Professional Documents

Culture Documents

SF 250 SST

Uploaded by

Soup PongsakornOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SF 250 SST

Uploaded by

Soup PongsakornCopyright:

Available Formats

CME/BO/04-00/02-00

Quotation number 2019200606

Prepared by Bindu Joseph

CORROSION TEST RANGE

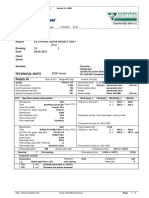

SF–250–SST

CM Envirosystems Pvt Ltd.Data Sheet |

Technical specifications are subject to change. 20-09-2019

CME/BO/04-00/02-00

Revision History SF-250-SST

REV No Description

0 Initial Offer

CM Envirosystems Pvt Ltd.Data Sheet |

Technical specifications are subject to change. 20-09-2019

Annexure I

Scope of Supply

SF-250-SST

1.0 Model SF-250-SST

1.1 Chamber Type Construction SST

1.2 Inner Chamber Width [mm] 800

1.3 Test Space Dimensions Inner Chamber Depth [mm] 535

1.4 [With Hood] Inner Chamber Height [mm] 1000

1.5 Total volume including canopy door [ltrs] 508

1.6 Inner Chamber Width [mm] 800

1.7 Test Space Dimensions Inner Chamber Depth [mm] 535

1.8 [Without Hood] Inner Chamber Height [mm] 600

1.9 Total volume excluding canopy door [ltrs] 267

1.10 Width [mm] 1665

1.11 External Dimensions [Approximate] Depth [mm] 875

1.12 Height [mm] 1225

1.13 Temperature range [°C] Min 5°C above ambient

1.14 Temperature range [°C] Max 55

1.15 Performance Data Temperature fluctuation [±°C] 1

1.16 Specimen Details Not disclosed

1.17 Low humidity in dry cycles [RH in %] NA

1.18 Humidity Range High humidity [RH in %] NA

1.19 Fluctuation [±RH in %] NA

1.20 Type of material used Fibre reinforced plastic, Acrylic & Nylon

1.21 Hood operation Pneumatic operated

1.22 Solution and air tubing Poly-Urethane tube

1.23 Mechanical Details Spray Mechanism Acrylic atomiser

1.24 Removable Angle Racks 1x16 slots [15 Deg inclination]

1.25 Fog fall out rate 0.5 to 2.5ml/80cm2/h

1.26 Noise Level [dbA] 50

1.27 Installation Location Thailand

1.28 Nominal voltage 1P/N/E 230VAC ±10% 50Hz

1.29 Nominal power 2.25 kW

1.30 Nominal current 10 A

Installation and Operations

1.31 [Refer Mechanical Layout for Site Power cable length 5 Mtr

requisites]

