Professional Documents

Culture Documents

S5 Cyl. Head Repair Flowchart

Uploaded by

CARLOS A.N. LANZILLOTTOCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

S5 Cyl. Head Repair Flowchart

Uploaded by

CARLOS A.N. LANZILLOTTOCopyright:

Available Formats

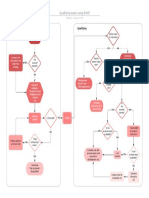

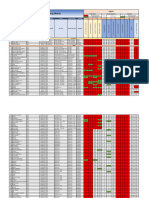

VHP Series 5 Cylinder Head (and S4 Xcooled) Repair Flowchart

Exterran’s Workshop External Workshop

YES

Is the head free of catastrophic

Workshkop reception Head reception & Visual control

damage

Head reception B

NO

Cleanning & delivery to Exterran’s

Head Dissasembly

workshop

B

A Head preliminary Cleaning

Repair the oil feed hole

(If necessary)

NO

Did the head casting pass Clean and dry

the visuals & dimensional controls C

YES NO

Did the head pass

Repair with Hall Toledo EDP

the Round Out test?

Remove plugs and repair any damage

threaded holes (If necessary)

YES

NO YES Did the head casting pass

Did the valve

the visuals & dimensional controls

bridges pins pass dimensional Replace vlave bridge guide pins

inspection?

NO

YES

Prussian Blue test to ensure proper valve

seat

YES

Recondition firedeck and/or oversize

Do they have

Install valves, springs, plates, rotators & C enough material to recondition?

seat pockets and/or guide bore to

retainers approved dimensions

Install new appropiate size guides, valve

bridge guides and seats A

NO

Clean to meet the cleanliness

requirement

Install new NPT plugs (If it necessary)

NO

YES

A

Marks as being requalified

A

Did the head pass

Install the spark plug slevee and flange

the leak test?

Apply a surface protection, paint and

package The head does not pass requalification

NO

Troubleshoot any tooling leakage if

Did the head pass

plugs, sparl plug sleeve, valve seat, or

the leak test?

other casting sections area leaking

Scrap protocol

Delivery to customer

YES

Last Revision Rev #

Documents printed from an electronic system are not controlled.

Pag. 1

Phase

© EXTERRAN All rights reserved.

07/21/2022 1

REFERENCIAS

xx Comienzo / FIN

Documento

XX

Asociado

xx Subproceso

XX Puesto responsable

Last Revision Rev #

Documents printed from an electronic system are not controlled.

Pag. 2

© EXTERRAN All rights reserved.

XX Mes 20XX 1

You might also like

- Discover the training secrets of legendary bodybuildersDocument129 pagesDiscover the training secrets of legendary bodybuildersfatmir100% (7)

- Chapter III Pharmacokinetics: Durge Raj GhalanDocument64 pagesChapter III Pharmacokinetics: Durge Raj GhalanDurge Raj Ghalan100% (3)

- Nissan Paint Film Quality Standard for Plastic and Chrome PartsDocument14 pagesNissan Paint Film Quality Standard for Plastic and Chrome PartsCARLOS A.N. LANZILLOTTO100% (1)

- STD-02-0860 Rev 5.0 Part Cleanliness StandardDocument8 pagesSTD-02-0860 Rev 5.0 Part Cleanliness StandardCARLOS A.N. LANZILLOTTONo ratings yet

- Unipack II ManualDocument30 pagesUnipack II ManualMarijaŽaper67% (3)

- Drug study on TegretolDocument2 pagesDrug study on TegretolSophia Kaye AguinaldoNo ratings yet

- Oil Record Book InstructionsDocument6 pagesOil Record Book InstructionsNamal Fernando100% (1)

- 1 Processs Flow Diagram - Lessons LearnedDocument2 pages1 Processs Flow Diagram - Lessons LearnedishuaibNo ratings yet

- Pharaoh Cabinet Upper PDFDocument6 pagesPharaoh Cabinet Upper PDFzokiNo ratings yet

