Professional Documents

Culture Documents

Energy Audit Questionnaire

Uploaded by

Elvin Jay TesoroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Energy Audit Questionnaire

Uploaded by

Elvin Jay TesoroCopyright:

Available Formats

ENERGY AUDIT QUESTIONNAIRE

END USER CONTRACT/P.O. NO.

CUSTOMER LOCATION

SITE DATE

EAC PERSONNEL

YES NO

1.0 Motors, Belts, Drives

1.1 Are standard efficiency motors installed?

Are motors running during periods when the equipment or process they are

1.2

driving is idle?

Does the facility utilize DC generator sets to provide variable speed control

1.3

of equipment?

1.4 Does the facility utilize Eddy Current drives for variable speed control?

1.5 Are motors installed that operate continuously at part load?

2.0 Pumps/Fans

2.1 Are pumps or fans installed that are not sized correctly for the task?

2.2 Does the facility have a cooling tower(s)?

2.3 Are pumps or fans being throttled in order to control the flow rate?

2.4 Is bypass control being utilized to vary the flow out of the pump?

3.0 Compressed Air System

Are large compressors serving minimal system needs during off-hours such

3.1 as maintaining the minimum pressure requirements for a Dry Fire

Suppression System?

Does the facility have centrifugal screw compressors that operate at less

3.2

than full load capacity for more than 70 percent of the time?

3.3 Is throttle control used to modulate the compressor output capacity?

3.4 Is turn valve control used?

3.5 Is poppet valve control used?

Does the facility have more than one compressor feeding into a common

3.6 header? Are these compressors operating at less than full output (cfm)

capacity?

3.7 Are compressors operating at zero capacity for extended periods of time?

3.8 Is the discharge pressure of the compressors higher than 110 psig?

Is high-pressure air being used for tasks that do not require high-pressure

3.9

air?

3.10 Does the compressed air system have significant air leaks?

3.11 Does the facility have rotary vane air compressors?

3.12 Does the facility have desiccant air dryers?

3.13 Is the compressor cooling water discharged to the sewer?

Is the pressure drop across auxiliary equipment such as dryers, oil

3.14

separators, or filters excessive?

4.15 Is compressed air the best utility for the given application?

4.16 Does the facility utilize any air nozzles?

3.17 Have the air nozzles been designed for maximum efficiency?

Is the Air Compressor on a Regular Maintenance Schedule? Review

3.18 maintenance logs to verify if the following is being done on a scheduled

basis.

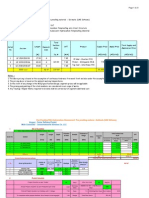

ENERGY AUDIT QUESTIONNAIRE

END USER Therma South, Inc. CONTRACT/P.O. NO.

CUSTOMER Therma South, Inc. LOCATION Brgy. Binugao, Toril, Davao City,

Davao del Sur (TSI Plant)

SITE Brgy. Binugao, Toril, Davao City, Davao DATE 12/6/2021

del Sur

EAC PERSONNEL

Fuel Company Name

Fuel Type Fuel Delivery Units (liters, tons, etc)

Fuel Use (entire facility, area,

Fuel cost / unit

equipment, etc.)

Year 2020-2021 No. of Months 12 First Month April, 2020

Month/Year Monthly Fuel Consumption(L)

Total Cost (Pesos/Liters)

Fuel Delivered Unit 1&2 (Station)

1.April, 2020 164,143.70 (April, 2020) 32.96

2.May, 2020 329,084.20 (May, 2020) 27.17

3. 240,258.80 (June, 2020) 23.66

4. 0 (July, 2020) 23.66

5. August, 2020 0 (August, 2020) 23.67

6. 9,108.10 (September, 2020) 23.67

7. 0 (October, 2020) 23.67

8. 0 (November, 2020) 23.67

9. 102,792.80 (December, 2020) 27.28

10. January, 2021 134,417.71 (January, 2021) 23.67

11. 0 (February, 2021) 24.78

12. 79,419.40 (March, 2021) 24.78

Total 1,059,224.71

You might also like

- ZX470LC-5G Hhejace1c00200043 202008Document11 pagesZX470LC-5G Hhejace1c00200043 202008Putera Bumi NusantaraNo ratings yet

- ZX470LC-5G Hhejace1k00200041 202008Document11 pagesZX470LC-5G Hhejace1k00200041 202008Putera Bumi NusantaraNo ratings yet

- Natural Gas Supply, Disposition, and PricesDocument9 pagesNatural Gas Supply, Disposition, and PricesNancy yepesNo ratings yet

