Professional Documents

Culture Documents

6 Years Maintenance Expert Cement Industry

Uploaded by

SobbyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6 Years Maintenance Expert Cement Industry

Uploaded by

SobbyCopyright:

Available Formats

PALANIKUMAR S

E 8 / 8, The Ramco Cements Limited., Govindapuram works, Ariyalur - 621 713, Tamil Nadu

Permanent Add: 4/356, Karuppanasari Patti, R.R.Nagar (Po), Virudhunagar (Dt) -626204 Tamil Nadu

Contact : +91 8870400397

E-mail: er.s.palani72@gmail.com

MAINTENANCE (CEMENT INDUSTRY)

6 years’ rich experience in Maintenance, Operations, to optimize operational efficiency

Establish professional credibility in the areas of plant operation, project support, technical specifications,

resource mobilization & planning and monitoring to ensure the execution within defined time/cost

parameters when shutdown & start-up occurred. Adopt myself in designing & implementing quality

systems and procedures to ensure strict adherence of quality parameters. Key competencies in devising

prompt maintenance solutions to ensure operational fitness of machines/utilities at all times for give up

maximum productivity. Core strengths in implementation of planned, preventive, & predictive maintenance

practices to optimize machines availability with constant endeavors to realize ZERO downtime.

Demonstrate the Excellency in man-management, time management, leadership and computer literacy.

Proficiency in brief:

Project Management ~ Preventive/Break Down Maintenance ~ Operations Management ~ Quality

Control/Assurance ~ Erection/Commissioning/Fabrication ~ Machine Utilization ~ Plant Operations ~

Safety & Compliance ~ Troubleshooting ~ Site Supervision ~ Crisis Management ~ Training &

Development ~ Analytical Skills

PROFESSIONAL ACHIEVEMENTS

Power saving in screw compressors pursuing by leakage arrest-purging-modifying the sequence.

Reducing the equipment numbers of aeration blowers by modifying the aeration lines after studying

the aeration systems in the material extraction from Dry flyash silo.

Recognized by awarding, “The best in the aspect of House keeping and Safety” as a Department In-

charge.

Won big applaud for introducing indigenous vendors for supply of spares instead of many imported

spares for reducing the spares procurement cost.

Credited for steering the implementation of IS 18001:2000, ISO 9001 & ISO 14001 in various

departments and maintaining its documentations.

Data co-ordinate vides MIS reporting, to update the up-to-date information to Management on regular

basis.

Designed, developed and worked within the budgeted cost & energy saving techniques/measures and

modifications to achieve substantial reduction in O&M expenditures.

Nominated as an “Incident Controller” to respond and take precautionary measures during any

emergency within the shortest possible time, and guide the colleagues to handle the emergency in

safe and effective manner.

CAREER HIGHLIGHTS

Dy – Manager (Mechanical)

The Ramco Cements Ltd., Ariyalur, Tamil Nadu, India

Formally known as MADRAS CEMENTS LTD., SINCE 2019

(A leading cement manufacturer in south India and a subsidiary of Ramco Group of companies)

Overall responsible for the operation/maintenance of Polycom and Ball Mill

Provide leadership to project teams and integrate their efforts to maximize operational

productivity.

Propagates Quality Circle movement and develops quality culture in the work force to achieve

quality leadership in the industry.

Reviewing existing systems & procedures and designed internal controls/quality audit checks for

various operational areas for achieving higher operational efficiency, resource rationalization and

cost reduction.

Introduce the concept of Condition based maintenance on equipment whenever required to extend

the life of spares.

Lead & guide the team in ensuring compliance to all Safety norms to minimize/achieve ZERO

accidents through appropriate fire protection system & safety equipments

Asst – Manager (Mechanical)

The Ramco Cements Ltd., Ariyalur, Tamil Nadu, India

Formally known as MADRAS CEMENTS LTD., Oct 2015 to April 2019

(A leading cement manufacturer in south India and a subsidiary of Ramco Group of companies)

Overall responsible for the operation/maintenance of Mechanical utilities ( Workshop, Screw

compressors and Waterworks)

Actively involved in trouble shooting of Belt conveyors, Unit bag filters, main bag filters and

Vibration monitoring for various rotating equipments, etc.

Deftly managing the maintenance of Conveying Equipments, Centrifugal Fans, dust handling

equipments, etc.

Formulates plan for inspection, shutdown jobs preparation & execution, Breakdown analysis &

action plans and preparation of annual maintenance plans.

Efficiently managing post maintenance (breakdown, shutdown, corrective and annual

maintenance) of all plant equipments and spare parts.