- Pipe Rack Pipe RackDocument1 pagePipe Rack Pipe RackRandi Ka MartaNo ratings yet

- 35 1207000 BLDocument1 page35 1207000 BLmikeNo ratings yet

- Floor plan layout with room labelsDocument1 pageFloor plan layout with room labelsRyan Cecilio AlbanielNo ratings yet

- Base Soil: Existing Beam 0.6m TK Existing Footing 0.85mDocument1 pageBase Soil: Existing Beam 0.6m TK Existing Footing 0.85mBhavanishankar shettyNo ratings yet

- Full - Final - Development That - Pays - Review PDFDocument9 pagesFull - Final - Development That - Pays - Review PDFManishNo ratings yet

- L06 - HQ OfficesDocument1 pageL06 - HQ OfficesDaveNo ratings yet

- Assembly 1Document1 pageAssembly 1lickmikehuntNo ratings yet

- Second Floor: Equipment Storage Trailer Loading and UnloadingDocument1 pageSecond Floor: Equipment Storage Trailer Loading and UnloadingDalton HigdonNo ratings yet

- H130 76-10526-Detail Design: Drainage - Level 2 Part 1Document1 pageH130 76-10526-Detail Design: Drainage - Level 2 Part 1Mazen IsmailNo ratings yet

- Microwave Brochure 2017 PDFDocument6 pagesMicrowave Brochure 2017 PDFiqadin0% (1)

- Dry Cooler Outdoor Installation: 200-5775-CV-201 Overland Conveyor #1 Length: 6515m Lift: 146m Power: 2 X 6000kWDocument1 pageDry Cooler Outdoor Installation: 200-5775-CV-201 Overland Conveyor #1 Length: 6515m Lift: 146m Power: 2 X 6000kWRavenShieldXNo ratings yet

- Untitled Spreadsheet - Sheet2Document1 pageUntitled Spreadsheet - Sheet2khaled ahmedNo ratings yet

- Oil Cooler - As Built-ModelDocument1 pageOil Cooler - As Built-ModelbasvkaranNo ratings yet

- Rachelle Shipley - Portfolio 2018 GenDocument28 pagesRachelle Shipley - Portfolio 2018 GenRachelle ShipleyNo ratings yet

- Autodesk Educational Product DocumentDocument1 pageAutodesk Educational Product DocumentRuana MeloNo ratings yet

- Rev ADocument10 pagesRev Aalexis cruz pradoNo ratings yet

- 01 Anti-Collision Workflow Poster 28-Sep-05Document2 pages01 Anti-Collision Workflow Poster 28-Sep-05Anonymous VNu3ODGavNo ratings yet

- 560 000 ST S 001 - 1 PDFDocument1 page560 000 ST S 001 - 1 PDFJohan Carranza AlvarezNo ratings yet

- MagenDocument1 pageMagenHirushan MenukaNo ratings yet

- Klaidu Kodai EnerconDocument7 pagesKlaidu Kodai EnerconLiteximNo ratings yet

- Chidambar - Approval PlanDocument1 pageChidambar - Approval PlanBHARATH KUMARNo ratings yet

- Proposed GF and FF plan of residential buildingDocument1 pageProposed GF and FF plan of residential buildingBHARATH KUMARNo ratings yet

- Key Plan NotesDocument1 pageKey Plan NotesMazen IsmailNo ratings yet

- Maple Homes BrochureDocument6 pagesMaple Homes BrochurerajuwithualwaysNo ratings yet

- You Are Best Teacher of The YearDocument5 pagesYou Are Best Teacher of The YearabhijeetbishnoiNo ratings yet

- ShaftDocument1 pageShaftgmNo ratings yet

- Havells Fans CatalogueDocument91 pagesHavells Fans CatalogueRaghava SrinidhiNo ratings yet

- Plano de Ubicación: Bocatoma IpalDocument1 pagePlano de Ubicación: Bocatoma IpalErixonNo ratings yet

- Amotcontrols ManualDocument16 pagesAmotcontrols ManualIvaylo IvanovNo ratings yet

