Professional Documents

Culture Documents

10-67-02 Field Welding Fusion & Fin Welded Walls

Uploaded by

JKK0 ratings0% found this document useful (0 votes)

11 views3 pagesOriginal Title

10-67-02 Field Welding Fusion & Fin Welded walls

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views3 pages10-67-02 Field Welding Fusion & Fin Welded Walls

Uploaded by

JKKCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

THIS STANDARD IS: STD NO : 10-67-02

Updated INDEX : 9.6.4

DESIGN STANDARD DATE : 20 JUNE 2001

OWNER : 9810

PAGE : 1 OF 3

SUBJECT : FIELD WELDING – FUSION AND FIN WELDED WALLS

PURPOSE : To provide Design Graphics with the information required to select

the applicable field welding procedure specifications for the various

tube wall materials.

REMARKS : This Standard to be effective immediately.

NOTES: 1. See Page 2 for Versions.

2. Changes to the text are indicated by vertical bars.

SR. ENGINEERING TECHNICIAN

PREPARED BY: S. GARCIA STANDARDS ENGINEERING – 8126

MANAGER

APPROVED FOR CONTENT: W. RICE PRESSURE PART ENGINEERING - 9810

PROGRAM MANAGER

APPROVED FOR PUBLICATION: T. MISKELL STANDARDS ENGINEERING - 8126

This document contains proprietary data and shall

not be reproduced or disclosed without permission of ALSTOM Power Inc.

SUBJECT: Field Welding – Fusion STD. NO. : 10-67-02

and Fin Welded Walls INDEX : 9.6.4

DATE : 20 JUNE 2001

OWNER : 9810

PAGE : 2 of 3

_____________________________________________________________________________________________________

UNITS: n ENGLISH; o METRIC; o BOTH; o NONE

PRODUCT LINES: CHECK THE PRODUCT LINES THAT THE STANDARD IS APPLICABLE TO

n ALL; o A = CONTROLLED CIRC. BOILERS o H = HEAT RECOVERY STEAM GENERATORS

o B = SUPERCRITICAL BOILERS o P = BOWL MILLS (PULVERIZERS)

o C = VU40 AND VU60 BOILERS o R = CHEMICAL RECOVERY BOILERS

o E = FLUIDIZED BED BOILERS (CFB) o S = SERVICES (AFTER MARKET USE)

o F = NATURAL CIRC. BOILERS (UTILITY)

Versions

Ver. 1 – Revised to show Construction Services

new field welding procedure specifications

covering fusion and welded wall construction.

Field Welding Procedures SP8A and SP8B are

now obsolete.

Ver. 2 – Updated Standard format; name

change to ALSTOM Power Inc.; revised

Paragraph 4.0.

SUBJECT: Field Welding – Fusion STD. NO. : 10-67-02

and Fin Welded Walls INDEX : 9.6.4

DATE : 20 JUNE 2001

OWNER : 9810

PAGE : 3 of 3

_____________________________________________________________________________________________________

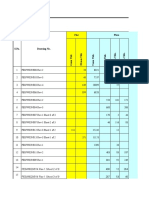

1.0 Scope 2.0 Selection of Field Welding Procedure

Specification

This standard will provide Design Graphics

with the information required to cover the field The Field Welding Procedure Specification

welding requirements on fusion and fin welded shall be selected from Table A based on the tube

walls, including butt welds, panel edge bar wall material. *

welding, erection slots, web gaps, etc.

Table A

Tube Wall Material *

Field Welding Procedure

Nominal Composition P-No. Group Specification Specification to be

Shown on the Drawings

Carbon Steel P-1 SA-192, 210 and 178 SMA-1.1Y-303

Carbon Moly P-3 SA-209 T1 SMA-3.3Z-300

1.00 Cr-0.5 Mo P-4 SA-213 T11, T12 SMA-4.4Z-302

1.25 Cr-0.5 Mo

2.25 Cr-1.0 Mo P-5 SA-213 T22 SMA-5.5Z-302

* Field Welding Procedure Specification only applies when tube material and fin material have the same

nominal composition and P-No. Contact Engineering for Field Welding Procedure when fin material and

tube material have different nominal composition and P-Nos.

