Professional Documents

Culture Documents

Laboratory Exercise No. 2-C Sieve Analysis and Abrasion Test of Aggregates

Uploaded by

Haziel DizonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Laboratory Exercise No. 2-C Sieve Analysis and Abrasion Test of Aggregates

Uploaded by

Haziel DizonCopyright:

Available Formats

MODULE: WEEK 5 [DATE]

5. Laboratory Exercise No. 2-C

Sieve Analysis and Abrasion Test of Aggregates

Introduction

Aggregate is one of the most important components of concrete mixture in construction industry. It is

divided into two parts, the fine aggregates commonly known as “sand” and coarse aggregates well-known as

“gravel”. The physical properties of aggregates are essential in concrete design mix used by either government

or private sector, like for instance the American Concrete Institute (ACI) and also in Bituminous Concrete

Surface Course.

Main Objective

1. To determine the quality test of aggregates

Topic 1:

Sieve Analysis of Aggregates (Grading

Analysis)

Specific Objective

1. To determine the grain size distribution of Aggregates

Apparatus

Digital balance, 5 kg cap

Standard set of sieves

Rectangular pan/ circular pan

Oven

Scoop

Density spoon

ENGR. FAUSTINO S. CASTAÑEDA 1

MODULE: WEEK 5 [DATE]

Ok activity time na……

Procedure

1. Weight the original sample oven dried.

2. Wash the sample using sieve No. 200 and oven dried. Performing washing needs additional sieve No.

16 so that sieve No. 200 will not risk.

3 Get the weight after drying.

4 Determine the weight of individual sieve.

5 Pass sample through the nested set of sieves. Sieving is finished when no material passing on

succeeding sieve.

6. Weigh the material retained on each sieve.

7. Calculate the cumulative percentage passing each sieve by dividing from original weight of sample.

ENGR. FAUSTINO S. CASTAÑEDA 2

MODULE: WEEK 5 [DATE]

Title: Sieve Analysis Name: Dizon, Haziel O.

Laboratory Exercise No.: 5 Class Code: CONMATLSL-4592

Date Performed: March 5, 2022 Group No.: 5

Date Submitted: March 14, 2022 Rating:

Data Sheet:

Fine Aggregate

Standard (mm) Alternate Weight Weight of Weight of Cumulative Percent Specification

US of Sieve + material Weight (%) % Passing

Standard Sieve Material Retained Retained Passing

Retained

9.500 (3/8’’) 100

4.750 (No. 4) 478.83 666.0 187.17 1812.83 90.64 95-100

2.360 (No. 8) 456.7 589.4 132.7 1680.13 84.01 -

1.180 (No. 16) 387.3 581.1 193.8 1486.33 74.32 45-80

0.600 (No. 30) 360.8 666.3 305.5 1180.83 59 -

0.300 (No. 50) 326.9 762.9 436 744.83 37.24 5-30

0.150 (No. 100) 307.2 732.1 424.9 319.93 16.00 0-10

0.075 (No. 200) 294.0 534.7 240.7 79.23 3.96

Pan 352.5 431.8 79 0.23 0.01

Computation:

ENGR. FAUSTINO S. CASTAÑEDA 3

MODULE: WEEK 5 [DATE]

Coarse Aggregate

Standard (mm) Alternate Weight Weight Weight Cumulative Cumulative Percent Specification

US of of Sieve of Weight Percent (%) % Passing

Standard Sieve + material Retained (%) Passing0

Material Retained Retained

Retained

37.5 1-1/2’’ 0 0 0 100 95-100

25 1’’ 118.7 118.7 3.96 96.04 -

19 ¾’’ 1415.3 1534 51.13 48.87 35-70

12.5 ½’’ 1127 2661 88.7 11.3 -

9.5 3/8’’ 30 2691 89.7 10.3 10-30

4.75 No 4. 170 2861 95.37 4.63 0-5

2.360 No 8. 139 3000 100 0

Pan

Computation:

Conclusion:

Following the activity, I concluded that testing the materials you would be using is critical to the success of your project.

You should also be able to test each one to see if it meets your requirements. The UTM is a fantastic device since it can

test the elasticity of steel bars. The activity was a positive learning experience for us, students, and will be beneficial in

the future.

