Professional Documents

Culture Documents

Steel Beam Design As Per AISC ASD

Uploaded by

mohsen0 ratings0% found this document useful (0 votes)

28 views3 pagesOriginal Title

Steel Beam Design as Per AISC ASD

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

28 views3 pagesSteel Beam Design As Per AISC ASD

Uploaded by

mohsenCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 3

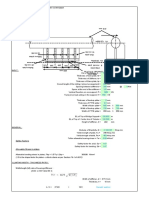

Steel Beam Design as per AISC ASD - 89

AISC Section Properties Beam W8x24

d 7.930 Inch

bf 6.500 Inch

tf 0.400 Inch

tw 0.245 Inch

Sx 20.900 Inch3

Sy 5.630 Inch3

Ix 82.700 Inch4

Iy 18.300 Inch4

rt 1.760 Inch

Ax 7.080 Inch2

rx 3.420 Inch

ry 1.610 Inch

Material Properties

Modulus of Elasticity of steel E 29000.000 Ksi

Yeild Stress Fy 36.000 Ksi

Ultimate tensile strength Fu 58.000 Ksi

Span Data

Unsupported Span Lb 10.000 Ft

Length for slenderness Lx 10.000 Ft

Length for slenderness Lz 10.000 Ft

Loading Data from Staad

Applied Moment about X - Axis Mx (Mz in staad) 46.210 Kip-Ft

Applied Moment about Y - Axis My 0.030 Kip-Ft

Axial Load fx 28.700 Kips

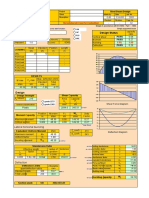

Check for Slenderness

K 1.000

Lx/rx 35.088

Ly/ry 74.534

Pass in Slenderness

Computed Stresses

Bending Stress @ X- Axis fbx = Mx / Sx 26.532 Ksi

Bending Stress @ Y- Axis fby = My / Sy 0.064 Ksi

Axial Stress fa= Fx/Ax 4.054 Ksi

Calculation Of Allowable Bending Stresses (Fb)

Limiting Width Thickness Ratio bf/tf 8.125 < 10.83333

Section is Compact

Critical Unbraced Length Lc1= 76bf / fy0.5 82.333

Lc2 = 20000 / (( d / Af ) fy )) 182.149 Inch

Lc = min( Lc1:Lc2) Lc 82.333 Inch

Lb > Lc

Lb/rt 68.182

319.374( Cb / fy)0.5 < lb/rt < 714.143( Cb / fy)0.5 Eq- 1

319.374( Cb / fy)0.5 < lb/rt > 714.143( Cb / fy)0.5 Eq-2

Cb 1.000

319.374( Cb / Fy)0.5 53.229

714.143( Cb / Fy) 0.5

119.024

Lb/rt 68.182

lb/rt Satifying Eq-1

Fbx =(2/3 - Fy ( lb/rt )2 / 1530000Cb ) )Fy;

Allowable Bending Stress @ X- Axis 170x103Cb/(lb/rt)2 20.062 Ksi

For any value of l/rt Fbx =12000Cb Af / (lb*d) 21.600 Ksi

Selected Allowable Bending Stress @ X-Axis Fbx = 21.600 Ksi

Max allowable Bending Stress @ Y-Axis Fby = 0.75 Fy 27.000 Ksi

Min allowable Bending Stress @ Y-Axis Fby = 0.6 Fy 21.600 Ksi

Calculated allowable Bending Stress @ Y-Axis Fby = Fy (1.075 - 0.005bf Fy0.5 / 2tf ) 29.925 Ksi

Selected allowable Bending Stress @ Y-Axis Fby = 27.000 Ksi

Calculation Of Allowable Axial Stresses (Fa)

Critical Klb/r 74.534

Cc = (2 p 2 E / Fy) 0.5 126.150

KL/r is Less than Cc

Fa = Fy ( 1 - 0.5 * ( Lb / r * Cc)2 /(1.667 + 0.375 * Lb / r * Cc - 0.125 * ( Lb / r *

Allowable Stress Cc )3); (12 p2 E/Fy)0.5

Allowable Axial Stress Fa= 15.956 < 0.7Fy

Interaction Checking

fa/Fa 0.254

Interaction Checking 1.485 (Eq H1-3)

fa/Fa + Cmxfbx/(1-fa/Fex)Fbx + Cmyfby/(1-fa/fey)Fby < 1.0 (Eq H1-1)

fa/0.6Fy + fbx/Fbx + fby/Fby < 1.0 (Eq H1-2)

fa/Fa + fbx/Fbx + fby/Fby < 1.0 (Eq H1-3)

