Professional Documents

Culture Documents

Oil filter and pressure regulating valve assembly

Uploaded by

Jesús Vázquez HerreroOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oil filter and pressure regulating valve assembly

Uploaded by

Jesús Vázquez HerreroCopyright:

Available Formats

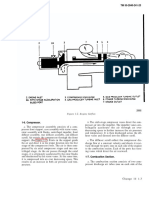

TM 55-2840-241-23

the two drain ports located on the aft face of the filter pressure and scavenge pump assembly is mounted

cover. Pressure taps are provided before and after within the power and accessory gearbox. (See figures

(labeled BF and AF) the filter element to permit mea- 1-6 and 1-7.) The oil filter, filter bypass valve, and pres-

surement of filter pressure drop if desired. sure regulating valve are in a unit which is located in

the upper right-hand side of the power and accessory

1-15. Double Check Valve. gearbox housing and are accessible from the top of the

engine. A check valve is located between the housing

The double check valve assembly is a mechanical and the filter unit. Indicating type magnetic chip

device placed in the governing pressure (Pg) circuit detectors are installed at the bottom of the power and

between the power turbine governor and the main fuel accessory gearbox, and at the engine oil outlet connec-

control to dampen surges in the Pg pressure signal. tion. All engine oil system lines and connections are

(See figure 1-4.) It incorporates two individual, internal with the exception of pressure and scavenge

diaphragm operated valves within one unit. The valves lines to the compressor front support, the gas producer

are located in parallel with each other and open in turbine support, and the power turbine support.

opposite directions. Movement of air through the check

valve assembly in either direction is permitted by one 1-20. Ignition System.

of the valves. However, when a stable signal is pro-

vided, a very small flow of air is experienced with the The engine ignition system consists of a low tension

valve toward its closed position. Any pressure surges in capacitor discharge ignition exciter, a spark igniter

the Pg signal will be dampened by spring loading on lead, and a shunted-surface gap spark igniter. The

the valve. system receives its input power from a 14 to 29-volt, d-c

power source.

1-16. Pc Air Filter.

The Pc air filter is a 10 micron filter located in the Pc 1-21. Temperature Measurement System.

air supply line leading from the diffuser scroll to the The temperature measurement system has four

power turbine governor. It incorporates a permanent chromel-alumel single junction thermocouples in the

type, wire mesh, cleanable element. It prevents the gas producer turbine outlet (TOT) and a associated

governor and fuel control pneumatic components from integral harness. The voltages of the four thermocou-

being contaminated with foreign particles by filtering ples are electrically averaged in the assembly and

Pc air flow to the governor and control. delivered by the assembly lead to an engine terminal

block for attachment to the airframe temperature indi-

1-17. Fuel Check Valve. cating system.

The fuel check valve is located in the fuel line

between the fuel control and the fuel nozzle. It has a 1-22. Anti-king System.

cracking pressure of 22-28 psi and serves to prevent

a. Anti-icing is provided for the compressor inlet

leakage of fuel through the fuel nozzle into the combus- guide vanes and front support hub by the use of com-

tion chamber if the fuel cutoff valve is inadvertently pressor discharge air. The air is taken from a port at

opened or leaks while the engine is not operating. the twelve o’clock position on the front face of the dif-

1-18. Fuel Nozzle. fuser scroll. An anti-icing air shutoff valve is installed

in the port and is manually operated from the flight

The fuel nozzle is a single-entry, dual-orifice type deck to control anti-icing airflow. Anti-icing air tubes

unit. It contains an integral valve for dividing primary direct the flow of air from the valve to fittings on each

and secondary flow. This fuel nozzle relies on the fuel side of the compressor front support. The air is then

check valve to provide fuel cutoff when the fuel mani- routed through an annulus around the OD of the front

fold pressure falls below a pre-determined pressure, to support and through the inlet guide vanes and is dis-

keep fuel out of the combustion chamber at shutdown. charged into the inlet air stream.

1-19. Lubrication System. b. The approximate effects of anti-icing air flow on

performance available to pilot at power levels above

The lubrication system is a dry sump type with an

40,000 N1 (gas producer) speed are immediate and

external reservoir and heat exchanger. A gear type

definite.

