Professional Documents

Culture Documents

Caustisizing Unit: Production of Cellulose Nano-Crystals (CNC) From Corn Husk Through Acid Hydrolysis Process Flow Diagram

Uploaded by

Hamza MughalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Caustisizing Unit: Production of Cellulose Nano-Crystals (CNC) From Corn Husk Through Acid Hydrolysis Process Flow Diagram

Uploaded by

Hamza MughalCopyright:

Available Formats

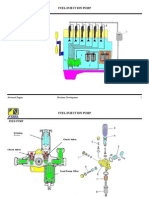

dw

Moisture

26 Caustisizing Unit

2 4

Feed(Corn Husk) White Liquor

1 3

Dried Corn Husk Make up

SR-101 Chemicals

ED-101 Sodium 18

Grinded Corn Husk 5 13 Water

4 Chlorite

Bleached Pulp

Sulphuric

White Liquor 15 16

Superheated Steam From Power House M-101 Acid

7

Feed Slurry 17

E-14

27 28 6

P-33 Product Stream

CNC Slurry

Vapors

19

Superheated Steam From Power House

30 Vapors Vapors

E-101

8 EC-101 TB-101 CR-101 CE-101 20

Saturated Steam 20 H2O

14

Waste (lignin removal) Waste (Acid Removal)

ED-102

FE-101 FE-102 FE-103 21

Condensate Condensate Condensate Condensate

Warm Water TD-101

Dried CNC

29

Conc. Black Liquor 70% Fresh Water 24

Treated Mixture 9 11 22

Weak Black Liquor 9-10%

Treated Mixture

12 23

10

Washed Pulp Molten Smelt

BT-101 W-101 DT-101 TK-101

RB-101

25

Green Liquor

Production Of Cellulose Nano-Crystals(CNC) From Corn Husk Through Acid Hydrolysis

Process Flow Diagram

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- H408 Fluid Friction Datasheet 0517Document4 pagesH408 Fluid Friction Datasheet 0517Hamza MughalNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Assignment No.1Document7 pagesAssignment No.1Hamza MughalNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Assignment#: EconomicsDocument7 pagesAssignment#: EconomicsHamza MughalNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Workshop Practice LabDocument21 pagesWorkshop Practice LabHamza MughalNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Wind EnergyDocument31 pagesWind EnergyHamza MughalNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- DepreciationDocument15 pagesDepreciationHamza MughalNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Environmental Engineering: Submitted by Muhammad ArslanDocument6 pagesEnvironmental Engineering: Submitted by Muhammad ArslanHamza MughalNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Bche Fa17 033Document3 pagesBche Fa17 033Hamza MughalNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Selection of The Most Feasible Wastewater Treatment Technology in Pakistan Using Multi-Criteria Decision-Making (MCDM)Document6 pagesSelection of The Most Feasible Wastewater Treatment Technology in Pakistan Using Multi-Criteria Decision-Making (MCDM)Hamza MughalNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Bche Fa17 017Document4 pagesBche Fa17 017Hamza MughalNo ratings yet

- Types of Separators - 12eleven Production Equipment v052020Document28 pagesTypes of Separators - 12eleven Production Equipment v052020Hamza MughalNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Methods For Calculating The Profitability:: ND ST NDDocument3 pagesMethods For Calculating The Profitability:: ND ST NDHamza MughalNo ratings yet

- Bche Fa17 027Document6 pagesBche Fa17 027Hamza MughalNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- SEMESTER 3 OutlineDocument6 pagesSEMESTER 3 OutlineHamza MughalNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Environmental Health and SafetyDocument12 pagesEnvironmental Health and SafetyHamza MughalNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Labelling Guide 2021 ENDocument31 pagesLabelling Guide 2021 ENHamza MughalNo ratings yet

- Impacts of Geothermal Energy On Environment by AliDocument6 pagesImpacts of Geothermal Energy On Environment by AliHamza MughalNo ratings yet

- Technical Presentation Skills For Engineers: Carl KrillDocument10 pagesTechnical Presentation Skills For Engineers: Carl KrillHamza MughalNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Nano Cellulose Presentation Group 21Document47 pagesNano Cellulose Presentation Group 21Hamza MughalNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hazard IdentificationDocument68 pagesHazard IdentificationHamza MughalNo ratings yet

- Danger, Warning, Caution SymbolDocument8 pagesDanger, Warning, Caution SymbolHamza MughalNo ratings yet

- Mathematical Modeling of A Tray Dryer For The DryingDocument5 pagesMathematical Modeling of A Tray Dryer For The DryingHamza MughalNo ratings yet

- Functional Groups: DefinitionDocument7 pagesFunctional Groups: DefinitionHamza MughalNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Chemical Engineering TerminologiesDocument548 pagesChemical Engineering TerminologiesHamza MughalNo ratings yet

- Two and ThreePhase SeparatorsDocument2 pagesTwo and ThreePhase SeparatorsHamza MughalNo ratings yet

