Professional Documents

Culture Documents

Practical Project V A R S

Uploaded by

Nachiket Patil0 ratings0% found this document useful (0 votes)

25 views4 pagesOriginal Title

practical project V A R S

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views4 pagesPractical Project V A R S

Uploaded by

Nachiket PatilCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 4

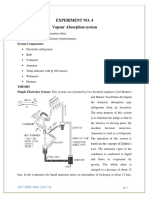

AIM:

TO DETERMINE THE COEFFICIENT OF PERFORMANCE OF DOMESTIC ELECTROLUX REFRIGERATOR.

SPECIFICATION:

REFRIGERATOR:- 41 LTR. HUNGARY MAKE ELECTROLUX REFRIGERATOR

THREE FLUID SYSTEM

1. AMMONIA (NH 3)

2. WATER (H2O)

3. HYDROGEN – (H2)

o HEATING – EXTERNALLY HEATED BY ELECTRIC RESISTANCE.

o EVAPORATOR – COIL TYPE EVAPORATOR

o VOLTAGE INPUT – 65 WATTS.

o ELECTRICAL CONSUMPTION – 0.8 KWH / 24 HOURS.

o ELECTRICAL VOLTAGE – SINGLE PHASE 220 VOLTS AC 50 HZ.

o DEFROST – AUTO DEFROST WITH FUZZY LOGIC SYSTEM.

CONTROLS PANEL BOARD: - CONSISTS OF FOLLOWING METERS.

1. DIGITAL VOLTMETER

2. DIGITAL AMMETER

3. DIGITAL TEMP. INDICATOR (PT – 100).

4. MAIN SWITCHES 32 AMP.

THEORY:

THE VAPOUR ABSORPTION REFRIGERATION SYSTEM IS ONE OF THE OLDEST METHOD

OF PRODUCING REFRIGERATING EFFECT. THE PRINCIPLE OF VAPOUR ABSORPTION WAS

FIRST DISCOVERED BY MICHAEL FARADAY IN 1824 WHILE PERFORMING A SET OF

EXPERIMENTS TO LIQUEFY CERTAIN GASES. A FRENCH SCIENTIST FERDINAND CARRE

DEVELOPED THE FIRST VAPOUR ABSORPTION REFRIGERATION MACHINE IN 1860. THIS

SYSTEM MAY BE USED IN BOTH THE DOMESTIC AND LARGE INDUSTRIAL

REFRIGERATING PLANTS. THE REFRIGERANT, COMMONLY USED IN A VAPOUR

ABSORPTION SYSTEM, IS AMMONIA.

THE VAPOUR ABSORPTION SYSTEM USES HEAT ENERGY, INSTEAD OF MECHANICAL

ENERGY AS IN VAPOUR COMPRESSION SYSTEMS, IN ORDER TO CHANGE THE

CONDITIONS OF THE REFRIGERANT REQUIRED FOR THE OPERATION OF THE

REFRIGERATION CYCLE.

IN THE VAPOUR ABSORPTION SYSTEM, AN ABSORBER, A PUMP, A GENERATOR AND A

PRESSURE-REDUCING VALVE REPLACE THE COMPRESSOR. THESE COMPONENTS IN

VAPOUR ABSORPTION SYSTEM PERFORM THE SAME FUNCTION AS THAT OF A

COMPRESSOR IN VAPOUR COMPRESSION SYSTEM. IN THIS SYSTEM, THE VAPOUR

REFRIGERANT FROM THE EVAPORATOR IS DRAWN INTO AN ABSORBER WHERE IT IS

ABSORBED BY THE WEEK SOLUTION OF THE REFRIGERANT FORMING A STRONG

SOLUTION. THIS STRONG

SOLUTION IS PUMPED TO THE GENERATOR WHERE IT IS HEATED BY SOME EXTERNAL

SOURCE. DURING THE HEATING PROCESS, THE VAPOUR REFRIGERANT IS DRIVEN OFF

BY THE SOLUTION AND ENTERS INTO THE CONDENSER WHERE IT IS LIQUEFIED. THE

LIQUID REFRIGERANT THEN FLOWS INTO THE EVAPORATOR AND THUS THE CYCLE IS

COMPLETED.