1.32 DM water inlet connection 8x6mm PU quick connector

1.33 Air inlet connection 8x6mm PU quick connector

1.34 Air exhaust connection 2 1/2'' & 2'' BSP male thread

1.35 Drain Connections 1'' BSP male thread

CM Envirosystems Pvt Ltd.Data Sheet |V2.1.1

Technical specifications are subject to change. 20-09-2019

Annexure I

Scope of Supply

SF-250-SST

1.36 Controller Type PID Micro Controller

1.37 Specimen Hanging Rods [FRP] 6 nos

1.38 Ethernet cable 3 Mtr

1.39 PU tube 6x8mm blue & clear 3 Mtr

Accessories Included

1.40 Isoprene tube 1 Ft

1.41 Funnel, Jar & rubber cork 1 Set

1.42 Wick cloth [With Humidity models] 1 Ft

1.43 Operation & Maintenance Manual 1 set

1.44 a. Manufacturer Calibration Certificate 1 no

1.45 Documents Included b. Warranty Certificate 1 no

1.46 c. Drawings & Test reports 1 set

1.47 Service Log Book 1 no

1.48 Shipping Details Net Weight [Kg] 150

1.49 [Approximate] Gross Weight [After packing] [Kg] 250

1.50 Transit Insurance by Customer

1.51 Freight by Customer

1.52 Unloading by Customer

Logistics Details

1.53 Chamber Placement by Customer

1.54 Unpacking of the Chamber by Customer

1.55 Transportation Documents E way bill

1.56 Optional Accessories & Spares Nil

1.57 Acceptance Test Plan Will be shared later

1.58 Additional Certification [If any] Specify

1.59 Pre Dispatch Inspection Yes

12 months from the date of

1.60 Warranty Period installation or 13 months from the

date of supply, whichever is earlier

1.61 Additional Information Equipment placement in lab condition Yes / No

1.62 Temperature at equipment location Deg C

1.63

CM Envirosystems Pvt Ltd.Data Sheet |V2.1.1

Technical specifications are subject to change. 20-09-2019

CME/BO/04-00/02-00

Mechanical Annexure II

Specifications SST - SF

The inner chamber shall be constructed using fibre reinforced plastic (FRP).

The test space floor shall handle a maximum uniform distributed load of 200kg and 30kg

2.1 Test Space

of point load. Channels for placement of shelves shall be provided where inclined rack or

rods can be placed to hang the unit under test (Inclined rack and FRP rods sold

separately)

The exterior of the chamber shall be constructed using fibre reinforced plastic (FRP) and

shall be coated with a white PU based paint.

The chamber shall comprise mainly of the test space, the electrical and the pneumatic

compartment. These compartments shall be isolated from each other to avoid any failure

of components due to corrosion.

2.2 Exterior

The electrical compartment shall be in front of the chamber and will have easy access to

all the electrical and controls. The colour of the compartment panel shall be dusty grey.

The pneumatic compartment shall be in the rear of the chamber and will have easy access

to all major components such as saturator and valves.

The canopy door shall have full access to the test space and shall be hinged to the rear of

the chamber.

These hinges shall be made using nylon.

2.3 Canopy Door The canopy door shall be of fibre reinforced plastic (FRP)

The canopy door shall be operated through a pneumatic cylinder. This cylinder shall be

mounted by the side of the chamber and shall be operated using pneumatic push button

switches.

The canopy door shall be sealed using a water channel. This water channel has to be

filled prior to operation of this chamber.

2.4 Sealing The canopy door support frame shall be immersed in this water channel creating a positive

seal and shall avoid any leak of the corrosive fog inside.

An overflow drain shall be provided for this water seal.

The chamber shall be mounted on levelling casters. These casters are a combination of

2.5 Mounting wheels for mobility and adjustable rubber mounts for levelling the chamber.

The chamber shall only be wheeled-in or fork lifted to the installation area.

The test space shall be insulated using multi layered mineral wool. This mineral wool shall

2.6 Insulation have a low `k' factor and high density of up to 48Kg/m3 This insulation shall be non

hygroscopic in nature and asbestos free.

CM Envirosystems Pvt Ltd.Data Sheet |

Technical specifications are subject to change. 20-09-2019

CME/BO/04-00/02-00

Air & Solution Annexure II

Specifications SF

The solution piping in the chamber shall be done using and silicone tubing and transparent

polyurethane tubing.

3.1 Solution Piping All polyurethane tubing shall be 8x6mm and PVC and nylon connectors shall be used.

A 2m tube shall be provided at the rear of the chamber which shall be immersed in the

solution reservoir. (Solution reservoir sold separately)

A peristaltic based solution pump shall be provided to dose the solution from the reservoir

to the atomiser nozzle.

The solution pump shall be a four roller system with a highly abrasion resistant isoprene

tube.

This isoprene tube shall be easily replaced as per the maintenance schedule by opening

3.2 Solution Pump

the transparent cover on the solution pump.

This solution pump is driven by a special continuous duty cycle motor with a high torque.

The solution pump speed shall be factory set to maintain popular salt spray standards.

This setting can be changed by accessing the pump drive which shall be placed in the

electrical compartment.

A float level switch shall be provided which can be immersed in the solution reservoir.