ENGR. FAUSTINO S. CASTAÑEDA 4

You might also like

- IGCSE Chemistry - States of Matter and Separation TechniquesDocument12 pagesIGCSE Chemistry - States of Matter and Separation TechniquesChemistryKlipz100% (24)

- UTA010 Engineering Design-II: Thapar University, Patiala Mechanical Engineering DepartmentDocument7 pagesUTA010 Engineering Design-II: Thapar University, Patiala Mechanical Engineering DepartmentRidham Arora0% (5)

- Chapter 8Document31 pagesChapter 8helloblarg100% (4)

- CHAPTER 3 and SIEVE ANALYSIS TESTDocument11 pagesCHAPTER 3 and SIEVE ANALYSIS TESTSiti Nurulsyazni RusliNo ratings yet

- Concrete Technology Practical PDFDocument21 pagesConcrete Technology Practical PDFPrashant SahNo ratings yet

- Sieve Analysis of Fine & Coarse Aggregates: Cie 309 - Construction Materials Lab Lab Report 3 - Astm C136Document11 pagesSieve Analysis of Fine & Coarse Aggregates: Cie 309 - Construction Materials Lab Lab Report 3 - Astm C136Seyoung MyiouNo ratings yet

- CE224L CMT Lab 4 Adrian DipayDocument5 pagesCE224L CMT Lab 4 Adrian DipayisaackotachieNo ratings yet

- CV3B EW1 Group5 Experiment2&3Document6 pagesCV3B EW1 Group5 Experiment2&3jml aguilarNo ratings yet

- Geotech Lab 1Document6 pagesGeotech Lab 1Marinella DimaanoNo ratings yet

- CE405 - E2 - Abello Braga Gavino Habichy Millona 1Document7 pagesCE405 - E2 - Abello Braga Gavino Habichy Millona 1Oren Hertz FaustoNo ratings yet

- 1 Sieve Analysis of Aggregates - MIOTENDocument20 pages1 Sieve Analysis of Aggregates - MIOTENEder Ducusin GacerNo ratings yet

- Material Reports K0835110Document52 pagesMaterial Reports K0835110ikaNo ratings yet

- Kapitulu Vi & VDocument36 pagesKapitulu Vi & VMariana CabralNo ratings yet

- WC (Water Content) Totadan Pan (W1) Todan Pan + Material Bokon (W2) Todan Pan + Material Nebe Hatama Ona Formo (W3)Document18 pagesWC (Water Content) Totadan Pan (W1) Todan Pan + Material Bokon (W2) Todan Pan + Material Nebe Hatama Ona Formo (W3)Jerry GilNo ratings yet

- Gradation of Course Aggregate: Sample No.2Document10 pagesGradation of Course Aggregate: Sample No.2Sudhir GautamNo ratings yet

- Three (3) Sample ComputationsDocument5 pagesThree (3) Sample ComputationsCARL JAMESNo ratings yet

- Sieve Analysis: Abdullah Gül UniversityDocument6 pagesSieve Analysis: Abdullah Gül UniversityYılmaz UçarNo ratings yet

- MMT 151.1 ComminutionDocument18 pagesMMT 151.1 Comminutionvince coNo ratings yet

- Amiel A. Cabatchete Bsce-4B Group No. 1 SEPTEMBER 19, 2017: Activity # 3Document10 pagesAmiel A. Cabatchete Bsce-4B Group No. 1 SEPTEMBER 19, 2017: Activity # 3EmanoAceNo ratings yet

- Equipo6 - REPORTE - Práctica2 - Gpo55 - SMIQ REVISADODocument10 pagesEquipo6 - REPORTE - Práctica2 - Gpo55 - SMIQ REVISADOEnya Vives BntzNo ratings yet

- Prac 2 Seive AnalysisDocument8 pagesPrac 2 Seive AnalysisPaul RwomwijhuNo ratings yet

- ClassificationDocument4 pagesClassificationMohammad SayimNo ratings yet

- C2-Seive Analysis and SG Coarse Aggregates ReportDocument17 pagesC2-Seive Analysis and SG Coarse Aggregates ReportMuhammad khairinNo ratings yet

- Lab Report 1,2,3 - Food Unit Operation 2Document46 pagesLab Report 1,2,3 - Food Unit Operation 2V THNo ratings yet

- Laboratory 4 ReportDocument10 pagesLaboratory 4 ReportFahad KudaratNo ratings yet

- Ball Charge Design - VDocument11 pagesBall Charge Design - VKaran_Agarwal_4807100% (2)

- LabRep 1Document6 pagesLabRep 1Red DeadNo ratings yet

- Lab 2 - Group 1Document4 pagesLab 2 - Group 1Pilar MNo ratings yet

- 7.sieve Analysis AhmedDocument9 pages7.sieve Analysis AhmedJin AhmedNo ratings yet

- Investigating Size Reduction OkDocument13 pagesInvestigating Size Reduction OkRoselynNo ratings yet

- Sieves Analysis For Coarse Aggregate: College of Engineering and ArchitectureDocument9 pagesSieves Analysis For Coarse Aggregate: College of Engineering and ArchitectureMARIBEL MAGAYONNo ratings yet