3.0 Drawing Note Required 4.0 Compliance of Field Welding

Procedure Specifications

Fusion or fin welded panel drawings

requiring field welding shall have a note added ô The above field welding procedure

indicating the applicable Field Welding Procedure specifications are in compliance with both the

Specification. The note should read as follows: ASME Code, Section I and Company Standards

for fusion and field welded wall construction.

“All field welding of the tube panels Therefore, no changes should be made to these

shall be in accordance with ALSTOM field welding procedure specifications without

Power Inc. Field Welding Procedure Engineering approval.

Specification _____________. For

the information contained in this

document, contact ALSTOM Power

Inc. Erection Representative.”

You might also like

- BSBSUS511 Project PortfolioDocument33 pagesBSBSUS511 Project PortfolioHira Raza33% (6)

- SESB Certified ContractorsDocument10 pagesSESB Certified Contractorsarvind raj100% (1)

- I150 Peristaltic Pump Operating ManualDocument20 pagesI150 Peristaltic Pump Operating ManualPunit PurshotamNo ratings yet

- Saes J 002Document31 pagesSaes J 002madinah123100% (1)

- 13-61-16 Field Welding Data Sheets & Location DrgsDocument17 pages13-61-16 Field Welding Data Sheets & Location DrgsJKKNo ratings yet

- 238-76-04 Pulverised Fuel Piping WeldsDocument3 pages238-76-04 Pulverised Fuel Piping WeldsJKKNo ratings yet

- 58-75-02 Field Welding Accessibility For Header Butt Weld JointDocument3 pages58-75-02 Field Welding Accessibility For Header Butt Weld JointJKKNo ratings yet

- 50-83-02 Spec. For Arc & Capacitor Discharge Weldingt of Pr. & Non-Pr. PartsDocument6 pages50-83-02 Spec. For Arc & Capacitor Discharge Weldingt of Pr. & Non-Pr. PartsJKKNo ratings yet

- 234-76-11 Longitudinal & Circumferencial Weld Joints & Seams For Pipes, Drums& VesselsDocument3 pages234-76-11 Longitudinal & Circumferencial Weld Joints & Seams For Pipes, Drums& VesselsJKKNo ratings yet

- 16-77-03 Field Welding of Fusion Welded PanelsDocument3 pages16-77-03 Field Welding of Fusion Welded PanelsJKKNo ratings yet

- 53-75-09 Butt Welded Joints Details & AssemblyDocument3 pages53-75-09 Butt Welded Joints Details & AssemblyJKKNo ratings yet

- 235-76-02 Det. & Assembly For Disk Type Orifice & Butt Welded Tube JointsDocument3 pages235-76-02 Det. & Assembly For Disk Type Orifice & Butt Welded Tube JointsJKKNo ratings yet

- 8-65-19 ''Pulsed Arc '' MIG Welding Stright Tubes in ChattanoogaDocument9 pages8-65-19 ''Pulsed Arc '' MIG Welding Stright Tubes in ChattanoogaJKKNo ratings yet

- 236-76-12 Welding Jiont Selections For Pipes & TubesDocument7 pages236-76-12 Welding Jiont Selections For Pipes & TubesJKKNo ratings yet

- Metal TempDocument101 pagesMetal TempJKKNo ratings yet

- Engineering Specification for Ceramic Fiber Blanket InsulationDocument5 pagesEngineering Specification for Ceramic Fiber Blanket InsulationlightsonsNo ratings yet

- 8 95 01 Weld Procedure Spec ChattanoogaDocument40 pages8 95 01 Weld Procedure Spec ChattanoogaJKKNo ratings yet

- Az - Zour R&M Furnace Dimensions - ADocument1 pageAz - Zour R&M Furnace Dimensions - AShameer MajeedNo ratings yet