This shall give an output to the controller when the solution reaches low level.

3.3 Low Solution float

A 2m tube shall be provided at the rear of the chamber which shall be immersed in the

solution reservoir. (Solution reservoir sold separately)

The water piping in the chamber shall be done using transparent polyurethane tubing.

All polyurethane tubing shall be 8x6mm and PVC and nylon connectors shall be used.

The main water inlet to the chamber shall be at the rear of the chamber and a 8x6mm PU

3.4 Water Piping

tube push-in quick connector shall be provided.

This water shall be mainly used for the operation of the saturator and humidification

system.

A non corrosive acrylic based saturator shall be used to saturate the air as per standard.

The construction is secured using tie rods and stainless steel plates.

3.5 Saturator

The saturator shall be assembled with components such as float switch, heater, sensors

and an air dispenser shall be provided for equal distribution of air.

A non corrosive acrylic based atomiser nozzle shall be used to produce the fine fog.

3.6 Atomiser The nozzle shall be placed in the centre of the chamber to ensure uniform fog collection.

The nozzle shall be capable of a fog fall out rate of 0.5 to 2.5ml / 80cm2 / h @12 to 18 PSI

The pneumatic piping in the chamber shall be done using blue polyurethane tubing.

3.7 Pneumatic Piping

All polyurethane tubing shall be 8x6mm and push-in quick connectors shall be used.

An air purge system shall be provided to vent out the corrosive fumes / salt fog from the

test space before opening the canopy door.

3.8 Air Purge

A non corrosive nylon based flat fan nozzle shall be provided with regulated compressed

air to drain out the fog.

The main air inlet to the chamber shall be at the rear of the chamber and a 8x6mm PU

tube push-in quick connector shall be provided. A pressure switch shall also be provided

to cut-off the chamber in case of a high or low inlet air pressure.

The compressed air of 5 to 6 kg/cm2 shall be provided. This air shall be regulated in the

3.9 Air Regulation

chamber by means of an air regulator and used for the operation of the pneumatic canopy

door operation.

The compressed air is further regulated to 1 to 3 kg/cm2 for the operation of the atomiser.

A pressure gauge shall be provided to indicate this pressure.

CM Envirosystems Pvt Ltd.Data Sheet |

Technical specifications are subject to change. 20-09-2019

CME/BO/04-00/02-00

Electrical Annexure II

Specifications SST - SF

Flexible test space heaters shall be embedded in the test space. These heaters shall be

covered with aluminium blankets for uniform distribution of heat.

The heater outputs shall be controlled either through solid state relays.

4.1 Test Space Heaters

The heater surface shall be mounted with a RTD Pt-100 sensor to cut-off the electrical

supply in case the surface temperature reaches critical limit. This limit shall be set by

safety controller placed in the electrical compartment.

A cartridge type heater suitable for de-mineralised water shall be used in the saturator.

This shall ensure high reliability of the heaters.

The heater outputs shall be controlled either through solid state relays.

4.2 Saturator Heater The heater surface shall be mounted with a RTD Pt-100 sensor to cut-off the electrical

supply in case the surface temperature reaches critical limit. This limit shall be set by

safety controller placed in the electrical compartment.

The automatic level control shall ensure adequate reservoir of water in the saturator and

avoid dry runs.

4.3 Circuit breakers Miniature circuit breakers shall be used for the protection of control circuit and heaters

A mushroom head emergency stop switch shall be provided on the operating panel of the

4.4 Emergency Stop

chamber for immediate shutdown of all chamber operations.

The power supply to the chamber shall be connected through the 5m cable provided with

the chamber. The power supply shall be as per the equipment label by the side of the

chamber.

4.5 Power Supply

A regulated power supply shall also be provided for the low voltage devices through EMI

filter. This combination of regulated power supply with EMI filter shall ensure protection

against power surge and spikes.

All electrical components shall be separately earthed to a common earth strip. This earth

strip shall be connected to a earth pit suitable to ensure the values between neutral and

ground are less than 2V.