- Compset™ Packers: Section 4: Sealbore Packers and AccessoriesDocument6 pagesCompset™ Packers: Section 4: Sealbore Packers and AccessoriesjosephbenettonNo ratings yet

- Group 4 - Lab 5Document21 pagesGroup 4 - Lab 5jia jun wanNo ratings yet

- Full Report - Dry SievingDocument12 pagesFull Report - Dry SievingDini NoordinNo ratings yet

- Sieve Analysis of Fine Aggregates: Materials Testing #1Document4 pagesSieve Analysis of Fine Aggregates: Materials Testing #1Maryll TapiaNo ratings yet

- Grade 100 Alloy ChainDocument1 pageGrade 100 Alloy ChainRameshwar PatilNo ratings yet

- Stud Bolts DIN 976-1: 2002-12: 1. ScopeDocument6 pagesStud Bolts DIN 976-1: 2002-12: 1. ScopejayNo ratings yet

- Soil Ex2Document7 pagesSoil Ex2Azeezan AlessaNo ratings yet

- Mix Design Beton NormalDocument13 pagesMix Design Beton NormalMansyur AnchuNo ratings yet

- Sieve Analysis: ASTM C.33-78Document14 pagesSieve Analysis: ASTM C.33-78Rifqi FirmansyahNo ratings yet

- New Era University: Construction Materials and Testing LabDocument5 pagesNew Era University: Construction Materials and Testing LabKaren AmpeloquioNo ratings yet

- BBC Superpave - 2Document47 pagesBBC Superpave - 2mido_20067581No ratings yet

- Sieve Analaysis of Coarse Aggregates PDFDocument3 pagesSieve Analaysis of Coarse Aggregates PDFbananaNo ratings yet

- Andi Love TaniaDocument12 pagesAndi Love Taniadebaslakapu22No ratings yet

- Marsal SisoDocument8 pagesMarsal SisoLaxman BaduwalNo ratings yet

- 1-Experiment 1-Handout PDFDocument10 pages1-Experiment 1-Handout PDFUfuk CevtekinNo ratings yet

- Gradation and Fineness Modulus of Fine AggregateDocument7 pagesGradation and Fineness Modulus of Fine AggregateAlbert JanssenNo ratings yet

- Improving The Dimensional Accuracy and Surface Roughness of FDM Parts Using Optimization TechniquesDocument5 pagesImproving The Dimensional Accuracy and Surface Roughness of FDM Parts Using Optimization TechniquesRaghuNo ratings yet

- Lampiran Bab 2 12 7Document9 pagesLampiran Bab 2 12 7Jhc-Graselita AdegThaNo ratings yet

- ET 310 Lab 4Document19 pagesET 310 Lab 4DylanNo ratings yet

- ACS Heat - Loss - Calculator Dryer 3050D X 21000L Thermal Analysis ReportDocument7 pagesACS Heat - Loss - Calculator Dryer 3050D X 21000L Thermal Analysis Reportdwi sutiknoNo ratings yet

- Tubos PVCDocument4 pagesTubos PVCcesar paitanNo ratings yet

- Bitumen Extraction - BBC (C) New 30.08.2019Document1 pageBitumen Extraction - BBC (C) New 30.08.2019Motaz AbdallahNo ratings yet

- AASHTO T 27, Sieve Analysis of Fine and Coarse Aggregates AASHTO T 11Document22 pagesAASHTO T 27, Sieve Analysis of Fine and Coarse Aggregates AASHTO T 11Yoisi Meza DominguezNo ratings yet

- CE405 Group 2 Experiment No.2Document4 pagesCE405 Group 2 Experiment No.2Liam FarenNo ratings yet

- Bitumen Extraction - BBC (A) New 13.10.2018Document1 pageBitumen Extraction - BBC (A) New 13.10.2018Motaz AbdallahNo ratings yet

- Expt No.03a Sieve Analysis of SoilDocument12 pagesExpt No.03a Sieve Analysis of SoilGlenda Lizel BiceraNo ratings yet

- Experiment 3 - FST559Document12 pagesExperiment 3 - FST559JAZMINA AZMANNo ratings yet

- DFDocument9 pagesDFJoshua CalaNo ratings yet

- Structural Theory Plate 6Document6 pagesStructural Theory Plate 6Haziel DizonNo ratings yet

- Structural Theory Plate 5Document6 pagesStructural Theory Plate 5Haziel DizonNo ratings yet

- Quantity Surveying Plate 4 MidtermsDocument5 pagesQuantity Surveying Plate 4 MidtermsHaziel DizonNo ratings yet

- Quantity Surveying Plate 2Document4 pagesQuantity Surveying Plate 2Haziel DizonNo ratings yet