- 3-77-06 Field Weld Ends Pumps& Valves Conrolled Circulation & CC UnitsDocument10 pages3-77-06 Field Weld Ends Pumps& Valves Conrolled Circulation & CC UnitsJKKNo ratings yet

- 18-70-05 Fillets Welds Allowable LoadsDocument6 pages18-70-05 Fillets Welds Allowable LoadsJKKNo ratings yet

- 2-1 Tech Spec Ashuganj R0Document181 pages2-1 Tech Spec Ashuganj R0Anup Mitra100% (1)

- Furnace 01490Document83 pagesFurnace 01490JKKNo ratings yet

- Turbine ModelsDocument4 pagesTurbine Modelsstupid143No ratings yet

- Fluidised 20bed 20combustion 20boilersDocument146 pagesFluidised 20bed 20combustion 20boilersjkhan_724384No ratings yet

- 01 - Cust - TRNG - Dec PDFDocument52 pages01 - Cust - TRNG - Dec PDFLakshmi NarayanNo ratings yet

- Modernization and Life ExtansionDocument67 pagesModernization and Life ExtansionDangolNo ratings yet

- Checklist - Stress AnalysisDocument2 pagesChecklist - Stress AnalysisRamalingam PrabhakaranNo ratings yet

- Air BlowersDocument4 pagesAir Blowersjkhan_724384No ratings yet

- 3 System Process Outline - SLP R2Document56 pages3 System Process Outline - SLP R2Pirun SirimangkaloNo ratings yet

- Method Statement For ACC BHELDocument7 pagesMethod Statement For ACC BHELHsebepl NkNo ratings yet

- 2X500 MW Neyveli New Thermal Power Project (NNTPP) Neyveli, Tamilnadu, IndiaDocument28 pages2X500 MW Neyveli New Thermal Power Project (NNTPP) Neyveli, Tamilnadu, IndiaHiltonNo ratings yet

- T219AB-384A9554 Rev E Deaerating Condenser Functional SpecificationDocument6 pagesT219AB-384A9554 Rev E Deaerating Condenser Functional SpecificationvankayalasuryaNo ratings yet

- SCR AlstomDocument6 pagesSCR Alstomcristi_molinsNo ratings yet

- AIr Heater CompareDocument15 pagesAIr Heater CompareRamalingam PrabhakaranNo ratings yet

- Session - 1 - A. - Tatsuo - Kondo - Steam TurbineDocument43 pagesSession - 1 - A. - Tatsuo - Kondo - Steam Turbinebagusahap3giNo ratings yet

- Technical Report: Subject / Title: Reference Place Date Author(s) Period of Time: Content Approved ReleasedDocument28 pagesTechnical Report: Subject / Title: Reference Place Date Author(s) Period of Time: Content Approved ReleasedMayurNo ratings yet

- Supercritical Boiler Cleanup Cycle: Ranjan KumarDocument23 pagesSupercritical Boiler Cleanup Cycle: Ranjan Kumarscentpcbarauni BARAUNINo ratings yet

- GT Bearings Six SigmaDocument12 pagesGT Bearings Six SigmaJJNo ratings yet

- ATT01 UTR01MEK - F21DM001 A Functional DescriptionDocument23 pagesATT01 UTR01MEK - F21DM001 A Functional DescriptionSUNILNo ratings yet

- 14 ACC Air Side PerformanceDocument24 pages14 ACC Air Side PerformanceShivakumarNo ratings yet

- Development of Steam DrumDocument8 pagesDevelopment of Steam DrumRaja SellappanNo ratings yet

- Surface Condenser - Parts List - : en HTGD 800 104 V0009 Total Pages: 16Document16 pagesSurface Condenser - Parts List - : en HTGD 800 104 V0009 Total Pages: 16tuynvNo ratings yet

- Basics of Boiler DesignDocument92 pagesBasics of Boiler DesignJitender SinghNo ratings yet