WORKING:

THE DOMESTIC ABSORPTION TYPE REFRIGERATOR WAS INVENTED BY TWO SWEDISH

ENGINEERS CARL MUNTERS AND BALTZER VAN PLATAN IN 1925WHILE THEY WERE

STUDYING FOR THEIR UNDER-GRADUATE COURSE OF ROYAL INSTITUTE OF

TECHNOLOGY IN STOCKHOLM. THE IDEA WAS FIRST DEVELOPED BY THE ‘ELECTROLUX

COMPANY’ OF LUTON, ENGLAND.

THIS TYPE OF REFRIGERATOR IS ALSO CALLED THREE- FLUIDS ABSORPTION SYSTEM.

THE MAIN PURPOSE OF THIS SYSTEM IS TO ELIMINATE THE PUMP SO THAT IN THE

ABSENCE OF MOVING PARTS, THE MACHINE BECOMES NOISE-LESS. THE THREE FLUIDS

USED IN THIS SYSTEM ARE AMMONIA, HYDROGEN AND WATER.

THE AMMONIA IS USED AS A REFRIGERANT BECAUSE IT POSSESSES MOST OF THE

DESIRABLE PROPERTIES. IT IS TOXIC, BUT DUE TO ABSENCE OF MOVING PARTS,

THERE ARE VERY LITTLE CHANGES FOR THE LEAKAGE AND THE TOTAL AMOUNT

OF REFRIGERATION USED IS SMALL.

THE HYDROGEN BEING THE LIGHTEST GAS IS USED TO INCREASE THE RATE OF

EVAPORATION OF THE LIQUID AMMONIA PASSING THROUGH THE EVAPORATOR.

THE HYDROGEN IS ALSO NON-CORROSIVE AND INSOLUBLE IN WATER. THIS IS

USED IN THE LOW-PRESSURE SIDE OF THE SYSTEM.

THE WATER IS USED AS A SOLVENT BECAUSE IT HAS THE ABILITY TO ABSORB

AMMONIA READILY.

THE STRONG AMMONIA SOLUTION FROM THE ABSORBER THROUGH HEAT EXCHANGER

IS HEATED IN THE GENERATOR BY APPLYING HEAT FROM AN EXTERNAL SOURCE

USUALLY A GAS BURNER. DURING THIS HEATING PROCESS, AMMONIA VAPOUR ARE

REMOVED FROM THE SOLUTION AND PASSED TO THE CONDENSER. A RECTIFIER OR A

WATER SEPARATOR FITTED BEFORE THE CONDENSER REMOVES WATER VAPOUR

CARRIED WITH THE AMMONIA VAPOUR, SO THAT DRY AMMONIA VAPOUR ARE

SUPPLIED TO

THE CONDENSER. THESE WATER VAPOUR, IF NOT REMOVED, THEY WILL ENTER INTO

THE EVAPORATOR CAUSING FREEZING AND CHOKING OF THE MACHINE. THE HOT WEAK

SOLUTION WHILE PASSING THROUGH THE EXCHANGER IS COOLED. THE HEAT REMOVED

BY THE WEAK SOLUTION IS UTILIZED IN RAISING THE TEMPERATURE OF STRONG

SOLUTION PASSING THROUGH THE HEAT EXCHANGER. IN THIS WAY, THE ABSORPTION

IS ACCELERATED AND THE IMPROVEMENT IN THE PERFORMANCE OF A PLANT IS

ACHIEVED.

