Professional Documents

Culture Documents

High-Strength Quenched and Tempered Fine-Grained Steels: Technical Terms of Delivery For Heavy Plates

Uploaded by

Edwin RodriguezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

High-Strength Quenched and Tempered Fine-Grained Steels: Technical Terms of Delivery For Heavy Plates

Uploaded by

Edwin RodriguezCopyright:

Available Formats

High-strength

quenched and tempered

fine-grained steels

Technical terms of delivery for heavy plates

voestalpine Grobblech GmbH

www.voestalpine.com/grobblech

High-strength

quenched and tempered

fine-grained steels

aldur® Q

Steel grades

aldur 500 Q, QL, QL1

aldur 550 Q, QL, QL1

aldur 620 Q, QL, QL1

aldur 700 Q, QL, QL1

Subject to change pursuant to further development.

The current version is available at www.voestalpine.com/grobblech.

Technical terms of delivery for heavy plates aldur® Q January 2013. 2

aldur® Q

The grades of the aldur® Q series are water-quenched and tempered, high-strength, weldable fine-

grained structural steels. Main applications are welded structures subjected to extreme loads, e.g. in

crane and vehicle manufacturing, for steel construction, in pressure vessel and pressure piping systems.

The steel grades are supplied in three groups:

Basic series aldur® ... Q

with guaranteed notch impact toughness at –20 °C

Low temperature series aldur® ...QL

with guaranteed notch impact toughness at –40 °C

Special low-temperature series aldur® ...QL1

with guaranteed notch impact toughness at –60 °C

The technical terms of delivery apply for plate thick-

nesses from 12 - 100 mm.

Steel grades

Steel grades Table 1:

Steel grades

Designation according

Steel grades EN 10025-6 Material number

aldur 500 Q S500Q 1.8924

aldur 500 QL S500QL 1.8909

aldur 500 QL1 S500QL1 1.8984

aldur 550 Q S550Q 1.8904

aldur 550 QL S550QL 1.8926

aldur 550 QL1 S550QL1 1.8986

aldur 620 Q S620Q 1.8914

aldur 620 QL S620QL 1.8927

aldur 620 QL1 S620QL1 1.8987

aldur 700 Q S690Q 1.8931

aldur 700 QL S690QL 1.8928

aldur 700 QL1 S690QL1 1.8988

Production process

aldur® Q steels are produced via the LD-route.

Technical terms of delivery for heavy plates aldur® Q January 2013. 3

Chemical composition

Heat analysis

Guaranteed values Table 2:

Chemical

Steel grades mass in % composition

C Si Mn P S Altot. N Cr Ni Mo Cu V Nb Ti B Zr

max. max. max. max. max. min. max. max. max. max. max. max. max. max. max. max.

aldur 500 Q, QL, QL1

aldur 550 Q, QL, QL1

0.20 0.80 1.70 0.020 0.010 0.018 0.015 1.50 2.00 0.70 0.50 0.12 0.06 0.05 0.0050 0.15

aldur 620 Q, QL, QL1

aldur 700 Q, QL, QL1

Carbon equivalent

Depending on the analyses employed, the following carbon equivalents result for varying plate

thicknesses.

Table 3:

Standard values carbon

equivalent

Carbon equivalent

mass in %

plate thickness in mm

Steel grades < 25 > 25 < 50 > 50 < 100

aldur 500 Q, QL, QL1 CEV 1) max. acc. EN 10025-6 0.47 0.47 0.70

CEV1) standard value 0.40 0.46 0.46

CET2) standard value 0.25 0.29 0.29

Steel grades < 50 > 50

aldur 550 Q, QL, QL1 CEV 1) max. acc. EN 10025-6 0.65 0.77

CEV1) standard value 0.45 0.46

CET2) standard value 0.29 0.29

Steel grades < 50 > 50 < 70 > 70

aldur 620 Q, QL, QL1 CEV 1) max. acc. EN 10025-6 0.65 0.77 0.77

CEV1) standard value 0.46 0.46 0.52

CCET2) standard value 0.29 0.29 0.32

Steel grades < 30 > 30 < 50 > 50 < 100

aldur 700 Q, QL, QL1 CEV 1) max. acc. EN 10025-6 0.65 0.65 0.77

CEV1) Richtwert 0.46 0.52 0.54

CET2) standard value 0.29 0.32 0.35

1) CEV = C + Mn/6 + (Cr + Mo +V)/5 + (Ni + Cu)/15, carbon equivalent according to IIW

2) CET = C + (Mn + Mo)/10 + (Cr + Cu)/20 + Ni/40, carbon equivalent according to SEW 088

As-delivered condition

The plates are delivered in water-quenched and tempered condition. Direct hardening after hot rolling

is permitted.

Technical terms of delivery for heavy plates aldur® Q January 2013. 4

Mechanical properties

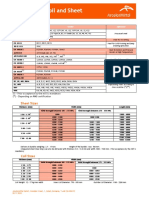

Mechanical properties at ambient temperature Table 4:

Mechanical

Yield strength YS1) Tensile strength UTS Fracture elongation properties

MPa, min. MPa L0 = 5,65 √ S0

Material plate thickness in mm plate thickness in mm min.

Steel grades number < 50 > 50 < 100 < 50 > 50 < 100 %

aldur 500 Q 1.8924

aldur 500 QL 1.8909 500 480 590 - 770 590 - 770 17

aldur 500 QL1 1.8984

aldur 550 Q 1.8904

aldur 550 QL 1.8926 550 530 640 - 820 640 - 820 16

aldur 550 QL1 1.8986

aldur 620 Q 1.8914

aldur 620 QL 1.8927 620 580 700 - 890 700 - 890 15

aldur 620 QL1 1.8987

aldur 700 Q 1.8931

aldur 700 QL 1.8928 700 650 770 - 940 760 - 930 14

aldur 700 QL1 1.8988

1) Where there is no distinct yield strength, the 0,2 %-proof stress (Rp 0,2) is established.

Notch impact energy (valid for Charpy V-notch samples) Table 5:

Notch impact

Notch impact energy AV1) energy

Sample J, min.

Steel grades direction testing temperature in °C

–60 –40 –20 +0

longitudinal – – 30 40

aldur 500 Q, aldur 550 Q, aldur 620 Q, aldur 700 Q

transversal – – 27 30

longitudinal – 30 40 50

aldur 500 QL, aldur 550 QL, aldur 620 QL, aldur 700 QL

transversal – 27 30 35

longitudinal 30 40 50 60

aldur 500 QL1, aldur 550 QL1, aldur 620 QL1, aldur 700 QL1

transversal 27 30 35 40

1) Notch impact test according to EN 10045 at longitudinal samples. Mean value from 3 individual samples must reach the specified

requirements. No individual value may be below 70 % of the guaranteed mean value. Testing temperature is –20 °C for the basic series

aldur Q, –40 °C for the low-temperature series aldur QL and –60 °C for the special low-temperature series aldur QL1.

Quality test

Test unit

Unless otherwise agreed upon ordering, 40 t of a heat or a smaller portion is used as test unit for the

mechanical properties. The test unit must consist of plates with the same steel grade and the same

thickness range for the yield strength according to table 4. The thickness of the plate in the test unit

may not differ more than 5 mm from the thickness of the sample.

Technical terms of delivery for heavy plates aldur® Q January 2013. 5

Position of test samples

The sample position in the rolled plate is at one end and at a quarter of the width.

Scope of testing

The following tests are carried out on the test samples:

Tensile test at ambient temperature on transverse samples

Notch impact test on longitudinal samples

The heat analysis is provided as proof of the chemical composition.

