Professional Documents

Culture Documents

Walkaround F-Ser 21B1004522

Uploaded by

Bilal VURALOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Walkaround F-Ser 21B1004522

Uploaded by

Bilal VURALCopyright:

Available Formats

Model L60F L70F L90F L110F L120F L150F L180F L220F L350F

Operating weight ton 11,0-13,3 12,7-15,0 15,0-17,0 18,0-20,0 19,0-21,0 23,0-26,0 26,0-29,0 31,0-33,0 50,0-56,0 Volvo construction equipment

Buckets Capacity Mount m3 1,6-5,0 2,0-6,4 2,1-7,0 2,7-9,5 2,6-9,5 3,1-12,0 3,7-14,0 4,5-14,0 6,2-12,7

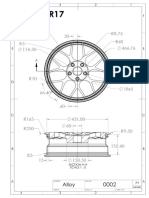

Tires

20.5 R25

600/65 R25

20.5 R25

600/65 R25

20.5 R25

650/65 R25

23.5 R25

750/65 R25

23.5 R25

750/65 R25

26.5 R25

775/65 R29

26.5 R25

775/65 R29

29.5 R25

875/65 R29

35/65 R33

875/65 R33

wALK aROUND guide

engine / TRANSMISSION Volvo D6E LC E3 D6E LB E3 D6E LA E3 D7E LB E3 D7E LA E3 D12D LB E3 D12D LA E3 D12D LB E3 D16E LA E3

F-sERIES VOLVO WHEEL LOADERS

23,3-28,3 23,3-26,7 28,3-30,0

Max power at r/s (rpm) 28,3 (1 700) 28,3 (1 700) 28,3 (1 700) 28,3 (1 700) 28,3 (1 700) 26,7 (1 600)

(1 400-1 700) (1 400-1 600) (1 700-1 800)

SAE J1995 gross kW (m hp) 115 (154) 126 (171) 129 (175) 170 (231) 180 (245) 210 (282) 235 (320) 261 (355) 397 (540)

ISO 9249, SAE J1349 net kW (m hp) 114 (153) 125 (170) 128 (174) 169 (230) 179 (243) 209 (280) 234 (318) 259 (352) 394 (536)

Transmission Countershaft Planetary*

Max speed forward/revers km/h 43,1 / 43,1 44,5 / 44,5 46,2 / 46,2 37,0 / 37,0 37,0 / 37,0 36,1 / 36,1 36,1 / 36,1 36,0 / 36,0 35,7 / 38,2

Specifications*

Static Tipping Load, at full turn kg 7 380 8 420 9 570 11 270 12 140 15 280 18 260 20 750 34 290

Breakout Force kN 82,9 95,4 118,5 156,7 164,0 184,7 214,7 224,5 472,8

Operating load, Bucket kg 3 470 3 882 4 622 5 300 5 700 7030 8 220 9 026 12 860

Operating load, Forks kg 4 350 4 900 5 700 6 800 7 450 9100 1 1000 12 650 18 840

Max Pin Height, Standard Boom mm 3 870 3 870 3 960 4 020 4 090 4340 4 470 4 670 5 340

Max Pin Height, Long Boom mm 4 390 4 340 4 390 4 530 4 610 4970 4 970 5 030 5 810

Dump Clearance mm** 2 830 2 790 2 850 2 860 2 910 3030 3 110 3 280 3 720

Dump Reach mm** 1 010 1 090 1 090 1 110 1 170 1 210 1 280 1 290 1 790

Overall Length (with bucket mm 7 270 7 390 7 510 7 890 8 020 8 590 8 790 9 090 11 070