- Mustard Oil: 1.0 Product and Its ApplicationsDocument6 pagesMustard Oil: 1.0 Product and Its Applicationsagarwal.rmNo ratings yet

- Machine Operating Information Report: CustomerDocument11 pagesMachine Operating Information Report: CustomerRAVEENDRA OFFICENo ratings yet

- Machine Operating Information Report: CustomerDocument14 pagesMachine Operating Information Report: Customer黄文兵No ratings yet

- FINAL C09145 Scopeofwork-ReportDocument35 pagesFINAL C09145 Scopeofwork-ReportMba Nang Ndong MohamedNo ratings yet

- Project 20230113Rs - DustiraDocument20 pagesProject 20230113Rs - DustiraHari goonawNo ratings yet

- REPRISM 2021 - UNIT START UP TIME REDUCTION FinalDocument12 pagesREPRISM 2021 - UNIT START UP TIME REDUCTION Finalravi singhNo ratings yet

- Using Energy Plus For ComplianceDocument25 pagesUsing Energy Plus For CompliancecloubuNo ratings yet

- Service Manual: Eleganza SmartDocument30 pagesService Manual: Eleganza Smartpm4002100% (1)

- HVAC Comparison (ZA)Document29 pagesHVAC Comparison (ZA)Sameer Aslam SNo ratings yet

- HEATLOAD CALCULATION For Terra RestaurantDocument28 pagesHEATLOAD CALCULATION For Terra RestaurantNIDHILNo ratings yet

- Annual Fixed Cost, P/Yr FC D+I+Hti: Net Income Generated, Ph/Yr Ni (Co - Ra-Dca) Ca OpDocument14 pagesAnnual Fixed Cost, P/Yr FC D+I+Hti: Net Income Generated, Ph/Yr Ni (Co - Ra-Dca) Ca OpJan James GrazaNo ratings yet

- Design of HVAC With VRF System For A Space House in AhmedabadDocument7 pagesDesign of HVAC With VRF System For A Space House in AhmedabadrkibNo ratings yet

- 722 - Buku Pegangan Teknik Tenaga Listrik Jilid IIIDocument160 pages722 - Buku Pegangan Teknik Tenaga Listrik Jilid IIIratien CjdwNo ratings yet

- Davao Del Norte - AlegroDocument51 pagesDavao Del Norte - AlegroJChris EsguerraNo ratings yet

- Relatório JDDocument4 pagesRelatório JDJoão FerreiraNo ratings yet

- Makerere UniversityDocument26 pagesMakerere UniversityDamulira DavidNo ratings yet

- Book 1Document59 pagesBook 1ceetpcNo ratings yet

- PP - Furnance 22PDocument22 pagesPP - Furnance 22PFederico HernandezNo ratings yet

- Final 4th Quarter Printed Civil Cost - Password (2011)Document173 pagesFinal 4th Quarter Printed Civil Cost - Password (2011)Yemi Eshetu MeeNo ratings yet

- Investment That Is To Use The Savings "To Promote The Production of Other Goods, Instead of BeingDocument10 pagesInvestment That Is To Use The Savings "To Promote The Production of Other Goods, Instead of BeingRalph Carlo EvidenteNo ratings yet

- Wockhardt Limited: Annexure To The Directors' ReportDocument4 pagesWockhardt Limited: Annexure To The Directors' ReportRahul DwivediNo ratings yet

- EP 1110-1-8 Vo4 PDFDocument501 pagesEP 1110-1-8 Vo4 PDFyodiumhchltNo ratings yet

- Dse7200 and Dse7300 Operator ManualDocument120 pagesDse7200 and Dse7300 Operator ManualFabio LiraNo ratings yet

- Prime Coat Rate AnalysisDocument1 pagePrime Coat Rate AnalysisCivil Engineering CalculationsNo ratings yet

- Annual Report 2006 07Document191 pagesAnnual Report 2006 07Ritu AgarawalNo ratings yet

- Capex Opex..Document6 pagesCapex Opex..Nurcahyo Djati WNo ratings yet

- CostingDocument21 pagesCostingDkPrince100% (5)

- Machine Operating Information Report: CustomerDocument8 pagesMachine Operating Information Report: CustomerTLK ChannelNo ratings yet

- Bread Manufacture ProjectDocument9 pagesBread Manufacture ProjectmanjeetsheokandNo ratings yet

- Fuel Fraud Detection in Fuel StationDocument17 pagesFuel Fraud Detection in Fuel StationNandan Poojary100% (1)