- Report on blade failure of LP last stages in a 210 MW steam turbineDocument5 pagesReport on blade failure of LP last stages in a 210 MW steam turbinemanojpuru100% (1)

- Kawasaki's Presentation on FGD and SCR SystemsDocument20 pagesKawasaki's Presentation on FGD and SCR Systemsjitendrashukla10836No ratings yet

- Evaporation Principles and Black Liquor Properties: David T. Clay, PH.DDocument6 pagesEvaporation Principles and Black Liquor Properties: David T. Clay, PH.DJKKNo ratings yet

- SEC A Bekasi Design SpecDocument20 pagesSEC A Bekasi Design Speccharleselitb92No ratings yet

- Critical PipingDocument49 pagesCritical PipingChakravarthi NagaNo ratings yet

- B&W Overfire AirDocument4 pagesB&W Overfire AirJose Lorenzo ToralNo ratings yet

- Kei-Rsos Maritime Limited MachineryDocument28 pagesKei-Rsos Maritime Limited MachineryTabitha MorinNo ratings yet

- 5of5mm 1Document119 pages5of5mm 1SamuelTrinandoNo ratings yet

- LPPJFF RL - Envi - 2013 04 04Document10 pagesLPPJFF RL - Envi - 2013 04 04Petros IosifidisNo ratings yet

- DBR Mechanical REV02Document34 pagesDBR Mechanical REV02abdellah faqdaniNo ratings yet

- Report Vibrasi Plant CP-2Document13 pagesReport Vibrasi Plant CP-2hafiz_hayat_44190215No ratings yet

- CCGT Cycle Selection CriteriaDocument29 pagesCCGT Cycle Selection CriteriapsmajuNo ratings yet

- This Document Contains Proprietary Data and Shall Not Be Reproduced or Disclosed Without The Permission of ALSTOM Power IncDocument3 pagesThis Document Contains Proprietary Data and Shall Not Be Reproduced or Disclosed Without The Permission of ALSTOM Power IncJKKNo ratings yet

- 9e ChinaDocument7 pages9e Chinanabil160874No ratings yet

- 1982 - Korner - Design Features of Steam PDFDocument6 pages1982 - Korner - Design Features of Steam PDFramakantinamdarNo ratings yet

- 0260-101-01-TR-PVM-U-020-03 Sizing Calculation of FurnaceDocument9 pages0260-101-01-TR-PVM-U-020-03 Sizing Calculation of Furnaceanil peralaNo ratings yet

- Insul & RefractoryDocument8 pagesInsul & RefractoryJKK0% (1)

- 306 Final PaperDocument14 pages306 Final PaperThanapaet RittirutNo ratings yet

- LP Turbine Exhaust Loss CurveDocument1 pageLP Turbine Exhaust Loss CurveShameer MajeedNo ratings yet

- Guide To Furnace SootblowingDocument40 pagesGuide To Furnace SootblowingnarayananaliveNo ratings yet

- Socket Welding Details for Steel FittingsDocument3 pagesSocket Welding Details for Steel FittingsJKKNo ratings yet

- Mechanical Turbine: Customer: Project: Project No: 1106Document6 pagesMechanical Turbine: Customer: Project: Project No: 1106JKKNo ratings yet

- Differential Pressure Transmitter (Smart)Document6 pagesDifferential Pressure Transmitter (Smart)JKKNo ratings yet

- Data Sheet Level Gauge: GeneralDocument5 pagesData Sheet Level Gauge: GeneralJKKNo ratings yet

- Level Gauge Data SheetDocument4 pagesLevel Gauge Data SheetJKKNo ratings yet

- COMPARISONDocument6 pagesCOMPARISONJKKNo ratings yet

- CPGCPL HP - LPDOSING Spec.Document18 pagesCPGCPL HP - LPDOSING Spec.JKKNo ratings yet

- BC01C1-Soot Blower Spec - R0Document6 pagesBC01C1-Soot Blower Spec - R0JKKNo ratings yet