Length (without bucket) mm 5 990 6 050 6 120 6 470 6 580 7 070 7 170 7 470 9 130

Width Over Tires mm 2 440 2 470 2 490 2 670 2 670 2 950 2 950 3 170 3 630

Height Over Cab mm 3 220 3 280 3 280 3 360 3 370 3 580 3 580 3 730 4 180

Bucket Width mm 2 500 2 550 2 650 3 000 3 000 3 200 3 200 3 400 3 970

Exterior Sound Levels dB (A) 104 105 106 106 106 107 108 108 111

Interior Noise Levels dB (A) 68 68 68 68 68 69 70 72 72

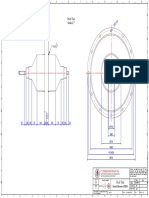

AxlEs

Differential Front 100% Differential Lock Conventional

Differential Rear Conventional

Brake type Dual Circuit Outboard Mounted Hydraulically Operated Wet DIsc

Brake Cooling Fully Sealed Oil Circulation-cooled

Hydraulics

System Type, Main and Steering Load Sensing

Pump Type, Main Axial Piston, variable 2 x Axial Piston, variable

Pump Type, Steering Axial Piston, variable

* with automatic Lock-Up ** Bucket: 2,1 m3 ** Bucket 2,3 m3 ** Bucket 2,5 m3 ** Bucket: 3,1 m3 ** Bucket: 3,4 m3 ** Bucket: 4,0 m3 ** Bucket: 4,6 m3 ** Bucket: 5,4 m3 ** Bucket: 6,9 m3

** Measured to the tip of the buckert teeth or bolt-on edges. (pin-on) with bolt-on (pin-on) with bolt-on (pin-on) with bolt-on straight with bolt-on straight with bolt-on straight edge with straight edge with straight edge with (8,6 yd3) straight with

Dump height to bucket edge. Measure at 45° edges, Tires: 20.5 edges, Tire: 20.5 R25 edges, Tire: 20.5 R25 edges, Tires: 23.5 edges, Tires: 23.5 bolt-on edges, tires: bolt-on edges, bolt-on edges, teeth and segments,

R25 L2, Std. boom L2, Std. boom L2, Std. boom R25 L2, standard R25 L2, standard 26.5 R25 L3, standard tires: 26.5 R25 L3, tires: 29.5 R25 L4, Tires 875/65 R33,

boom boom boom standard boom standard boom standard boom

Volvo Construction Equipment reserves the right to change any data or equipment,

as well as instructions regarding maintenance and other service procedures, without any

prior notice. The illustrations do not necessarily show the standard version of the machine.

Some products shown are not sold in all markets.

Ref. No. 21 B 100 4522 English

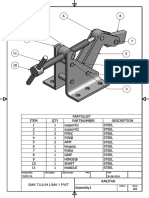

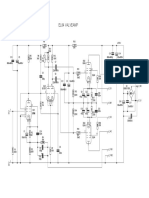

A machine you can always trust Volvo Contronic Monitoring System

• Network monitors operation and performance in real-time

• The Contronic system warns the operator in time, making it

World-class, Volvo Care Cab easier for the service technician to troubleshoot, and helps the

• Larger, more spacious cab interior with large storage compartments machine owner tailor the wheel loader to the application

• Care Cab features the market’s best cab filtration system • Fast and easy electronic level checks of oils and fluids

• Front pillar-mounted switches • Display shows continuous operating data, warning texts, Volvo Designed and Manufactured Engine

• Fully adjustable steering wheel, operator’s seat, armrest*, lever and error messages • Turbocharged Volvo V-ACT, Tier 3/Stage IIIA-

carrier, and steering column • Monitors fuel consumption, cycle times, and service intervals approved engines provides tremendous power

• Improved allround visibility includes wide, laminated front windshield • Available in 24 languages and impressive low-end torque

and floor-to-ceiling glass • Combines outstanding fuel economy, high

• Viscous damping helps to eliminate unwanted noise and vibrations reliability, and durability with low levels of noise

and exhaust emissions

• Engine control with overspeed protection for

Access and Serviceability optimal performance in all operating conditions

• Easily accessed hatches and service points • Hydrostatically driven, electronically controlled

