Professional Documents

Culture Documents

QCP For Structure

Uploaded by

Hema NandhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QCP For Structure

Uploaded by

Hema NandhCopyright:

Available Formats

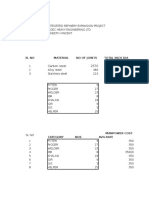

THERMAL SYSTEMS (HYDERABAD) PVT. LTD. QUALITY CONTROL PLAN FOR QCP Nr. : B611.01.00.IA.

001

BOLLARAM, HYDERABAD - 502 325, INDIA Rev :A

FABRICATION OF STRUCTURE Date : 18.10.2021

Customer : Welspun Corporation Limited Third Party : --

Inspection Agency

Project : 1 X 92.5 tpd COB,Anjar Statutory Inspection : '-- Makers No. : B611.01

Customer Ref. No. : WML/ ANJAR/143 Dt.10.7.2021 PED Conformity : ----- Drawing No. : --

RECORD OF REVISIONS Bollaram Code Of Construction : Nil

Rev. Date Change ASME Certificate

A 18.10.2021 FIRST ISSUE of Authorisation --

Expiry Date

-- ABBREVIATIONS USED

I TSPL : Thermal Systems (Hyderabad) Pvt. Ltd.

N P Drg. : Drawing

The Records of inspection are maintained and shall be made available to the IA/AI

S O R - Review Point Spec. : Specification

during subsquent visits.

P I I.R : Inspection Report

E N P.T : Liquid Penetrant Examination

A stage of inspection in production for which sufficient notification shall be provided to

C T RW - Random Witness R.T : Radiographic Examination

IA/AI , beyond which work may proceed . Record of examination is maintained and

T S W - Witness Point PWHT : Post Weld Heat Treatment

shall be available to IA/AI for verification .

I Temp : Temperature

O A stage of inspection in production beyond which work shall not proceed until the N.D.E : Non Destructive Examination

H - Hold Point

N stage is signed off IA/AI WPS : Welding Procedure Specification

PQR : Procedure Qualification Record

WPQ : Welder/Welding operator performance qualification record

QCP : Quality Control Plan

WCL : Welspun Corporation Limited

Prepared By Reviewed & Approved By Approved By Customer Reviewed & Accepted by Inspection Agency

(TSPL) (TSPL)

Sadik Ali B.Surya Prakash

Manager-Q.A GM - QUALITY & WT

Date: 18.10.2021 Date:18.10.2021 Date Date

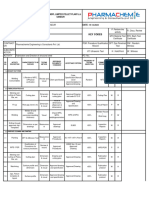

THERMAL SYSTEMS (HYD) PVT. LTD. QUALITY CONTROL PLAN FOR DOC Nr. : B611.01.00.IA.001

BOLLARAM, HYDERABAD - 502 325, INDIA Rev :A

FABRICATION OF STRUCTURE Date : 18.10.2021

Ref. CHECK Acceptance INSPECTION POINTS & INSPECTION BY

QC Activity Record

Nr. Characteristic Method Extent Standard /

CONTRACTOR TSPL

Ref doc.

1.0 Review of QCP Code/Customer - Review 100% Drawings / Approved QCP H --

Requirements

2.0 Review of WPS/PQR/WPQ Code requirements - Review 100% ASME SEC-IX, AWS PQR/WPS/WPQ H R

D1.1

3.0 Raw Material Identification -Material Test Certificates - Review 100% - Matl.Spec MTC

- Dimension - Review 100% - Matl. Spec / IR H R

Drawing

- Visual Inspection -Visual 100%

Drawing

- Identification Marking -Visual 100%

4.0 Marking ,Cutting of the - Dimensions -Measurement 100% Drawing IR H R

plate/beam/channel/angle

etc(as applicable )

- Straightness -Measurement 100% 1 mm / Mtr up to

10mm Max

- Weld preparation -Visual 100% Free from notches

/Cleaning of flame cut edges / cutting burrs

5.0 Drilling of Holes ( As - Dimensions -Measurement 100% Drawing/IS 7215 IR H RW

Applicable)

- Orientation -Visual 100% Drawing

- No of holes by count -Visual 100% Drawing

- Hole finish -Visual 100% Free from Surface

defeats

THERMAL SYSTEMS (HYD) PVT. LTD. QUALITY CONTROL PLAN FOR DOC Nr. : B611.01.00.IA.001

BOLLARAM, HYDERABAD - 502 325, INDIA Rev :A

FABRICATION OF STRUCTURE Date : 18.10.2021

Ref. CHECK Acceptance INSPECTION POINTS & INSPECTION BY

QC Activity Record

Nr. Characteristic Method Extent Standard /

CONTRACTOR TSPL

Ref doc.

