Professional Documents

Culture Documents

QAD - Forms 1 To 55

Uploaded by

Parthasarathi H ROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QAD - Forms 1 To 55

Uploaded by

Parthasarathi H RCopyright:

Available Formats

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 38

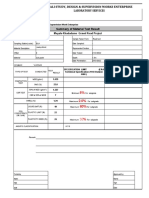

FORM – F1

DATA SHEET FOR ATTERBERG LIMITS

(As per IS : 2720 (PART 5))

BORROW PIT NO: DATE OF SAMPLING :

LOCATION/CHAINAGE: DATE OF TESTING :

SAMPLE NO & DEPTH (m) : SAMPLING BY :

TESTED BY :

Wt. Of Wt. Of dry Moisture

Weight Wt. Of Can

Wt. Of Can & Water soil Content(%)

Sl. No.of Can of can & dry soil

Wet Soil (W2) (W2-W3), 100x m

No. Blows No. (W1) (W3) (W3-W1) =ds

m ds

(gms) (gms) (gms) (gms) (gms) (%)

1.

2.

3.

4.

5.

PLASTIC LIMIT

1.

2.

3.

Liquid Limit (%) : ……………….. Plastic Limit (%) ………… Plasticity Index (%) …………..

(from Semi-log graph plotted between moisture content and no. of blows –

moisture content corresponding to 25 blows)

When plastic limit test is not possible (Cohesion less soils), the PI should be reported as zero.

Remarks : Approved/Not Approved.

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 39

FORM – F2

DATA SHEET FOR GRAIN SIZE ANALYSIS OF SOIL (WET/DRY)

(As per IS : 2720 – Part 4) 1985

BORROW PIT NO : DATE OF SAMPLING :

LOCATION/CHAINAGE: DATE OF TESTING :

SAMPLE NO & DEPTH (m) : SAMPLING BY :

METHOD OF SIEVING : DRY/WET TESTED BY :

WT. OF DRY SAMPLE TAKEN FOR TEST (gms):

Weight of Cumulative Remarks

IS Sieve Soil Cumulative

Soil percent Approved/

Designation Retained Percentage

Retained retained Not

(mm) (%) Passing (%)

(gms) (%) approved

100.00

75.00

40.00

25.00

19.00

10.00

4.75

2.00

0.60

0.30

0.15

0.075

PAN

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 40

FORM – F3

DATA SHEET FOR NATURAL MOISTURE CONTENT

(AS PER IS : 2720 (PART 2) – 1973

BORROW PIT NO: DATE OF SAMPLING :

LOCATION/CHAINAGE: DATE OF TESTING :

SAMPLE NO & DEPTH (m) : SAMPLING BY :

TESTED BY :

T E S T NO. 1 2 3 4 5 6

Container No.

Wt. Of Container (W1), gm

Wt. Container + Wet Soil (W2) gm

Wt. Of Container +Oven-Dry-Soil

(W3) gm

Wt, of water (W2-W3) gm

Wt, of Oven Dry Soil (W3-W1) gm

Moisture Content

100 x (W2-W3)/(W3-W1) %

Average Moisture Content = ………..%

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 41

FORM – F4

DATA SHEET FOR MODIFIED PROCTOR TEST

(AS PER IS : 2720 (PART 8))

BORROW PIT NO: DATE OF SAMPLING :

LOCATION/CHAINAGE: DATE OF TESTING :

SAMPLE NO & DEPTH (m) : SAMPLING BY :

TESTED BY :

Volume of Mould : cc

1. DENSITY

Total No. 1 2 3 4 5 6

Wt. of mould (gms)

Wt. of mould + Sample (gms)

Wt. of Sample (gms)

WET Density of Sample (gms / ml)

2. MOISTURE CONTENT

Trial No. 1 2 3 4 5 6

Container No.

Wt. of container, g

Wt. of container + sample, g

Wt. of container + dry sample, g

Wt. of dry sample, g

Wt. of water, g

Moisture content (%)

Dry Density of Sample (gms / cc)

MAX. DRY DENSITY: gm / CC O.M.C.: %

(from graph)

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 42

FORM – F5

DATA SHEET FOR FREE SWELLING INDEX

(AS PER IS : 2720 (PART 40))

BORROW PIT NO: DATE OF SAMPLING :

LOCATION/CHAINAGE: DATE OF TESTING :

SAMPLE NO & DEPTH (m) : SAMPLING BY :

TESTED BY :

OBSERVATIONS

Height of the Soil Height of the Soil Free Swelling

Sl. Location /

Depth Specimen in Specimen in Index F.S.I = Remarks

No. Chainage

Kerosene (H1) mm Water (H2 ) mm 100*(H2-H1)/H1

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 43

FORM – F6

DATA SHEET FOR CALFORNIA BEARING RATIO TEST

(AS PER IS : 2720 (PART 16))

Road Section : _______________________ Date : ____________

Location : ___________________________ Contract No: ________

PIT No. : ___________ Chainage _____________ Sample No: ___________

Sample Design ____________Description of Soil/Materials ______________________

Mould No mm

Height of Specimen in Mould (h) cc

Vol. Of Mould V2

m

Type of Test (Unsoaked/Soaked)

Method of Preparation (No. of Blows x No. of layers)

Max. Dry Density (Yar) - IS : 2720 – 8 Gm/cc

Q.M.C. (Wo) %

Initial Moisture Content (W1) %

Weight of Soil Sample Taken, (m1) gm

Water Added, M1 x (Wo-W1) cc

(100 + W1)

Weight of Mould + Base plate, M2 gm

Weight of Mould + Base Plate + Soil (Before Soaking) gm

Weight of Soil, m3-m2 (Before Soaking) %

Can No. (For Moisture Content of Composition) gm/cc

Moisture Content of Composition, Wc gm/cc

Bulk Density (Unsoaked), Y = M3-M2 hrs

Vm

Dry Density, (Unsoaked), Yd = 100y kg

100 + Wc

Total Time of Soaking hrs

Surcharge Weight kg

Wt of Mould + Base Plate + Soil, (After soaking), m4 gm

Water Content after soaking,

W3 = %

Swell Reading (in mm) offer Hours 0 hrs

24 hrs

48 hrs

72 hrs

96 hrs

Percent Swelling %

CBR Value (From Graph) of Penetration 2.5/5.0 mm

Moisture Content after Penetration %

NOTE : Rammer as Per AASHTO T-180 (Contd…)

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 44

CONTRACT NO: NAME OF LABORATORY:

BORROW PIT NO: DATE OF TESTING:

LOCATION/CHAINAGE: MOULD NO :

SAMPLE NO & DEPTH (M): NO. OF BLOWS :

DESCRIPTION OF SOIL/MATERIALS: LOAD : 1 DIV. = Kg

(Dial Guage)

Penetra Force Dial Force on Corrected *

tion of Reading Plunger (Kg) Force (Kg) Standard CBR %

Remarks

Plunger Force (Kg)

(mm) *Top Bottom Top Bottom Top Bottom Top Bottom

0.00 After Seating Load of 4.0 Kg

0.25

0.50

0.75

1.00

1.25

1.50

1.75

2.00

2.25

2.50 1370

2.75

3.00

3.25

3.50

3.75

4.00

4.25

4.50

4.75

5.00 2055

5.50

6.00

6.50

7.00

7.50

* Corrected force to be obtained from Load Penetration graph.

FORM – F7

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 45

DATA SHEET FOR FIELD DRY DENSITY TEST (SAND REPLACEMENT METHOD)

(AS PER IS:2720-PART-8)

Operator :

Date :

Description of Material :

CALIBRATION OF SAND

Sample No. :

Calibration

Mean mass of sand in cone (of pouring cylinder) (m2) g

Volume of calibrating container (V) cm3

Mass of sand (+Cylinder) before pouring (m1) g

Mean mass of sand (+Cylinder) after pouring (m 3) g

Mass of sand to fill calibrating container

(ma = m1 - m3 - m2 ) g

Bulk density of sand Ps = ma

gm/cm3

v

(Contd…)

FIELD DRY DENSITY TEST(SAND REPLACEMENT METHOD)

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 46

CHAINAGE: BORROW PIT NO. :

LAYER NO. : O M C (%) :

M D D (gm/cc) :

O.M.C (I.S. 2720 : Part 8) : %)