Closely monitoring the Maintenance of Belt conveyors and Material handling systems.

Initiated the procurement activities with defined schedules and tendered all capital/ revenue

nature of works. Regularly followed up with suppliers for on-time deliveries.

Organize various training sessions for the team to enhance their performance.

Graduate Engineer Trainee

The Ramco Cements Ltd., Ariyalur, Tamil Nadu, India

Formally known as MADRAS CEMENTS LTD., Oct 2014 to Oct 2015

(A leading cement manufacturer in south India and a subsidiary of Ramco Group of companies)

Associated diligently in erection and commissioning of RABH

Drove the efforts for identifying areas on unexpected failures and took steps to rectify system.

Exercised in all industrial quality standards with key emphasis on improving quality.

Meticulously kept maintenance records of all mechanisms and effectively utilized the same to evolve

breakdown solutions.

ACADEMIA

B.E. (Mechanical) from M.I.E.T College of Engineering Trichy, Anna University.

Diploma in Mechanical Engineering from PAC Ramasamyraja polytechnic, Rajapalayam

TRAINING/SEMINAR

‘Energy conference’ – externally conducted by CII.

‘Lubrication’ – externally conducted by Indian Oil Corporation

PERSONAL INFO

Date of Birth: 09 May 1993 Nationality: Indian Languages Known : English & Tamil

You might also like

- Naveen Kumar Singh: Knowledge PurviewDocument4 pagesNaveen Kumar Singh: Knowledge PurviewForceFieldNo ratings yet

- CV - SamBen Jose 2023Document4 pagesCV - SamBen Jose 2023MECH SAMNo ratings yet

- Resume Summary for Mechanical EngineerDocument4 pagesResume Summary for Mechanical Engineersuresh kumarNo ratings yet

- Senior Mechanical Engineer Seeking Challenging Energy Audit AssignmentsDocument2 pagesSenior Mechanical Engineer Seeking Challenging Energy Audit AssignmentsShankker KumarNo ratings yet

- Mechanical Engineer Resume - 40+ Years ExperienceDocument7 pagesMechanical Engineer Resume - 40+ Years ExperienceTHEOPHILUS ATO FLETCHERNo ratings yet

- BrijBihari_13459796_-08_00-_1Document4 pagesBrijBihari_13459796_-08_00-_1Mayur ShindeNo ratings yet

- CV-Thanigaivelan PalaniDocument4 pagesCV-Thanigaivelan PalaniThanigaivelan PalaniNo ratings yet

- Awadelkarem AbdullahDocument3 pagesAwadelkarem AbdullahAwad AbdallaNo ratings yet

- Aadil - 12YRS - MECHANICAL MAINTENENCE SUPERVISORDocument3 pagesAadil - 12YRS - MECHANICAL MAINTENENCE SUPERVISORAadil AsgahrNo ratings yet

- K.S.Venkatraman: Core Competencies Brief OverviewDocument3 pagesK.S.Venkatraman: Core Competencies Brief OverviewHariNo ratings yet

- XXXXXXXXXX: Corrective Actions. Effective Communicator & Negotiator With Strong Analytical, ProblemDocument2 pagesXXXXXXXXXX: Corrective Actions. Effective Communicator & Negotiator With Strong Analytical, ProblemashaNo ratings yet

- Awadelkarem Abdallah Mohgoub Mechanical Maintenance TEAM LEADER Khartoum Sudan Phone (+249) 912505873 Mobile (+249) 912951728Document3 pagesAwadelkarem Abdallah Mohgoub Mechanical Maintenance TEAM LEADER Khartoum Sudan Phone (+249) 912505873 Mobile (+249) 912951728Awad AbdallaNo ratings yet

- Mahmed Ajruddin Adam PatelDocument3 pagesMahmed Ajruddin Adam PatelAircrafte PatelNo ratings yet

- ResumeDocument5 pagesResumeVaibhav Vithoba NaikNo ratings yet

- Maintenance Engineer Seeking New OpportunityDocument7 pagesMaintenance Engineer Seeking New OpportunityTHEOPHILUS ATO FLETCHERNo ratings yet

- Sadhish CVDocument8 pagesSadhish CVSadhish KumarNo ratings yet

- CBM Ramakrishna ResumeDocument6 pagesCBM Ramakrishna ResumeramakrishnaNo ratings yet

