50% found this document useful (2 votes)

5K views3 pagesGarment Quality Control Checklist

Save time by using digital forms instead of paper checklists. It's free to use the digital quality control checklist at www.monitorQA.com. The digital form allows you to attach photos and collect essential garment quality control information across categories like style/color conformity, defects, measurements, quality conformity, marking/labeling, on-site testing, and signatures. It provides a concise digital alternative to a paper checklist for garment quality inspection.

Uploaded by

shreejit sarkarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

50% found this document useful (2 votes)

5K views3 pagesGarment Quality Control Checklist

Save time by using digital forms instead of paper checklists. It's free to use the digital quality control checklist at www.monitorQA.com. The digital form allows you to attach photos and collect essential garment quality control information across categories like style/color conformity, defects, measurements, quality conformity, marking/labeling, on-site testing, and signatures. It provides a concise digital alternative to a paper checklist for garment quality inspection.

Uploaded by

shreejit sarkarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

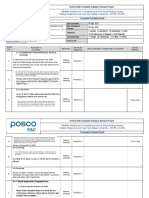

- Batch Sample Information: Provides essential details about the batch sample including client description, order quantity, and other identifiers.

- Measurement Check: Includes measurement criteria to ensure sample garments meet specified dimensions.

- Style/Color Conformity: Checks consistent style and color conformity against client specifications with a pass/fail criteria.

- Quality Conformity: Summarizes overall quality conformity checks assessing if samples meet inspection standards.

- Inspection Criteria Sheet: Details inspection criteria for garment quality, listing defects and critical observation points.

- Testing Procedures: Outlines various tests performed on garments including marking, labeling, packaging and several performance tests.

- Inspection Conclusion and Signatures: Concludes the inspection with pass/fail results and spaces for required signatures.

![Not Finished Quantity

Sample Size [Packed Lot]

Sample Size [Unpacked Lot]

Marking / Label/ Packaging

Attach summary of](https://screenshots.scribd.com/Scribd/252_100_85/326/591152105/2.jpeg)