M.D.D - IS : 2720 – 8 gm/cc

Bulk Density of Sand , Ps gm/cc

Sand retained in cone ,m gm/cc

Test Number 1 2 3 4 5 6

Mass of wet soil from hole (mw) gm/cc

Mass of sand + cylinder before pouring gm

Mass of sand + cylinder after pouring gm

Mass of sand, ( mb = m1-m2-m) gm

Bulk density, p = mv X Ps gm/cc

mb

Container Number

Wt. of container, w gm

Wt. of wet soil container, w1 gm

Wt. of dried soil +Container, w2 gm

Wt. of moisture , w3 = (w1-w2) gm

Wt. of dry Soil w4 = (w2 –w) gm

Moiture Content m = w 3 x100 gm

w4

Dry density y = 100 p gm/cc

100+m

% compaction

Average moisture content %

Average compaction %

Acceptance Criteria

As per MORT&H specification

Clause No. 903

FORM – F8

DATA SHEET FOR GRADATION OF AGGREGATES

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 47

(AS PER IS : 2386)

BORROW PIT NO: DATE OF SAMPLING :

LOCATION/CHAINAGE: DATE OF TESTING :

SAMPLE NO & DEPTH (m) : SAMPLING BY :

TESTED BY :

OBSERVATIONS

Mass of soil Cumulative

Is Sieve Cumulative Mass Percentage

retained in percentage Remarks

Designation retained in qms. passing

gms retained

45 mm

37.5 mm

26.5 mm

22.4 mm

19.00 mm

13.2 mm

11.2 mm

9.5 mm

5.6 mm

4.75 mm

1.80 mm

2.36 mm

300 mic

90 mic

75 mic

Pan

Total

FORM – F9

DATA SHEET FOR GRADATION OF SAND

(AS PER IS : 2386)

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 48

Ref : MORT & H Specifications Clause No. 1008

BORROW PIT NO: DATE OF SAMPLING :

LOCATION/CHAINAGE: DATE OF TESTING :

SAMPLE NO & DEPTH (m) : SAMPLING BY :

TESTED BY :

GRADATION OF SAND

Cumulative Cumulative

I.S.Sieve Wt. Retained % Retained As Per Code

% Retained % Retained

10 mm

4.75 mm

2.36 mm

1.18 mm

600 mic

300 mic

150 mic

Pan

Zone :

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 49

FORM – F10

DATA SHEET FOR - NUCLEAR MOISTURE-DENSITY GAUGE

(AS PER ASTM:D 3017-88, D 2922-81, D 2950-91)

BORROW PIT NO: DATE OF SAMPLING :

LOCATION/CHAINAGE: DATE OF TESTING :

SAMPLE NO & DEPTH (m) : SAMPLING BY :

TESTED BY :

OBSERVATIONS

1. Test No. 1 2 3 4 5 6 7 8 9 10 11 12

Test Longitudinal KM

2.

Location Transverse M

3. Test depth CM

4. Count Time, sec

5. Mode of Test

6. Density bias, g/cm3

7. Moisture bias, g/cm3

MDD g/cm3

8. LAB

OMC %

9. Bulk Density g/cm3

10. Moisture Content %

11. Dry Density g/cm3

12. Compaction %

13. Avg. Compaction %

Specified Minimum

14.

Compaction %

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 50

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 51

FORM – F12

DATA SHEET FOR GRADATION FOR COARSE GRADED GRANULAR SUB-BASE

(AS PER IS:2386 & MORT&H SPECIFICATIONS Table No.400-1)

BORROW PIT NO: DATE OF SAMPLING :

LOCATION/CHAINAGE: DATE OF TESTING :

SAMPLE NO & DEPTH (m) : SAMPLING BY :

TESTED BY :

OBSERVATIONS

Mass of Cumulative Limits Percentage Passing

Cumulative

Is sieve Soil Mass Percentage is Sieve for (Table 400-1)

Percentage

Designation Retained Retained Passing

Retained Grading Grading Grading

(gm.) (gm.)

I II III

75.0 mm

53.0 mm

26.5 mm

4.75 mm

2.36 mm

0.425 mm

0.075

PAN

GRADATION CURVE

10

0

90

PERCENTAGE

80

70

60

50

40

30

20

10

0

SIEVE DESIGNATION (LOG - SCALE)

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 52

FORM – F13

DATA SHEET FOR GRADATION FOR CLOSE GRADED GRANULAR SUB-BASE

(AS PER IS:2386)

BORROW PIT NO: DATE OF SAMPLING :

LOCATION/CHAINAGE: DATE OF TESTING :

SAMPLE NO & DEPTH (m) : SAMPLING BY :

TESTED BY :

OBSERVATIONS

Mass of Cumulative Limits Percentage Passing

Cumulative is Sieve for

Is sieve Soil Mass Percentage

Percentage

Designation Retained Retained Passing Grading Grading Grading

Retained

(gm.) (gm.) I II III

75.00 mm 100 - -

53.00 mm 80 - 100 100 -

26.50 mm 55 - 90 70 - 100 100

9.50 mm 35 - 65 50 - 80 65 - 95

4.75 mm 25 - 55 40 - 65 50 - 80

2.36 mm 20 - 40 30 - 50 40 - 65

0.425 mm 10 - 25 15 – 25 20 - 35

0.075 3 - 10 3 - 10 3 - 10

PAN

GRADATION CURVE

10

0

90

PERCENTAGE

80

70

60

50

40

30

20

10

0

SIEVE DESIGNATION (LOG - SCALE)

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 53

FORM – F14

DATA SHEET FOR TEN PERCENT FINES VALUE (AS PER IS:2386 (PART-4))

BORROW PIT NO: DATE OF SAMPLING :

LOCATION/CHAINAGE: DATE OF TESTING :

SAMPLE NO & DEPTH (m) : SAMPLING BY :

TESTED BY :

SAMPLE - GRANULAR SUB BASE

Depth of penetration: 20 mm

Time of penetration: 10 mins

Test No. 1 2 3 Remarks

Weight of aggregate passing I.S. Sieve 125 mm and

retained on 10 mm I.S.Sieve

Weight of fraction passing I.S.Sieve 2.36 mm after the

test

Weight of fraction retained on I.S.Sieve 2.36 mm after

test

Percent passing I.S.Sieve 2.36 mm

Max compressive force (KN)

10 percent fines value =

14 x X

Y+4

Where X = Loading tones

Y = mean percentages of fines from two

tests at X tones load

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 54

FORM - F15

SUMMARY OF TEST RECORD - GRANULAR SUB-BASE MATERIAL

BORROW PIT NO: DATE OF SAMPLING :

LOCATION/CHAINAGE: DATE OF TESTING :

SAMPLE NO & DEPTH (m) : SAMPLING BY :

TESTED BY :

Sl.

Tests Specified Valued Test Results

No.

1. Sample Location -

2. Date of Test -

3. Sample Identification No. -

4. Grading (Sieve Size) (See Note)

75 mm 100

53 mm

26.5 mm 55-75

9.5 mm

4.75 mm 10-30

2.36 mm

0.425 mm

0.075 mm < 10

Plasticity Modulus

Max. 90

(P.I x % Passing 0.425 mm)

5. 10% Fines Value (Wet) Max. 50 KN

6. Water Absorption 2%

7. Soundness

8. CBR at 98% of MDD Min. 75

9. MDD & OMC -

10. LL and PI 15%, 0%

11. Deleterious Constituents Nil

12. Suitability / Remarks -

13. Tested / Checked by -

14. Checked / Approved by -

Note : 1. Circle or underline non-confirming values.

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 55

FORM – F16

DATA SHEET FOR GRADATION FOR WET MIX MACADAM

BORROW PIT NO: DATE OF SAMPLING :

LOCATION/CHAINAGE: DATE OF TESTING :

SAMPLE NO & DEPTH (m) : SAMPLING BY :

TESTED BY :

OBSERVATIONS

Mass of Soil Cumulative Cumulative

Is sieve Percentage Limits Percentage

Retained Mass Retained Percentage

Designation Passing Passing

(gm.) (gm.) Retained

53.00 mm 100

45.00 mm 95 - 100

22.40 mm 60 - 80

11.20 mm 40 - 60

4.75 mm 25 - 40

2.36 mm 15 - 30

0.60 mm 8 - 22

0.075 mm 0-8

PAN

GRADATION CURVE

100

PERCENTAGE PASSING

90

80

70

60

50

40

30

20

10

0

SIEVE DESIGNATION (LOG - SCALE)

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 56

FORM – F17

SUMMARY OF TEST RECORD – WET MIX MACADAM MATERIAL FOR SUBBASE/BASE

BORROW PIT NO: DATE OF SAMPLING :

LOCATION/CHAINAGE: DATE OF TESTING :

SAMPLE NO & DEPTH (m) : SAMPLING BY :

TESTED BY :

Sl.

Tests Specified Valued Test Results

No.