4.6 Earthing

The doors and the test space shall be connected to ensure complete chamber earthing.

A residual current circuit breaker (RCCB) shall be provided to protect against any leakage

current.

CM Envirosystems Pvt Ltd.Data Sheet |

Technical specifications are subject to change. 20-09-2019

CME/BO/04-00/02-00

Application Annexure II

Considerations SF

Certain application constraints should be considered when installing corrosion test

chambers. The reliability is often dependent upon proper and complete compliance with

5.1 General these considerations. Where the application varies from the guidelines presented, it should

be reviewed with your local installation engineer. The chamber is designed, constructed

and manufactured for the sole application of corrosion tests.

A base or foundation is not required if the selected location is level and strong enough to

support the chambers weight.

Provide lateral clearance as per the recommendations depicted in the layout diagram of the

5.2 Chamber Placement

corrosion test chamber.

Clearances to the side of the chamber provide access to maintaining the major

components.

Dirt, scale, products of corrosion, and other foreign material in the water will adversely

affect the performance of the corrosion test chamber. Proper water treatment must be

5.3 Water Treatment

determined locally and depends on the type of system and local water characteristics.

Please refer the water quality guidelines.

The corrosion test chambers are designed for use in laboratory conditions in ambient

5.4 Ambient Limitations

ranging from 20°C to 25°C and humidity between 20% to 70% RH.

The corrosion test chamber shall be connected to a common drain to drain out the water

5.5 Condensate Drain condensate.

The chamber is fitted with an internal BSP screw threaded R 1”.

The sound pressure level emitted from the corrosion test chamber is approximately

5.6 Sound 60dB(A) measured at a distance of 1m from the front of the chamber, in a non

reverberating room.

The corrosion test chamber cannot be used for tests on explosive, toxic or easy

inflammable materials nor with specimens generating or releasing such materials. This

applies particularly to all tests with liquids that boil easily, fuel, hydraulic fluids, lubricants

and the like.

In this case, the information on the material safety data sheet is to be kept in mind. Prior to

Unit Under Test

5.7 commencement of the tests, the operator has to check the material compatibility of the

Limitations

materials fitted in the test space (fibre reinforced plastic, acrylic, nylon, polyurethane,

silicone) to the materials/ gases which might be discharged by the test material. The latter

can form acids or bases when exposed to humidity. The leaking materials/gases can lead

to extensive damage of the chamber.

No living being is allowed to stay in the test chamber. There is danger to life.

The CCT chambers are fitted with exhaust ports and shall be connected by a flexible hose

and vented outside the laboratory.

5.8 Exhaust Port

The first chamber exhaust port is fitted with an external BSP screw threaded R 2 1/2”

The second air circulator exhaust port is fitted with an external BSP screw threaded R 2”

CM Envirosystems Pvt Ltd.Data Sheet |

Technical specifications are subject to change. 20-09-2019

CME/BO/04-00/02-00

Water quality Annexure II

Guidelines SF

This guideline for the water quality of tap water used in plate heat exchangers of stainless

steel [EN No. 1.4404 ~ AISI 316L] brazed with pure copper. The water which flows in these

plate heat exchangers varies a lot from application to application and corrosion can be a

problem in some situations.

5.1.1 Consideration

It is important to point out that the water specification is not a guarantee against corrosion,

but it must be considered as a tool to avoid the most critical water applications. A summary

of the parameters and their recommended quality limits are listed in the table below.

In general, an increase in temperature will increase the corrosion rate of most metals. For

copper in heated water, the likelihood of pitting is higher at temperatures above 60°C.

5.1.2 Temperature Parameter

Also the risk of stress corrosion cracking of stainless steel will increase at temperatures

above 60°C, and pitting and crevice corrosion in stainless steel is also temperature

dependent [see the section about chloride].

General corrosion of copper mainly depends on pH and the risk of corrosion is lowest if pH

5.1.3 pH Parameter is kept above 7.5 and below 9.0. [1, 2, 3] However, one must expect a pH around 7 in

normal tap water, but it is recommendable to avoid water with a pH below 7.