6.0 Fit up of plate to plate/ - Dimensions -Measurement 100% Drawing IR H W

beam/channel / angle / pipe

- Squareness -Measurement 100% Max 2mm

- Straightness -Measurement 100% 1 mm / Mtr up to

10mm

- Flatness of base Plate -Measurement 100% Max 1 mm

- Weld Preparation Template 100% Drawing

7.0 Welding of plate to plate/ - Dimensions -Measurement 100% Drawing IR H R

beam/channel / angle / pipe

- Straightness on length -Measurement 100% 1 mm / Mtr up to

10mm Max

- Squareness -Measurement 100% Max 2mm

- Weld joint soundness - PT 100% Free from Surface IR

defeats

8.0 Final Dimensional & Visual -Overall dimensions -Measurement 100% Drawing IR H H

Inspection

-Overall Length -Measurement 100% ± 5mm upto 10m &

± 0.0005L mm above

10m upto ±8mm Max

Max 2mm

- Squareness -Measurement 100% -Uniform welding &

free from defects

- Weld Finish -Visual 100%

Drawing

- welding of all attachments -Visual 100%

THERMAL SYSTEMS (HYD) PVT. LTD. QUALITY CONTROL PLAN FOR DOC Nr. : B611.01.00.IA.001

BOLLARAM, HYDERABAD - 502 325, INDIA Rev :A

FABRICATION OF STRUCTURE Date : 18.10.2021

Ref. CHECK Acceptance INSPECTION POINTS & INSPECTION BY

QC Activity Record

Nr. Characteristic Method Extent Standard /

CONTRACTOR TSPL

Ref doc.

9.0 Surface Preparation and -Surface Cleanliness -- Visual 100% Min Drawing IR H W

Painting -Measurement at 10

- DFT Check Places

10.0 Issue of Inspection -- -- -- Drawing /QCP IRN H H

Release Note

(As applicable)

11.0 Final Documentation - Inspection Report Review 100% Final inspection IR H R

Report

Prepared By Reviewed & Approved By Approved By Customer Reviewed & Accepted By Authorised inspector

(TSPL) (TSPL)

Sadik Ali Surya Prakash.B

Manager-Q.A GM - QUALITY & WT

Date: 18.10.2021 Date: 18.10.2021 Date Date

You might also like

- IRJET Stabilization of Black Cotton SoilDocument5 pagesIRJET Stabilization of Black Cotton SoilRithYNo ratings yet

- Basalt RockDocument25 pagesBasalt Rocksaqib mujtabaNo ratings yet

- SR No Approved Make - Sub-Vendor List: Civil Reinforcement SteelDocument49 pagesSR No Approved Make - Sub-Vendor List: Civil Reinforcement SteelRanjan KumarNo ratings yet

- P5504mew SWK 10 SS V PPR 001 - ADocument14 pagesP5504mew SWK 10 SS V PPR 001 - Avignesh558855No ratings yet

- Technical Specifications For BuildingsDocument340 pagesTechnical Specifications For BuildingsTanvir Shahrier MahmudNo ratings yet

- LHS-DI-MAR-MEP-042 - Duct and Pipe Support - Diamond - R0 PDFDocument2 pagesLHS-DI-MAR-MEP-042 - Duct and Pipe Support - Diamond - R0 PDFMelvin Angelo LopenarioNo ratings yet

- ADC Part 5Document1 pageADC Part 5Maung PDDNo ratings yet

- NCC Assessment ProcedureDocument1 pageNCC Assessment ProcedureGeorge GeorgianNo ratings yet

- Labour Productivity in The Construction IndustryDocument13 pagesLabour Productivity in The Construction Industryrodop82100% (1)

- An Experimental Investigation On HPC Using Basalt Rock FiberDocument19 pagesAn Experimental Investigation On HPC Using Basalt Rock FiberIJRASETPublicationsNo ratings yet

- Assignment 2Document12 pagesAssignment 2Wâqâr ÂnwârNo ratings yet

- Approved Vendor List Substations May 2017Document12 pagesApproved Vendor List Substations May 2017Thiyagu PmNo ratings yet

- ONGC Suggested Vendor List PDFDocument70 pagesONGC Suggested Vendor List PDFmanishaNo ratings yet