For Restrained against rotation Cmx,y = 0.850

fex = 12*p *E / ( 23*Lex / rx )

2 2

121.392

fey=12*p *E / ( 23*Ley / ry )

2 2

26.902

Interaction Checking 1.337 (Eq H1-1)

Interaction Checking 1.418 (Eq H1-2)

Govering Stress Ratio 1.48 (Eq H1-3)

You might also like

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsFrom EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNo ratings yet

- Hilti Bolt Connection-6 anchor-HSTDocument5 pagesHilti Bolt Connection-6 anchor-HSTTuấnThanhNo ratings yet

- Pipe Rack Foundation DesignDocument29 pagesPipe Rack Foundation DesignYatendra TyagiNo ratings yet

- Column Effective LengthDocument1 pageColumn Effective LengthjanethNo ratings yet

- Steel Grating AnalysisDocument17 pagesSteel Grating AnalysisDhanraj VasanthNo ratings yet

- Structural Steelwork Connections: Bolted Gusset Plate Connection For Truss B.S. 5950 Part 1 Calculations & ScketchesDocument4 pagesStructural Steelwork Connections: Bolted Gusset Plate Connection For Truss B.S. 5950 Part 1 Calculations & ScketchessitheeqNo ratings yet

- Base Plate DesignDocument19 pagesBase Plate DesignLeah Ann ManuelNo ratings yet

- Stability CritariaDocument9 pagesStability CritariaAbu Bakar Siddke RumiNo ratings yet

- Calculation of No. of Bolts For Individual Members Bolt DiameterDocument1 pageCalculation of No. of Bolts For Individual Members Bolt DiametercharanNo ratings yet

- Turkey temporary facility pedestal designDocument23 pagesTurkey temporary facility pedestal designMyunSu GooNo ratings yet

- Deck Girder - Top GirderDocument3 pagesDeck Girder - Top GirdervibishnanNo ratings yet

- M1 195 C195 AO34-4-07-X00-MC-0-DD-S164: (MM) (MM) (MM) (MM) (MM) (MM)Document2 pagesM1 195 C195 AO34-4-07-X00-MC-0-DD-S164: (MM) (MM) (MM) (MM) (MM) (MM)innovativekarthiNo ratings yet

- Lashing FormulaDocument1 pageLashing FormulaMuhammad FitrahNo ratings yet

- Bearing CheckDocument6 pagesBearing CheckdhanushkaNo ratings yet

- Design Base Plate For I Beam - Bottom BracketDocument1 pageDesign Base Plate For I Beam - Bottom BracketCon CanNo ratings yet

- Pad Eye DesignDocument2 pagesPad Eye DesignREYNo ratings yet

- Padeye Design Cheekxls CompressDocument3 pagesPadeye Design Cheekxls CompressDixon Antonio MaradiagaNo ratings yet

- Design of ring foundation for 18m diameter tankDocument6 pagesDesign of ring foundation for 18m diameter tankSher AfganNo ratings yet

- Ulitization Ratio:: Check Bolt Bearing CapacityDocument1 pageUlitization Ratio:: Check Bolt Bearing CapacitySkylerYuanNo ratings yet

- Loadings and structural analysis of buildingDocument38 pagesLoadings and structural analysis of buildingarif_rubinNo ratings yet

- MOMENT CONNECTION-AISC-extended-r5Document24 pagesMOMENT CONNECTION-AISC-extended-r5raghav abudhabi0% (1)

- Derbyshire loss section modulus calculationsDocument2 pagesDerbyshire loss section modulus calculationsdakidofdaboomNo ratings yet

- API 650 Pipe Column DesignDocument4 pagesAPI 650 Pipe Column DesignJoselito CalagosNo ratings yet

- Annex A:Lifting Lug CalculationDocument3 pagesAnnex A:Lifting Lug CalculationVilas AndhaleNo ratings yet

- Controlling Forces Wind FactorDocument3 pagesControlling Forces Wind FactorRajib MaharjanNo ratings yet

- MSF Bridge Support Stiffener DesignDocument7 pagesMSF Bridge Support Stiffener DesignSai SushankNo ratings yet

- Effective Length CalculationDocument15 pagesEffective Length CalculationUMER AZIQNo ratings yet