A transverse sample has to be taken for the tensile test at ambient temperature. Usually flat samples are

used for thicknesses up to 42 mm (aldur 500, 550, 620) resp. up to 20 mm (aldur 700); at least one rolled

surface shall remain on the sample. Round samples are permitted. For plate thicknesses higher than men-

tioned above round samples are used in any case.

Unless otherwise agreed, 3 longitudinal samples are taken from each position for the notch impact tests.

For plate thicknesses of up to 40 mm, one side of the sample must be as near as possible to the rolled

surface. In the case of plate thicknesses above 40 mm, the samples are taken in such a manner that

their longitudinal axes are at a distance of a quarter of the plate thickness from the surface, or as near

as possible to this point. The notch must be vertical to the plate surface.

Tolerances and surface finish

Unless otherwise agreed, tolerances according to EN 10029 (thickness tolerance according to class A,

flatness tolerance according to class N) and surface finish according to EN 10163-A1 are valid.

Marking

In general, marking consists of:

voestalpine symbol

Steel grade designation

Heat number

Plate number

Material testing certificate

Type of certificate according to EN 10204 must be agreed upon ordering.

Technical terms of delivery for heavy plates aldur® Q January 2013. 6

Processing guidelines

Cold forming

aldur® Q plates are well-suited for the standard cold forming processes in general

steel construction work.

Recommended minimum bending radii Table 6:

Minimum

Bending line transverse parallel to the rolling direction bending radii

Bending radius >3 >4 x plate thickness

The recommended minimum bending radius is only valid on condition that cut edges

have been removed and that the bending process is done professional.

Hot forming

Hot forming at temperatures above the permissible maximum stress-relief

temperature (560 °C) can influence the original tempered condition. In that case

water-quenching and tempering must be repeated after hot forming.

Welding

General information

A prerequisite for high-quality welding is adherence to the generally valid and

accepted rules for the welding of low-alloyed, higher-strength fine-grain structural

steels, according to EN 1011-2 and STAHL-EISEN Werkstoffblatt (SEW) 088.

Weld preparation, thermal cutting

Weld preparation can be done by machining or flame cutting. In general aldur Q

plates do not require preheating for workpiece temperatures above +5 °C. We recom-

mend preheating up to 100 °C for thicknesses above 50 mm.

Welding process

All standard automatic and manual welding processes can be employed, particularly

shielded metal arc, inert gas shielded and submerged arc welding.

Filler materials and welding conditions

(preheating, welding parameters)

The filler materials should be selected in that way, that the weld material matches

the mechanical-technological properties of the base material. The filler materials

listed in tables 7 and 8 are used in daily practice.

For preventing of cold cracking, care should be taken to ensure a low hydrogen

content of HD < 5 ml/100 g WM. This is generally guaranteed by inert gas shielded

welding with solid wire. Basic electrodes and welding powder must be subjected to

secondary drying in accordance with manufacturers instructions.

In order to prevent excessive hardening of the micro structure in the heat affected

zone (HAZ) and to achieve better resistance to hydrogen-induced cold cracking,

apart from the control of the hydrogen content, preheating is recommended in

accordance with the information given in tables 7 and 8.

Technical terms of delivery for heavy plates aldur® Q January 2013. 7

Preheating has the effect of reducing the hardening of the microstructure in the HAZ through an extension

of the cooling time t8/5 and has a dominating influence on the time available in the temperature range

below 300 °C for hydrogen effusion out of the weld region. In order to prevent cracks in the HAZ and in

the weld material, low-hydrogen annealing (postheating) in accordance with the conditions shown in

table 7 and 8 is recommended for plate thicknesses above 50 mm. In order to attain the high-strength and

excellent toughness properties of the base material also in the HAZ, heat input should be limited to max.

20 kJ/cm and multi-layer welding is to be employed as temper bead technique. Welding conditions,which

lead to cooling times t8/5 of 5 - 20 seconds, have proved effective. Following appropriate checks, welding

can take place with other cooling times if the requirements on the component are fulfilled.