• Centralized, ground level lubrication banks and fan works only when needed, which saves fuel

grouped pressure check connections

• Lubricated-for-life rear axle bearings

• Slip protected service platforms, handrails,

wide and angled cab ladders provide safety Volvo HTE Heavy-Duty Transmission

• Long lubrication intervals allow more time • Automatic Power Shift (APS) with

for productive work automatic mode selector

• The transmission automatically down-

shifts to first gear when needed

• Smooth shifts and high comfort with

Volvo Lift Arm System

Pulse Width

• Volvo TP-Linkage** - unique

• Modulation (PWM) gear selector valve

patented lift arm system

• Provides superior force throughout the

lift cycle

• Optimized attachment visibility and great

rollback angles Volvo AWB Heavy-Duty Axles

• Dual pin seals prevent contamination of pins • Dual circuit service brakes and automatic

parking brake application

• Outboard-mounted wet disc brakes and

planetary hub reductions

Volvo Genuine Attachments

• Differential lock with 100% locking on the

• Volvo’s comprehensive attachment range makes it front axle***

possible to tailor the wheel loader exactly for the

• Optional axle oil cooling provides maximized

applications and conditions on your work site

Commitment to Volvo’s Core Values: Quality, Safety cooling capacity*

and Care for the Environment • Simple checking of brake pads with brake

• Roll Over Protection System (ROPS) provides safe operation wear indicator on all wheels

Volvo Load-Sensing Hydraulics • Non-return valves prevent leakage of both hydraulic and Volvo frames

• Load-sensing hydraulic system provides exact fuel tanks in case of roll-over • High-quality steel provides stress resistance

flow and pressure – when and where it’s needed • High-quality breather filters on all major components and operational stability

3rd* and 4th* hydraulic functions for hydraulic • Optional biodegradable hydraulic oil allows environment- • Low vibrations and incredibly quiet sound levels

attachments friendly operation • Well organized articulation joint provides very easy

• All Volvo wheel loaders are more than 95% recyclable * Optional equipment

access for inspection and maintenance

• All electrical wiring is routed through high-quality conduits • Upper and lower joints designed for the ** Volvo Z-bar linkage on L350F

with sealed connectors highest stress ensure long life and reliability *** L60F - L220F

You might also like

- SOCIAL-MEDIA-MARKETING-TO-CONSUMERS-BUYING-BEHAVIOR-ResponsesDocument26 pagesSOCIAL-MEDIA-MARKETING-TO-CONSUMERS-BUYING-BEHAVIOR-ResponsesPsalmAngel morenoNo ratings yet

- Catalogo BDR RecamicRH 08marzo16 (Rev 04 2016)Document3 pagesCatalogo BDR RecamicRH 08marzo16 (Rev 04 2016)Pablo MolinaNo ratings yet

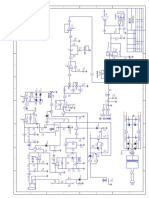

- AIR - Wiring Diagram Viewer - Driver SideDocument1 pageAIR - Wiring Diagram Viewer - Driver SideBejan TiberiuNo ratings yet

- 스터디캐드캠 - 3D 모델링 연습도면 527Document1 page스터디캐드캠 - 3D 모델링 연습도면 527Khánh ThiNo ratings yet

- PSM12P: ©2008 LOUD Technologies Inc. All Rights Re Served PSM12P Powered Speakers SchematicsDocument2 pagesPSM12P: ©2008 LOUD Technologies Inc. All Rights Re Served PSM12P Powered Speakers SchematicsCamila SuarezNo ratings yet

- Free Style 2dDocument11 pagesFree Style 2dsukimanNo ratings yet

- General Tire 2019 PDFDocument32 pagesGeneral Tire 2019 PDFLuis Eduardo PuertoNo ratings yet

- CATIA V5 Practice Part DrawingsDocument19 pagesCATIA V5 Practice Part DrawingsSebastianNo ratings yet