If the content of hydrogen carbonate [HCO3-] in the water is very low, i.e. below 60 mg/l,

5.1.4 Alkalinity Parameter corrosion products of copper will dissolve and it will be released into the system. It is also

recommendable not to exceed a HCO3 concentration of 300 mg/l.

A high conductivity in the tap water means that the water has a high concentration of ionic

substances. In general, an increase in conductivity of tap water will increase the corrosion

5.1.5 Conductivity Parameter

rate of most metals. A maximum conductivity of 500 µS/cm is in general an appropriate limit

value.

Copper is susceptible to corrosion in very soft water and the [Ca2+, Mg2+] / [HCO3-] ratio

5.1.6 Hardness Parameter

should therefore be more than 0.5.

Presence of chloride in the drinking water will increase the risk of localized corrosion of

stainless steel. The limit value will depend on temperature according to table.

5.1.7 Chloride Parameter

High concentrations of sulphate will increase the risk of pitting in copper. A maximum

5.1.8 Sulphate Parameter sulphate concentration of 100 mg/l is recommendable, but corrosion can also take place at

lower concentrations if [HCO3-] / [SO42-] is below 1.

Nitrate ions have an influence similar to that of sulphate, and a maximum nitrate

5.1.9 Nitrate Parameter

concentration of 100 mg/l is recommendable.

CM Envirosystems Pvt Ltd.Data Sheet |

Technical specifications are subject to change. 20-09-2019

CME/BO/04-00/02-00

Test Standard Annexure II

Compliance SST / CCT - SF

Salt Spray - Chamber Temperature - 35°C; Saturator Temperature - 45°C

6.1 ASTM B117 Exposed to a continuous indirect spray of neutral (pH 6.5 to 7.2) salt water solution, which

falls-out on to the specimens at a rate of 1.0 to 2.0ml/80cm²/hour, in a chamber

temperature of +35C.

Salt Spray - Chamber Temperature - 35°C; Saturator Temperature - 45°C

6.2 ASTM B287 Exposed to a continuous indirect spray of acidified (pH 3.1 to 3.3) salt water solution,

which falls-out on to the specimens at a rate of 0.75 to 2.0ml/80cm²/hour, in a chamber

temperature of +35C.

Salt Spray - Chamber Temperature - 49°C; Saturator Temperature - 60°C

6.3 ASTM B368 Exposed to a continuous indirect spray of acidified (pH 3.1 to 3.3) salt water solution,

which falls-out on to the specimens at a rate of 1to 2.0ml/80cm²/hour, in a chamber

temperature of +49C.

Salt Spray - Chamber Temperature - 38°C; Saturator Temperature - 45°C

6.4 ASTM D1735

Exposed to a continuous indirect spray water, which falls-out on to the specimens at a

rate of 1.5 to 3.0ml/80cm²/hour, in a chamber temperature of +38C.

Salt Spray - Chamber Temperature - 35°C; Saturator Temperature - 45°C

6.5 ASTM G85 Annex-1 Exposed to a continuous indirect spray of acidified (pH 3.1 to 3.3) salt water solution,

which falls-out on to the specimens at a rate of 1.0 to 2.0ml/80cm²/hour, in a chamber

temperature of +35C.

Salt Spray - Chamber Temperature - 35°C; Saturator Temperature - 45°C

6.6 AS 2331 method 3.1

Exposed to a continuous indirect spray water, which falls-out on to the specimens at a

rate of 1.5 to 3.0ml/80cm²/hour, in a chamber temperature of +35C.

Salt Spray - Chamber Temperature - 35°C; Saturator Temperature - 45°C

6.7 AS 2331 method 3.2 Exposed to a continuous indirect spray of acidified (pH 3.1 to 3.3) salt water solution,

which falls-out on to the specimens at a rate of 1.0 to 2.0ml/80cm²/hour, in a chamber

temperature of +35C.