THE AMMONIA VAPOUR IN THE CONDENSER IS CONDENSED BY USING EXTERNAL

COOLING SOURCE. THE LIQUID REFRIGERANT LEAVING THE CONDENSER FLOWS UNDER

GRAVITY TO THE EVAPORATOR WHERE IT MEETS THE HYDROGEN GAS. THE HYDROGEN

GAS WHICH IS BEING FED TO THE EVAPORATOR PERMITS THE LIQUID AMMONIA TO

EVAPORATE AT A LOW PRESSURE AND TEMPERATURE ACCORDING TO DALTON’S

PRINCIPAL. DURING THE PROCESS OF EVAPORATION, THE AMMONIA ABSORBS LATENT

HEAT FROM THE REFRIGERATED SPACE AND THUS PRODUCES COOLING EFFECT.

THE MIXTURE OF AMMONIA VAPOUR AND HYDROGEN IS PASSED TO THE ABSORBER

WHERE AMMONIA IS ABSORBED IN WATER WHILE THE HYDROGEN RISES TO THE TOP

AND FLOWS BACK TO THE EVAPORATOR.

THE MAIN DISADVANTAGE OF ELECTROLUX REFRIGERATOR IS:

IT CAN NOT BE USED FOR INDUSTRIAL PURPOSE AS THE COP OF THE SYSTEM IS

VERY LOW.

OBSERVATION:

T1 = EVAPORATOR TEMPERATURE = ______________ 0C = _____________ 0K

T2 = CONDENSER TEMPERATURE = ______________ 0C = _____________ 0K

T3 = GENERATOR TEMPERATURE = _______________ 0C = ____________ 0K

WHERE, T1 < T2 < T3

CO-EFFICIENT OF PERFORMANCE

T1 T3 – T2

C.O.P = ---------- X ----------

T2 – T1 T3

SCHEMATIC DIAGRAM OF VAPOUR ABSORPTION REFRIGERATION SYSTEM

You might also like

- Rac, Module 3-NoteDocument81 pagesRac, Module 3-NoteShan Mathews VettikuzhiyilNo ratings yet

- Expt No 4 Trial On Vapor Absorption SystemDocument6 pagesExpt No 4 Trial On Vapor Absorption Systemtimepass9580No ratings yet

- VarsDocument25 pagesVarsRuturaj UmaranikarNo ratings yet

- Ashutosh Final SeminarrrrrrrRDocument22 pagesAshutosh Final SeminarrrrrrrRmangeshNo ratings yet

- Unit IvDocument39 pagesUnit IvKalyan KalapalaNo ratings yet

- Refrigeration and Air-Conditioning: Unit - 3Document30 pagesRefrigeration and Air-Conditioning: Unit - 3SAATVIK JAINNo ratings yet

- Unit 2 RacDocument40 pagesUnit 2 Racozair arshadNo ratings yet

- Chapter 3 RACDocument26 pagesChapter 3 RACSameer AhmadNo ratings yet

- Vapour AbsorptionDocument15 pagesVapour AbsorptionSatheesh ChandranNo ratings yet

- Vapour Absorption Refrigeration Test RigDocument7 pagesVapour Absorption Refrigeration Test RigSwapnil DeyNo ratings yet

- Vapour Absorption Refrigeration SystemDocument26 pagesVapour Absorption Refrigeration SystemRushikesh Dandagwhal100% (8)

- Ijert: Design Analysis of 3 TR Aqua Ammoniavapour Absorption Refrigeration SystemDocument6 pagesIjert: Design Analysis of 3 TR Aqua Ammoniavapour Absorption Refrigeration SystemnandaNo ratings yet

- Study of Vapour Absorption RefrigeratorDocument5 pagesStudy of Vapour Absorption RefrigeratorMohdQasimNo ratings yet

- Non-Conventional Refrigeration SystemsDocument21 pagesNon-Conventional Refrigeration SystemsNishit ParmarNo ratings yet