1-10 Change 14

You might also like

- D JetronicDocument20 pagesD Jetronicapi-3850227100% (4)

- Pierburg 2E3Document13 pagesPierburg 2E3Michiel Dequidt67% (3)

- VW Digifant ManualDocument43 pagesVW Digifant ManualChris Rimmer100% (6)

- Turbine Engine Fuel Control and Governor ManualDocument14 pagesTurbine Engine Fuel Control and Governor ManualLeonel E. Morales100% (1)

- Ottawa Air Brakes Service ManualDocument32 pagesOttawa Air Brakes Service ManualcbudkuleyNo ratings yet

- Compressor Installation GuideDocument21 pagesCompressor Installation GuideDavid GarciaNo ratings yet

- Tr7-8fi ManualDocument82 pagesTr7-8fi ManualClint CooperNo ratings yet

- Functional Specification Export Gas Compressor PDFDocument7 pagesFunctional Specification Export Gas Compressor PDFdndudcNo ratings yet

- Zenith Carburetor Model 29 Service ManualDocument11 pagesZenith Carburetor Model 29 Service ManualMatt FerdockNo ratings yet

- Instruction and Maintenance Manual For Alfa Romeo 2000 Fuel Injection Models U.S.A. VersionDocument42 pagesInstruction and Maintenance Manual For Alfa Romeo 2000 Fuel Injection Models U.S.A. VersionVladimirNo ratings yet

- Ficha Tecnica Valvula Control LeslieDocument9 pagesFicha Tecnica Valvula Control Lesliesergio andres villate ulloaNo ratings yet

- Moon SalutationDocument2 pagesMoon SalutationSolange PardoNo ratings yet

- Weber Injection-Ignition SystemDocument27 pagesWeber Injection-Ignition SystemjohnvandurenNo ratings yet

- CH - 36Document5 pagesCH - 36mpusNo ratings yet

- BOSCH D JetronicDocument18 pagesBOSCH D JetronicRaul Quispe RamirezNo ratings yet

- Turbine Gland Steam CondenserDocument4 pagesTurbine Gland Steam CondenserSai Swaroop100% (1)

- BMW E12 L-Jetronic Fuel Injection GuideDocument38 pagesBMW E12 L-Jetronic Fuel Injection Guidecasecaseinter7No ratings yet

- Drager Cato Ventilator - Service ManualDocument20 pagesDrager Cato Ventilator - Service ManualEdwin Salazar OrtizNo ratings yet

- Functional Description of The Vacuum Pump Set-1Document8 pagesFunctional Description of The Vacuum Pump Set-1jigneshluharNo ratings yet

- Zaude ModrnDocument47 pagesZaude ModrnZewdeneh AsemieNo ratings yet

- Compressor Extraction Air Processing SystemDocument2 pagesCompressor Extraction Air Processing SystemObayemisi AtuNo ratings yet

- 06 Mem341Document17 pages06 Mem341Muhammad AbdullahNo ratings yet

- Air Compressor ManualDocument15 pagesAir Compressor ManualfanagomNo ratings yet

- 1.1 Control Philosophy CAS-1 NMDCDocument36 pages1.1 Control Philosophy CAS-1 NMDCkoushik42000No ratings yet

- Subaru evaporative emissions systems explainedDocument8 pagesSubaru evaporative emissions systems explainedpivillamilNo ratings yet

- Atr72 Air PDFDocument34 pagesAtr72 Air PDFEhsan Ul HaqueNo ratings yet

- # Air Conditioning - General:: Note For CPC Manual ModeDocument30 pages# Air Conditioning - General:: Note For CPC Manual Modejontis jasoliyaNo ratings yet

- Diesel Engine ManagementDocument56 pagesDiesel Engine Managementbravo6dNo ratings yet

- Anti Surge ControlDocument33 pagesAnti Surge Controlgopinath87100% (1)

- E5050 Diesel Engines Electronic Management (TCT Transmission, 170 HPDocument9 pagesE5050 Diesel Engines Electronic Management (TCT Transmission, 170 HPomid yadegariNo ratings yet

- Turbine Engine Fuel System: Basic Maintenance Training Manual Module 14 PropulsionDocument10 pagesTurbine Engine Fuel System: Basic Maintenance Training Manual Module 14 PropulsionccoyureNo ratings yet

- TSC 802 (A)Document2 pagesTSC 802 (A)KarmandeepBrarNo ratings yet

- Steam Turbine Maintenance Manual-1Document244 pagesSteam Turbine Maintenance Manual-1Trie Wahyudi100% (4)

- A320 78exhaust SystemDocument8 pagesA320 78exhaust SystemSudip AcharyyaNo ratings yet

- SECTION 5.35: Exhaust SystemDocument30 pagesSECTION 5.35: Exhaust SystemLUISA FERNANDA TORRES MANOSALVANo ratings yet

- Treadle ValveDocument8 pagesTreadle ValveBOB100% (1)

- Gaseous Fuel SystemDocument5 pagesGaseous Fuel Systemchdeepak96No ratings yet

- ElectricalDocument540 pagesElectricalCaza GeorgeNo ratings yet

- Neumatic Control For Robotics and Industrial AutomationDocument12 pagesNeumatic Control For Robotics and Industrial AutomationJeet PawarNo ratings yet