- PPS 1005Document6 pagesPPS 1005Boom08No ratings yet

- US116340 Apply Costing Principles To Municipal OperationsDocument106 pagesUS116340 Apply Costing Principles To Municipal OperationskudasanyahNo ratings yet

- 2021 Bobcat T590 Skidsteer - Risk Assessment - LJD Civil Pty LTDDocument16 pages2021 Bobcat T590 Skidsteer - Risk Assessment - LJD Civil Pty LTDengrmcabNo ratings yet

- Estimating Tool-AMGINCDocument8 pagesEstimating Tool-AMGINChasanNo ratings yet

- Improvement Works at Block 5 Server RoomDocument5 pagesImprovement Works at Block 5 Server Roomatienzajury24No ratings yet

- K02 Group 2 Production of MethanolDocument70 pagesK02 Group 2 Production of MethanolnaaaNo ratings yet

- GOOD WORK DONE Up To 31 - 3 - 21Document36 pagesGOOD WORK DONE Up To 31 - 3 - 21divisional electrical enggNo ratings yet

- Corrugated Boxes1Document8 pagesCorrugated Boxes1abhi050191No ratings yet

- False TrueDocument3 pagesFalse TrueCATHNo ratings yet

- EP 1110-1-8 Vo9 PDFDocument501 pagesEP 1110-1-8 Vo9 PDFyodiumhchltNo ratings yet

- Machine Operating Information Report: CustomerDocument8 pagesMachine Operating Information Report: CustomerTLK ChannelNo ratings yet

- 9830 20200110 HGX34e-380-4 S R404ADocument9 pages9830 20200110 HGX34e-380-4 S R404ANyein KoNo ratings yet

- Commercial Energy Audit Report PDFDocument17 pagesCommercial Energy Audit Report PDFEphraim MatemaNo ratings yet

- Admin KM Project - FinalDocument25 pagesAdmin KM Project - Final1954No ratings yet

- Flow Measuring ApparatusDocument15 pagesFlow Measuring Apparatusgeorgekenjiputra67% (3)

- Pamplona AIRCON ADDL DEC5Document11 pagesPamplona AIRCON ADDL DEC5EDWIN ACHANZARNo ratings yet

- Ventilation Sizing Summary For CORRIDOR 1Document1 pageVentilation Sizing Summary For CORRIDOR 1mechmohsin4745No ratings yet

- Chassis PDFDocument1,037 pagesChassis PDFDamir MilisaNo ratings yet

- 5-Appendix 4 - HSE Turnaround Requirements For Contractor-FINALDocument20 pages5-Appendix 4 - HSE Turnaround Requirements For Contractor-FINALgarciahoNo ratings yet

- Machine Operating Information Report: CustomerDocument9 pagesMachine Operating Information Report: CustomerHaris PrayogoNo ratings yet

- Mine & Mill Equipment Costs Estimator's Guide, Capital & Operating Costs CostMineDocument1 pageMine & Mill Equipment Costs Estimator's Guide, Capital & Operating Costs CostMineglenraven52833% (3)

- 2011 Cost Models SectionDocument56 pages2011 Cost Models Sectionoduk odbayarNo ratings yet

- Experiment No 8. Diesel Engine PerformanceDocument4 pagesExperiment No 8. Diesel Engine PerformanceMariel MirafloresNo ratings yet

- Machineries Inspection Checklist FormDocument1 pageMachineries Inspection Checklist Formputra farithNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Process Plant Design: Heinemann Chemical Engineering SeriesFrom EverandProcess Plant Design: Heinemann Chemical Engineering SeriesRating: 3.5 out of 5 stars3.5/5 (11)

- Automotive Air Conditioning and Climate Control SystemsFrom EverandAutomotive Air Conditioning and Climate Control SystemsRating: 4 out of 5 stars4/5 (6)

- New Summative Quarter 4Document2 pagesNew Summative Quarter 4Elvin Jay TesoroNo ratings yet

- Math Mini Research - FinalDocument23 pagesMath Mini Research - FinalElvin Jay TesoroNo ratings yet

- 9.2 ScriptDocument1 page9.2 ScriptElvin Jay TesoroNo ratings yet

- 9.1 ScriptDocument2 pages9.1 ScriptElvin Jay TesoroNo ratings yet

- GANTT CHART ExcelDocument1 pageGANTT CHART ExcelAlexNo ratings yet

- 10th Sco Paper-A Jee-Main Wtm-6 Key&Solutions Exam DT 09-09-2023Document14 pages10th Sco Paper-A Jee-Main Wtm-6 Key&Solutions Exam DT 09-09-2023zaid khanNo ratings yet