- Shoaib Ismail CVDocument5 pagesShoaib Ismail CVMisbhasaeedaNo ratings yet

- Shashi Dinanath Thakur Resume (MBA + B.E.Mechanical)Document4 pagesShashi Dinanath Thakur Resume (MBA + B.E.Mechanical)shashithkr5489100% (1)

- Syed Ibrahim ResumeDocument3 pagesSyed Ibrahim ResumeSYED IBRAHIM100% (1)

- 17+ years Maintenance Head automotive sectorDocument2 pages17+ years Maintenance Head automotive sectoravinenderNo ratings yet

- Condition Monitoring Engineer ResumeDocument6 pagesCondition Monitoring Engineer Resumeramakrishna100% (1)

- Production Planning Expert with 14+ Years of ExperienceDocument4 pagesProduction Planning Expert with 14+ Years of Experiencesureshsri1976No ratings yet

- CV - ThiraviyamDocument4 pagesCV - ThiraviyamRamasamy ThiraviyamNo ratings yet

- Rajat Baran Chakravarty: ST THDocument4 pagesRajat Baran Chakravarty: ST THSAMSON GLOBALNo ratings yet

- AwadelkaremDocument4 pagesAwadelkaremAwad AbdallaNo ratings yet

- Balraj Singh: Aintenance Ervice NgineerDocument4 pagesBalraj Singh: Aintenance Ervice Ngineerbjrock123No ratings yet

- Asad AliDocument5 pagesAsad AliMisbhasaeedaNo ratings yet

- Mechanical EngineerDocument4 pagesMechanical EngineerKhalid MahmoudNo ratings yet

- Resume: Sunil Kumar Morwal Oct. Mechanical Engineer Project & CommissioningDocument4 pagesResume: Sunil Kumar Morwal Oct. Mechanical Engineer Project & CommissioningSunil kumar MorwalNo ratings yet

- Maintenance Expertise SummaryDocument4 pagesMaintenance Expertise SummaryMohamed ElnagdyNo ratings yet

- Introductory Letter of ARMMCONDocument4 pagesIntroductory Letter of ARMMCONtelakshayNo ratings yet

- CV Mechanical Engineer Malaysia Maintenance ManagerDocument2 pagesCV Mechanical Engineer Malaysia Maintenance ManagerArip HardiansyahNo ratings yet

- Saravanan M - Resume NewDocument3 pagesSaravanan M - Resume NewjillNo ratings yet

- Resumesuresh JLLDocument3 pagesResumesuresh JLLsuresh kumarNo ratings yet

- Resume: 16+ Years Quality Management ExperienceDocument7 pagesResume: 16+ Years Quality Management ExperiencesadathNo ratings yet

- CV RPT 4Document3 pagesCV RPT 4tiwari171964No ratings yet

- Ankush CV-1Document4 pagesAnkush CV-1Ankush SehgalNo ratings yet

- Umair Yaseen Resume PDFDocument1 pageUmair Yaseen Resume PDFBjkaaNo ratings yet

- M. Nabeel WahidDocument2 pagesM. Nabeel WahidmakalikhanNo ratings yet

- Kumar Rohit CV-1Document4 pagesKumar Rohit CV-1leechadffpopNo ratings yet

- Balraj Singh: Aintenance Ervice NgineerDocument3 pagesBalraj Singh: Aintenance Ervice Ngineerbalraj bawaNo ratings yet

- Amit Tiwari TPM 21.7.22Document6 pagesAmit Tiwari TPM 21.7.22vaishaliNo ratings yet

- Curriculam Vitae Objective Engineer .: Yyyyy 3. Indian 4. 5. 6Document3 pagesCurriculam Vitae Objective Engineer .: Yyyyy 3. Indian 4. 5. 6Arshad Rashid ShahNo ratings yet

- Imran Sadiq: Operation Foreman Senior at ADCODocument5 pagesImran Sadiq: Operation Foreman Senior at ADCOmghauriNo ratings yet

- Plant Operation & MaintenanceDocument19 pagesPlant Operation & Maintenancejuliyanto88100% (2)

- E AwadelkaremDocument2 pagesE AwadelkaremAwad AbdallaNo ratings yet

- Plant Maintenance Cost Reduction Nov KL NadeemDocument5 pagesPlant Maintenance Cost Reduction Nov KL NadeemSyedNadeemAhmedNo ratings yet

- Aerospace Engineer Resume SummaryDocument6 pagesAerospace Engineer Resume SummaryVasudevan GovindarajNo ratings yet

- Elavarasan LeanDocument2 pagesElavarasan LeanSai AshzwathNo ratings yet

- Preserve Centrifugal Pump During CommissioningDocument24 pagesPreserve Centrifugal Pump During CommissioningJumaidi AbdyNo ratings yet

