Professional Documents

Culture Documents

Is 210 - 5

Is 210 - 5

Uploaded by

SvapneshOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Is 210 - 5

Is 210 - 5

Uploaded by

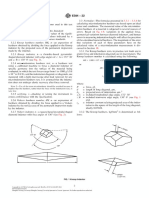

SvapneshCopyright:

Available Formats

15 210 : 2009

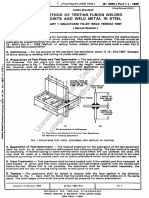

FIG . I M ACHINED T ENSIl.E TEST PI ECE

Tabl e 2 Dimen sion s of Machined Tensile Test Piece

(Clause 14 )

All d imen sions in rnillimctre s.

G a uge Machinin g Minimum '\i n imum Plain Ends Sc r ewed Ends

l>ia meter -T n le r a n ce Parallel Radius A .A

D for the

G a uge

I.ength ' Milllmum

Diameter

M inim u n~

I.engt h

' M inimum

Dia at

M inimum

Leng th

"

l>ia meter Root

L R d, L d, L

(I) (2) (3 ) (4 ) (5) (6 )

" (7) (8 )

20 ± 0.5 55 25 23 65 25 30

NOTE - With screwed- ends. a ny form o f thread may be used provided that the d iam eter at the roo t o f the thread is not less

than th at s pecified .

15 TENSILE STRENGTH accordance with the method g iven in IS 1500 . Brineil

hardness values for different grades of grey iro n

When tested in accordance with the requirements

castings shall be as specified in Table 3.

of 14 the test piece shall comply with the minimum

requiremen ts specified in Table 3 . Th e tensile 16.1.1 The hardness te s t shall be c o nd ucted at

strength specified is that obtained from test bars cast specific point on the cast ings . This specific po int

separately from th e castings to wh ich they refer. The sha ll be such that they are ame ndable for hardness

test values represent, therefore, only the quality of checking to ro ut ine procedure and shall be a s agreed

the metal from which the casting s have been poured . to bet ween the purchaser and the manu facturer.

16 HARDNESS TEST 17 TRANSVERSE TEST

16.1 The Br inell hardness te st shall be carried out in Ifrequi red , the tr an sverse test may be ca rried o ut by

the manufac turer in accordanc e with the method

Table 3 Mechanical Test Requirements

giv en in Anne x E. T he min imum test requi rem ents

(Clauses 15 and 16.1)

shall be agreed upon at the time of enquiry and order.

Grade Tensile Strrngth Brinrll

(su IS 4843) Min Hardness 18 HYDROSTATIC TEST

Mra (N/OJ.') HBW

If speci fied at the time of e nq ui ry an d o rde r th e

(I) (2) (J)

ca stin gs ma y be te sted for the hydro st at ic test

FG 150 150 IJO to 180 pressure. Th e requirements for the test pressure shall

FG 200 200 160 to 220 be mutu all y agree d to between the purcha se r an d

FG 220 22 0 180 to no the manufacturer.

FG 260 260 180 to 230

19 RETESTS

FG 300 30 0 180 to 23 0

FG 350 350 1 0 7 to 24 1 19.1 If on be ing tested any test p iece shows obviou s

FG 400 400 20 7 to 270 sig ns o f a cas ting de fect. the res u lts o f the te st may

be discarded and a furthe r test be mad e.

NO TE - Altho ugh mech ani cal prope rties a re speci fied tor

G rade FG 150 the m aterial shall be only tested if required by 19.2 lf an y sound te st piec e fails. two fur th er tests

the pur ch ase r.

sha ll be mad e. should e ithe r of these test piece s fail.

You might also like

- Ferrite Transformer TestingDocument16 pagesFerrite Transformer TestingHoang Thanh VanNo ratings yet

- Ammonia: Valves For Ammonia ServiceDocument2 pagesAmmonia: Valves For Ammonia ServiceArun Babu0% (1)

- MssDocument8 pagesMssGuillermo Gonzales AmayaNo ratings yet

- Turbine TroubleshootingDocument15 pagesTurbine TroubleshootingBrian ASNo ratings yet

- Asme B18.8.2 2000Document39 pagesAsme B18.8.2 2000Jesse ChenNo ratings yet

- 11 - RefrigerationDocument4 pages11 - RefrigerationMuzzamil ShahzadNo ratings yet

- Spherical Shells (7.4.3) EN 13445-3Document3 pagesSpherical Shells (7.4.3) EN 13445-3met-calcNo ratings yet