- Donidi (1) - Cad1Document1 pageDonidi (1) - Cad1Donidi Simpasim SalarNo ratings yet

- Kisi-Kisi Prototype Modeling LKS 2021Document5 pagesKisi-Kisi Prototype Modeling LKS 202136. ZAKIALITSEL GEBRILIENNo ratings yet

- Approve Date Design Check TitleDocument9 pagesApprove Date Design Check TitleJuan RizNo ratings yet

- Truck & Bus BrochureDocument8 pagesTruck & Bus BrochureAkhilesh RaiNo ratings yet

- Deton MP 184 A SCHDocument5 pagesDeton MP 184 A SCHcarlos.antouryNo ratings yet

- Belimo CCV Databook V8.6 05.2017 8Document12 pagesBelimo CCV Databook V8.6 05.2017 8kautukNo ratings yet

- AUTOCADDocument12 pagesAUTOCADmyakalshridhar7No ratings yet

- EHX Black Finger PDFDocument1 pageEHX Black Finger PDFГеоргий Ельцов100% (1)

- Taller 4 2018 - ADocument1 pageTaller 4 2018 - Ajose alejandro jara piñaNo ratings yet

- GMK 4080 SpecificationsDocument3 pagesGMK 4080 Specificationsmossamorris0% (1)

- Light Duty Pole Band-S3P2 - (229-254mm) : Eng. Eugene Busigazi 05/08/2020 Coast Concrete Pole LTDDocument1 pageLight Duty Pole Band-S3P2 - (229-254mm) : Eng. Eugene Busigazi 05/08/2020 Coast Concrete Pole LTDEugene BusigaziNo ratings yet

- Caremax 3Document1 pageCaremax 3Ariel UrtarteNo ratings yet

- Series: Static Three Wheel RollerDocument2 pagesSeries: Static Three Wheel Rolleragus yuliantoNo ratings yet

- Pa inDocument1 pagePa inChris TrikNo ratings yet

- RX15 - SchematicsDocument1 pageRX15 - SchematicsRainhardfrostNo ratings yet

- Tugas Akhir M3 Widi NDocument11 pagesTugas Akhir M3 Widi N643437 ANo ratings yet

- Bai Tap9 2DDocument1 pageBai Tap9 2D20021171 Nguyễn Thế NghĩaNo ratings yet

- Garage Smart Menu - January 2022Document176 pagesGarage Smart Menu - January 2022kevalNo ratings yet

- 50 2d Cad Exercises PDFDocument50 pages50 2d Cad Exercises PDFrichardkwofieNo ratings yet

- JBL Digital 12 Bu120e Pa 2000 SCHDocument1 pageJBL Digital 12 Bu120e Pa 2000 SCHbernardNo ratings yet

- Tugas GTM 2Document1 pageTugas GTM 2L KarimNo ratings yet

- Belimo CCV Databook V8.6 05.2017 7Document1 pageBelimo CCV Databook V8.6 05.2017 7kautukNo ratings yet

- Pdf Created With Fineprint Pdffactory Trial Version: 07版Solo5,6,7系列.SchDocument3 pagesPdf Created With Fineprint Pdffactory Trial Version: 07版Solo5,6,7系列.SchkylanNo ratings yet

- ACS800 GeneralDocument14 pagesACS800 GeneralAnonymous AMQMyB2EbNo ratings yet

- 1 - E-1 - Rev RADocument1 page1 - E-1 - Rev RAavinashkeswaniNo ratings yet

- 1 - E-1 - Rev RADocument1 page1 - E-1 - Rev RAavinashkeswaniNo ratings yet

- Air Conditioning (Manual Control) ,: Code AFPDocument5 pagesAir Conditioning (Manual Control) ,: Code AFPigor dvkvNo ratings yet

- Zed10 - zed10FX Master 003-970Document2 pagesZed10 - zed10FX Master 003-970Lalo JonerNo ratings yet