- Senior Manager's ResumeDocument4 pagesSenior Manager's ResumeElango SundaramNo ratings yet

- 8 Page CV: SA ARJUN ADI WARMAN: Mechanical EngineerDocument8 pages8 Page CV: SA ARJUN ADI WARMAN: Mechanical EngineerSa Arjun Adi WarmanNo ratings yet

- 24 yrs operations expert seeks plant head roleDocument3 pages24 yrs operations expert seeks plant head roledhnugujarNo ratings yet

- Hassan FarooqDocument2 pagesHassan FarooqStrategic ThinkingNo ratings yet

- Technical Consultant Shares Expertise in Energy EfficiencyDocument5 pagesTechnical Consultant Shares Expertise in Energy Efficiencyarshiahmed30No ratings yet

- Resume UpdatedDocument7 pagesResume UpdatedMarella KaleshwarNo ratings yet

- L.C JainDocument4 pagesL.C JainLeela Chand JainNo ratings yet

- Preventive Maintenance Engineer (CMRP)Document8 pagesPreventive Maintenance Engineer (CMRP)ShaherYar KhanNo ratings yet

- Guide for Asset Integrity Managers: A Comprehensive Guide to Strategies, Practices and BenchmarkingFrom EverandGuide for Asset Integrity Managers: A Comprehensive Guide to Strategies, Practices and BenchmarkingNo ratings yet

- 1109Document3 pages1109SobbyNo ratings yet

- S.Achudhan: Automotive-Sales EngineerDocument2 pagesS.Achudhan: Automotive-Sales EngineerSobbyNo ratings yet

- Eswarya.V: Contact: +91-8072955883Document4 pagesEswarya.V: Contact: +91-8072955883SobbyNo ratings yet

- Fathima A: ContactDocument2 pagesFathima A: ContactSobbyNo ratings yet

- U. Jeevidesh: ObjectiveDocument1 pageU. Jeevidesh: ObjectiveSobbyNo ratings yet

- Jaxen Alex: Career ObjectiveDocument3 pagesJaxen Alex: Career ObjectiveSobbyNo ratings yet

- 2491Document2 pages2491SobbyNo ratings yet

- 1889Document3 pages1889SobbyNo ratings yet

- Dheena V: ResumeDocument2 pagesDheena V: ResumeSobbyNo ratings yet

- HDFC Bank Deputy Manager Seeks Challenging RoleDocument2 pagesHDFC Bank Deputy Manager Seeks Challenging RoleSobbyNo ratings yet

- Wi Pro, TCS, Maveri Csystemspr Ovi Dedmet Heoppor T Uni T I Est Owor Ki Ncor E Banki NG (RB)Document8 pagesWi Pro, TCS, Maveri Csystemspr Ovi Dedmet Heoppor T Uni T I Est Owor Ki Ncor E Banki NG (RB)SobbyNo ratings yet

- Shyam Sunder PalDocument2 pagesShyam Sunder PalSobbyNo ratings yet

- Resume: Post Applied ForDocument2 pagesResume: Post Applied ForSobbyNo ratings yet

- Ms. Jyoti Vilas Wagh: E-Mail: MOBILE: +91 7745063810Document2 pagesMs. Jyoti Vilas Wagh: E-Mail: MOBILE: +91 7745063810SobbyNo ratings yet

- 401 Strategic Management Study Notes - Issue Date 11-April-2022Document64 pages401 Strategic Management Study Notes - Issue Date 11-April-2022SobbyNo ratings yet

- Technical Skills: TH THDocument2 pagesTechnical Skills: TH THSobbyNo ratings yet

- Tirzah Eleanor Royal S.: No. 354, 13 Street, Baba Nagar, Villivakkam, Chennai-600 049. Email: - Phone: 9514344265Document2 pagesTirzah Eleanor Royal S.: No. 354, 13 Street, Baba Nagar, Villivakkam, Chennai-600 049. Email: - Phone: 9514344265SobbyNo ratings yet

- 2747Document3 pages2747SobbyNo ratings yet

- New Issue Market: Financial Markets and ServicesDocument15 pagesNew Issue Market: Financial Markets and ServicesSobbyNo ratings yet

- Admit CardDocument1 pageAdmit CardSobbyNo ratings yet

- 62f76adb9673fHPURCM ScMathsList1Document2 pages62f76adb9673fHPURCM ScMathsList1SobbyNo ratings yet