Recommended fillers and heat control during welding

aldur 500 and 550 Q, QL, QL1 Table 7:

Fillers and

Filler material Pre- Interpass Post- heat control

Welding Standard heating temp. heating aldur 500 Q

process AWS-ASME II/C Designation °C °C °C - hrs aldur 550 Q

Shielded metal arc A 5.5-SFA 5.5 E 8018-G

80 max. 250 - 3

Inert gas shielded A 5.28-SFA 5.28 ER 90 S-G

s > 30 mm 150 s > 50 mm

Submerged arc A 5.23-SFA 5.23 F9A8-EF1-F1

aldur 620 and 700 Q, QL, QL1 Table 8:

Fillers and

Filler material Pre- Interpass Post- heat control

Welding Standard heating temp. heating aldur 620 Q

process AWS-ASME II/C Designation °C °C °C - hrs aldur 700 Q

Shielded metal arc A 5.5-SFA 5.5 E 11018-G

100 max. 250 - 3

Inert gas shielded A 5.28-SFA 5.28 ER 110 S-G

s > 12 mm 150 s > 50 mm

Submerged arc A 5.23-97 F10-A4-EM4-M2

Technical terms of delivery for heavy plates aldur® Q January 2013. 8

Recommended welding consumables Table 9:

Recommended

Base material Welding process – consumable welding

EN Material- SAW consumables

voestalpine SMAW GTAW GMAW

10025-6 number wire flux

aldur 500 Q S500Q 1.8924 You will find more

FOX EV 65 NiMo1-IG NiMo1-IG 3 NiMo1-UP BB 24 information at

aldur 500 QL S500QL 1.8909

Phoenix SH Ni 2 K90 Union NiMo Union MoNi Union S 3 NiMo UV 421 TT www.boehler-

aldur 500 QL1 S500QL1 1.8984 welding.com and

aldur 550 Q S550Q 1.8904 www.t-put.com.

FOX EV 65

NiMo1-IG NiMo1-IG 3 NiMo1-UP BB 24 Experienced

aldur 550 QL S550QL 1.8926 FOX EV 75

Union NiMo Union MoNi Union S 3 NiMo UV 421 TT welding

Phoenix SH Ni 2 K90

aldur 550 QL1 S550QL1 1.8986 engineers are

aldur 620 Q S620Q 1.8914 at your disposal.

FOX EV 85 NiCrMo 2,5-IG NiCrMo 2,5-IG 3 NiCrMo 2,5-UP BB 24

aldur 620 QL S620QL 1.8927 Phoenix SH Ni 2 K100 _ Union NiMoCr Union S 3 NiMoCr UV 421 TT

Union X85

aldur 620 QL1 S620QL1 1.8987

aldur 700 Q S690Q 1.8931

FOX EV 85 NiCrMo 2,5-IG NiCrMo 2,5-IG 3 NiCrMo 2,5-UP BB 24

aldur 700 QL S690QL 1.8928 Phoenix SH Ni 2 K100 _ Union NiMoCr Union S 3 NiMoCr UV 421 TT

Union X85

aldur 700 QL1 S690QL1 1.8988

Stress-reliefing

Where stress-relief annealing is required due to the structure and/or processing conditions, tempera-

tures < 560 °C must be used. For optimum toughness properties of the weld we recommend stress

relief annealing up to max. 520 °C.

Technical terms of delivery for heavy plates aldur® Q January 2013. 9

Dimensions

aldur 500 Q, QL, QL1 and aldur 550 Q, QL, QL1

Thickness

(mm)

100

95

90

85

80

75

70

65

60

55

50

45

40

35

30

25

20

12

Width

1,500

1,600

1,700

1,800

1,900

2,000

2,100

2,200

2,300

2,400

2,500

2,600

2,700

2,800

2,900

3,000

3,100

3,200

3,300

3,400

3,500

3,600

3,700

3,800

(mm)

Maximum length: 13,200 mm

Different dimensions on request.

