS ErgotamineawanaNo ratings yet

- KF 23 e Laser CoolantDocument13 pagesKF 23 e Laser CoolantyilmazmacitNo ratings yet

- QAS 14 - 20 PD: Instruction Manual For AC GeneratorsDocument62 pagesQAS 14 - 20 PD: Instruction Manual For AC GeneratorslucasNo ratings yet

- VWP Installation and Operation ManualDocument14 pagesVWP Installation and Operation ManualDenzil StephensonNo ratings yet

- MS Confined Space B.DamansaraDocument47 pagesMS Confined Space B.DamansaraHana SeiadiNo ratings yet

- Construction of Pre-Cast Concrete BridgeDocument8 pagesConstruction of Pre-Cast Concrete BridgeRhap Lumaban93% (14)

- MST For Roof Slab WaterproofingDocument6 pagesMST For Roof Slab Waterproofingdina gunasekeraNo ratings yet

- New SMP For Cable Tray WorkDocument9 pagesNew SMP For Cable Tray WorkGaurav KhandelwalNo ratings yet

- Fall Protection Exam - Worksite Safety11Document6 pagesFall Protection Exam - Worksite Safety11Ian Jeff Landingin DumayasNo ratings yet

- Day 3 PPE (Handout)Document10 pagesDay 3 PPE (Handout)mike camsNo ratings yet

- Working at HeightDocument9 pagesWorking at HeightDebby WijayantiNo ratings yet

- MSDSDocument100 pagesMSDSyoyohairymonsterNo ratings yet

- Flygt 3153: Installation, Operation, and Maintenance ManualDocument72 pagesFlygt 3153: Installation, Operation, and Maintenance ManualvyshakhNo ratings yet

- Workplace Safety Powerpoint PresentationDocument16 pagesWorkplace Safety Powerpoint PresentationkasoziNo ratings yet