- Technical Information Technical Information: InjectionDocument4 pagesTechnical Information Technical Information: InjectionwilsonNo ratings yet

- Manual Trident Klasik 200Document12 pagesManual Trident Klasik 200DanielMachadopovoa100% (1)

- Bendix Atr1dc Antilock Traction RelayDocument12 pagesBendix Atr1dc Antilock Traction RelayHenry NicaraguaNo ratings yet

- Fuel Gas System DescriptionDocument16 pagesFuel Gas System DescriptionMaulik100% (3)

- 11.16 Pneumatic/Vacuum (ATA 36) : Basic Maintenance Training Manual Module 11 Aircraft Structures and SystemsDocument14 pages11.16 Pneumatic/Vacuum (ATA 36) : Basic Maintenance Training Manual Module 11 Aircraft Structures and Systemsnajib0% (1)

- UntitledDocument8 pagesUntitledPMG Bhuswal ProjectNo ratings yet

- Aircraft Pneumatic and Vacuum SystemsDocument38 pagesAircraft Pneumatic and Vacuum SystemsAman OjhaNo ratings yet

- Heavy Equipment Technician Air Brake ComponentsDocument75 pagesHeavy Equipment Technician Air Brake ComponentsrenimoNo ratings yet

- PLT 224 Pneumatic SystemsDocument95 pagesPLT 224 Pneumatic SystemsNazer Mangirapin BarisNo ratings yet

- ML B 300 b350mm609Document5 pagesML B 300 b350mm609Alejandro BenavidesNo ratings yet

- CAD Control Systems ManualDocument27 pagesCAD Control Systems Manualnds2006sNo ratings yet

- Oil Burner ManualDocument42 pagesOil Burner Manualguru22100% (1)

- Triplex Systems 4Document2 pagesTriplex Systems 4Eng.Gihad EladlNo ratings yet

- Gas Turbine - Part 1Document82 pagesGas Turbine - Part 1Manuel L Lombardero100% (2)

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesFrom EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesRating: 1 out of 5 stars1/5 (2)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Oral and Practical Review: Reflections on the Part 147 CourseFrom EverandOral and Practical Review: Reflections on the Part 147 CourseNo ratings yet

- MM-1 42Document1 pageMM-1 42Jesús Vázquez HerreroNo ratings yet

- MM-1 40Document1 pageMM-1 40Jesús Vázquez HerreroNo ratings yet

- Special tools and test equipment for aircraft engine maintenanceDocument1 pageSpecial tools and test equipment for aircraft engine maintenanceJesús Vázquez HerreroNo ratings yet

- MM-1 37Document1 pageMM-1 37Jesús Vázquez HerreroNo ratings yet

- MM-1 43Document1 pageMM-1 43Jesús Vázquez HerreroNo ratings yet

- MM-1 32Document1 pageMM-1 32Jesús Vázquez HerreroNo ratings yet

- MM-1 38Document1 pageMM-1 38Jesús Vázquez HerreroNo ratings yet

- MM-1 41Document1 pageMM-1 41Jesús Vázquez HerreroNo ratings yet

- MM-1 31Document1 pageMM-1 31Jesús Vázquez HerreroNo ratings yet

- MM-1 36Document1 pageMM-1 36Jesús Vázquez HerreroNo ratings yet

- MM-1 26Document1 pageMM-1 26Jesús Vázquez HerreroNo ratings yet

- MM-1 23Document1 pageMM-1 23Jesús Vázquez HerreroNo ratings yet

- MM-1 30Document1 pageMM-1 30Jesús Vázquez HerreroNo ratings yet

- MM-1 34Document1 pageMM-1 34Jesús Vázquez HerreroNo ratings yet

- MM-1 33Document1 pageMM-1 33Jesús Vázquez HerreroNo ratings yet

- MM-1 29Document1 pageMM-1 29Jesús Vázquez HerreroNo ratings yet

- MM-1 27Document1 pageMM-1 27Jesús Vázquez HerreroNo ratings yet

- MM-1 21Document1 pageMM-1 21Jesús Vázquez HerreroNo ratings yet

- MM-1 24Document1 pageMM-1 24Jesús Vázquez HerreroNo ratings yet

- MM-1 25Document1 pageMM-1 25Jesús Vázquez HerreroNo ratings yet

- MM-1 16Document1 pageMM-1 16Jesús Vázquez HerreroNo ratings yet

- MM-1 22Document1 pageMM-1 22Jesús Vázquez HerreroNo ratings yet

- MM-1 20Document1 pageMM-1 20Jesús Vázquez HerreroNo ratings yet

- MM-1 28Document1 pageMM-1 28Jesús Vázquez HerreroNo ratings yet

- MM-1 18Document1 pageMM-1 18Jesús Vázquez HerreroNo ratings yet

- MM-1 17Document1 pageMM-1 17Jesús Vázquez HerreroNo ratings yet

- MM-1 15Document1 pageMM-1 15Jesús Vázquez HerreroNo ratings yet

- MM-1 14Document1 pageMM-1 14Jesús Vázquez HerreroNo ratings yet

- MM-1 19Document1 pageMM-1 19Jesús Vázquez HerreroNo ratings yet

- Vocational Bridge Course - Physical ScienceDocument784 pagesVocational Bridge Course - Physical ScienceSarvan KumarNo ratings yet