- C++ - Exerc++ 5Document4 pagesC++ - Exerc++ 5Haziel DizonNo ratings yet

- Worksheet Activity 2 PL: C++Document3 pagesWorksheet Activity 2 PL: C++Haziel DizonNo ratings yet

- Engineering Management - Assignment 1Document7 pagesEngineering Management - Assignment 1Haziel DizonNo ratings yet

- Structural Theory Quiz 1Document1 pageStructural Theory Quiz 1Haziel DizonNo ratings yet

- Tunnelling For Randstadrail in RotterdamDocument9 pagesTunnelling For Randstadrail in RotterdamHarold TaylorNo ratings yet

- Bihar Cement Plant Environment Compliance April Sep 2020Document26 pagesBihar Cement Plant Environment Compliance April Sep 2020Kumar Saurabh SinghNo ratings yet

- Report On CondenserDocument5 pagesReport On CondenserDheeraj Shukla100% (1)

- Norma Astm F794Document7 pagesNorma Astm F794WalterRamosNo ratings yet

- Mixed Flowing Gas (MFG) Tests For Electrical ContactsDocument11 pagesMixed Flowing Gas (MFG) Tests For Electrical ContactsEugene OgosiNo ratings yet

- 7 Interlining, FusingDocument54 pages7 Interlining, FusingARYAN RATHORENo ratings yet

- A A 2017 Wintech S.R.L. Paper Aplusa2017.2500212 20old9qiRJq69hdzvqJPnw PDFDocument5 pagesA A 2017 Wintech S.R.L. Paper Aplusa2017.2500212 20old9qiRJq69hdzvqJPnw PDFkaleeswaranNo ratings yet

- Case Study: Materials For Blood Bags: WWW - Blood.co - UkDocument6 pagesCase Study: Materials For Blood Bags: WWW - Blood.co - UkBijuChudraponvelilThomasNo ratings yet

- Stainless Steel Tube Stock DataDocument18 pagesStainless Steel Tube Stock DataFU SHING STAINLESS STEEL CO.No ratings yet

- CH 7 ObjDocument4 pagesCH 7 ObjchongpeisiNo ratings yet

- Chap-5 Framed StructuresDocument12 pagesChap-5 Framed StructurestekalignNo ratings yet

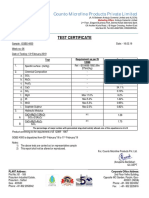

- Test Certificate: Counto Microfine Products Private LimitedDocument1 pageTest Certificate: Counto Microfine Products Private LimitedSiddhesh Kamat MhamaiNo ratings yet

- PlasticsDocument69 pagesPlasticsMyrna TabernillaNo ratings yet

- Tream Paper 2.8.editedDocument5 pagesTream Paper 2.8.editedPartho BasakNo ratings yet

- Alkanes and HalogenoalkanesDocument67 pagesAlkanes and HalogenoalkanesRAFIDNo ratings yet

- Solcart B PDFDocument8 pagesSolcart B PDFMohammad AshrafNo ratings yet

- Cobalch Aps - PTFE DetailDocument25 pagesCobalch Aps - PTFE DetailMorteza DianatfarNo ratings yet

- 2020 Kimdas CH8Document34 pages2020 Kimdas CH8febrikaNo ratings yet

- Carboguard 890 PDSDocument2 pagesCarboguard 890 PDSsalamrefighNo ratings yet

- TENSILEDocument16 pagesTENSILESahithi SahiNo ratings yet

- Effect of Si, Cu and Processing Parameters On Al-Si-Cu HPDC CastingsDocument24 pagesEffect of Si, Cu and Processing Parameters On Al-Si-Cu HPDC Castingskt rajaNo ratings yet

- Water Spliting On Titanate Photocatalysts PDFDocument9 pagesWater Spliting On Titanate Photocatalysts PDFDanCosminNo ratings yet

- Iec60599 (Ed3 0) BDocument82 pagesIec60599 (Ed3 0) Bnamsaigon316No ratings yet

- Mil I 46058CDocument15 pagesMil I 46058Cyamuna yamuNo ratings yet

- Xfs Sub Surface Dripline Performance ChartsDocument2 pagesXfs Sub Surface Dripline Performance ChartsYASSER SHAALANNo ratings yet

- Mineral and Power Resources of Chhota Nagpur RegionDocument10 pagesMineral and Power Resources of Chhota Nagpur RegionJasvinder Singh0% (1)

- Isoreactive Red He3bDocument3 pagesIsoreactive Red He3bscribd_user2010No ratings yet

- Sabp A 014 PDFDocument22 pagesSabp A 014 PDFShubhodeep SarkarNo ratings yet