- 2 To Study VASDocument5 pages2 To Study VASAnand GujaratiNo ratings yet

- Report On Vapor Absorption Refrigeration System: Ubmited by Sourav Mondal B. E. Power Engg. Jadavpur UniversityDocument14 pagesReport On Vapor Absorption Refrigeration System: Ubmited by Sourav Mondal B. E. Power Engg. Jadavpur UniversitysouravNo ratings yet

- Basic Civil and Mechanical Engineering Unit V Refrigeration and Airconditioning Support NotesDocument9 pagesBasic Civil and Mechanical Engineering Unit V Refrigeration and Airconditioning Support NotesA.R. Pradeep Kumar100% (1)

- Vapour Absorption SystemDocument5 pagesVapour Absorption Systemhwaj100% (1)

- Vapour Absorption RefrigerationDocument29 pagesVapour Absorption RefrigerationmuthuNo ratings yet

- 12 Chapter 03Document37 pages12 Chapter 03Eman El DsoukyNo ratings yet

- Vapour Absorption Refrigeration SystemDocument12 pagesVapour Absorption Refrigeration SystemHarshNo ratings yet

- What Is Vapour Absorption Refrigeration System Working of Vapour Absorption Refrigeration System Components in Vapour AbsorDocument1 pageWhat Is Vapour Absorption Refrigeration System Working of Vapour Absorption Refrigeration System Components in Vapour Absordhoom 760No ratings yet

- EVAPORATORDocument4 pagesEVAPORATORElizabeth De GalaNo ratings yet

- 3.4 Three Fluid RefDocument3 pages3.4 Three Fluid RefShaik mahammad ArifNo ratings yet

- Refrigeration and Air ConditioningDocument6 pagesRefrigeration and Air ConditioningIbrahim HossainNo ratings yet

- Fundamentals of RefrigerationDocument17 pagesFundamentals of RefrigerationReymond AbayonNo ratings yet

- Unit6 N 7Document46 pagesUnit6 N 7Shanku Raajashree100% (1)

- Cws Class GetDocument83 pagesCws Class GettclrajeevNo ratings yet

- UEE Unit 5 - GKDocument55 pagesUEE Unit 5 - GKRajvir Kaur SidhuNo ratings yet

- Solar Powered Vapour Absorption System: Presented By: Ravi Shankar Shivek Tiwari Shivam Singh Chauhan Vimal PandeyDocument23 pagesSolar Powered Vapour Absorption System: Presented By: Ravi Shankar Shivek Tiwari Shivam Singh Chauhan Vimal PandeyAnuj TripathiNo ratings yet

- Study and Performance Test On VARSDocument11 pagesStudy and Performance Test On VARSBhavit JainNo ratings yet

- Refrigeration & Air Conditioning: Arun Jose Tom, Rac, CcetDocument340 pagesRefrigeration & Air Conditioning: Arun Jose Tom, Rac, CcetRubin JosephNo ratings yet

- Presented By:: Shruti Ranjan Parida 1101348076 MechanicalDocument43 pagesPresented By:: Shruti Ranjan Parida 1101348076 MechanicalFarhan Ur RehmanNo ratings yet

- Lab 9Document5 pagesLab 9axe furyNo ratings yet

- Removal of Water From Industrial Ammonia SystemsDocument10 pagesRemoval of Water From Industrial Ammonia SystemsMTOLNo ratings yet

- Rac ExpDocument44 pagesRac ExpAkash Kumar DevNo ratings yet

- ProjectDocument13 pagesProjectSiva NarayanaNo ratings yet

- Indusss Final ShitsDocument19 pagesIndusss Final Shitsjolly antNo ratings yet

- Understanding Ammonia SystemsDocument8 pagesUnderstanding Ammonia Systemshatassa100% (1)

- Term Paper Review of Thermal Engg.: Topic:-Application of VapourDocument3 pagesTerm Paper Review of Thermal Engg.: Topic:-Application of Vapouramit9779198918No ratings yet