1. Sample Location (Km + meter) -

2. Date of Test -

3. Sample Identification No. -

4. Layer -

5. AIV Max 30%

6. Los Angeles Abrasion (alt to AIV) Max 40%

7. Flakiness & Elongation Index (total) Max 30%

8. Plasticity Index (%) Max 6

9. Water Absorption Max 2%

CBR Value > 100

Max 12% with

10. Soundness (if absorption exceeds 2%)

sodium sulphate

11. MDD (by heavy compaction) gm/cc -

12. OMC % -

13. Grading Percentage

I.S Sieve Size Passing

53 mm 100

45 mm 95 - 100

26.5 mm -

22.4 mm 60 - 80

11.2 mm 40 - 60

4.75 mm 25 - 40

2.36 mm 15 - 30

600 micron 8 - 22

75 micron 0-8

14. Suitability / Remarks -

15. Tested by -

16. Checked / Approved by -

FORM – F18

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 57

DATA SHEET FOR FIELD DENSITY OF BITUMINOUS MACADAM

(AS PER AASHTO:T-166)

LOCATION/CHAINAGE : DATE OF SAMPLING :

SAMPLING BY : DATE OF TESTING :

TESTED BY :

OBSERVATIONS

Location Density (gm./cm3) Marshall Compaction %

Weight S.S.D. Average

Core Thickness Weight in Density

Offset L/R in water Weight Compaction

No. (mm) Air (gm) 8 = 5 x dw (gm./ 10 = 8 x 100

Chainage from Centre (gm) (gm) %

7x6 0.997 cm3) 9

Line

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11)

* Test Temperature of Water = ………………..0C

* dw = Density of Water at Test Temperature = ……………gm./cm 3

FORM – F19

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 58

DATA SHEET FOR MARSHALL DENSITY OF BITUMINOUS MACADAM

(AS PER AASHTO:D-1559)

LOCATION/CHAINAGE : DATE OF SAMPLING :

SAMPLING BY : DATE OF TESTING :

TESTED BY :

OBSERVATIONS

Bitumen Specimen Specimen Saturated Surface Volume of Marshall

Sample

Content Weight in Air Weight in Dry Weight in Air Specimen Density

No.

% (gm.) Water (gm.) (gm) (cm3) (gm./cm3)

7=

1 2 3 4 5 6=5-4

(3/6)x(dw/0.997)

* Test Temperature of Water = ………………..0C

* dw = Density of Water at Test Temperature = ……………gm./cm 3

FORM – F20

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 59

DATA SHEET FOR BINDER CONTENT

(AS PER IRC:SP-11)

LOCATION/CHAINAGE : DATE OF SAMPLING :

SAMPLING BY : DATE OF TESTING :

TESTED BY :

OBSERVATIONS

Sl.

Description Sample 1 Sample 2 Sample 3 Remarks

No.

1 Weight of Mix, W (gm.)

Weight of Sample (BOWL + MIX) Before

2

Extraction, W1 (gm.)

Weight of Sample (BOWL + MIX) After

3

Extraction, W2 (gm.)

Weight of Filter Paper Before Extraction,

4

W3 (gm.)

Weight of Filter Paper After Extraction,

5

W4 (gm.)

Bitumen Content by WT. of MIX % =

6

[( W1 - W2 ) – (W4 – W3 ) / W] x 100

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 60

FORM – F21

DATA SHEET FOR SPECIFIC GRAVITY OF BITUMEN

(AS PER IS:1202)

LOCATION/CHAINAGE : DATE OF SAMPLING :

SAMPLING BY : DATE OF TESTING :

TESTED BY :

OBSERVATIONS

Sl. Sample Sample Sample

Description Average

No. No. 1 No. 2 No. 3

1 Weight of Pycnometer ( W1)

2 Weight of Pycnometer + Sample (W2)

3 Weight of Pycnometer + Sample + Water (W3)

4 Weight of Pycnometer + Full of Water (W4 )

5 Weight of Sample (W2 - W1)

6 Specific Gravity of Sample ( W2 - W1 )

(W4 - W1 ) – (W3 – W2)

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 61

FORM – F22

DATA SHEET FOR STRIPPING VALUE OF ROAD AGGREGATES

(AS PER IS:6241)

LOCATION/CHAINAGE : DATE OF SAMPLING :

SAMPLING BY : DATE OF TESTING :

TESTED BY :

OBSERVATIONS

Sl. No. Stripping Percentage Remarks

Average Value :

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 62

FORM – F23

DATA SHEET FOR GRADATION FOR BITUMINOUS MACADAM (OVERLAY)

(AS PER IS:2386)

LOCATION/CHAINAGE : DATE OF SAMPLING :

SAMPLING BY : DATE OF TESTING :

TESTED BY :

OBSERVATIONS

Limits Limits

Mass of Soil Cumulative Cumulative

Is Sieve Percentage Percentage Percentage

Retained Mass Retained Percentage

Designation Passing Passing Passing

(gm.) (gm.) Retained

Grading – I Grading – II

45.0 mm 100 -

37.5 mm 90 - 100 -

26.5 mm 75 - 100 100

22.4 mm 60 - 95 75 - 100

11.2 mm 30 - 55 50 - 85

5.6 mm 15 - 35 20 - 40

2.8 mm 5 - 20 5 - 20

0.09 mm 0-5 0-5

PAN

GRADATION CURVE

100

90

PERCENTAGE PASSING

80

70

60

50

40

30

20

10

0

SIEVE DESIGNATION (LOG - SCALE)

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 63

FORM – F24

DATA SHEET FOR GRADATION FOR BITUMINOUS MACADAM

(PROFILE CORRECTIVE COURSE)

(AS PER IS:2386)

LOCATION/CHAINAGE : DATE OF SAMPLING :

SAMPLING BY : DATE OF TESTING :

TESTED BY :

OBSERVATIONS

Is Sieve Mass of Soil Cumulative Cumulative Limits Percentage

Percentage

Designatio Retained Mass Retained Percentage Passing Grading

Passing

n (gm.) (gm.) Retained for P.C.C

13.2 mm 100

9.5 mm 85 - 100

6.7 mm 30 - 60

3.35 mm 15 - 25

0.075 mm 2-7

PAN

GRADATION CURVE

100

PERCENTAGE PASSING

90

80

70

60

50

40

30

20

10

0

SIEVE DESIGNATION (LOG - SCALE)

FORM – F25

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 64

DATA SHEET FOR MARSHALL PROPERTIES OF ASPHALTIC MIX

(DAILY PRODUCTION)

LOCATION/CHAINAGE : DATE OF SAMPLING :

SAMPLING BY : DATE OF TESTING :

TESTED BY :

Specimen Numbers 1 2 3 4

Weight in Air (Dry)

Weight in Air (with Wax)

Bitumen Percent : ………..……………

Weight in Water

Pen. Type AC :….. ……….……………

Bulk Volume (Cm3) Avg. Sp. Gr. Agg : ………..……………

Bulk Sp. Gr. Compacting Temp : ....…..……………

Avg. Bulk Sp. Gr. No. of Blows on each Face : …………

Theo Max. Sp. Gr. Effect Sp. Gr. : …..…………….………

Sp. Gr. Bitumen : ….…………..………

V.I.M (%)

Sp. Gr. Of Paraffin wax :……..………

Bitumen by Volume (%)

V.M.A. (%)

V.F.B. (%)

Stability Measured (kgf)

Volume Correction Factor

Corrected Stability (kgf)

Flow (mm)

Average Flow (mm)

Stiffness (kg / mm)

Test Method

FORM – F26

DATA SHEET FOR SPECIFIC GRAVITY OF FILLER

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 65

LOCATION/CHAINAGE : DATE OF SAMPLING :

SAMPLING BY : DATE OF TESTING :

TESTED BY :

Sample No. 1 2

Weight of Bottle

Weight of Sample + Water

Weight of Sample

Weight of Bottle + Solvent

Weight of Bottle + Solvent + Sample

Density of Solvent

Sp. Gr. of Filler

Avg. Sp. Gr. of Filler

Remarks

FORM – F27

DATA SHEET FOR COMBINED SPECIFIC GRAVITY OF HOT BIN AGGREGATES

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 66

LOCATION/CHAINAGE : DATE OF SAMPLING :

SAMPLING BY : DATE OF TESTING :

TESTED BY :

Size of Material % Used Average of Bulk Sp. Gravity

Combined SG :

FORM – F28

DATA SHEET FOR - DUCTILITY TEST

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 67

LOCATION/CHAINAGE : DATE OF SAMPLING :

SAMPLING BY : DATE OF TESTING :

TESTED BY :

Trial 1 Trial 2

Grade of Bitumen = Cm Cm

Determination of ductility expressed as the

distance in centimeter to which a standard

briquette of bitumen under standard conditions

can be stretched before the thread breaks.