- Designing A BEM Heat ExchangerRev1Document22 pagesDesigning A BEM Heat ExchangerRev1Steve WanNo ratings yet

- Jis G 3505 LC W RodsDocument1 pageJis G 3505 LC W RodsRamesh DattaNo ratings yet

- Rolled Shells (7.4.2) According To Standards EN 13445-3: Values For CalculationDocument3 pagesRolled Shells (7.4.2) According To Standards EN 13445-3: Values For Calculationmet-calcNo ratings yet

- Working Clearance For Outdoor Installation Ref IEC 61936 Fig 3 Safety Clearance Sectional Clearance Safety ClearanceDocument1 pageWorking Clearance For Outdoor Installation Ref IEC 61936 Fig 3 Safety Clearance Sectional Clearance Safety ClearanceMeghavahinaNo ratings yet

- Multiphase Flow RegimeDocument42 pagesMultiphase Flow RegimerizalabdaNo ratings yet

- Durco Pressure Leaf Sulfur FiltrationDocument3 pagesDurco Pressure Leaf Sulfur FiltrationBhusarapu SrinivasNo ratings yet

- (Chemical Engineering Laboratory 2) : Experiment 5: Series and Parallel PumpDocument20 pages(Chemical Engineering Laboratory 2) : Experiment 5: Series and Parallel PumpAbdulrazzaqAL-MalikyNo ratings yet

- Licensed To Arun Kumar Das: Method of Testing Fusi0.N Welded Joints and Weld Metal in SteelDocument2 pagesLicensed To Arun Kumar Das: Method of Testing Fusi0.N Welded Joints and Weld Metal in SteelIndira BanerjeeNo ratings yet

- Surface Roughness Machine ToolDocument3 pagesSurface Roughness Machine ToolDieselNo ratings yet

- Module-2: Two Probe and Four Probe Methods-Van Der Pauw MethodDocument10 pagesModule-2: Two Probe and Four Probe Methods-Van Der Pauw MethodDevi Arumugam100% (1)

- Industrial Application of Creep - Fatigue Crack Initiation and Growth Procedures For Remaining Life Analysis of Steam Turbine ComponentsDocument10 pagesIndustrial Application of Creep - Fatigue Crack Initiation and Growth Procedures For Remaining Life Analysis of Steam Turbine ComponentsFilipNo ratings yet

- CT PTDocument20 pagesCT PTtalha0703097100% (1)

- File 01133Document16 pagesFile 01133giriNo ratings yet

- UNIT 3 (EMI) Part 1Document25 pagesUNIT 3 (EMI) Part 1ShivaniNo ratings yet

- Control of The Continuous Rheocasting Process 2Document6 pagesControl of The Continuous Rheocasting Process 2vubahieu02No ratings yet

- Fall-of-Potential Ground Testing, Clamp-On Ground Testing ComparisonDocument4 pagesFall-of-Potential Ground Testing, Clamp-On Ground Testing ComparisonRicky Respondo TindocNo ratings yet

- Unit 1 (Emi)Document21 pagesUnit 1 (Emi)ShivaniNo ratings yet

- Department of Mechanical Engineering: Prepared By.. Prof - Sachin Kumar NikamDocument22 pagesDepartment of Mechanical Engineering: Prepared By.. Prof - Sachin Kumar NikamAishwarya SNo ratings yet

- Digital Voltmeters: Uogx - Eceg4155 - Chapter 4Document38 pagesDigital Voltmeters: Uogx - Eceg4155 - Chapter 4Abdi ExplainsNo ratings yet

- Simulating Three Phase Induction Motor Performance During Different Voltage Sag TypesDocument7 pagesSimulating Three Phase Induction Motor Performance During Different Voltage Sag TypesJOHN MINKHANTNo ratings yet

- Mi 3102 BT Eurotestxe: Auto Sequence Tester With TN, TT and It Earthing Systems SupportDocument2 pagesMi 3102 BT Eurotestxe: Auto Sequence Tester With TN, TT and It Earthing Systems SupportThanh Tam NguyenNo ratings yet

- State Standards: - 2 - H V V LDocument3 pagesState Standards: - 2 - H V V LMihai TataroiNo ratings yet

- BE3251 BEEE QB 01 - by WWW - Learnengineering.inDocument101 pagesBE3251 BEEE QB 01 - by WWW - Learnengineering.inrd gamingNo ratings yet

- ASTM E384 (2022) - Part2Document1 pageASTM E384 (2022) - Part2david4231993No ratings yet