Technical terms of delivery for heavy plates aldur® Q January 2013. 10

Dimensions

aldur 620 Q, QL, QL1

Thickness

(mm)

100

95

90

85

80

75

70

65

60

55

50

45

40

35

30

25

20

12

Width

1,500

1,600

1,700

1,800

1,900

2,000

2,100

2,200

2,300

2,400

2,500

2,600

2,700

2,800

2,900

3,000

3,100

3,200

3,300

3,400

3,500

3,600

3,700

3,800

(mm)

Maximum length: 13,200 mm

Different dimensions on request.

Technical terms of delivery for heavy plates aldur® Q January 2013. 11

Dimensions

aldur 700 Q, QL, QL1

Thickness

(mm)

100

95

90

85

80

75

70

65

60

55

50

45

40

35

30

25

20

12

Width

1,500

1,600

1,700

1,800

1,900

2,000

2,100

2,200

2,300

2,400

2,500

2,600

2,700

2,800

2,900

3,000

3,100

3,200

3,300

3,400

3,500

3,600

3,700

3,800

(mm)

Maximum length: 16,000 mm for thicknesses of up to 30 mm (18,000 mm on request)

13,200 mm for thicknesses > 30 - 100 mm

Different dimensions on request.

Technical terms of delivery for heavy plates aldur® Q January 2013. 12

Technically more advanced. Successful together.

voestalpine Steel Division – the partner you can trust.

High-quality materials are the basis for our products. We strive to be the best partner for our

customers and want to provide them with the best-possible solution. We focus our expertise

on two aspects:

The personal aspect, with dedicated and highly competent employees

The technical aspect, with high-quality methods, products and services

The companies in the voestalpine Steel Division and their employees understand partnership

to be the following:

Understanding for their customers’ business

Expertise and reliability

Responsibility for satisfactory project completion

Partnerships based on trust

Many years of successful partnerships with our customers prove our point.

voestalpine Grobblech GmbH

voestalpine-Straße 3

4020 Linz, Austria

T. +43/50304/15-9440

F. +43/50304/55-9440

grobblech@voestalpine.com

www.voestalpine.com/grobblech

You might also like

- The Essentials of Material Science and Technology for EngineersFrom EverandThe Essentials of Material Science and Technology for EngineersRating: 5 out of 5 stars5/5 (1)

- Heavy - Plate - TTD - ALDUR 500-960 - EN - 0816Document16 pagesHeavy - Plate - TTD - ALDUR 500-960 - EN - 0816Putra Panca WardhanaNo ratings yet

- Arcelormittal Pressure Vessel PDFDocument10 pagesArcelormittal Pressure Vessel PDFImmanuel SNo ratings yet

- Arcelormittal Pressure VesselDocument12 pagesArcelormittal Pressure VesselAnonymous UoHUagNo ratings yet

- Cast Steel Valve: Service FeaturesDocument1 pageCast Steel Valve: Service FeaturesSasanNo ratings yet

- Histar ASTM A913 Seismic Ncee en PDFDocument10 pagesHistar ASTM A913 Seismic Ncee en PDFGicuNo ratings yet

- Steels For Seismic Applications: Astm A913 Grade 50 and Grade 65Document10 pagesSteels For Seismic Applications: Astm A913 Grade 50 and Grade 65Edwin RamirezNo ratings yet

- SA 387 Grade 91 Class 2Document4 pagesSA 387 Grade 91 Class 2briang-2No ratings yet

- 03 Weglowski Modern Toughened Steels Properties and AdvantagesDocument12 pages03 Weglowski Modern Toughened Steels Properties and AdvantagessudhavelNo ratings yet

- Primacorelw-71 en PDFDocument2 pagesPrimacorelw-71 en PDFsattar12345No ratings yet