- CH5 PH and TSDocument19 pagesCH5 PH and TSDAWIT GIRMANo ratings yet

- ENERGETICS EbookDocument96 pagesENERGETICS Ebooklianchen251110No ratings yet

- Carburetor and Fuel Injection SystemDocument33 pagesCarburetor and Fuel Injection SystemPrabesh PoudelNo ratings yet

- Vgbe S 821 91 2021 12 en - Ebook A4 ShopDocument76 pagesVgbe S 821 91 2021 12 en - Ebook A4 ShopPietroNo ratings yet

- Session 4. Carbon Business & Green HydrogenDocument11 pagesSession 4. Carbon Business & Green HydrogenMaintenance PTGSNo ratings yet

- 1104C 44TA Parts BookDocument203 pages1104C 44TA Parts BookTaller AntofagastaNo ratings yet

- Test Carried Out For Test Description Test Result / Remark Sr. NoDocument15 pagesTest Carried Out For Test Description Test Result / Remark Sr. NoGANESH KNo ratings yet

- 1DZ EngineDocument181 pages1DZ EngineGonçalo SousaNo ratings yet

- Science Investigatory Project Paper 1Document8 pagesScience Investigatory Project Paper 1marieavril63No ratings yet

- Bass Preamp Di EngDocument3 pagesBass Preamp Di EngBabarNo ratings yet

- Fuels and Combustion: - Calorific Value - Significance and Comparison Between LCV andDocument46 pagesFuels and Combustion: - Calorific Value - Significance and Comparison Between LCV andSandhya SundarNo ratings yet

- Bill of Supply of Electricity: You Can Pay Using NEFT/RTGSDocument2 pagesBill of Supply of Electricity: You Can Pay Using NEFT/RTGSKrushna chandra PandaNo ratings yet

- Rigorous MethodDocument4 pagesRigorous MethodNRCM EEENo ratings yet

- Flash Arrestors RegulatorDocument2 pagesFlash Arrestors RegulatorcarlosNo ratings yet

- Chapter 06: The X-Ray Tube Bushong: Radiologic Science For Technologists: Physics, Biology, and Protection, 11th EditionDocument6 pagesChapter 06: The X-Ray Tube Bushong: Radiologic Science For Technologists: Physics, Biology, and Protection, 11th EditionNaseem Al tajerNo ratings yet

- Atmospheric Weather VariablesDocument3 pagesAtmospheric Weather VariablesSachin Srivastava100% (1)

- Cat c15 Acert Spec SheetDocument5 pagesCat c15 Acert Spec SheetХусниддин ГаниевNo ratings yet

- Question Paper Code:: Reg. No.Document3 pagesQuestion Paper Code:: Reg. No.CjananiNo ratings yet

- Group 1-6 HvacDocument22 pagesGroup 1-6 Hvacryan bhinogNo ratings yet

- DOL - SD Starter LeafletDocument2 pagesDOL - SD Starter Leafletoneops techNo ratings yet

- Modelling of Substation Grounding Grids: A. El-Morshedy, PH.D., A.G Zeitoun, PH.D., and M.M. GhourabDocument6 pagesModelling of Substation Grounding Grids: A. El-Morshedy, PH.D., A.G Zeitoun, PH.D., and M.M. GhouraboscarNo ratings yet

- Product Range Catalogue - SalicruDocument40 pagesProduct Range Catalogue - SalicruKiệt TrầnNo ratings yet

- Seminar Report 032Document32 pagesSeminar Report 032046 KISHORENo ratings yet

- Surge Arrester and Insulator Electrical Test ProgramDocument3 pagesSurge Arrester and Insulator Electrical Test ProgramArjun -No ratings yet

- The Basic Science of Therapeutic ModalityDocument52 pagesThe Basic Science of Therapeutic ModalityNQorianaNo ratings yet

- Cylinder ConditionDocument15 pagesCylinder ConditionManuel Armando Salazar BravoNo ratings yet

- Mixed Used Development Case Study: Dove Kumru, Ankara Kohinoor Square, Dadar One Cenntral Park, SydneyDocument16 pagesMixed Used Development Case Study: Dove Kumru, Ankara Kohinoor Square, Dadar One Cenntral Park, SydneykattyNo ratings yet

- Schematic Electric D6R TTTDocument18 pagesSchematic Electric D6R TTTEva AprianaNo ratings yet