- Design of Cantilever Slab As Per Is 456 2000Document2 pagesDesign of Cantilever Slab As Per Is 456 2000dhanasekaran33% (3)

- DESIGN OF PLATE GIRDERS USING IS:800-2007Document45 pagesDESIGN OF PLATE GIRDERS USING IS:800-2007Afia S HameedNo ratings yet

- RCC DESIGN OF CANTILEVER CHAJJADocument32 pagesRCC DESIGN OF CANTILEVER CHAJJAjaffnaNo ratings yet

- PadeyeDocument14 pagesPadeyeMarshall Minggat AmpiNo ratings yet

- Vessel Side Shell Check CalculationsDocument5 pagesVessel Side Shell Check CalculationsShahir MeledathNo ratings yet

- Calculations of hoop bar diameter for columns according to ductile detailingDocument1 pageCalculations of hoop bar diameter for columns according to ductile detailingRahul AggarwalNo ratings yet

- Brgplt9-Beam Bearing Plate DesignDocument4 pagesBrgplt9-Beam Bearing Plate DesignRafael ReyesNo ratings yet

- Store Steel Structure Analysis & DesignDocument12 pagesStore Steel Structure Analysis & DesignAnonymous T7v17KhnwcNo ratings yet

- Connection design shear and tension capacityDocument1 pageConnection design shear and tension capacitySuman NakarmiNo ratings yet

- Repport Steel Structure PDFDocument111 pagesRepport Steel Structure PDFAnonymous fxqnhfKNo ratings yet

- Retaining wall design calculationsDocument13 pagesRetaining wall design calculationsHanafiahHamzahNo ratings yet

- DmTank Ring Wall Foundation+&+Annular+RaftDocument4 pagesDmTank Ring Wall Foundation+&+Annular+RaftAtul WanodeNo ratings yet

- 03 Section 2 Example Bridge (E)Document11 pages03 Section 2 Example Bridge (E)Diego Benavides KNo ratings yet

- Project: Cgmppharma Column Stirrup CalculationDocument4 pagesProject: Cgmppharma Column Stirrup CalculationumarNo ratings yet

- Fentek Marine Systems: Project TitleDocument6 pagesFentek Marine Systems: Project TitleTeo Keng ChauNo ratings yet

- Cranebeam v1 2 AramadaDocument1 pageCranebeam v1 2 AramadaronyNo ratings yet

- (Joint 1760) : PT - Technip IndonesiaDocument12 pages(Joint 1760) : PT - Technip IndonesiariandiNo ratings yet

- IS 456 Fig 4: y S T Req. T Prov. T 2 2Document23 pagesIS 456 Fig 4: y S T Req. T Prov. T 2 2Rahul Aggarwal100% (1)

- BasePlate 1 Check 46.8TDocument63 pagesBasePlate 1 Check 46.8TrustamriyadiNo ratings yet

- Substructure Final PDFDocument34 pagesSubstructure Final PDFSushmit Sharma100% (1)

- Determine The Bearing Plate DimensionsDocument9 pagesDetermine The Bearing Plate DimensionsNiranjan ShresthaNo ratings yet

- Daniel Tian Li: Simply Supported Beam Design With Torsional Loading Based On AISC 13th (AISC 360-05)Document11 pagesDaniel Tian Li: Simply Supported Beam Design With Torsional Loading Based On AISC 13th (AISC 360-05)Nabil YassarNo ratings yet

- Design of Plate GirdersDocument30 pagesDesign of Plate GirdersTHULASI MNo ratings yet

- HSS Flange Plate Moment Connection - Temporary SteelDocument9 pagesHSS Flange Plate Moment Connection - Temporary SteelrajedmaglinteNo ratings yet

- 3.5 POT Weld Length - 600mmDocument1 page3.5 POT Weld Length - 600mmSantosh ZunjarNo ratings yet

- Embedded PlateDocument2 pagesEmbedded PlateAlma M. LaraNo ratings yet

- X Y and Partners: Steel Beam DesignDocument35 pagesX Y and Partners: Steel Beam DesignAndré SantosNo ratings yet

- Pedestal DesignDocument11 pagesPedestal DesignNikhil TawadeNo ratings yet

- Wind Pressure Calculation As per SP-1275Document7 pagesWind Pressure Calculation As per SP-1275Siva baalanNo ratings yet

- Braking Test: Vehicle Laboratory 2Document20 pagesBraking Test: Vehicle Laboratory 2Steven SullivanNo ratings yet