- FINAL GRP Catalogue Feb2024 v3Document70 pagesFINAL GRP Catalogue Feb2024 v3Riki AngganaNo ratings yet

- Patrones de Dureza y PenetradoresDocument2 pagesPatrones de Dureza y Penetradoresdanielbo2220No ratings yet

- Dembla Gate ValvesDocument20 pagesDembla Gate ValvesMohit AroraNo ratings yet

- Steel Cleanliness ReportDocument8 pagesSteel Cleanliness ReportSiva SubramaniNo ratings yet

- Voestalpine Heavy Plate TTD ALDUR E 14012013Document13 pagesVoestalpine Heavy Plate TTD ALDUR E 14012013Dragan JerčićNo ratings yet

- Filler Wire For Gtaw PDFDocument27 pagesFiller Wire For Gtaw PDFrezaNo ratings yet

- CONECTOR BURNDY - KSU26 - SpecsheetDocument2 pagesCONECTOR BURNDY - KSU26 - SpecsheetSIMON S. FLORES G.No ratings yet

- Arcelormittal 9 Percent NickelDocument5 pagesArcelormittal 9 Percent NickelAdisak AumpiemNo ratings yet

- Datasheet-Sandvik-254-Smo-En-V2021-04-22 18 - 35 Version 1Document10 pagesDatasheet-Sandvik-254-Smo-En-V2021-04-22 18 - 35 Version 1darioNo ratings yet

- Aws Standards Library Publication Order Form: Publication Number Rev TitleDocument3 pagesAws Standards Library Publication Order Form: Publication Number Rev TitleRafael Torres SabalzaNo ratings yet

- Datasheet 2205 Code Plus Two Hpsa Imperial Outokumpu en Americas PDFDocument6 pagesDatasheet 2205 Code Plus Two Hpsa Imperial Outokumpu en Americas PDFhurduzaNo ratings yet

- BURNDY KSU27 SpecsheetDocument2 pagesBURNDY KSU27 SpecsheetwerehoNo ratings yet

- HT Mobilgear 600 Series EngDocument2 pagesHT Mobilgear 600 Series Engmgamal1080No ratings yet

- AK9ch - АК9ч Aluminium Casting Alloys gost standardDocument2 pagesAK9ch - АК9ч Aluminium Casting Alloys gost standardVivek GoudNo ratings yet

- Automig 90S-G / Tigfil 90S-G: Classification: ApprovalsDocument1 pageAutomig 90S-G / Tigfil 90S-G: Classification: ApprovalsJagannath SahuNo ratings yet

- A525-79 11770Document10 pagesA525-79 11770Oscar ÁlvarezNo ratings yet

- Astm A928Document6 pagesAstm A928iuiuiooiuNo ratings yet

- Saer 5974 PDFDocument31 pagesSaer 5974 PDFZhiguo YangNo ratings yet

- Coefficient of Friction PDFDocument8 pagesCoefficient of Friction PDFWaris La Joi WakatobiNo ratings yet

- Wire Electrode ShipbuildingDocument30 pagesWire Electrode ShipbuildingMuhammad BaqiNo ratings yet

- 2205 InfoDocument6 pages2205 InfoMave75No ratings yet

- Heavy Plates CapabilitiesDocument26 pagesHeavy Plates Capabilitieswindsurferke007No ratings yet

- Series Description: Universal Product Line: Steel Externals - Jacketed PumpsDocument9 pagesSeries Description: Universal Product Line: Steel Externals - Jacketed PumpsAnonymous uCYIu1No ratings yet

- Duplex-Alloy-2205-Stress ValuesDocument5 pagesDuplex-Alloy-2205-Stress ValuesShiniNo ratings yet

- Bohler GradesDocument19 pagesBohler GradesYudistira IjoNo ratings yet

- Piping FabricationDocument36 pagesPiping FabricationMouchartStéphanieNo ratings yet