- Rotorua: Protection of The Missed ApproachDocument2 pagesRotorua: Protection of The Missed ApproachSebastian VasquesNo ratings yet

- MULTIMETERS Schematic Diagram: ACV (9K /V) Dcma Batt DC (20K /V) SWDocument1 pageMULTIMETERS Schematic Diagram: ACV (9K /V) Dcma Batt DC (20K /V) SWqanhepNo ratings yet

- Rail-52 KG Per MeterDocument1 pageRail-52 KG Per MeterGanesh KhandareNo ratings yet

- Produced by An Autodesk Student VersionDocument1 pageProduced by An Autodesk Student VersionramiroNo ratings yet

- Pyramid Glass: Item Matl Weght DateDocument6 pagesPyramid Glass: Item Matl Weght DatemahmoudNo ratings yet

- VinothDocument1 pageVinothminions kumarNo ratings yet

- Series: Static Three Wheel RollerDocument2 pagesSeries: Static Three Wheel RollerFahri Alvian NoorNo ratings yet

- Botones 3Document1 pageBotones 3123 NpNo ratings yet

- Transmission and Chain Tensioner: RS48-11C ROLL N' SPIKE GOLF GREENS ROLLER - Operation, Maintenance & Parts ManualDocument1 pageTransmission and Chain Tensioner: RS48-11C ROLL N' SPIKE GOLF GREENS ROLLER - Operation, Maintenance & Parts ManualAnonymous fvnsbqNo ratings yet

- Portofolio 1Document2 pagesPortofolio 1Lukman Arsyanto WibowoNo ratings yet

- Glass Shower HingeDocument2 pagesGlass Shower HingeJirapong ThailandNo ratings yet

- Ampeg BA115HPTDocument3 pagesAmpeg BA115HPTFederico BrunoNo ratings yet

- ISIS - Professional - Prueba 12 Reloj v6 - Prueba - 12Document1 pageISIS - Professional - Prueba 12 Reloj v6 - Prueba - 12Llyhayl Criss Ramirez JaliriNo ratings yet

- Air Conditioning (Manual Control) : Wiring DiagramDocument5 pagesAir Conditioning (Manual Control) : Wiring DiagramArmando RiveraNo ratings yet

- Nepse Chart - Nepal Stock InformationDocument2 pagesNepse Chart - Nepal Stock InformationkabyaNo ratings yet

- Drawing - Hub Tension Ring 67BE08Document3 pagesDrawing - Hub Tension Ring 67BE08Rizki MWNo ratings yet

- No 3Document1 pageNo 3rigaboNo ratings yet

- 4 Equal Risers @150MM 9 Equal RISERS@150MM 9 Equal RISERS@150MM 600 600 1350 1350Document1 page4 Equal Risers @150MM 9 Equal RISERS@150MM 9 Equal RISERS@150MM 600 600 1350 1350Richard AkelaNo ratings yet

- Soldering Atari ITX BottomDocument1 pageSoldering Atari ITX BottomskyddNo ratings yet

- Tubeamp EL84Document1 pageTubeamp EL84kosarobNo ratings yet

- Floor Model (1) انور - 5Document62 pagesFloor Model (1) انور - 5انور عبودNo ratings yet

- No 2Document1 pageNo 2rigaboNo ratings yet

- Job Sheet CAD 2DDocument9 pagesJob Sheet CAD 2DMuhammad Noor Fitriyanto100% (1)

- Enviro Decl Wlo 21C1003293Document9 pagesEnviro Decl Wlo 21C1003293Bilal VURALNo ratings yet

- ApplBro LogHandl 21A1003717Document16 pagesApplBro LogHandl 21A1003717Bilal VURALNo ratings yet

- ApplBro ScrapHandling Eng WebVersionDocument12 pagesApplBro ScrapHandling Eng WebVersionBilal VURALNo ratings yet

- EXC Environm Decl INT EN 30B1004931Document8 pagesEXC Environm Decl INT EN 30B1004931Bilal VURALNo ratings yet