- Annexure 5A - ITP For Alloy Steel Seamless & Forged Fittings A234WP5 WP9 WP91 A182 F5 F9 & F91 For Normal NACE & IBRDocument3 pagesAnnexure 5A - ITP For Alloy Steel Seamless & Forged Fittings A234WP5 WP9 WP91 A182 F5 F9 & F91 For Normal NACE & IBRPranav JadhavNo ratings yet

- 100 KLPD of 2G Ethanol From Biomass at Iocl PanipatDocument7 pages100 KLPD of 2G Ethanol From Biomass at Iocl PanipatSuraj ShettyNo ratings yet

- A20-11, DLF, Phase 1, GurugramDocument30 pagesA20-11, DLF, Phase 1, GurugramarjunNo ratings yet

- LELE131223WOD22000017Document8 pagesLELE131223WOD22000017BAPPADITTYA PAULNo ratings yet

- DR Fixit Fastflex 12kg Bn4d170030 17.12.14Document1 pageDR Fixit Fastflex 12kg Bn4d170030 17.12.14mcgNo ratings yet

- 4C. STD Specification-MotorsDocument12 pages4C. STD Specification-MotorsSagar ChandegaraNo ratings yet

- Sgs Pca Nigeria Datasheet A4 en v21Document6 pagesSgs Pca Nigeria Datasheet A4 en v21Chukwu Uchenna marvellousNo ratings yet

- 240 2011-08-18 549729 PDFDocument95 pages240 2011-08-18 549729 PDFasitdeyNo ratings yet

- Method Statement: For Power Cables & Branch Circuit WiringDocument3 pagesMethod Statement: For Power Cables & Branch Circuit WiringNIRANo ratings yet

- List of Registered Vendor PGVCLDocument54 pagesList of Registered Vendor PGVCLvijay kNo ratings yet

- Ogp 2023 Exhibitors ListDocument1 pageOgp 2023 Exhibitors ListSuman BaligaNo ratings yet

- Surya Complete PDFDocument168 pagesSurya Complete PDFnshankar77No ratings yet

- Erection ChecklistDocument3 pagesErection ChecklistKunwar VjNo ratings yet

- Process Data Sheet For Main Air Compressor Rev00Document4 pagesProcess Data Sheet For Main Air Compressor Rev00mahan moradiNo ratings yet

- RN 02 00001 06 11 El WBG DG 000757Document1 pageRN 02 00001 06 11 El WBG DG 000757eiohat100% (1)

- Power Generation:: AreospaceDocument6 pagesPower Generation:: AreospacededicatemindsNo ratings yet

- Presentation Formate TKDocument33 pagesPresentation Formate TKEngr Mohammad Al-AminNo ratings yet

- Tender For Hiring of Porta Cabin in Rajamundhary 19.12.2017Document133 pagesTender For Hiring of Porta Cabin in Rajamundhary 19.12.2017Tarun MaheshwariNo ratings yet

- Master Copy of Saad Othman JSADocument11 pagesMaster Copy of Saad Othman JSAM. MagnoNo ratings yet

- Catalogue SeAH Engineering - Turbo Air Blower PDFDocument12 pagesCatalogue SeAH Engineering - Turbo Air Blower PDFShrikant AglaweNo ratings yet

- Radiography Statement For A/G Piping: Report No: DateDocument23 pagesRadiography Statement For A/G Piping: Report No: DateBiswajit DeyNo ratings yet

- Company Profile: Contact UsDocument20 pagesCompany Profile: Contact Usengnajeeb75No ratings yet

- Specification Deviation Request (SDR) : From Vendor From Sub-Contractor From ContractorDocument4 pagesSpecification Deviation Request (SDR) : From Vendor From Sub-Contractor From ContractorrmdarisaNo ratings yet

- Harish Raval Rajkot.: Civil ConstructionDocument4 pagesHarish Raval Rajkot.: Civil ConstructionNilay GandhiNo ratings yet

- DPR, Ocr, WPC, PTFF ArDocument27 pagesDPR, Ocr, WPC, PTFF ArRAJADEVANNo ratings yet

- 6.sand Filling-Inspection Test Plan-Bb IDocument5 pages6.sand Filling-Inspection Test Plan-Bb IShikari ShikarwalaNo ratings yet

- Falling Ball BDocument18 pagesFalling Ball BLeidi UrquijoNo ratings yet

- E-PROC-ENG-B1-111 Rev006Document32 pagesE-PROC-ENG-B1-111 Rev006Jonicus-DextoreNo ratings yet