- Pile Cap DimensionsDocument13 pagesPile Cap DimensionsEr Navneet JassiNo ratings yet

- ECCENTRICALLY LOADED WELD GROUP ANALYSISDocument11 pagesECCENTRICALLY LOADED WELD GROUP ANALYSISSneyder NeyNo ratings yet

- Flexible Pavement Design - Page 1Document1 pageFlexible Pavement Design - Page 1RigonDECNo ratings yet

- Rectangular Spread Footing Design CalculationsDocument11 pagesRectangular Spread Footing Design CalculationspravinNo ratings yet

- Eurocode 1 Perfectionnement. Combinaiso... T, MétalDocument33 pagesEurocode 1 Perfectionnement. Combinaiso... T, MétalmohsenNo ratings yet

- A Simplified Approach For Analysis and ..Document18 pagesA Simplified Approach For Analysis and ..mohsenNo ratings yet

- Wind Load Calculation SummaryDocument5 pagesWind Load Calculation SummaryRigonDECNo ratings yet

- Axial Force AfDocument37 pagesAxial Force AfmohsenNo ratings yet

- Taxonomy With Ids - en USDocument124 pagesTaxonomy With Ids - en USSuman KumarNo ratings yet

- Oil Storage Tank Foundation DesignDocument5 pagesOil Storage Tank Foundation Designsugianto100% (2)

- Wind Load Calculation SummaryDocument5 pagesWind Load Calculation SummaryRigonDECNo ratings yet

- Oracle Hyperion Epm System Certific 131801Document142 pagesOracle Hyperion Epm System Certific 131801mohsenNo ratings yet

- Program For Combined Foundation Design With PilesDocument15 pagesProgram For Combined Foundation Design With PilesAbhay ThakurNo ratings yet

- RC Elements Analysis & Design ProjectDocument51 pagesRC Elements Analysis & Design ProjectAbhay YadavNo ratings yet

- Crack Width CalculationDocument3 pagesCrack Width CalculationgvgbabuNo ratings yet

- Dixon 1980Document259 pagesDixon 1980mohsenNo ratings yet

- Vertical Equipment FoundationDocument15 pagesVertical Equipment FoundationThaungMyintNo ratings yet

- Crack Width CalculationDocument3 pagesCrack Width CalculationgvgbabuNo ratings yet

- Cement Storage Silos - Cement Silo Design Parameters - Cement SiloDocument7 pagesCement Storage Silos - Cement Silo Design Parameters - Cement SilomohsenNo ratings yet

- Mat Foundation Design for 7-Storey BuildingDocument79 pagesMat Foundation Design for 7-Storey Buildingعبدالمجيد قبيصيNo ratings yet

- Axial Force AfDocument37 pagesAxial Force AfmohsenNo ratings yet

- Oracle Hyperion Epm System Certific 131801Document142 pagesOracle Hyperion Epm System Certific 131801mohsenNo ratings yet

- Brute Force Attack EstimatorDocument6 pagesBrute Force Attack EstimatormohsenNo ratings yet

- Ufc 3 260 01 2019Document622 pagesUfc 3 260 01 2019mohsenNo ratings yet

- Designing Hoppers, Bins, and Silos For Reliable Flow - AIChEDocument13 pagesDesigning Hoppers, Bins, and Silos For Reliable Flow - AIChEmohsenNo ratings yet

- SHEAR-TEST - Silo Calculation For Mass Flow - Funnel FlowDocument5 pagesSHEAR-TEST - Silo Calculation For Mass Flow - Funnel FlowmohsenNo ratings yet

- Wind ON Chimneys: PressureDocument44 pagesWind ON Chimneys: PressuremohsenNo ratings yet

- Heredia Chavez Daniel (EMSHIP Thesis Feb 2013) UNIGEDocument36 pagesHeredia Chavez Daniel (EMSHIP Thesis Feb 2013) UNIGEmohsenNo ratings yet

- Oil Storage Tank Foundation DesignDocument5 pagesOil Storage Tank Foundation Designsugianto100% (2)

- Extended "Mononobe-Okabe" Method For Seismic Design of Retaining WallsDocument15 pagesExtended "Mononobe-Okabe" Method For Seismic Design of Retaining WallsmohsenNo ratings yet

- Design and Analysis of The Properties of The Delta Inverse RobotDocument7 pagesDesign and Analysis of The Properties of The Delta Inverse RobotmohsenNo ratings yet