- 38 661 000 Flushing Cistern GD 2: Product DescriptionDocument2 pages38 661 000 Flushing Cistern GD 2: Product DescriptionAnuj AggarwalNo ratings yet

- This Month, Your Company Is Going To Develop A Rec...Document3 pagesThis Month, Your Company Is Going To Develop A Rec...Wan Nur FakhiraNo ratings yet

- 998-1268169 GMA-US A Interactive 2Document179 pages998-1268169 GMA-US A Interactive 2Cbdtxd PcbtrNo ratings yet

- Air Conditioning System Sizing For Pure Electric Vehicle: EVS28 KINTEX, Korea, May 3-6, 2015Document7 pagesAir Conditioning System Sizing For Pure Electric Vehicle: EVS28 KINTEX, Korea, May 3-6, 2015Naveen kumarNo ratings yet

- Typical AcceleratorslDocument42 pagesTypical AcceleratorslKRISHNA KUMAR GODARANo ratings yet

- BAC Website CXVE EN 2021Document30 pagesBAC Website CXVE EN 2021Mahmoud AbubakrNo ratings yet

- ABB Auxillary RelayDocument12 pagesABB Auxillary RelayBenigno Sayaboc TaradelNo ratings yet

- Currentwatch Current Sensors 1: DescriptionDocument52 pagesCurrentwatch Current Sensors 1: DescriptionFlorin MNo ratings yet

- JET-FLO Spa HeaterDocument3 pagesJET-FLO Spa HeaterAljohn Stephen Dela cruzNo ratings yet

- Footstep Power Generation Using Piezoelectric SensorDocument6 pagesFootstep Power Generation Using Piezoelectric SensorJeet DattaNo ratings yet

- Fulltext02Document77 pagesFulltext02faizaNo ratings yet

- Sheet 3 - 1 ST Law of ThermodynamicDocument2 pagesSheet 3 - 1 ST Law of Thermodynamicmohammed sallemNo ratings yet

- RADIATION SHIELDING ShultisDocument26 pagesRADIATION SHIELDING ShultisPanchapakesan SrinivasanNo ratings yet

- About Spark PlugsDocument9 pagesAbout Spark PlugsfadiharmoushNo ratings yet

- ST MicroInverter SchemeticDocument12 pagesST MicroInverter Schemeticpuspendu janaNo ratings yet

- CH 50-480 enDocument2 pagesCH 50-480 enАлександр ЩербаковNo ratings yet

- Express Limited Warranty: FORM 6315 First EditionDocument2 pagesExpress Limited Warranty: FORM 6315 First EditionLei LiNo ratings yet

- Gölcük VET Scenario - Oil Tempereture HighDocument1 pageGölcük VET Scenario - Oil Tempereture HighCantekin CeNo ratings yet

- Pa-18 Pa-18a Inspection Reportv1999Document4 pagesPa-18 Pa-18a Inspection Reportv1999Jessey StonerNo ratings yet

- Q400 - 12. PropellersDocument14 pagesQ400 - 12. PropellersDavid Owen100% (1)

- Full Bridge SMPS - BidirectionalDocument1 pageFull Bridge SMPS - BidirectionalNdidi KennethNo ratings yet

- Po - Act 5 Coal MiningDocument12 pagesPo - Act 5 Coal MiningKristine Georgia PoNo ratings yet

- Model QP-Physics For Electrical StreamDocument3 pagesModel QP-Physics For Electrical StreamBruce LeeNo ratings yet

- LSA 50.2 - 4 POLES: AlternatorsDocument24 pagesLSA 50.2 - 4 POLES: Alternators02031989No ratings yet

- E32 Usermanual EN v1.30-10Document1 pageE32 Usermanual EN v1.30-10Sergey SevruginNo ratings yet

- Manual de Taller CF150 PDFDocument190 pagesManual de Taller CF150 PDFMotorcycles Workshop Amigos PulsarNo ratings yet

- Planta Cummins MDKDDocument2 pagesPlanta Cummins MDKDColor XpressNo ratings yet