Average

Result : Ductility Value =

IS : 1208 – (1979)

FORM – F29

DATA SHEET FOR PENETRATION VALUE OF BITUMEN

LOCATION/CHAINAGE : DATE OF SAMPLING :

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 68

SAMPLING BY : DATE OF TESTING :

TESTED BY :

OBSERVATIONS

Penetration in Penetration in

Sl. Type of Temp. Initial Reading Initial Reading

1 / 10 mm 1 / 10 mm Remarks

No. Material in (0C) 1/10 mm (R1) 1/10 mm (R2)

(R2 - R1) (Average)

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 69

FORM – F30

DATA SHEET FOR - TIME AND TEMPERATURE RECORD OF BITUMEN MIX

LOCATION/CHAINAGE : DATE OF SAMPLING :

SAMPLING BY : DATE OF TESTING :

TESTED BY :

Departur Location of Paving site

Temp. At Arrival

Sl. e Time Temp. at Laying

Tipper No. departure Time at

No. from site Temp. From To

from HMP site

HMP

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 70

FORM – F31

DATA SHEET FOR BITUMEN EXTRACTION OF BM (PROFILE CORRECTIVE COURSE) / BM

(OVERLAY) / MSS

LOCATION/CHAINAGE : DATE OF SAMPLING :

SAMPLING BY : DATE OF TESTING :

TESTED BY :

Recoded By

Recoded By

Reference

Reference

Layer No.

Layer No.

Remarks

Remarks

Bitumen

Bitumen

Content

Content

Km / m

Km / m

Sl. NO.

Sl. NO.

1 2 3 4 5 6 7 1 2 3 4 5 6 7

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 71

FORM – F32

DATA SHEET FOR TIME AND TEMPERATURE RECORD FOR BM / MSS / SD

LOCATION/CHAINAGE : DATE OF SAMPLING :

SAMPLING BY : DATE OF TESTING :

TESTED BY :

Recorded by

Recorded by

Temperature Temperature

half hourly)

half hourly)

Time (min

Time (min

Remarks

Remarks

Km / m

Km / m

Sl. NO.

Sl. NO.

Date

Date

Rolling

Rolling

Laying

Laying

Binder

Binder

Aggr.

Aggr.

Mix

Mix

1

1 2 3 4 5 6 7 8 9 10 11 1 2 3 4 5 6 7 8 9 11

0

FORM – F33

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 72

DATA SHEET FOR AGGREGATE CHARACTERISTICS FOR BITUMINOUS MACADAM (OVELAY)

LOCATION/CHAINAGE : DATE OF SAMPLING :

SAMPLING BY : DATE OF TESTING :

TESTED BY :

E.I + Water Stripping

Remarks

Location

Grading % Passing IS Sieve A.I.V

Recorde

Km / m

Sl. NO.

F.I Absorption Value

d By

45 26.5 22.4 11.2 5.6 2.8 0.09 Ref

Ref

Ref

Ref

Ref

m mm mm mm m m mm

%

m m m

1 1 1

1 2 3 4 5 6 7 8 9 10 14 15 16 17 18 19 20

1 2 3

FORM – F34

DATA SHEET FOR AGGREGATE CHARACTERISTICS FOR BITUMINOUS MACADAM

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 73

(PROFILE CORRECTIVE COURSE)

LOCATION/CHAINAGE : DATE OF SAMPLING :

SAMPLING BY : DATE OF TESTING :

TESTED BY :

E.I

Grading % Passing IS Sieve (mm)

Recorded By

Water Stripping

AIV +

Layer No.

Remarks

Location

Absorption Value

Km / m

Sl. NO.

F.I

45 37.5 26.5 13.2 4.75 2.36 0.3 0.075

mm mm mm mm mm mm mm mm

%

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

FORM – F35

SUMMARY OF TEST RECORD - AGGREGATE FOR BITUMINOUS CONCRETE

LOCATION/CHAINAGE : DATE OF SAMPLING :

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 74

SAMPLING BY : DATE OF TESTING :

TESTED BY :

1. Sample Location (Km + meter) -

2. Date of Test -

3. Sample Identification No. -

4. Aggregate Impact Value (AIV) Max 24 %

5. Flakiness & Elongation Index (combined) Max 30%

6. Stripping Value Min Coating 95%

a) Soundness in Sodium Sulphate Max 12 %

7.

b) Soundness in Magnesium Sulphate Max 18 %

8. Water Absorption Max 2 %

9. Grading Percentage

Grading No. Sieve Size passing

Grading 1 45 mm -

37.5 mm -

26.5 mm 100

19 mm 79-100

13.2 mm 59-79

9.5 mm 52-72

4.75 mm 35-55

2.36 mm 28-44

1.18 mm 20-34

0.6 mm 15-27

0.3 mm 10-20

0.15 mm 5-13

0.075 mm 2-8

10. Suitability / Remarks -

11. Tested by -

12. Checked/Approved By -

Note : See special specification for the specified grading number of aggregate.

FORM – F36

SUMMARY OF TEST RECORD - AGGREGATE FOR DENSE BITUMINOUS MACADAM

LOCATION/CHAINAGE : DATE OF SAMPLING :

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 75

SAMPLING BY : DATE OF TESTING :

TESTED BY :

Sl.

Tests Specified Value Test Results

No.

1. Sample Location (Km + meter) -

2. Date of Test -

3. Sample Identification No. -

4. Aggregate Impact Value Max 27 %

5. Flakiness & Elongation Index (total) Max 30%

6. Coating and Stripping Min Coating 95%

a). Soundness in Sodium Sulphate Max 12 %

7.

b). Soundness in Magnesium Sulphate Max 18 %

8. Water Absorption Max 2 %

9. Sand Equivalent Value Not < 50

10. Percentage passing

Sieve size

Gr I Gr II

Nominal agg. Size 40 25

45 100 -

37.5 95 - 100 100

26.5 63 - 93 90 - 100

19 - 71 - 95

13.2 55 - 75 56 - 80

4.75 38 - 54 38 – 54

2.36 28 - 42 28 - 42

0.3 7 - 21 7 - 21

0.075 2-8 2-8

10. Suitability / Remarks -

11. Tested by -

12. Checked/Approved By -

FORM – F37

SUMMARY OF TEST RECORD AGGREGATE FOR DENSE BITUMINOUS MACADAM MIX

LOCATION/CHAINAGE : DATE OF SAMPLING :

SAMPLING BY : DATE OF TESTING :

TESTED BY :

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 76

Sl.

Tests JMF Specified Valued Test Results

No.

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 77

1. Sample Location (Km + meter) - -

2. Date of Test - -

3. Sample Identification No. - -

Binder Content (by weight) + 0.30 %

4.

variations

5. Grading % passing

Grading No. Sieve size For base / binder For wearing course

> 19 mm +8 +7

13.2 / 9.5 mm +7 +6

4.75 mm +6 +5

2.36, 1.18 mm,

+5 +4

600 mm

300 mic , 150 mic +4 +3

75 micron +2 + 1.5

6. Mixing Temperature + 100 C

7. Mix Properties Requirement

a) Marshal Stability Min 820 kg at 75 blows 600 C

b) Marshal Flow 2 - 4 mm

c) Air Voids 4 -7 %

d) VMA 10 -12

e) VFB 65 – 75 %

f) Binder content % by Wt.

Not less than 4.5%

Of total mix

g) Stability to flow ratio 205 - 410

h) Air voids in mix by 300

3%

blows

8. Passed / Failed Remarks -

9. Tested by -

10. Checked / approved by -

Note : 1. Fill up JMF (Job Mix Formula) column using Mix Design results

2. Location on road bed, where the mix under test is laid, is to be linked from return copy of chalan delivering

the load of mix.

3. Circle or underline the results not conforming to specification. If more than one out of 10 values of any

sample fail, investigate reasons.

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 78

FORM – F38

SUMMARY OF TEST RECORD - AGGREGATE FOR BITUMINOUS CONCRETE

LOCATION/CHAINAGE : DATE OF SAMPLING :

SAMPLING BY : DATE OF TESTING :

TESTED BY :

Sl.

Tests Specified Value Test Results

No.