- Basalt CostDocument9 pagesBasalt CostAnand ThiyagarajanNo ratings yet

- CBF & Pultrusion Basalt Composite Materials Production Project in ArmeniaDocument16 pagesCBF & Pultrusion Basalt Composite Materials Production Project in ArmeniaAnonymous LhmiGjONo ratings yet

- A133 1361 1020 Enq Rev0 PDFDocument227 pagesA133 1361 1020 Enq Rev0 PDFshank100No ratings yet

- NTPC Project MonitoringDocument38 pagesNTPC Project Monitoringbali_jepalli100% (1)

- Sca Aac 280 2023 PDFDocument6 pagesSca Aac 280 2023 PDFJOv ElNo ratings yet

- CPVC - Price List - 7th Oct 2022Document16 pagesCPVC - Price List - 7th Oct 2022Vijay SharmaNo ratings yet

- Three Fundamental Building Blocks of Profiting From InnovationDocument5 pagesThree Fundamental Building Blocks of Profiting From InnovationKudzayi MatekaireNo ratings yet

- Tata Power Annual ReportDocument340 pagesTata Power Annual ReportKumar RajNo ratings yet

- Mainline Under Ground HydrotestingDocument12 pagesMainline Under Ground HydrotestingrexNo ratings yet

- ONGC Media Presentation-29082023Document44 pagesONGC Media Presentation-29082023RACHNA SAHANo ratings yet

- NSE Stocks 22 Nov 2021Document735 pagesNSE Stocks 22 Nov 2021Ajay VaswaniNo ratings yet

- VOLUME VIII Vendor LIstDocument14 pagesVOLUME VIII Vendor LIstHR UAENo ratings yet

- Thejo Engg-Final OS1Document98 pagesThejo Engg-Final OS1Jithu Jose ParackalNo ratings yet

- Mes Profile 2022Document26 pagesMes Profile 2022رعد الكعودNo ratings yet

- Electrode Issue SlipDocument1 pageElectrode Issue SlipHasan ShahriarNo ratings yet

- QAP1Document2 pagesQAP1akshaymehra2354No ratings yet

- (Itp For Cast Insitu Foundation) 4172-Genon-1!25!0002-ADocument45 pages(Itp For Cast Insitu Foundation) 4172-Genon-1!25!0002-ARajesh SinghNo ratings yet

- Inspection and Test PlanDocument6 pagesInspection and Test PlanReduddboy100% (1)

- Document Number: P1066-Ctd-Qac-Itp-003 Document Title: Inspection & Test Plan For Fabrication, Erection & Testing of Piping WorkDocument16 pagesDocument Number: P1066-Ctd-Qac-Itp-003 Document Title: Inspection & Test Plan For Fabrication, Erection & Testing of Piping WorkEILA545 QAQCNo ratings yet

- MTC-2 - Service STRCDocument1 pageMTC-2 - Service STRCHema NandhNo ratings yet

- Acc - Fqap - P3011 - R2 - RewaDocument2 pagesAcc - Fqap - P3011 - R2 - RewaHema NandhNo ratings yet

- VRMP REFINERY Milestone Summary For Project..Document2 pagesVRMP REFINERY Milestone Summary For Project..Hema NandhNo ratings yet

- Piping EstimationDocument19 pagesPiping EstimationHema NandhNo ratings yet

- Acc Fqap Rev 1 - DundigalDocument2 pagesAcc Fqap Rev 1 - DundigalHema NandhNo ratings yet

- QAP For Ducting V1 R0Document1 pageQAP For Ducting V1 R0Hema NandhNo ratings yet

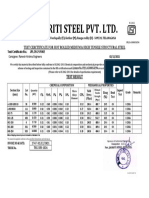

- Jagriti Steel Pvt. LTD.: Test Cerctificate For Hot Rolled Medium & High Tensile Structural SteelDocument1 pageJagriti Steel Pvt. LTD.: Test Cerctificate For Hot Rolled Medium & High Tensile Structural SteelHema NandhNo ratings yet

- Ahp 2X660 (WPS) )Document17 pagesAhp 2X660 (WPS) )Hema NandhNo ratings yet

- HRSG PDFDocument248 pagesHRSG PDFHema Nandh100% (1)

- Consumables NormsDocument24 pagesConsumables NormsHema Nandh100% (1)

- Pipe Support StandardDocument32 pagesPipe Support StandardHema Nandh100% (1)