- Course - HRM 05Document112 pagesCourse - HRM 05Lyka Mia QuitorianoNo ratings yet

- Coal PDFDocument36 pagesCoal PDFurjanagarNo ratings yet

- Information Requirements For Welding of Pressure Containing Equipment and PipingDocument20 pagesInformation Requirements For Welding of Pressure Containing Equipment and PipingPramod Athiyarathu100% (1)

- Performance Appraisal at UFLEX Ltd.Document29 pagesPerformance Appraisal at UFLEX Ltd.Mohit MehraNo ratings yet

- Science 10 - Q1 - W5 - D2Document1 pageScience 10 - Q1 - W5 - D2zenaida a academiaNo ratings yet

- Office & Branches: Head Office PT Indosat Mega Media (IM2)Document4 pagesOffice & Branches: Head Office PT Indosat Mega Media (IM2)satriamesumNo ratings yet

- Bachelor of Computer Applications: Pondicherry UniversityDocument49 pagesBachelor of Computer Applications: Pondicherry Universitybalaanand_mcaNo ratings yet

- Quiz II - Company MissionDocument4 pagesQuiz II - Company MissionSuraj SapkotaNo ratings yet

- Crafted Furniture Business PlanDocument30 pagesCrafted Furniture Business PlanSufianNo ratings yet

- Ensure Data Quality in Oracle TCA with DQMDocument17 pagesEnsure Data Quality in Oracle TCA with DQManand.g7720No ratings yet

- توصية - مستشار زيوت التشحيمDocument4 pagesتوصية - مستشار زيوت التشحيمhasm caadNo ratings yet

- Amphenol PV Cable AssembliesDocument1 pageAmphenol PV Cable AssembliesLeonardo CoelhoNo ratings yet

- 4) Transport and InsuranceDocument10 pages4) Transport and InsuranceBianca AlecuNo ratings yet

- Electrical design for proposed residential buildingDocument24 pagesElectrical design for proposed residential buildingMALABIKA MONDALNo ratings yet

- User Manual Rish Insu 10Document10 pagesUser Manual Rish Insu 10Manoj TyagiNo ratings yet

- This Study Resource WasDocument6 pagesThis Study Resource WasRian RorresNo ratings yet

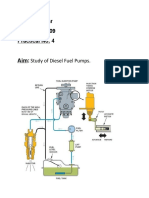

- Study of Diesel Fuel Pumps ComponentsDocument6 pagesStudy of Diesel Fuel Pumps ComponentsPro GamerssNo ratings yet

- 2017-02-02 - Moneysaver - Lewis-Clark EditionDocument20 pages2017-02-02 - Moneysaver - Lewis-Clark EditionDavid ArndtNo ratings yet

- 10 Days 7 NightsDocument5 pages10 Days 7 NightsSisca SetiawatyNo ratings yet

- VerizonClaimAffidavit 448952883 PDFDocument2 pagesVerizonClaimAffidavit 448952883 PDFJanetheNo ratings yet

- GT Protection Type TestDocument24 pagesGT Protection Type Testashwani2101100% (1)

- Decentralization in the Philippines: A Review of Fiscal, Political and Service Delivery AspectsDocument13 pagesDecentralization in the Philippines: A Review of Fiscal, Political and Service Delivery AspectsDaniel Paulo MangampatNo ratings yet

- Introduction, Concepts, Scope of Community Health NursingDocument32 pagesIntroduction, Concepts, Scope of Community Health Nursingmuthukumar82% (28)

- Modeling Drop Structures in HEC-RAS 3.1Document29 pagesModeling Drop Structures in HEC-RAS 3.1reluNo ratings yet

- Assignment 2 QP MPMC - ITDocument1 pageAssignment 2 QP MPMC - ITProjectsNo ratings yet

- Network Fundamentals - Chapter 4 Exam AnswersDocument4 pagesNetwork Fundamentals - Chapter 4 Exam AnswersBart AbraasNo ratings yet

- Evolution of Arbitration in IndiaDocument8 pagesEvolution of Arbitration in IndiaPururaj AggarwalNo ratings yet

- Microwave Engineering FundamentalsDocument24 pagesMicrowave Engineering Fundamentalsjm m100% (1)

- Training and Development in Consumer IndustriesDocument31 pagesTraining and Development in Consumer IndustriesKiran kumar SahuNo ratings yet

- Health 10 Performance TaskDocument4 pagesHealth 10 Performance TaskMary Kryss DG SangleNo ratings yet

- Nfpa Codes PDFDocument12 pagesNfpa Codes PDFphe zenNo ratings yet