1. Sample Location (Km + meter) -

2. Date of Test -

3. Sample Identification No. -

4. Aggregate Impact Value Max AIV 24 %

Flakiness & Elongation Index

5. Max 30%

(combined)

6. Coating and Stripping Min Coating 95%

a) Soundness in Sodium Sulphate Max 12 %

7. b) Soundness in Magnesium Max 18 %

Sulphate

8. Water Absorption Max 2 %

9. Sand Equivalent Value Min 50

10. Stone polishing Value Min 55

11. Grading

Sieve Size Grade I Grade II

26.5 mm 100 -

19 mm 79 - 100 100

9.5 mm 59 - 72 70 - 88

4.75 mm 35 - 55 53 - 79

2.36 mm 28 - 44 42 - 58

1.18 mm 20 - 34 34 - 48

600 micron 15 - 27 26 - 38

300 micron 10 - 20 18 - 28

150 micron 5 - 13 12 - 20

75 micron 2-8 4 - 10

12. Suitability / Remarks -

13. Tested by -

14. Checked / Approved By -

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 79

FORM – F39

SUMMARY OF TEST RECORD - BITUMINOUS CONCRETE MIX

LOCATION/CHAINAGE: DATE OF SAMPLING :

SAMPLE NO & DEPTH (m) : DATE OF TESTING :

SAMPLING BY : TESTED BY :

Sl.

Tests JMF Specified Value Test Results

No.

1. Sample Location (Km + meter) - -

2. Date of Test - -

3. Sample Identification No. - -

4. Binder Content (by weight) + 0.30 %

5. Grading % passing

Grading No. Sieve size For base / binder For wearing course

> 19 mm +8 +7

13.2 / 9.5 mm +7 +6

4.75 mm +6 +5

2.36, 1.18 mm,

+5 +4

600 mm

300 mic , 150 mic +4 +3

75 micron +2 + 1.5

0

6. Mixing Temperature + 10 C

7. Mix Properties Requirement

a) Marshal Stability Min 1200 kg at 75 blows 600 C

b) Marshal Flow 2 - 4 mm

c) Air Voids 4-7%

d) VMA 11 - 13% 11 - 13%

i) VFB 65 – 75 %

j) Water Sensitivity (retained

Min 75 %

strength)

k) Swell Max 1.5 %

l) Binder content by Wt. Of total

Min 5.5%

mix

m) Stability flow ratio 205 - 410

n) Air voids in mix using 300

3%

blows

8. Passed / Failed Remarks -

9. Tested by -

10. Checked / approved by -

Note : 1. Fill up JMF (Job Mix Formula) column using Mix Design results

2. Location on road bed, where the mix under test is laid, is to be linked from return copy of chalan delivering

be load of mix.

3. Circle or underline the results not conforming to specification. If more than one out or 10 values of any

sample fail, investigate reasons.

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 80

FORM – F40

DATA SHEET FOR FLAKINESS INDEX AND ELONGATION INDEX

LOCATION/CHAINAGE: DATE OF SAMPLING :

NAME OF QUARRY : DATE OF TESTING :

SAMPLING BY : TESTED BY :

OBSERVATIONS

Flakiness Index Elongation Index

Passing Retained on

Sl. through I.S. I.S. Sieve Weight of the Weight of aggregate Weight of Non- Weight of aggregate

No. Sieve in size (mm) aggregate taken in each fraction Flaky aggregate in each fraction not

Size (mm) in each fraction passing Thickness taken in each passing the length

(gm.) gauge (gm.) fraction (gm.) gauge (gm.)

1. 63 50

2. 50 40

3. 40 25

4. 31.5 25

5. 25 20

6. 20 16

7. 16 12.5

8 12.5 10

9 10 6.3

W: w: W1: w1:

(w / W) x 100 : % (w1 / W1) x 100 : %

Combined F.I. + E.I = ________________%

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 81

FORM – F41

DATA SHEET FOR TESTS ON FINE AGGREGATES / SAND

LOCATION/CHAINAGE: DATE OF SAMPLING :

NAME OF QUARRY : DATE OF TESTING :

SAMPLING BY : TESTED BY :

SPECIFIC GRAVITY OF FINE AGGREGATES / SAND

Description 1 2 3 Average

Wt. of empty pycnometer (gms) A1

Wt. of empty pycnometer + dry sand (gms) A2

Wt. of empty pycnometer + dry sand + water

(gms) A3

Wt. of dry sand (gms) A2 - A1 = A

Wt. of pycnometer + water (gms) A4

Wt. of wet sand (gms) A3 - A4 = B

Specific Gravity of Sand = A / (A-B)

SIEVE ANALYSIS OF FINE AGGREGATES / SAND

Mass of Sand % age Cumulative

%age I.S.Zone I.S.Zone I.S.Zone

I.S.Sieve Retained Mass %age

Passing I II III

(gm) Retained Retained

10 mm 100 100 100

4.75 mm 90 - 100 90 - 100 90 - 100

2.36 mm 60 – 95 15 - 100 85 - 100

1.18 mm 30 - 70 55 - 90 75 - 100

600 micron 15 – 34 35 - 59 60 - 79

300 micron 5 - 20 8 - 30 12 - 40

150 micron 0 - 10 0 - 10 0 - 10

Total

Weight

Fineness Modulus :

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 82

FORM – F42

DATA SHEET FOR SPECIFIC GARVITY & WATER ABSORPTION TESTS ON COARSE

AGGREGATES

(AS PER IS : 2386- PART 3)

LOCATION/CHAINAGE: DATE OF SAMPLING :

NAME OF QUARRY : DATE OF TESTING :

SAMPLING BY : TESTED BY :

COARSE AGGREGATE SIZE LARGER THAN 10 MM

Weight of saturated aggregate in water (A)* (gm)

Weight of saturated surface-dry aggregate (gm)

in air (B)

Weight of oven dried aggregate in air (C) (gm)

Specific Gravity= C/(B-A)

Apparent specific gravity = C/(C-A)

Water absorption (% of dry weight)=100(B-C)/C %

COARSE AGGREATEB SIZE SMALLER THAN 10 MM

Weight of saturated surface-dry sample (A)** (gm)

Weight of pycnometer or gas jar with sample

and distilled water (B) (gm)

Weight of pycnometer or gas jar with distilled

water only (C) (gm)

Weight of oven-dried sample (D) (gm)

Specific gravity = D/(A-(B-C))

Apparent specific gravity = D/(D-(B-C)

Water absorption (% of dry weight)=100 (A-D)/D

NOTE : *Minimum sample Weight 2000gms

**Minimum Sample Weight 1000gms.

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 83

FORM – F43

DATA SHEET FOR SOUNDNESS OF AGGREGATE

(AS PER IS : 2386- PART 5)

LOCATION/CHAINAGE: DATE OF SAMPLING :

NAME OF QUARRY : DATE OF TESTING :

SAMPLING BY : TESTED BY :

Recording Test Data

Grading of Weight of Test Percentage

Sieve Size Weight

Original Sample Fractions Passing

Percentage Remarks

Percent Before Test Designated

Passing Retained Loss

(Retained) (gms) After Test

Soundness of Fine Aggregates

150 mic -

300 mic 150 mic

600 mic 300 mic

1.18 mm 600 mic

2.36 mm 1.18 mm

4.75 mm 2.36 mm

10 mm 4.75 mm

Total

Soundness of Coarse Aggregates

63 mm 50 mm

50 mm 40 mm

40 mm 25 mm

25 mm 20 mm

20 mm 12 mm

12 mm 10 mm

10 mm 4.75 mm

Totals

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 84

FORM – F44

DATA SHEET FOR LOS ANGELES ABRASION VALUE TEST

(AS PER IS : 2386- PART 4)

LOCATION/CHAINAGE: DATE OF SAMPLING :

NAME OF QUARRY : DATE OF TESTING :

SAMPLING BY : TESTED BY :

Cycles (33 R.P.M.) 500 No. 1 2

Initial Wight A …………….. gm

Weight Retained after Test on No. 12

B …………….. gm

Sieve

A–B

LAV = ------- x 100

A

% By Weight Passing No. 12 Sieve ………….. gm

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 85

FORM – F45

DATA SHEET FOR AGGREGATE IMPACT VALUE TEST

(AS PER IS : 2386- PART 4)

LOCATION/CHAINAGE: DATE OF SAMPLING :

NAME OF QUARRY : DATE OF TESTING :

SAMPLING BY : TESTED BY :

TEST NO

S.No. DESCRIPTION ACCEPTABLE UNIT

1 2

1. Wt. of cylindrical measure (W1) (gms)

2. Wt. of cylindrical measure + test

sample (W2) (gms)

3. Wt. of test sample placed in cylindrical

(W2-W1) (gms)

4. Wt. of crushed material passing

IS sieve 2.36 mm . (W3) (gms)

5. Aggregate impact value %

100*W3/(W2-W1)

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 86

FORM – F46

DATA SHEET FOR SUMMARY OF TEST RESULTS FOR ORDINARY PORTLAND CEMENT

(AS PER IS : 269- 1989)

SOURCE : DATE OF SAMPLING :

QUANTITY (M.TONNES): DATE OF TESTING :

SAMPLING BY : TESTED BY :

SL.