Salt Spray - Chamber Temperature - 50°C; Saturator Temperature - 60°C

6.8 AS 2331 method 3.3 Exposed to a continuous indirect spray of acidified (pH 3.1 to 3.3) salt water solution,

which falls-out on to the specimens at a rate of 1.0 to 2.0ml/80cm²/hour, in a chamber

temperature of +50C.

Salt Spray - Chamber Temperature - 35°C; Saturator Temperature - 45°C

6.9 BS 5466 P2 Exposed to a continuous indirect spray of acidified (pH 3.1to 3.3) salt water solution, which

falls-out on to the specimens at a rate of 1.0 to 2.0ml/80cm²/hour, in a chamber

temperature of +35C.

Salt Spray - Chamber Temperature - 35°C; Saturator Temperature - 45°C

6.10 BS 7479 Exposed to a continuous indirect spray of neutral (pH 6.5 to 7.2) salt water solution, which

falls-out on to the specimens at a rate of 1.0 to 2.0ml/80cm²/hour, in a chamber

temperature of +35C.

Salt Spray - Chamber Temperature - 35°C; Saturator Temperature - 45°C

6.11 BS-EN-ISO 7253

Exposed to a continuous indirect spray water, which falls-out on to the specimens at a

rate of 1.5 to 3.0ml/80cm²/hour, in a chamber temperature of +35C.

CM Envirosystems Pvt Ltd.Data Sheet |

Technical specifications are subject to change. 20-09-2019

CME/BO/04-00/02-00

Test Standard Annexure II

Compliance SST / CCT - SF

Salt Spray - Chamber Temperature - 35°C; Saturator Temperature - 45°C

6.12 BS-EN-60068-2-11 ka Exposed to a continuous indirect spray of neutral (pH 6.5 to 7.2) salt water solution, which

falls-out on to the specimens at a rate of 1.0 to 2.0ml/80cm²/hour, in a chamber

temperature of +35C.

Salt Spray - Chamber Temperature - 35°C; Saturator Temperature - 45°C

6.13 BS-EN-6052-11-6 Exposed to a continuous indirect spray of neutral (pH 6.5 to 7.2) salt water solution, which

falls-out on to the specimens at a rate of 1.0 to 2.0ml/80cm²/hour, in a chamber

temperature of +35C.

Salt Spray - Chamber Temperature - 35°C; Saturator Temperature - 45°C

6.14 BS-EN-60512-11-6 Exposed to a continuous indirect spray of neutral (pH 6.5 to 7.2) salt water solution, which

falls-out on to the specimens at a rate of 1.0 to 2.0ml/80cm²/hour, in a chamber

temperature of +35C.

Salt Spray - Chamber Temperature - 35°C; Saturator Temperature - 45°C

6.15 BS 2011 Part 2.1 Ka

Exposed to a continuous indirect spray water, which falls-out on to the specimens at a

rate of 1.0 to 2.0ml/80cm²/hour, in a chamber temperature of +35C.

Salt Spray - Chamber Temperature - 35°C; Saturator Temperature - 45°C

6.16 BS 3900 F12 Exposed to a continuous indirect spray of neutral (pH 6.5 to 7.2) salt water solution, which

falls-out on to the specimens at a rate of 1.0 to 2.5ml/80cm²/hour, in a chamber

temperature of +35C.

Salt Spray - Chamber Temperature - 35°C; Saturator Temperature - 45°C

6.17 BS 5466 P1 Exposed to a continuous indirect spray of neutral (pH 6.5 to 7.2) salt water solution, which

falls-out on to the specimens at a rate of 1.0 to 2.0ml/80cm²/hour, in a chamber

temperature of +35C.

Salt Spray - Chamber Temperature - 50°C; Saturator Temperature - 60°C

6.18 BS 5466 P2 Exposed to a continuous indirect spray of acidified (pH 3.1to 3.3) salt water solution, which

falls-out on to the specimens at a rate of 1.0 to 2.0ml/80cm²/hour, in a chamber

temperature of +50C.