- School of Nursing DetailsDocument1 pageSchool of Nursing DetailsMohamed Abdi HassanNo ratings yet

- E Brochure CRDDocument4 pagesE Brochure CRDplzmeetmeNo ratings yet

- LB BL1 (L1) R0Document5 pagesLB BL1 (L1) R0ridwan wilujengNo ratings yet

- Y JunctionDocument1 pageY JunctionAjay KunduNo ratings yet

- All About That BassDocument3 pagesAll About That BassJohn Manuel Restrepo RuedaNo ratings yet

- BdcastlegatemenuDocument2 pagesBdcastlegatemenupeperkompNo ratings yet

- Repairing ProcedureDocument1 pageRepairing ProcedureYahya ALMaawaliNo ratings yet

- Tampak Depan NewjjjbbbDocument1 pageTampak Depan Newjjjbbbahmad fauziNo ratings yet

- Chemistry PT1 (A, C, D)Document24 pagesChemistry PT1 (A, C, D)lorddevil1909No ratings yet

- SULAIRmap09-10 DBLSDDocument2 pagesSULAIRmap09-10 DBLSDeleanor_brown1372No ratings yet

- Case Wearing DE & NDEDocument1 pageCase Wearing DE & NDEDanil AdityaNo ratings yet

- Varsity Ville Storage House-1Document1 pageVarsity Ville Storage House-1Michael KiwingaNo ratings yet

- 2696-1-001 Location PlanDocument1 page2696-1-001 Location PlanJim GooseNo ratings yet

- Joint Pipe Intercooler Hose - 1Document1 pageJoint Pipe Intercooler Hose - 1Perkasa EngineeringNo ratings yet

- Lead Qualification Using BANTDocument1 pageLead Qualification Using BANTNAIK ABHISHEKNo ratings yet

- 33kV Standard DrawingDocument15 pages33kV Standard DrawingsheshidharrajubNo ratings yet

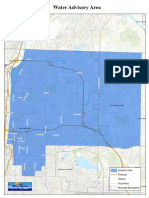

- Water Advisory AreaDocument1 pageWater Advisory AreaWXMINo ratings yet

- Installation Instruction: SPT Pro - ProfileDocument4 pagesInstallation Instruction: SPT Pro - ProfileAntoni WangNo ratings yet

- Ceiling PlanDocument1 pageCeiling PlanNehemiah KoechNo ratings yet

- Master of FPJO Internal Training MatrixDocument30 pagesMaster of FPJO Internal Training MatrixTraining DepartmentNo ratings yet

- Bp2021-C026s-Jwn-A01-Drainage System-Dl-1001-Standard Details-1Document1 pageBp2021-C026s-Jwn-A01-Drainage System-Dl-1001-Standard Details-1Mohammad IsmailNo ratings yet

- Office layout plan front and side viewsDocument1 pageOffice layout plan front and side viewsjohan WijayaNo ratings yet

- Key Plan for Reinforced Concrete StructureDocument1 pageKey Plan for Reinforced Concrete StructureZahangir AlamNo ratings yet

- Superelevation DiagramsDocument1 pageSuperelevation DiagramsTapasNo ratings yet

- IPP 11255 R190 OverallDocument1 pageIPP 11255 R190 OverallAndrew GoadNo ratings yet

- Slab DetailsDocument1 pageSlab Detailshomitech LEBANONNo ratings yet

- Map of Stanford LibrariesDocument2 pagesMap of Stanford LibrariesgreeninfocenterNo ratings yet

- RI Manual of ProcedureDocument80 pagesRI Manual of ProcedureCARLOS A.N. LANZILLOTTONo ratings yet

- Code of Policies Rotary International enDocument499 pagesCode of Policies Rotary International enCARLOS A.N. LANZILLOTTONo ratings yet

- Tier 4 I E E A I Manual C4.4 To C 7.1 Industrial Products TPD1726E1Document29 pagesTier 4 I E E A I Manual C4.4 To C 7.1 Industrial Products TPD1726E1EduardoCastilloNo ratings yet