NO. TEST RESULT ACCEPTABLE LIMIT

1. Fineness by BLAINE’S air permeability method Not less than 225

as per IS: 4031 (Part 2) , m2/Kg.

2. Compressive strength as per IS:4031

(Part 6), Mpa :

a. 72 1 hour Not less than 160

b. 168 2 hours Not less than 220

c. 672 4 hours Not less than 330

3. Setting time as per IS :4031 (Part 5), minutes :

a. Initial Not less than 300

b. Final Not more than 600

4. Soundnees (as per IS: 4031 (Part 3)) :

a. Lechatelier method , mm Not more than 1.

b. Autoclave method , percent Not more than 0.

5. Total Chloride content % by mass of Not more than 0.05 %

cement , as per IS: 12423- 1988

6. Total Sulphur content % (as SO3) Not more than 2.5 % &

3.0% *

7. Normal Consistency, %

CONFORMS TO SPECIFICATION DOES NOT CONFORM

(* - when tri calcium aluminate percent by mass is up to 5 or greater than 5 respectively)

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 87

FORM – F47

DATA SHEET FOR SUMMARY OF TEST RESULTS FOR CEMENT (CHEMICAL COMPOSITION)

(AS PER IS : 269- 1989 & IS : 8112)

SOURCE : DATE OF SAMPLING :

QUANTITY (M.TONNES): DATE OF TESTING :

SAMPLING BY : TESTED BY :

SI. TEST RESULT ACCEPTABLE LIMIT

NO.

Ratio of percentage of lime to that of silica Not greater than 1.02 and not

1.

alumina and iron oxide less than 0.66

2. % of alumina/% Iron oxide Not less than 0.66

3. Insoluble residue, %by mass Not more than 2%

4. Magnesia , % by mass Not more than 6%

I) Not more than 2.5

5. Sulphur content, calculated as SO3,%by mass

when C3A not more

than 5%.

II) Not more than 3.0

when C3A is greater

than 5%.

6. Total chloride content, % of mass of cement

(to be treated as per IS: -1988). Not more than 0.05%.

CONFORMS TO SPECIFICATION DOES NOT CONFORM

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 87

FORM – F48

CONCRETE POUR CARD

SOURCE : DATE OF SAMPLING :

QUANTITY (M.TONNES): DATE OF TESTING :

SAMPLING BY : TESTED BY :

Drawing No. Type of Concrete Mix :

Concrete Source : Site Batching Plant Total Vol. of Concrete:

Time Time Time Time Cumulative

Load Truck Air Concrete Quantity Concrete

Concrete Concrete Start Finish Slump Quantity in Remarks

No. No. Temp. Temp in M3 sample

Batch Arrive Pour Pour M3

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 88

FORM – F49

DATA SHEET FOR SUMMARY OF TEST RESULTS OF SAND FOR CONCRETE WORKS

(AS PER IS : 383 & IS : 2386)

SOURCE : DATE OF SAMPLING :

QUANTITY (M.TONNES): DATE OF TESTING :

SAMPLING BY : TESTED BY :

NAME OF QUARRY :

SI. ACCEPTABLE RANGE

TESTS RESULTS

NO.

1. Grading (zone) zone I, II, III

3

2. Bulk Density (Kg/m )

3. Moisture content (%)

4. Percentage of bulking

5. Coal & lignite (%by weight) Max 1.0

6. Clay lump (%by wt.) Max 1.0

7. Material finer than 75 micron Max 3.0*

IS sieve (% by wt)

8. Shale (% by wt.) Max 1.0

9. Soundness I) 10% in sodium

sulphate.

ii) 15% in magnesium

sulphate

10. Chloride content as Cl (%)

11. Sulphate as SO4 (%)

* 15% for crushed fine aggregate

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 89

FORM – F50

DATA SHEET FOR SUMMARY OF TEST RESULTS OF COARSE AGGREGATE FOR CONCRETE

WORKS (AS PER IS : 383 & IS : 2386)

SOURCE : DATE OF SAMPLING :

SAMPLING BY : DATE OF TESTING :

NAME OF QUARRY : TESTED BY :

SI TEST RESULT ACCEPTABLE LIMIT

NO

1. Grading 40/20/10 mm

graded aggregate

2. Coal and lignite (% by wt.) Max 1.0

3. Clay lumps (% by wt) Max 1.0

4. Material finer than 75 micron IS sieve (% by wt) Max 3.0

5. Soft flagments Nil *

6. Aggregate Impact (%) 30 %

7. Aggregate Abrasion value (%) 30 for wearing surface &

50 for others

8. Soundness (I) 12% in sodium

sulphate

(II) 18% in magnesium

sulphate

9. Flakiness Index (%) 35 %

10. Angularity Number -

11. bulk density/voids -

12. Specific gravity -

*3% for uncrushed aggregate.

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 90

FORM – F51

DATA SHEET FOR STRIPPING VALUE OF ROAD AGGREGATES (AS PER IS : 6241:1971)

SOURCE : DATE OF SAMPLING :

QUANTITY (M.TONNES): DATE OF TESTING :

SAMPLING BY : TESTED BY :

NAME OF QUARRY :

STRIPPING VALUE OF ROAD AGGREGATES

METHOD : IS - 6241: 1971

Sample No. 1 2 3 4 5

Stripping value at 40

(1)

deg C (%)

(2)

(3)

Av:

Stripping value at 60

(1)

deg C (Additional to IS

6241-1971)

(2)

(3)

Av:

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 91

FORM – F52

DATA SHEET FOR – SOUNDNESS OF CEMENT (AS PER IS : 4031 (PART 3) – 1988)

SOURCE : DATE OF SAMPLING :

QUANTITY (M.TONNES): DATE OF TESTING :

SAMPLING BY : TESTED BY :

SOUNDNESS OF CEMENT

AS PER IS : 4031 (PART 3) - 1998

1 2 Average

Initial length of the specimen = A (mm)

Final Length of the Specimen = B (mm)

Expansion = (B-A) mm

Remarks :

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 92

FORM – F53

SUMMARY OF TEST RESULTS FOR RC PIPES

(AS PER IS: 458 – 1988 & IS : 3597 – 1985)

SUPPLIER/MANUFACTURERS: CLASS OF PIPE :

PLACE OF TESTS: DATE OF TESTING :

INSPECTION & TESTING BY :

SL.NO Tests/Checks Test Method Results Acceptable Range

1. Dimensional Tolerances

a) Internal Diameter IS : 458 As per Table 4.10

b) Wall thickness As per Table 4.10

2. Water Absorption Tests IS: 3597 i) 2.5% for first 10

minutes immersion

ii) 6.5% for 20 hrs

immersion

3. 3-edge bearing tests IS: 3597 As per Table-3 of

(load to produce 0.25 mm IS:458-1988

crack)

4. Ultimate Load IS: 3597 As per Table-3 of

IS:458-1988

5. Hydrostatic Pressure Tests IS: 516

6. Concrete Cube compressive

strength

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 93

FORM – F54

SUMMARY OF TEST RESULTS OF WATER

(AS PER IS : 3025 – 1964)

SOURCE/LOCATION : DATE OF SAMPLING :

TO BE USED IN STRUCTURE NO: …………… DATE OF TESTING :

SAMPLING BY :

TESTED BY :

SL. PERMISSIBLE LIMIT

TEST RESULT

NO. (MAXIMUM)

1. pH Value Greater than 6

2. Chlorides, mg/1 2000 (PCC)

1000 (RCC)

500 (PSC)

3. Sulphates, mg/1 500

4. Organic solid, mg/1 200

5. Inorganic Solid, mg/1 3000

6. Suspended Solid, mg/1 2000

7. Qty. of 0.1 normal NaOH to neutralize 200 ml sample of 2 ml

water

8. Qty. of 0.1 normal NC1 to neutralize 200 ml sample of 10 ml

water

CONFORMS OF SPECIFICATION DOES NOT CONFORM

For Contractor For Consultant

Project: 4 Laning of Maddur – Mysore Road Section (km 82+500 to km 135+350

Excluding km 97+200 to km 101+000) of SH-17 (Bangalore - Mysore Road)

Quality Assurance Document Page : 94

FORM – F55

SUMMARY OF TEST RESULTS OF REINFORCEMENT HYSD BARS

(AS PER IS : 1786 (GRADE 415) )

SUPPLIER/MANUFACTURER : DATE OF SAMPLING

:

DIA OF BAR, mm : DATE OF TESTING :

SAMPLING BY :

QUANTITY (M. TONNE) : TESTED BY :

TO BE USED IN STRUCTURE (name) :

SL. PERMISSIBLE

TEST RESULT

NO.