- Alform 620-1100 Grobblech TLB EN 1401Document16 pagesAlform 620-1100 Grobblech TLB EN 1401Bui Chi TamNo ratings yet

- Roof Panels Series 2500Document2 pagesRoof Panels Series 2500miguelq_scribdNo ratings yet

- Worm Gear - KHKDocument9 pagesWorm Gear - KHKMarco ViniciusNo ratings yet

- AL-6XN SourcebookDocument59 pagesAL-6XN SourcebooklkrzyzanNo ratings yet

- Ficha Tecnica Astm 514Document1 pageFicha Tecnica Astm 514Ruben Dario Mamani ArellanoNo ratings yet

- Corrosion Resistant A890 SulzerDocument6 pagesCorrosion Resistant A890 SulzerwkfilhoNo ratings yet

- S690QLDocument4 pagesS690QLReginaldo Matias NunesNo ratings yet

- LNG Tank FabricationDocument1 pageLNG Tank FabricationtndeshmukhNo ratings yet

- ASME II A 1 (2015) .PDF ExtractDocument7 pagesASME II A 1 (2015) .PDF ExtractPedro Montes Marin100% (1)

- fm82 1Document1 pagefm82 1harikrishnanNo ratings yet

- Inconel 82 PDFDocument1 pageInconel 82 PDFMiguel MorenoNo ratings yet

- Cold Rolled SteelpdfDocument16 pagesCold Rolled Steelpdfimrahim07No ratings yet

- A684A684M-14 Standard Specification For Steel, Strip, High-Carbon, Cold-RolledDocument10 pagesA684A684M-14 Standard Specification For Steel, Strip, High-Carbon, Cold-Rolledtjt4779100% (1)

- Cast Steel Is EquivalentDocument15 pagesCast Steel Is EquivalentParmasamy SubramaniNo ratings yet

- Primacore MW 71Document2 pagesPrimacore MW 71rjan7peNo ratings yet

- Cladding & Overlay - Ni InstituteDocument24 pagesCladding & Overlay - Ni Institutesajid aslamNo ratings yet

- Casting Material CE3MN SS2507Document3 pagesCasting Material CE3MN SS2507dkaranthsNo ratings yet

- Sa 36Document4 pagesSa 36edisson_barreraNo ratings yet

- Stainless Steel Grade 630Document6 pagesStainless Steel Grade 630mazaher.ramazaniNo ratings yet

- 08 14 13 Awwa C300 FinalDocument16 pages08 14 13 Awwa C300 FinalsuronocaturatmojoNo ratings yet

- f6nm PDFDocument5 pagesf6nm PDFasprclms durgapur100% (1)

- Copper and Copper Alloy Ingots and CastingsDocument2 pagesCopper and Copper Alloy Ingots and CastingspoopNo ratings yet

- CST ArcelorDocument20 pagesCST ArcelorSuvro ChakrabortyNo ratings yet

- MTS3000 Equipo Hole DrillingDocument2 pagesMTS3000 Equipo Hole DrillingEdwin RodriguezNo ratings yet

- Datos Prueba Strain GageDocument4 pagesDatos Prueba Strain GageEdwin RodriguezNo ratings yet

- Carbon EpoxyDocument22 pagesCarbon EpoxyEdwin RodriguezNo ratings yet

- Hole Drilling TechniqueDocument49 pagesHole Drilling TechniqueEdwin RodriguezNo ratings yet

- Stress Analysis XRDDocument27 pagesStress Analysis XRDEdwin RodriguezNo ratings yet

- Process of Jewelry Manufacturing - CastingDocument3 pagesProcess of Jewelry Manufacturing - CastingS Sonia100% (1)

- Bobst PDFDocument52 pagesBobst PDFAbdul BasitNo ratings yet

- CNC ReportDocument39 pagesCNC Reportrasaiya69% (13)

- Processing The DentureDocument8 pagesProcessing The DentureMody ShaheenNo ratings yet