- Refrigeration: Principles of RefrigerationDocument3 pagesRefrigeration: Principles of RefrigerationHamza MughalNo ratings yet

- Flow Measuring Devices: DefinitionDocument6 pagesFlow Measuring Devices: DefinitionHamza MughalNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Technical PresentationDocument3 pagesTechnical PresentationHamza MughalNo ratings yet

- Free Energy SurpriseDocument21 pagesFree Energy SurpriseJeanJones100% (3)

- 2016-04-01716 PT 1 ReportDocument30 pages2016-04-01716 PT 1 ReportdaudiNo ratings yet

- Fab 03 Non - Destructive TestingDocument25 pagesFab 03 Non - Destructive TestingRaghu vamshiNo ratings yet

- MCQ For Midsem - Ind - Inst.Document5 pagesMCQ For Midsem - Ind - Inst.Nirav ChauhanNo ratings yet

- Government of India Ministry of Railways: Infrastructure Requirements For Manufacturing, Testing & Supply ofDocument3 pagesGovernment of India Ministry of Railways: Infrastructure Requirements For Manufacturing, Testing & Supply ofkapilparyaniNo ratings yet

- How To Choose An EPC Contractor For PV ProjectsDocument14 pagesHow To Choose An EPC Contractor For PV Projectsavnish_parashar9292No ratings yet

- Cesium and Rubidium Salts of Keggin-TypeDocument146 pagesCesium and Rubidium Salts of Keggin-TypeChau MaiNo ratings yet

- JEE Main 2019 Detailed Analysis January Attempt Shift - 2 (09th January, 2019)Document8 pagesJEE Main 2019 Detailed Analysis January Attempt Shift - 2 (09th January, 2019)Resonance Eduventures100% (2)

- ORTON - Company Profile 31-12-09Document14 pagesORTON - Company Profile 31-12-09Fabrizio DelledonneNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- JFR Ratings Available PDFDocument1 pageJFR Ratings Available PDFMarcosNo ratings yet

- Electrical Characteristics (KA7812A) : Parameter Symbol Conditions Min. Typ. Max. UnitDocument3 pagesElectrical Characteristics (KA7812A) : Parameter Symbol Conditions Min. Typ. Max. UnitSec!No ratings yet

- Component Maintenance Manual With Illustrated Parts ListDocument62 pagesComponent Maintenance Manual With Illustrated Parts ListRaymond Zamora100% (7)

- Smo Management Audit Report Q2f19-FoiDocument12 pagesSmo Management Audit Report Q2f19-FoiBob MackinNo ratings yet

- Propane Workshop PPTDocument71 pagesPropane Workshop PPTch.kashifpervez100% (1)

- Light PD1Document4 pagesLight PD1Lily Suhany MahmoodNo ratings yet

- 4fuel Injection PumpDocument9 pages4fuel Injection PumpJoko Sukariono100% (2)

- Servo MotorDocument6 pagesServo Motorimtiaz eemelNo ratings yet

- Lab 5 - Wireless Power Transfer PDFDocument2 pagesLab 5 - Wireless Power Transfer PDFRuben CollinsNo ratings yet

- Pressure - Enthalpy Diagram For The Refrigerant R-22: Li Q U IdDocument1 pagePressure - Enthalpy Diagram For The Refrigerant R-22: Li Q U IdRifki AuliaNo ratings yet

- Tim HortonsDocument194 pagesTim HortonsShashank Vatsavai100% (2)

- TM 5-6115-20PDocument193 pagesTM 5-6115-20PAdvocate100% (1)

- Engineering Guide Custom Battery PacksDocument16 pagesEngineering Guide Custom Battery PacksAndrew PNo ratings yet

- Earthing RequirementDocument7 pagesEarthing RequirementSandy ChoudhariNo ratings yet

- Operation Refilling and Maintenance Manual: Hatsuta Seisakusho Co. LTDDocument9 pagesOperation Refilling and Maintenance Manual: Hatsuta Seisakusho Co. LTDNego1975No ratings yet

- Quantum Mechanics Tunneling & Harmonic OscillatorDocument33 pagesQuantum Mechanics Tunneling & Harmonic Oscillatorvivek patelNo ratings yet

- 0051-1104 Method Statement Pneumatic TestingDocument9 pages0051-1104 Method Statement Pneumatic TestingHasif Mohammed67% (3)

- 1-Field Life CycleDocument18 pages1-Field Life CycleAlberto100% (2)

- Abb Make Hybrid Switchgear PassDocument23 pagesAbb Make Hybrid Switchgear PassAjith AjiNo ratings yet

- Characterization of Surface Deposits On Human HairDocument12 pagesCharacterization of Surface Deposits On Human HairpigcognitoNo ratings yet

- Riello Burner Handbook PDFDocument169 pagesRiello Burner Handbook PDFfsijest50% (2)