1. Weight in Kg/m As per IS: 1786

2. 0.2% Proof stress/Yield stress, N/mm2 415 (min.)

(as per IS: 1608 – 1972)

10% more than actual

3. Tensile strength, N/mm2 0.2% proof stress but not

(as per IS:1608 – 1972) less than 485 N/mm2

4. Elongation, %, on gauge length 5.65 A 14.5 (min.)

where A = Sectional area of test piece

(as per IS: 1608 – 1972).

5. Bend Test, as per IS:1599 – 1974

6. Rebend Test as per 1786

7. Deformations and Surface Characteristics

as per IS: 1786

8. Chemical Composition as per IS: 1786.

CONFORMS OF SPECIFICATION DOES NOT CONFORM

For Contractor For Consultant

You might also like

- National Highways Authority of IndiaDocument2 pagesNational Highways Authority of IndiajitendraNo ratings yet

- All Lab FormatDocument285 pagesAll Lab FormatStupidity Talks100% (2)

- Field Dry Density CalculationDocument3 pagesField Dry Density CalculationAhteshaam MullaNo ratings yet

- Format 2Document77 pagesFormat 2Lab DAK-5 Sec 02No ratings yet

- Sub Base - Insitu Density TestDocument1 pageSub Base - Insitu Density TestEzire Ejiro L.No ratings yet

- Grain Size, LL, PLDocument13 pagesGrain Size, LL, PLGitanjali PandaNo ratings yet

- Construction Density Test ResultsDocument5 pagesConstruction Density Test ResultsChris AdaminovicNo ratings yet

- S03H A Rev4Document1 pageS03H A Rev4ruchiraNo ratings yet

- Soil GSB WMM by Sand Replacement MethodDocument2 pagesSoil GSB WMM by Sand Replacement MethodBrahammanand BairwaNo ratings yet

- Construction of Flyover at Km.77+750 on NH-44 in MaharashtraDocument1 pageConstruction of Flyover at Km.77+750 on NH-44 in MaharashtraMangeysh S. Chauhan100% (1)

- Testing Formats PDFDocument9 pagesTesting Formats PDFRohit NegiNo ratings yet

- Formate 1Document1 pageFormate 1liziaolaosanNo ratings yet

- Field Dry Density (Sand Replacement Method)Document3 pagesField Dry Density (Sand Replacement Method)Anurag ChaturvediNo ratings yet

- For GSB GR V & WMMDocument16 pagesFor GSB GR V & WMMSasanka SekharNo ratings yet

- Field Density Test by Sand Replacement MethodDocument6 pagesField Density Test by Sand Replacement MethodJ Marees Kumar ThangarathinamNo ratings yet

- Four Laning of Munger to Mirzachauki (NH-80)-Start From Kharia Village Junction to the Exisiting Bhagalpur Bypass (PKG-2-CH: KM 95+580 to KM 125+000) on Hybrid Annuity Mode in the State of BiharDocument1 pageFour Laning of Munger to Mirzachauki (NH-80)-Start From Kharia Village Junction to the Exisiting Bhagalpur Bypass (PKG-2-CH: KM 95+580 to KM 125+000) on Hybrid Annuity Mode in the State of BiharAmit MaityNo ratings yet

- FIELD DRY DENSITY TEST (Sand Replacement MethodDocument1 pageFIELD DRY DENSITY TEST (Sand Replacement MethodRR CONSTRUCTIONSNo ratings yet

- Grain Size Analysis For SoilsDocument11 pagesGrain Size Analysis For SoilsyogananthanNo ratings yet

- DensityDocument2 pagesDensityEngineeri TadiyosNo ratings yet

- Coring For 19ga0004Document1 pageCoring For 19ga0004Strip Club PhNo ratings yet

- fdd (1)Document3 pagesfdd (1)sudhaNo ratings yet

- National Highways Authority of India: FIELD DRY DENSITY TEST (By Sand Replacement Method)Document2 pagesNational Highways Authority of India: FIELD DRY DENSITY TEST (By Sand Replacement Method)SalimNo ratings yet

- GPL-NZ-Quality-F-12, 32 - 37, 110-115Document49 pagesGPL-NZ-Quality-F-12, 32 - 37, 110-115lavekushNo ratings yet

- Field Density Test (SRM)Document2 pagesField Density Test (SRM)manish upadhyay0% (1)

- Prasad Infrabuild Projects PVT LTD: Sample No. No G. G. G. CC G/CCDocument17 pagesPrasad Infrabuild Projects PVT LTD: Sample No. No G. G. G. CC G/CCAnil Kumsr T BNo ratings yet

- Sub Ballast CBR 25 10 2022Document5 pagesSub Ballast CBR 25 10 2022Naimur Rahman ShocchoNo ratings yet

- FDD FormatsDocument1 pageFDD FormatsSandeep JoshiNo ratings yet

- Chimney Drainage Zona 1 Sta 0+240-0+280 Stage 16Document7 pagesChimney Drainage Zona 1 Sta 0+240-0+280 Stage 16Nahli Kiddy AuliaNo ratings yet

- CH 0 + 100 - 0 + 500 Sub BaseDocument4 pagesCH 0 + 100 - 0 + 500 Sub Basesolomonejila54No ratings yet

- Material Testing Division: Soil Testing Information Office Use OnlyDocument16 pagesMaterial Testing Division: Soil Testing Information Office Use OnlyPramukh Test houseNo ratings yet

- Civ T Qac 00134 ProctorDocument6 pagesCiv T Qac 00134 ProctorIsaiahogedaNo ratings yet

- Daily Painting Inspection Report 01Document1 pageDaily Painting Inspection Report 01Oussama Ben AbbesNo ratings yet

- Soil WorksheetDocument19 pagesSoil WorksheetdhwaniNo ratings yet

- Material Test FormatDocument6 pagesMaterial Test FormatमधुNo ratings yet

- Field Density Test ReportDocument6 pagesField Density Test ReportAnmol PatelNo ratings yet

- Sancone SalinanDocument2 pagesSancone SalinanAnwarNo ratings yet

- 0239.22 - Tharratt Freitag Cartage Sand - SANS MDD CBR INDDocument1 page0239.22 - Tharratt Freitag Cartage Sand - SANS MDD CBR INDEzekiel SeanegoNo ratings yet

- Field Density Test (Sand Bath Method) - Stone DustDocument55 pagesField Density Test (Sand Bath Method) - Stone DustShesha ShayanNo ratings yet

- Leighton-OSE JV Indore-Khalghat Highway soil density testsDocument3 pagesLeighton-OSE JV Indore-Khalghat Highway soil density testsEnd EndNo ratings yet

- Proposed Soil Investigation Works at Lot 73682, Bukit Changgang, Banting For Kenting Development Sdn. BHDDocument29 pagesProposed Soil Investigation Works at Lot 73682, Bukit Changgang, Banting For Kenting Development Sdn. BHDCalvin KewNo ratings yet

- Field Register FormsDocument64 pagesField Register FormsveevimalNo ratings yet

- S3 Soil Sample of DudahidaDocument7 pagesS3 Soil Sample of DudahidaSahalii SahaliiNo ratings yet

- Client Caterpillar Signs PMC Compaction Test by Sand ReplacementDocument1 pageClient Caterpillar Signs PMC Compaction Test by Sand ReplacementBrahammanand BairwaNo ratings yet

- Soil Compaction Test ReportDocument7 pagesSoil Compaction Test ReportAkash SharmaNo ratings yet

- QC Form 6Document1 pageQC Form 6rashid ahmadiNo ratings yet

- Concrete Pour CardDocument68 pagesConcrete Pour CardBhagirath jonpuriNo ratings yet

- Pipe Insulation: Qa / QC FormDocument1 pagePipe Insulation: Qa / QC FormShyam Sundar GayenNo ratings yet

- Irjmets ArticleDocument7 pagesIrjmets ArticleSuraj PandeyNo ratings yet

- Trichy Tollway Private Limited: Ijm (India) Infrastructure LimitedDocument24 pagesTrichy Tollway Private Limited: Ijm (India) Infrastructure LimitedSureshKumarNo ratings yet

- Leak TestDocument10 pagesLeak Testsiddiquiee74No ratings yet

- Test Report Field Density Test Sand Replacement Method: Project NameDocument25 pagesTest Report Field Density Test Sand Replacement Method: Project NameKreesthu ReddyNo ratings yet

- National Highways Authority of India Construction Project Laboratory Test ResultsDocument12 pagesNational Highways Authority of India Construction Project Laboratory Test ResultsvikasNo ratings yet