- Meat Technology Update: Refrigeration PrinciplesDocument4 pagesMeat Technology Update: Refrigeration PrinciplesDebasis Dasgupta100% (1)

- Rac Lab ManualDocument36 pagesRac Lab ManualAftab Alam100% (2)

- Thermal Engineering Unit 5Document23 pagesThermal Engineering Unit 5MohanCool100% (1)

- Vapor Absorption Refrigeration System (VARS)Document11 pagesVapor Absorption Refrigeration System (VARS)Syed Imtiaz Ali ShahNo ratings yet

- Basic RefrigerationDocument9 pagesBasic RefrigerationDarren Jeff Manuel MicumaoNo ratings yet

- Explain Rankin Cycle With Its Efficiency: WaterDocument7 pagesExplain Rankin Cycle With Its Efficiency: WaterJustine SomentacNo ratings yet

- Ammonia AbsorptionDocument5 pagesAmmonia Absorptionfarzad100% (1)

- Absorption RefrigeratorDocument5 pagesAbsorption RefrigeratorThanveer Ahmed SNo ratings yet

- Lecture 7Document13 pagesLecture 7Shubham SinghNo ratings yet

- 6 Absorption Refrigeration System PDFDocument28 pages6 Absorption Refrigeration System PDFJITENDRA PATILNo ratings yet

- Literature Review of Vapour Absorption Refrigeration SystemDocument7 pagesLiterature Review of Vapour Absorption Refrigeration SystemnqdpuhxgfNo ratings yet

- Simple Vapor-Absorption Refrigeration SystemDocument49 pagesSimple Vapor-Absorption Refrigeration SystemnaccfrancNo ratings yet

- Basic Civil and Mechanical Engineering Unit VDocument37 pagesBasic Civil and Mechanical Engineering Unit VA.R. Pradeep Kumar100% (1)

- Report TaqaDocument15 pagesReport Taqaraghunandanr1993No ratings yet

- Ammonia Ref CycleDocument11 pagesAmmonia Ref CycleJom BonhayagNo ratings yet

- Vapour Absorption Refrigeration System Research PaperDocument4 pagesVapour Absorption Refrigeration System Research Paperc9hpjcb3No ratings yet

- Fundamentals in FF DesignDocument131 pagesFundamentals in FF DesignKaye OleaNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Absorption RefrigerationDocument5 pagesAbsorption Refrigerationdan_artimofNo ratings yet

- Sequencing of Clamping & Feeding Operation: Using Hydraulic SystemDocument49 pagesSequencing of Clamping & Feeding Operation: Using Hydraulic SystemNachiket PatilNo ratings yet

- Migracion de MonitorDriverDocument10 pagesMigracion de MonitorDriverErick ZagalNo ratings yet

- F3000 Manual CompleteDocument20 pagesF3000 Manual CompleteNachiket PatilNo ratings yet

- Operating Manual F4500Document44 pagesOperating Manual F4500Nachiket PatilNo ratings yet

- User Instruction: Operating Instructions Medic Air Tester F3004Document8 pagesUser Instruction: Operating Instructions Medic Air Tester F3004Nachiket Patil0% (1)

- Operating Manual 4504Document42 pagesOperating Manual 4504Nachiket PatilNo ratings yet

- Operating Manual F4000Document32 pagesOperating Manual F4000Nachiket PatilNo ratings yet

- Capillary TubesDocument3 pagesCapillary TubesKhawaja Abdul Basit SohailNo ratings yet

- SensorDocument3 pagesSensorANo ratings yet

- EvaporatorDocument1 pageEvaporatorHabibiAriaNo ratings yet

- Sugarbeet ProcessingDocument12 pagesSugarbeet ProcessingyanatryNo ratings yet

- ASHRAE - Series Series Counterflow For Central Chilled Water PlantsDocument7 pagesASHRAE - Series Series Counterflow For Central Chilled Water PlantsAntonio LebrunNo ratings yet