- 3 6 Test Bar Fixed or Order The As 5.: (Clause 17)Document1 page3 6 Test Bar Fixed or Order The As 5.: (Clause 17)SvapneshNo ratings yet

- 09 Site Investigations IIIDocument13 pages09 Site Investigations IIIAlvaro B. Galarce JerezNo ratings yet

- Skin Rejuvenation Voyager 3Document6 pagesSkin Rejuvenation Voyager 377yr72cdh6No ratings yet

- Flexural Strength of Concrete (Using Simple Beam With Center-Point Loading)Document4 pagesFlexural Strength of Concrete (Using Simple Beam With Center-Point Loading)CHON SaophornNo ratings yet

- Rheology Applications Note: Automatic Gap ClosureDocument3 pagesRheology Applications Note: Automatic Gap ClosuretadirambabuNo ratings yet

- HSFG Bolt PDFDocument6 pagesHSFG Bolt PDFSatish PawarNo ratings yet

- 2 Lett 1 2 Lette 1 3 LetteDocument9 pages2 Lett 1 2 Lette 1 3 Lettemohamed100% (1)

- Module 3 Em&iDocument44 pagesModule 3 Em&iharshashetty988No ratings yet

- Ec694 Prospekt GBDocument6 pagesEc694 Prospekt GBAnonymous oPOqLDTuYjNo ratings yet

- Bearings Datahandbook PDFDocument8 pagesBearings Datahandbook PDFKiran ThunuguntlaNo ratings yet

- Accepted Manuscript Not Copyedited: Assessment of Fracture Toughness Using Small Punch Tests of Pre Notched SpecimensDocument12 pagesAccepted Manuscript Not Copyedited: Assessment of Fracture Toughness Using Small Punch Tests of Pre Notched SpecimensRizal MaulanaNo ratings yet

- Information and Experience Exchange: D M 6/ (S. Y), (1)Document4 pagesInformation and Experience Exchange: D M 6/ (S. Y), (1)Salma FarooqNo ratings yet

- 15EC35 - Electronic Instrumentation - Module 4Document33 pages15EC35 - Electronic Instrumentation - Module 4Anish AnniNo ratings yet

- Diesel Engine Misfire Detection Utilizing Time-FrequencyDocument16 pagesDiesel Engine Misfire Detection Utilizing Time-FrequencyAli ElmaihyNo ratings yet

- Protection Relay: REF 542 Plus Manufacturer: ABB Relay Description: Bay Control and Protection Unit Protection FunctionsDocument15 pagesProtection Relay: REF 542 Plus Manufacturer: ABB Relay Description: Bay Control and Protection Unit Protection FunctionsHatem HusseinNo ratings yet

- Automatic Inspection MethodsDocument11 pagesAutomatic Inspection MethodssubhashNo ratings yet

- Gas Turbine Disc Stress CalculationsDocument3 pagesGas Turbine Disc Stress CalculationsKishore MylavarapuNo ratings yet

- Charpy Impact Testing MachineDocument2 pagesCharpy Impact Testing MachineSupratim RoyNo ratings yet

- BS EN 1993-1-8:2005 EN 1993-1-8:2005 (E) : 3.10.4 Lug AnglesDocument5 pagesBS EN 1993-1-8:2005 EN 1993-1-8:2005 (E) : 3.10.4 Lug Anglesmn4webNo ratings yet

- Adobe Scan 12 Oct 2022Document22 pagesAdobe Scan 12 Oct 2022harsh sharmaNo ratings yet

- Astm D 2137-75Document3 pagesAstm D 2137-75chaivatNo ratings yet

- Exp 1 Ohm's LawDocument4 pagesExp 1 Ohm's LawaryendrapariharNo ratings yet

- Caterpillar Operation and Maintenance Manual Sr4b Generators (85 93)Document9 pagesCaterpillar Operation and Maintenance Manual Sr4b Generators (85 93)AlexNo ratings yet

- Meter TestDocument5 pagesMeter TestKasiviswanathan ANo ratings yet

- Mining Science and Technology 1991 Vol.12 p.79 88Document10 pagesMining Science and Technology 1991 Vol.12 p.79 88Dicki SetiawanNo ratings yet

- ASTM E384 (2022) - Part3Document1 pageASTM E384 (2022) - Part3david4231993No ratings yet

- Unit 6 Testing of Ic EngineDocument15 pagesUnit 6 Testing of Ic EngineComedy CircleNo ratings yet

- The Strength of Struts: A C K eDocument21 pagesThe Strength of Struts: A C K eLênon Guimarães Silva AlípioNo ratings yet