- PMI - VCE - 150310 - Marketing Materials - AllDocument13 pagesPMI - VCE - 150310 - Marketing Materials - AllBilal VURALNo ratings yet

- Suppl Bro - Comfort Drive Control - Web VersDocument2 pagesSuppl Bro - Comfort Drive Control - Web VersBilal VURALNo ratings yet

- PMI - WLO - 150110 - A - Optional Equipments - L60F - L350F - AllDocument2 pagesPMI - WLO - 150110 - A - Optional Equipments - L60F - L350F - AllBilal VURALNo ratings yet

- Sales 13 eDocument2 pagesSales 13 eBilal VURALNo ratings yet

- PMI WLO 150110 C OptiShift L150F L180F L220F AllDocument2 pagesPMI WLO 150110 C OptiShift L150F L180F L220F AllBilal VURALNo ratings yet

- TREESPADEDocument1 pageTREESPADEBilal VURALNo ratings yet

- Sales Pav 02 06 enDocument1 pageSales Pav 02 06 enBilal VURALNo ratings yet

- IT14GDocument20 pagesIT14GBilal VURALNo ratings yet

- Hydraulic ExcavatorDocument16 pagesHydraulic ExcavatorBilal VURALNo ratings yet

- sk500xdlc 10 sk520xdlc 10Document16 pagessk500xdlc 10 sk520xdlc 10Bilal VURALNo ratings yet

- 922e Stage IiibDocument2 pages922e Stage IiibBilal VURALNo ratings yet

- EC60EDocument24 pagesEC60EBilal VURALNo ratings yet

- MF Cx130 GBDocument262 pagesMF Cx130 GBBilal VURAL100% (1)

- Sales Pav 13 07 enDocument1 pageSales Pav 13 07 enBilal VURALNo ratings yet

- Sk500 Sk520xdlc TurDocument16 pagesSk500 Sk520xdlc TurBilal VURALNo ratings yet

- Brochure l60gz l90gz t3 en 30 20046481 CDocument24 pagesBrochure l60gz l90gz t3 en 30 20046481 CBilal VURALNo ratings yet

- SKF Roller Screw Jack Actuator: Linear MotionDocument3 pagesSKF Roller Screw Jack Actuator: Linear MotionBilal VURALNo ratings yet

- Sales Pav 09 06 enDocument1 pageSales Pav 09 06 enBilal VURALNo ratings yet

- Ec350e Ec380e DWGDocument1 pageEc350e Ec380e DWGBilal VURALNo ratings yet

- Ballscrew Manuf TourDocument5 pagesBallscrew Manuf TourBilal VURALNo ratings yet

- CATM317FDocument36 pagesCATM317FBilal VURALNo ratings yet

- Sany Sy16cDocument4 pagesSany Sy16cBilal VURALNo ratings yet

- Euro Pallet ÖlçüleriDocument2 pagesEuro Pallet ÖlçüleriBilal VURALNo ratings yet

- Lf29 ENDocument2 pagesLf29 ENBilal VURALNo ratings yet

- ZX490 - 530 7 DWGDocument2 pagesZX490 - 530 7 DWGBilal VURALNo ratings yet

- Cat323d2 L-DWGDocument1 pageCat323d2 L-DWGBilal VURALNo ratings yet

- Rules, Scripts and BeanshellDocument7 pagesRules, Scripts and BeanshelltgudyktzxNo ratings yet

- HNBR Material TestDocument16 pagesHNBR Material TestskyerfreeNo ratings yet

- LatheDocument74 pagesLatheChandrakantha K100% (1)

- Automotive Solutions: Setting The Pace For InnovationDocument36 pagesAutomotive Solutions: Setting The Pace For InnovationAda TopanNo ratings yet

- Relayoperationprinciples 141126065914 Conversion Gate01Document43 pagesRelayoperationprinciples 141126065914 Conversion Gate01kenlavie2No ratings yet