- Safety Valves (Drum & SH) - Form 8Document1 pageSafety Valves (Drum & SH) - Form 8JKKNo ratings yet

- Differential Pressure SwitchDocument3 pagesDifferential Pressure SwitchJKKNo ratings yet

- Analysis of Washery RejectsDocument3 pagesAnalysis of Washery RejectsJKKNo ratings yet

- Enmas GB Power Systems Projects Limited: Sub Delivery IndentDocument1 pageEnmas GB Power Systems Projects Limited: Sub Delivery IndentJKKNo ratings yet

- 1 Dolochar Including Char Lump Sample and Char Fines Sample: E C C CDocument5 pages1 Dolochar Including Char Lump Sample and Char Fines Sample: E C C CJKKNo ratings yet

- Sks Ispath Metallic Expansion Bellows Specifications - (Additional)Document1 pageSks Ispath Metallic Expansion Bellows Specifications - (Additional)JKKNo ratings yet

- 415V LT Motors Technical SpecificationDocument13 pages415V LT Motors Technical SpecificationJKKNo ratings yet

- Sks Ispath Metallic Expansion Bellows Specifications - (Additional)Document1 pageSks Ispath Metallic Expansion Bellows Specifications - (Additional)JKKNo ratings yet

- Flat Plate: Sks - Ispat LTD - Ducting and Support MaterialsDocument5 pagesFlat Plate: Sks - Ispat LTD - Ducting and Support MaterialsJKKNo ratings yet

- Technical Specification for Loop Seal BlowersDocument5 pagesTechnical Specification for Loop Seal BlowersJKKNo ratings yet

- Project: 1 X 80 TPH CFBC Boiler Client: M/S. Nova Iron & Steel Title: Technical Data Sheet For Actuator SL No Description Unit Data Vendor To FillDocument1 pageProject: 1 X 80 TPH CFBC Boiler Client: M/S. Nova Iron & Steel Title: Technical Data Sheet For Actuator SL No Description Unit Data Vendor To FillJKKNo ratings yet

- SKS ISPAT LTD MATERIAL TAKEOFF AND SPECIFICATIONSDocument8 pagesSKS ISPAT LTD MATERIAL TAKEOFF AND SPECIFICATIONSJKKNo ratings yet

- CFBF315230004 00Document1 pageCFBF315230004 00JKKNo ratings yet

- Duct Drawing Weight SummaryDocument8 pagesDuct Drawing Weight SummaryJKKNo ratings yet

- Header&pipe Sizes - 00361Document9 pagesHeader&pipe Sizes - 00361JKKNo ratings yet

- 415V LT Motors Technical SpecificationDocument13 pages415V LT Motors Technical SpecificationJKKNo ratings yet

- Tilting Tangential Firing System SelectionDocument78 pagesTilting Tangential Firing System SelectionJKKNo ratings yet

- Metal Temperatures Program User Manual and Validation SheetDocument94 pagesMetal Temperatures Program User Manual and Validation SheetJKKNo ratings yet

- Enmas GB Power Systems Projects Limited: Sub Delivery IndentDocument1 pageEnmas GB Power Systems Projects Limited: Sub Delivery IndentJKKNo ratings yet

- 415V LT Motors Technical SpecificationDocument13 pages415V LT Motors Technical SpecificationJKKNo ratings yet

- Ignitor & Scanner Air ControlDocument5 pagesIgnitor & Scanner Air ControlJKKNo ratings yet

- This Document Contains Proprietary Data and Shall Not Be Reproduced or Disclosed Without The Permission of ALSTOM Power IncDocument10 pagesThis Document Contains Proprietary Data and Shall Not Be Reproduced or Disclosed Without The Permission of ALSTOM Power IncJKKNo ratings yet

- Metal TempDocument101 pagesMetal TempJKKNo ratings yet

- 1015p Io BoardDocument13 pages1015p Io BoardContreras CarlosNo ratings yet

- 04 PPT Mine Fan General PresentationDocument52 pages04 PPT Mine Fan General PresentationHeri WibowoNo ratings yet