- Ensayo de CuñaDocument3 pagesEnsayo de CuñazokytoNo ratings yet

- Single 2013 MI 3102 BT EurotestXE Ang PDFDocument2 pagesSingle 2013 MI 3102 BT EurotestXE Ang PDFDejanTomasevicNo ratings yet

- Design Considerations For Diaphragm Pressure TransducersDocument6 pagesDesign Considerations For Diaphragm Pressure Transducerstoan04No ratings yet

- CYCLE-2:Experiment 1 Steady-State Performance of A 3-Phase Induction MotorDocument32 pagesCYCLE-2:Experiment 1 Steady-State Performance of A 3-Phase Induction MotorSumit SinghNo ratings yet

- Vibration Characteristics of Hard Disk Drives With Different Internal Air PressuresDocument2 pagesVibration Characteristics of Hard Disk Drives With Different Internal Air PressuresE-533 Kangane machhidranath subhashNo ratings yet

- 1.08 PistonesDocument15 pages1.08 PistonesJaderNo ratings yet

- SM Triaxial Compression Test 1983 PDFDocument6 pagesSM Triaxial Compression Test 1983 PDFNicolás SilvaNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- (Rpo, 2) in The CaseDocument1 page(Rpo, 2) in The CaseSvapneshNo ratings yet

- Is 1608 - 2005 - 36Document1 pageIs 1608 - 2005 - 36SvapneshNo ratings yet

- Is 1608 - 2005 - 39Document1 pageIs 1608 - 2005 - 39SvapneshNo ratings yet

- Table K.1 - Results From Interlaboratory Tensile Tests: Test Programme ADocument1 pageTable K.1 - Results From Interlaboratory Tensile Tests: Test Programme ASvapneshNo ratings yet

- J.2.3 Total Measurement Uncertainty: IS 1608: 2005 ISO 6892: 1998Document1 pageJ.2.3 Total Measurement Uncertainty: IS 1608: 2005 ISO 6892: 1998SvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: Width Original Gauge Lengtn Original Cross - Sec - Ronal Area Thickness MMDocument1 pageIS 1608: 2005 ISO 6892: 1998: Width Original Gauge Lengtn Original Cross - Sec - Ronal Area Thickness MMSvapnesh100% (1)

- IS 1608: 2005 ISO 6892: 1998: 2,5 D From The GripDocument1 pageIS 1608: 2005 ISO 6892: 1998: 2,5 D From The GripSvapneshNo ratings yet

- ISO 6892: 1998 Annex K: Related To Material. TestDocument1 pageISO 6892: 1998 Annex K: Related To Material. TestSvapneshNo ratings yet

- J2 J2 J2 J4 J2: Parameter Tensile PropertiesDocument1 pageJ2 J2 J2 J4 J2: Parameter Tensile PropertiesSvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: C.2.3Original Gauge Length C.2.3.1 Proportional Test PiecesDocument1 pageIS 1608: 2005 ISO 6892: 1998: C.2.3Original Gauge Length C.2.3.1 Proportional Test PiecesSvapneshNo ratings yet

- Is 1608 - 2005 - 30Document1 pageIs 1608 - 2005 - 30SvapneshNo ratings yet

- Is 1608 - 2005 - 27Document1 pageIs 1608 - 2005 - 27SvapneshNo ratings yet

- Is 1608 - 2005 - 25Document1 pageIs 1608 - 2005 - 25SvapneshNo ratings yet

- (Ijo) N: Is 1608: 2005 Iso 6892: 1998Document1 page(Ijo) N: Is 1608: 2005 Iso 6892: 1998SvapneshNo ratings yet

- Is 1608 - 2005 - 24Document1 pageIs 1608 - 2005 - 24SvapneshNo ratings yet

- Is 1608 - 2005 - 29Document1 pageIs 1608 - 2005 - 29SvapneshNo ratings yet

- Is 1608 - 2005 - 31Document1 pageIs 1608 - 2005 - 31SvapneshNo ratings yet

- Annex 0: D, and Its Shape Shall Be Such That It Does Not Interfere With The Gauge LengthDocument1 pageAnnex 0: D, and Its Shape Shall Be Such That It Does Not Interfere With The Gauge LengthSvapneshNo ratings yet

- Is 1608 - 2005 - 15Document1 pageIs 1608 - 2005 - 15SvapneshNo ratings yet

- Is 1608 - 2005 - 23Document1 pageIs 1608 - 2005 - 23SvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: Figure 3 - Proof Strength, Non-Proportional ExtensionDocument1 pageIS 1608: 2005 ISO 6892: 1998: Figure 3 - Proof Strength, Non-Proportional ExtensionSvapneshNo ratings yet