- Fish Town - Harper Road Project Phase 1 Fish Town - Harper Road Project Phase 1Document1 pageFish Town - Harper Road Project Phase 1 Fish Town - Harper Road Project Phase 1kwameNo ratings yet

- Leighton - OSE JV Indore - Khalghat Highway Calibration ReportDocument17 pagesLeighton - OSE JV Indore - Khalghat Highway Calibration ReportEnd EndNo ratings yet

- Cement Testing ReportsDocument29 pagesCement Testing ReportstejakandulaNo ratings yet

- Mix Design Manual PDFDocument98 pagesMix Design Manual PDFB R Paul FortinNo ratings yet

- Principles of Concrete Mix Design ACCDocument8 pagesPrinciples of Concrete Mix Design ACCSunil ReddyNo ratings yet

- Bayong - Static Load Test Recording Form (Ok)Document7 pagesBayong - Static Load Test Recording Form (Ok)Kelvin Lau Hin HuatNo ratings yet

- MUMBAI NAGPUR EXPRESSWAY CONSTRUCTIONDocument60 pagesMUMBAI NAGPUR EXPRESSWAY CONSTRUCTIONAtanu PaulNo ratings yet

- Check List - Plumbing & Sanitary - InternalDocument1 pageCheck List - Plumbing & Sanitary - InternalParthasarathi H RNo ratings yet

- SITE GRADING CHECKLISTDocument1 pageSITE GRADING CHECKLISTParthasarathi H RNo ratings yet

- LBSyllabuswef 01062020Document6 pagesLBSyllabuswef 01062020Spb KumarNo ratings yet

- Model Question Paper for Valuation ExamDocument16 pagesModel Question Paper for Valuation ExamAnshul Chauhan50% (2)

- Check List - Post ConcretingDocument3 pagesCheck List - Post ConcretingParthasarathi H RNo ratings yet

- PILE DYNAMIC TESTINGDocument9 pagesPILE DYNAMIC TESTINGParthasarathi H RNo ratings yet

- Check List - Masonry Work - CC BlocksDocument1 pageCheck List - Masonry Work - CC BlocksParthasarathi H RNo ratings yet

- Check List - Masonry Work - BricksDocument1 pageCheck List - Masonry Work - BricksParthasarathi H RNo ratings yet

- Roles & Responsibilities - QS EngrDocument1 pageRoles & Responsibilities - QS EngrParthasarathi H RNo ratings yet

- Income Tax Department - Depreciation RatesDocument16 pagesIncome Tax Department - Depreciation RatesParthasarathi H RNo ratings yet

- Check List - Masonry Work - StoneDocument1 pageCheck List - Masonry Work - StoneParthasarathi H RNo ratings yet

- Metalkraft - Decking and Roofing Brochure - NEWDocument6 pagesMetalkraft - Decking and Roofing Brochure - NEWParthasarathi H RNo ratings yet

- Check List - Electrification Works - ExternalDocument2 pagesCheck List - Electrification Works - ExternalParthasarathi H RNo ratings yet

- Check List - Marking Out & Setting OutDocument1 pageCheck List - Marking Out & Setting OutParthasarathi H RNo ratings yet

- Check List - Electrification Works - Post PlasteringDocument3 pagesCheck List - Electrification Works - Post PlasteringParthasarathi H RNo ratings yet

- Check List - Electrification Works - GeneralDocument1 pageCheck List - Electrification Works - GeneralParthasarathi H RNo ratings yet

- QAD - TABLE 1 To 6CDocument15 pagesQAD - TABLE 1 To 6CParthasarathi H RNo ratings yet

- Check List - Electrification Works - InternalDocument1 pageCheck List - Electrification Works - InternalParthasarathi H RNo ratings yet

- Check List - Foundation ExcavationDocument1 pageCheck List - Foundation ExcavationParthasarathi H RNo ratings yet

- Area & VolumeDocument15 pagesArea & VolumeParthasarathi H RNo ratings yet

- Check List - Anti Termite TreatmentDocument2 pagesCheck List - Anti Termite TreatmentParthasarathi H RNo ratings yet

- REDECON 2022 BrochureDocument4 pagesREDECON 2022 BrochureParthasarathi H RNo ratings yet

- Quality control plan for bituminous constructionDocument10 pagesQuality control plan for bituminous constructionParthasarathi H RNo ratings yet

- Protein DenaturationDocument12 pagesProtein DenaturationAhmed Elhakim100% (2)

- Definitions: - : I) Soft PalateDocument30 pagesDefinitions: - : I) Soft PalateNikita AggarwalNo ratings yet

- HTTP Gryllus - Net Blender 3DDocument3 pagesHTTP Gryllus - Net Blender 3Dmohsindalvi87No ratings yet

- Checklist On Continuous Ambulatory Peritoneal Dialysis (Capd)Document3 pagesChecklist On Continuous Ambulatory Peritoneal Dialysis (Capd)Sheryl Ann Barit PedinesNo ratings yet

- Safety Solenoid Valve Nominal Width RP 1/2 - RP 2 SV SV-D Sv-DleDocument8 pagesSafety Solenoid Valve Nominal Width RP 1/2 - RP 2 SV SV-D Sv-DleAgustantoNo ratings yet

- + 20db/decade High-Pass Filter (1Document26 pages+ 20db/decade High-Pass Filter (1Rashid ShababNo ratings yet

- General ToolsDocument280 pagesGeneral ToolssanjeevvangeNo ratings yet

- ChemistryDocument84 pagesChemistryMaria Regina SantosNo ratings yet

- 11th Science Maths Answer KeyDocument15 pages11th Science Maths Answer KeyBhavesh AsapureNo ratings yet

- Understanding Gases Through Kinetic TheoryDocument20 pagesUnderstanding Gases Through Kinetic TheoryJaimeNo ratings yet

- 12TH CS TERM 2 - PythonDocument8 pages12TH CS TERM 2 - PythonAnbuchelvan VKNo ratings yet

- Chemistry Form 6 Sem 3 Chapter 1Document47 pagesChemistry Form 6 Sem 3 Chapter 1Yuzamrah Awang Noh50% (2)

- Cambridge International AS & A Level: PHYSICS 9702/42Document24 pagesCambridge International AS & A Level: PHYSICS 9702/42Công Phạm BáNo ratings yet

- Chapter 6 Designing Global Supply Chain NetworksDocument22 pagesChapter 6 Designing Global Supply Chain NetworksRashadafaneh100% (1)

- High Grade Water Soluble SOP For FertigationDocument2 pagesHigh Grade Water Soluble SOP For FertigationRómulo Del ValleNo ratings yet

- Introduction To NanophotonicsDocument49 pagesIntroduction To NanophotonicsArashiNo ratings yet

- E06 - CONSTANTINACHE PompiliuDocument4 pagesE06 - CONSTANTINACHE PompiliuNgô Hải ĐăngNo ratings yet

- Manual de Servicio Jac 5 InglésDocument375 pagesManual de Servicio Jac 5 InglésJT Pe100% (1)

- Basic CommandsDocument13 pagesBasic Commandsramana6nNo ratings yet

- Matlab R2008b-Installation InstructionDocument2 pagesMatlab R2008b-Installation InstructionDicky Chandra SuryaNo ratings yet

- VHP Engine Datasheet 7044Document2 pagesVHP Engine Datasheet 7044RafaqatAliNo ratings yet

- Si924x - Class D Audio Driver With Precision Dead-Time GeneratorDocument1 pageSi924x - Class D Audio Driver With Precision Dead-Time GeneratorBen M'rad SkanderNo ratings yet

- 1 Gravity IntroductionDocument13 pages1 Gravity IntroductionPerry SegereNo ratings yet

- JUST GIVE ME A REASONDocument1 pageJUST GIVE ME A REASONS fu fuNo ratings yet

- Suzanne Saroff - Year 9 Exam AnnaDocument1 pageSuzanne Saroff - Year 9 Exam Annaapi-569107627No ratings yet

- Tanque: Equipment Data SheetDocument1 pageTanque: Equipment Data SheetAlonso DIAZNo ratings yet

- Everything You Need to Know About SigmaPipeDocument8 pagesEverything You Need to Know About SigmaPipeMauro RuaNo ratings yet

- Theory of Solidification - CompressDocument401 pagesTheory of Solidification - CompressKarthik RaoNo ratings yet

- 3rd Quarter Mathematics Home Take Final Exam For Grade 10Document4 pages3rd Quarter Mathematics Home Take Final Exam For Grade 10John DejuNo ratings yet

- 1993 Engines Eurovan - 2.5L 5-CylinderDocument20 pages1993 Engines Eurovan - 2.5L 5-Cylinderfrancesco pavanNo ratings yet