- Fluid Mechanics Assignment-5 (Momentum Conservation) : Aditya BandopadhyayDocument9 pagesFluid Mechanics Assignment-5 (Momentum Conservation) : Aditya BandopadhyayGunda Venkata SaiNo ratings yet

- DESIGN QUALIFICATION FOR PURIFIED WATER STORAGE & DISTRIBUTION SYSTEM - Pharmaceutical GuidanceDocument30 pagesDESIGN QUALIFICATION FOR PURIFIED WATER STORAGE & DISTRIBUTION SYSTEM - Pharmaceutical GuidanceMohamad IsmailNo ratings yet

- VW Passat B5 Secondary Air Injection, Engine Aug AwmDocument14 pagesVW Passat B5 Secondary Air Injection, Engine Aug AwmNPNo ratings yet

- Energy Conversion and Management: Daniel Chemisana, Joan Ignasi RosellDocument8 pagesEnergy Conversion and Management: Daniel Chemisana, Joan Ignasi RosellElie ZorbaNo ratings yet

- Adafruit Mics5524 Gas Sensor BreakoutDocument12 pagesAdafruit Mics5524 Gas Sensor BreakoutWerliock MorlorumNo ratings yet

- Chapter 8 Internal Forced ConvectionDocument26 pagesChapter 8 Internal Forced ConvectionDazuky UkyNo ratings yet

- Revised Fee-From 2019 AprilDocument13 pagesRevised Fee-From 2019 AprildeepusvvpNo ratings yet

- Wolfson Eup3 Ch34 Test BankDocument17 pagesWolfson Eup3 Ch34 Test BankifghelpdeskNo ratings yet

- MFL67477506 - English + HindiDocument38 pagesMFL67477506 - English + HindiFarhanNo ratings yet

- Drilling horizontal wells with electric downhole motorsDocument10 pagesDrilling horizontal wells with electric downhole motorsGregory DemerjiNo ratings yet

- Success Story CJPP BatangDocument2 pagesSuccess Story CJPP BatangQurratA.AbuAyubNo ratings yet

- GrabowskiPietrykowskiWendeker AVLSimulationToolsDocument96 pagesGrabowskiPietrykowskiWendeker AVLSimulationToolsCao Đào Nam K.CKNo ratings yet

- Core of Yoga: EnglishDocument39 pagesCore of Yoga: EnglishVivekananda KendraNo ratings yet

- SPC-0804.02-20.04 Rev D2 General Welding and NDE Requirements For Pressure VesselDocument15 pagesSPC-0804.02-20.04 Rev D2 General Welding and NDE Requirements For Pressure VesselPadmanabhan VenkateshNo ratings yet

- INSULATIONDocument33 pagesINSULATIONsudeesh kumarNo ratings yet

- TE50 Service ManualDocument133 pagesTE50 Service ManualJeferson SilvaNo ratings yet

- Energy Systems Explained for PE & HealthDocument14 pagesEnergy Systems Explained for PE & HealthLuzielEstradaEscalonaNo ratings yet

- PXF5 PXF9 ManualDocument24 pagesPXF5 PXF9 ManualGabriel LukodaNo ratings yet

- Catalogo SA Ingles AUMADocument32 pagesCatalogo SA Ingles AUMAEsteban Martinez I.No ratings yet

- IEE Harmonized Colours PDFDocument4 pagesIEE Harmonized Colours PDFCaspar HeerkensNo ratings yet

- Project Cost AnalysisDocument1 pageProject Cost AnalysisSamuel ArelianoNo ratings yet

- Mechanism of Bioenergy HealingDocument11 pagesMechanism of Bioenergy HealingHayley As Allegedly-Called YendellNo ratings yet

- Asco Froment 6000 Series Combined Manual PDFDocument114 pagesAsco Froment 6000 Series Combined Manual PDFEdward OsoreNo ratings yet

- Tabela LubrimotorsDocument1 pageTabela LubrimotorsjaburecaNo ratings yet