- Refrigeration SystemDocument54 pagesRefrigeration SystemEdrian Diaz100% (1)

- Perrys TabsDocument10 pagesPerrys TabsCharles Amiel DionisioNo ratings yet

- Catalogo de Sporlan de Válvula de EspansionDocument40 pagesCatalogo de Sporlan de Válvula de EspansionLuciano FloresNo ratings yet

- Hetran TEMA Sheet ExamplesDocument39 pagesHetran TEMA Sheet ExamplesAriesNo ratings yet

- Refrigeration and Air Conditioning Technology 72 6th AlllDocument30 pagesRefrigeration and Air Conditioning Technology 72 6th AlllZabed HossainNo ratings yet

- 495 - Colmac DX Ammonia Piping Handbook 2nd Ed (Rev 0)Document57 pages495 - Colmac DX Ammonia Piping Handbook 2nd Ed (Rev 0)botaratoNo ratings yet

- Roy-Mandal2020 Article Thermo-economicAnalysisAndMultDocument15 pagesRoy-Mandal2020 Article Thermo-economicAnalysisAndMultAhmed RagabNo ratings yet

- Pharmaceutical EngineeringDocument18 pagesPharmaceutical EngineeringPriya Sharma50% (2)

- Far East Group Limited Prospectus PDFDocument262 pagesFar East Group Limited Prospectus PDFBilly LeeNo ratings yet

- Analysis of A Refrigeration Cycle With Coolprop PDFDocument6 pagesAnalysis of A Refrigeration Cycle With Coolprop PDFDario MendezNo ratings yet

- IWPDocument71 pagesIWPAnonymous qMGUwI6KNo ratings yet

- RCD Ebara Absorption ChillerDocument24 pagesRCD Ebara Absorption Chillera_salehi83% (6)

- Lab Manual Sem 1 2020-2021 PDFDocument24 pagesLab Manual Sem 1 2020-2021 PDFDinesh RaviNo ratings yet

- Ipc CG 2017 PDFDocument132 pagesIpc CG 2017 PDFTài NguyễnNo ratings yet

- Intro To Methyl Chloride Plant 1Document57 pagesIntro To Methyl Chloride Plant 1Kimberly ConleyNo ratings yet

- Window Ac: Ashi Chandak Akriti Dubey Ritvika Singh Shweta BaisDocument25 pagesWindow Ac: Ashi Chandak Akriti Dubey Ritvika Singh Shweta BaisAshi ChandakNo ratings yet

- Project Presentation: Refrigeration Using Waste Heat in CarsDocument16 pagesProject Presentation: Refrigeration Using Waste Heat in CarsDevanshu SinghNo ratings yet

- Installation and Commissioning Manual Commissioning Manual: 20X, 30S, 35X, 40X, 50XDocument30 pagesInstallation and Commissioning Manual Commissioning Manual: 20X, 30S, 35X, 40X, 50XNikolay KapitanovNo ratings yet

- Air ConditioningDocument26 pagesAir Conditioningsamuel kaluNo ratings yet

- Laporan Prakerin SMKN Krangkeng Inggris-1Document24 pagesLaporan Prakerin SMKN Krangkeng Inggris-1Galuh XxieNo ratings yet

- g3 Thermodynamics ExperimentsDocument42 pagesg3 Thermodynamics Experimentsarda Максим50% (2)

- Gree2011 en Ac Installation Service ManualDocument136 pagesGree2011 en Ac Installation Service ManualJuli Nugroho SuSantoNo ratings yet

- Fish Meal-Technical SpecificationDocument2 pagesFish Meal-Technical SpecificationHitendra Nath BarmmaNo ratings yet

- Variable Refrigerant Flow Systems PDFDocument38 pagesVariable Refrigerant Flow Systems PDFRafael SalazarNo ratings yet

- Lab Report 560751c42519eDocument16 pagesLab Report 560751c42519eNadiaNo ratings yet