- Prominence of Hadfield Steel in Mining and MineralDocument9 pagesProminence of Hadfield Steel in Mining and MineralCARLOS A.N. LANZILLOTTONo ratings yet

- Paint Film Quality of Plastic Parts and Chrome Plated Parts: M5081 - 2018-N Nissan Engineering StandardDocument14 pagesPaint Film Quality of Plastic Parts and Chrome Plated Parts: M5081 - 2018-N Nissan Engineering StandardCARLOS A.N. LANZILLOTTONo ratings yet

- Beginning Algebra 9th Edition Tobey Solutions Manual 1Document39 pagesBeginning Algebra 9th Edition Tobey Solutions Manual 1kyle100% (30)

- A Study On Satisfaction Level of Employees With Special Reference Textile IndustryDocument12 pagesA Study On Satisfaction Level of Employees With Special Reference Textile Industrysai kiran bade100% (1)

- Group 3Document11 pagesGroup 3Sharp MIER TVNo ratings yet

- Midterm Exam Reviewer: Surgical Handwashing QuizDocument9 pagesMidterm Exam Reviewer: Surgical Handwashing QuizOfficially RandomNo ratings yet

- 0210 Pop Labels BSDocument1 page0210 Pop Labels BSThe London Free PressNo ratings yet

- Wartsila Tribo PackDocument7 pagesWartsila Tribo Packsuper_seeker100% (1)

- Chapter 8Document8 pagesChapter 8Melissa NagyNo ratings yet

- The Electrooculogram (EOG)Document34 pagesThe Electrooculogram (EOG)Prasidha PrabhuNo ratings yet

- Ecl7000 enDocument2 pagesEcl7000 ensuchaya tupyangNo ratings yet

- HN E-Catalog CableDocument36 pagesHN E-Catalog CableMin Min AungNo ratings yet

- Urban Heat Island effect document answersDocument4 pagesUrban Heat Island effect document answersAlainDelonTahilLanaNo ratings yet

- Rakovic Dejan - Arandjelovic Slavica - Micovic Mirjana - Quantum-Informational Medicine QIM 2011 PDFDocument150 pagesRakovic Dejan - Arandjelovic Slavica - Micovic Mirjana - Quantum-Informational Medicine QIM 2011 PDFPrahovoNo ratings yet

- Planet X Restaurant Menu v2Document5 pagesPlanet X Restaurant Menu v2Chinthaka WilliamsNo ratings yet

- Fire Prevention and Response Plan for Greenergie PlantDocument8 pagesFire Prevention and Response Plan for Greenergie PlantMelba MangabatNo ratings yet

- Oet Listening 1Document9 pagesOet Listening 1English Around The WorldNo ratings yet

- M 200Document3 pagesM 200Rafael Capunpon VallejosNo ratings yet

- 465 886 1 SMDocument8 pages465 886 1 SM17Annisa Muthmainnah067No ratings yet

- Reactor & Impeller Design in Hydrogenation: GBHE Technical Bulletin CTB #79Document13 pagesReactor & Impeller Design in Hydrogenation: GBHE Technical Bulletin CTB #79manuNo ratings yet

- Jear C PB 2018 PDFDocument174 pagesJear C PB 2018 PDFArasu RajendranNo ratings yet

- The Suitcase ProjectDocument27 pagesThe Suitcase Projectshubhamkumar9211No ratings yet

- Blood Bank Case Study 5bDocument2 pagesBlood Bank Case Study 5bbalqis jaberNo ratings yet

- Ecosystem Components and InteractionsDocument31 pagesEcosystem Components and InteractionsBirraa TajuNo ratings yet

- Public Stormwater Management With Green StreetsDocument90 pagesPublic Stormwater Management With Green StreetsPranay ManwarNo ratings yet

- Concrete Pump Hose TDSDocument2 pagesConcrete Pump Hose TDSAlaa Abu KhurjNo ratings yet

- Mutual Funds: Rajinder S Aurora PHD Professor in FinanceDocument33 pagesMutual Funds: Rajinder S Aurora PHD Professor in FinanceRahulJainNo ratings yet