- Surveying PDFDocument215 pagesSurveying PDFShaira Mae Cañedo100% (1)

- B I 1A Fundamentals of Reservoir Phase Behavior PDFDocument92 pagesB I 1A Fundamentals of Reservoir Phase Behavior PDFsereptNo ratings yet

- LSMW To Update Customer Master Records With Standard ObjectDocument9 pagesLSMW To Update Customer Master Records With Standard ObjectShahid_ONNo ratings yet

- SB 234Document9 pagesSB 234JolettitoNo ratings yet

- Ali Math Competition 3 English Reference SolutionsDocument11 pagesAli Math Competition 3 English Reference SolutionsJEREMIAH ITCHAGBENo ratings yet

- SampleDocument43 pagesSampleSri E.Maheswar Reddy Assistant ProfessorNo ratings yet

- Class Problems Sentences 13 The DDocument20 pagesClass Problems Sentences 13 The DKnowledgeIsTruePowerNo ratings yet

- How Can Dust Make Planets More Suitable For Life?: Authors: Associate EditorDocument4 pagesHow Can Dust Make Planets More Suitable For Life?: Authors: Associate EditorLucien GbezeNo ratings yet

- All The Questions of Section - A Are in Google Form and The Link To Attempt Them Is " Https://Forms - Gle/Jfvq8Wszicewchrj7 " 12 M Section - BDocument4 pagesAll The Questions of Section - A Are in Google Form and The Link To Attempt Them Is " Https://Forms - Gle/Jfvq8Wszicewchrj7 " 12 M Section - BKamal AnandNo ratings yet

- Datasheet Cpu 416-2Document13 pagesDatasheet Cpu 416-2Danu MaldinoNo ratings yet

- Sample Questions Paper 2 - TNQT Digital-4July19Document6 pagesSample Questions Paper 2 - TNQT Digital-4July19Gudimetla KowshikNo ratings yet

- 02 Minerals Library Basic Objects 5p1s4aDocument113 pages02 Minerals Library Basic Objects 5p1s4aman_y2k100% (1)

- BXE Experiment No.3Document8 pagesBXE Experiment No.3DsgawaliNo ratings yet

- EMDCSS DatasheetDocument5 pagesEMDCSS DatasheetHoracio UlloaNo ratings yet

- Assignments CHSSCDocument7 pagesAssignments CHSSCphani12_chem5672No ratings yet

- Seafloor Spreading TheoryDocument16 pagesSeafloor Spreading TheoryMark Anthony Evangelista Cabrieto100% (1)

- Dell's Guide To Server Basics: Click On The Questions Below To Learn More About Servers: 1. 2. 3. 4. 4.1. 4.2. 4.3. 5. 6Document11 pagesDell's Guide To Server Basics: Click On The Questions Below To Learn More About Servers: 1. 2. 3. 4. 4.1. 4.2. 4.3. 5. 6rameshNo ratings yet

- SPE15010Document11 pagesSPE15010Leandro NavarroNo ratings yet

- EIE3123 Dynamic Electronic Systems - p1-p57Document57 pagesEIE3123 Dynamic Electronic Systems - p1-p57Safwat KhairNo ratings yet

- Case StudyDocument6 pagesCase Studyzaid bin shafiNo ratings yet

- FAR21x7 28x7 Operator's Manual P 4-8-11Document312 pagesFAR21x7 28x7 Operator's Manual P 4-8-11Miguel PerezNo ratings yet

- Rationalizing The Seismic Coefficient Method PDFDocument41 pagesRationalizing The Seismic Coefficient Method PDFandremr15100% (1)

- Eaton Xeffect Industrial Switchgear Range Catalog Ca003002en en UsDocument379 pagesEaton Xeffect Industrial Switchgear Range Catalog Ca003002en en UsMAURIZIO MARININo ratings yet

- Pump Station System Curves Session 1Document29 pagesPump Station System Curves Session 1Toan LeNo ratings yet