- Brochure Tjs BBPP 2012Document8 pagesBrochure Tjs BBPP 2012ValentVeeNo ratings yet

- DW Uhp UsDocument9 pagesDW Uhp UsnotengofffNo ratings yet

- PDS M365Document2 pagesPDS M365prabhunmayNo ratings yet

- EKS - Feburary 2023 - 570 - FinalDocument2 pagesEKS - Feburary 2023 - 570 - FinalMONEY WEALTH HUBNo ratings yet

- Edco Incinerator Plant 2: Refractory Lining at IncineraterDocument1 pageEdco Incinerator Plant 2: Refractory Lining at IncineraterNic RicNo ratings yet

- What Is Draft AllowanceDocument3 pagesWhat Is Draft AllowanceAshok Pradhan100% (3)

- Hydraulic Seal Identification ChartDocument29 pagesHydraulic Seal Identification ChartAnonymous K6mLK72AaNo ratings yet

- Xcesx:: Stainless Steel Explosionproof Control EnclosuresDocument4 pagesXcesx:: Stainless Steel Explosionproof Control EnclosuresOcktafriandi HendraNo ratings yet

- Commercial Bid FormDocument68 pagesCommercial Bid FormKasarachi AmadiNo ratings yet

- Purification by Fractional Distillation - Crystallisation (Theory) - Organic Chemistry Virtual Lab - Chemical Sciences - Amrita Vishwa Vidyapeetham Virtual LabDocument2 pagesPurification by Fractional Distillation - Crystallisation (Theory) - Organic Chemistry Virtual Lab - Chemical Sciences - Amrita Vishwa Vidyapeetham Virtual LabParth AnadkatNo ratings yet

- AMT - Course PlanDocument4 pagesAMT - Course PlanKvs PhaniNo ratings yet

- Reacting Gas MixturesDocument2 pagesReacting Gas MixturesAxel Flores GonzalezNo ratings yet

- Pigging Training Course Mod 5 Rev 1Document46 pagesPigging Training Course Mod 5 Rev 1Suparerk SirivedinNo ratings yet

- How To Size An IBM MachineDocument1 pageHow To Size An IBM MachineFaisal AftabNo ratings yet

- Material Kapal Bki Wi Ui AlimsaadiDocument12 pagesMaterial Kapal Bki Wi Ui AlimsaadiSaadi AlimNo ratings yet

- Food Fish Processing 10-Q2-Week 2Document10 pagesFood Fish Processing 10-Q2-Week 2IlY-MyraTorresDeJesusNo ratings yet

- MS Masterflex 700Document3 pagesMS Masterflex 700Ajit Singh RathoreNo ratings yet

- Lime As Building MaterialDocument11 pagesLime As Building MaterialManshaNo ratings yet

- Tool and Cutter PDFDocument15 pagesTool and Cutter PDFKiwishooter50% (4)

- DHP Product Information Sheet EXPAND O LIZER BSDocument2 pagesDHP Product Information Sheet EXPAND O LIZER BSyelena-sNo ratings yet

- Factors Influencing The Grinding EfficiencyDocument27 pagesFactors Influencing The Grinding Efficiencynoelbaba71100% (1)

- 20MVA TransformerDocument12 pages20MVA TransformerMehul PatelNo ratings yet

- Crane SpecififctaionDocument2 pagesCrane SpecififctaionGandhi elumalaiNo ratings yet

- Section 06400 Architectural WoodworkDocument13 pagesSection 06400 Architectural WoodworkMØhãmmed ØwięsNo ratings yet

- AWS SWPS MatrixDocument12 pagesAWS SWPS MatrixMalcolm DiamondNo ratings yet

- SMP PPT No. 32 - Paint and Pigments - Vadivel RajaDocument11 pagesSMP PPT No. 32 - Paint and Pigments - Vadivel Rajaraja kundiiNo ratings yet