- Info Eksperimen Tepung JagungDocument4 pagesInfo Eksperimen Tepung JagungFatin Najiha IsmailNo ratings yet

- Model: RO-PURE: Installation, Operation and Maintenance ManualDocument28 pagesModel: RO-PURE: Installation, Operation and Maintenance Manualnermeen ahmedNo ratings yet

- Construction Waste Recycling GuidelinesDocument7 pagesConstruction Waste Recycling GuidelinesKalai Selvan0% (1)

- He Dressmaking Gr9 q1 Module-2Document23 pagesHe Dressmaking Gr9 q1 Module-2reymilyn zuluetaNo ratings yet

- SKF - Large Diameter Seals - 6404 EngDocument116 pagesSKF - Large Diameter Seals - 6404 EngDiegoAlvarezHuguezNo ratings yet

- Thermal Engineering for 500 MW BoilerDocument31 pagesThermal Engineering for 500 MW BoilerRituraaj Singh RajputNo ratings yet

- Evaporator: Department of Chemical EngineeringDocument16 pagesEvaporator: Department of Chemical EngineeringspidyNo ratings yet

- Annual Foreign Trade Statistics (2074-75)Document1,545 pagesAnnual Foreign Trade Statistics (2074-75)Ajay GauroNo ratings yet

- Shotcrete Slope StabilizationDocument7 pagesShotcrete Slope StabilizationJ. Kumar Infraprojects Ltd100% (1)

- Friedman2007 Cineticade DegradaciónDocument13 pagesFriedman2007 Cineticade DegradaciónWilson D Caicedo ChacónNo ratings yet

- EKOplus BS TypeaDocument2 pagesEKOplus BS TypeaAhmedRamadanNo ratings yet

- DME Blended LPG As A Cooking Fuel Option For Indian Household PDFDocument11 pagesDME Blended LPG As A Cooking Fuel Option For Indian Household PDFSundari RaviNo ratings yet

- Quality ControlDocument10 pagesQuality ControlB&R-QC KSPPLNo ratings yet

- Cyclic TriaxialDocument2 pagesCyclic TriaxialnkotiaNo ratings yet

- Underground Waste DisposalDocument39 pagesUnderground Waste Disposala4abhirawatNo ratings yet

- Pipeline Defect Assessment ManualDocument18 pagesPipeline Defect Assessment Manualhadi13775% (4)

- LAB 1X2 COMPLETIONDocument17 pagesLAB 1X2 COMPLETIONEng Hinji RudgeNo ratings yet

- A Review On The Viable Technology For Construction Waste RecyclingDocument13 pagesA Review On The Viable Technology For Construction Waste Recyclingعمير حسن אמיר חסןNo ratings yet

- Fatai Kolawole Ikumapayi Lic2010Document182 pagesFatai Kolawole Ikumapayi Lic2010Gaurav MeshramNo ratings yet

- HLB System Crodas Time Saving Guide To SDocument22 pagesHLB System Crodas Time Saving Guide To SRishiNo ratings yet

- Chapter 7 - Strain EnergyDocument35 pagesChapter 7 - Strain EnergyWee Soon Chai100% (1)

- CM20150421 35555 26171Document68 pagesCM20150421 35555 26171motasem alqaisiNo ratings yet

- Jfe SteelDocument44 pagesJfe SteelTuấn Phạm AnhNo ratings yet

- Meat PH Tester: Refilling The ElectrodeDocument2 pagesMeat PH Tester: Refilling The ElectrodeFranco YnquillaNo ratings yet

- Jotashield Colourlast MattDocument3 pagesJotashield Colourlast Mattمحمد عزتNo ratings yet

- Exergy: A Measure of Work Potential Study Guide in PowerpointDocument27 pagesExergy: A Measure of Work Potential Study Guide in PowerpointKent_RichieanNo ratings yet

- Fire Fighting Training 13.11.2021-1Document27 pagesFire Fighting Training 13.11.2021-1Vikash Kumar RayNo ratings yet

- Glass To Metal JointsDocument11 pagesGlass To Metal JointsNeilNo ratings yet

- Civil Soil Testing Lab Report SummaryDocument48 pagesCivil Soil Testing Lab Report SummaryShailendra YadavNo ratings yet

- General Ser Vice Ball Valves: GB SeriesDocument13 pagesGeneral Ser Vice Ball Valves: GB SeriesRyan DuhonNo ratings yet