- Figure 9 - Machined Test Pieces of Rectangular Cross SectionDocument1 pageFigure 9 - Machined Test Pieces of Rectangular Cross SectionSvapneshNo ratings yet

- MM MM: A.2 Dimensions of The TestDocument1 pageMM MM: A.2 Dimensions of The TestSvapneshNo ratings yet

- Is 1608 - 2005 - 18Document1 pageIs 1608 - 2005 - 18SvapneshNo ratings yet

- 11 Determination of Percentage Elongation After FractureDocument1 page11 Determination of Percentage Elongation After FractureSvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: III IIIDocument1 pageIS 1608: 2005 ISO 6892: 1998: III IIISvapneshNo ratings yet

- Is 1608 - 2005 - 14Document1 pageIs 1608 - 2005 - 14SvapneshNo ratings yet

- Is 1608 - 2005 - 10Document1 pageIs 1608 - 2005 - 10SvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 998 11.4 in Order in May Described inDocument1 pageIS 1608: 2005 ISO 6892: 998 11.4 in Order in May Described inSvapneshNo ratings yet

- Is 1608 - 2005 - 11Document1 pageIs 1608 - 2005 - 11SvapneshNo ratings yet

- Lec-12 - Distillation of Non-Ideal SystemDocument28 pagesLec-12 - Distillation of Non-Ideal SystemsamrahamidNo ratings yet

- HV 600 PDFDocument1 pageHV 600 PDFamitNo ratings yet

- CFD Study of Fluid Flow and Temperature DistributiDocument5 pagesCFD Study of Fluid Flow and Temperature DistributiДенис ЛяпуновNo ratings yet

- Crude Oil - 2Document9 pagesCrude Oil - 2husseinNo ratings yet

- Check ValvesDocument12 pagesCheck ValvesddphilosophyNo ratings yet

- BROAERO - Aerolon Brochure PDFDocument20 pagesBROAERO - Aerolon Brochure PDFNikhil MohanNo ratings yet

- Grupo Alvica: Control ValveDocument7 pagesGrupo Alvica: Control ValveHernan YanezNo ratings yet

- PVM - Cast Iron PVMX - 316 Stainless Steel: Vertical Multistage Pumps 60 HertzDocument36 pagesPVM - Cast Iron PVMX - 316 Stainless Steel: Vertical Multistage Pumps 60 Hertzcarlos yepezNo ratings yet

- Appendices A) WWTP HanovilleDocument7 pagesAppendices A) WWTP HanovilleAHMEDNo ratings yet

- 5706.westergaard Added Mass (PLAXIS V20Update1) PDFDocument9 pages5706.westergaard Added Mass (PLAXIS V20Update1) PDFmumarbsc7244No ratings yet

- Gi v4 n3Document14 pagesGi v4 n3juanva_123No ratings yet

- Bell e Mehta 1989Document4 pagesBell e Mehta 1989Nelson LondoñoNo ratings yet

- Festo CataloogDocument220 pagesFesto CataloogLuc SchramNo ratings yet

- HEC Liquid Polymer: Product StabilityDocument2 pagesHEC Liquid Polymer: Product Stabilitysatish78038No ratings yet

- Product Catalog De: Catalogue ProduseDocument16 pagesProduct Catalog De: Catalogue ProduseGioni FlorinNo ratings yet

- 1.6 Surface Tension and Capillarity - CE 309-CE22S2 - Fluid MechanicsDocument4 pages1.6 Surface Tension and Capillarity - CE 309-CE22S2 - Fluid MechanicsRusselNo ratings yet

- Class 12 Chapter 4 Chemical KineticsDocument51 pagesClass 12 Chapter 4 Chemical Kineticskopal94135No ratings yet

- Effect of Free SilicaDocument2 pagesEffect of Free Silicamahendra senNo ratings yet

- CAT 3800 HYD UK Series 6600 Fittings Catalogue EnglishDocument2 pagesCAT 3800 HYD UK Series 6600 Fittings Catalogue EnglishJUANPANIAGUANo ratings yet

- Manual de Instalacion, Operacion y Mantenimiento de Bomba Gorman Rupp Serie vg3c3Document30 pagesManual de Instalacion, Operacion y Mantenimiento de Bomba Gorman Rupp Serie vg3c3muahdib100% (1)

- Peripheral Pump: Your Search TermDocument2 pagesPeripheral Pump: Your Search TermJalil Satria WNo ratings yet