- Session I - II - Power Cycle Piping PDFDocument122 pagesSession I - II - Power Cycle Piping PDFHema NandhNo ratings yet

- BS en Iso 15792-1Document12 pagesBS en Iso 15792-1Bart Ho100% (1)

- LSAT Reading Comprehension WorkbookDocument9 pagesLSAT Reading Comprehension Workbookpeter MensahNo ratings yet

- Powersafe Vfrontterminal BatteryrangesummaryDocument2 pagesPowersafe Vfrontterminal Batteryrangesummarye_vendrellNo ratings yet

- AN9003 - A Users Guide To Intrinsic SafetyDocument20 pagesAN9003 - A Users Guide To Intrinsic SafetyLucas MendonçaNo ratings yet

- Pooja 12Document19 pagesPooja 12arthiNo ratings yet

- Pom 90Document2 pagesPom 90busyNo ratings yet

- RPT Form 4 Physics 2022Document30 pagesRPT Form 4 Physics 2022NoorNo ratings yet

- Chapter Three Velocity AnalysisDocument57 pagesChapter Three Velocity Analysismekete mulualemNo ratings yet

- Articles On Tachyon Energy - Advanced Tachyon TechnologyDocument1 pageArticles On Tachyon Energy - Advanced Tachyon Technologygaetano confortoNo ratings yet

- Technological Institute of The Philippines-ManilaDocument17 pagesTechnological Institute of The Philippines-ManilaRoscarl GorospeNo ratings yet

- Speed Control Using Fuzzy Controller For A Four Switch Sensorless BLDC MotorDocument7 pagesSpeed Control Using Fuzzy Controller For A Four Switch Sensorless BLDC MotorInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Understanding Voltammetry Chapther 2-Electrode KineticsDocument42 pagesUnderstanding Voltammetry Chapther 2-Electrode KineticsFelipe Cepeda SilvaNo ratings yet

- 003 - Presentation From Nabors Drilling PDFDocument16 pages003 - Presentation From Nabors Drilling PDFVi Et100% (1)

- Check List For Review of Afbc P&Id Air&Flue Gas System: ProjectDocument2 pagesCheck List For Review of Afbc P&Id Air&Flue Gas System: Projectctraminst_81No ratings yet

- Double Sided Drift Method Reduces The Effect of Crystals' Inhomogeneity To Si (Li) Detector's ElectroPysicsal CharacteristicsDocument4 pagesDouble Sided Drift Method Reduces The Effect of Crystals' Inhomogeneity To Si (Li) Detector's ElectroPysicsal CharacteristicsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 5TH Sem SyllabusDocument16 pages5TH Sem SyllabusHunter HarshaNo ratings yet

- Plasma TechnologyDocument27 pagesPlasma TechnologyAtul Mittal100% (2)

- THEM Edieval Science o F Weights: (Scientia de Ponderibus)Document224 pagesTHEM Edieval Science o F Weights: (Scientia de Ponderibus)Mónica MondragónNo ratings yet

- ME-6201 AEP Stress Function Polar CoordinateDocument32 pagesME-6201 AEP Stress Function Polar CoordinatePrabhataNo ratings yet

- Ilovepdf MergedDocument23 pagesIlovepdf MergedAhmad AdnanNo ratings yet

- PS 312fDocument1 pagePS 312fNick MargieNo ratings yet

- LED Power Driver TesterDocument9 pagesLED Power Driver TesterLISUN GROUPNo ratings yet

- Installation DEH40087R8 Latest 1Document37 pagesInstallation DEH40087R8 Latest 1ehteshamNo ratings yet

- CP03 Tube Clamp PPT March 05Document120 pagesCP03 Tube Clamp PPT March 05Leon PeterNo ratings yet

- 2 Ig (Q&a)Document17 pages2 Ig (Q&a)EaintNo ratings yet

- Presentation On Lexan (Co-Polymer)Document26 pagesPresentation On Lexan (Co-Polymer)Saleha SohailNo ratings yet

- Mall Installation PlanningDocument7 pagesMall Installation PlanningDirrty ClubNo ratings yet

- Chemistry XI (Annual Exam Paper 2021)Document20 pagesChemistry XI (Annual Exam Paper 2021)jaleelahmed370No ratings yet

- Nkrfa 078 5009 08Document2 pagesNkrfa 078 5009 08Nguyễn Quang HuyNo ratings yet

- Design of Bolted JointsDocument30 pagesDesign of Bolted JointsKrishna VamsiNo ratings yet