Salt Spray - Chamber Temperature - 35°C; Saturator Temperature - 45°C

6.19 DIN 50 021 SS

Exposed to a continuous indirect spray water, which falls-out on to the specimens at a rate

of 1.5 to 3.0ml/80cm²/hour, in a chamber temperature of +35C.

Salt Spray - Chamber Temperature - 35°C; Saturator Temperature - 45°C

6.20 DIN 50 021 ESS Acetic Acid Salt Spray Test, pH 3.1to 3.3, continuous indirect spray of acidified (pH 3.1to

3.3) salt water solution, which falls-out on to the specimens at a rate of 1.0 to

2.0ml/80cm²/hour, in a chamber temperature of +35C.

Salt Spray - Chamber Temperature - 50°C; Saturator Temperature - 60°C

6.21 DIN 50 021 CASS Acetic Acid Salt Spray Test, pH 3.1to 3.3, continuous indirect spray of acidified (pH 3.1to

3.3) salt water solution, which falls-out on to the specimens at a rate of 1.0 to

2.0ml/80cm²/hour, in a chamber temperature of +50C.

Salt Spray - Chamber Temperature - 35°C; Saturator Temperature - 45°C

6.22 FIAT 50180 A1 Exposed to a continuous indirect spray of neutral (pH 6.5 to 7.2) salt water solution, which

falls-out on to the specimens at a rate of 1.0 to 2.0ml/80cm²/hour, in a chamber

temperature of +35C.

CM Envirosystems Pvt Ltd.Data Sheet |

Technical specifications are subject to change. 20-09-2019

CME/BO/04-00/02-00

Test Standard Annexure II

Compliance SST / CCT - SF

Salt Spray - Chamber Temperature - 35°C; Saturator Temperature - 45°C

6.23 FIAT 50180 A2 Exposed to a continuous indirect spray of acidified (pH 3.1 to 3.3) salt water solution,

which falls-out on to the specimens at a rate of 1.0 to 2.0ml/80cm²/hour, in a chamber

temperature of +35C.

Salt Spray - Chamber Temperature - 50°C; Saturator Temperature - 60°C

6.24 FIAT 50180 A3 Exposed to a continuous indirect spray of acidified (pH 3.1 to 3.3) salt water solution,

which falls-out on to the specimens at a rate of 1.0 to 2.0ml/80cm²/hour, in a chamber

temperature of +50C.

Salt Spray - Chamber Temperature - 35°C; Saturator Temperature - 45°C

6.25 FORD FLTM BI 103-01 Exposed to a continuous indirect spray of neutral (pH 6.5 to 7.2) salt water solution, which

falls-out on to the specimens at a rate of 1.0 to 2.0ml/80cm²/hour, in a chamber

temperature of +35C.

Salt Spray - Chamber Temperature - 35°C; Saturator Temperature - 45°C

6.26 GM 4298P Exposed to a continuous indirect spray of neutral (pH 6.5 to 7.2) salt water solution, which

falls-out on to the specimens at a rate of 1.0 to 2.0ml/80cm²/hour, in a chamber

temperature of +35C.

Salt Spray - Chamber Temperature - 38°C; Saturator Temperature - 45°C

6.27 GM 4465P Exposed to a continuous indirect spray of neutral (pH 6.5 to 7.2) salt water solution, which

falls-out on to the specimens at a rate of 1.0 to 2.0ml/80cm²/hour, in a chamber

temperature of +38C.

Salt Spray - Chamber Temperature - 50°C; Saturator Temperature - 60°C

6.28 ISO 3770 Exposed to a continuous indirect spray of acidified (pH 3.1 to 3.3) salt water solution,

which falls-out on to the specimens at a rate of 1.0 to 2.0ml/80cm²/hour, in a chamber

temperature of +50C.

Salt Spray - Chamber Temperature - 35°C; Saturator Temperature - 45°C

6.29 ISO 3768 Exposed to a continuous indirect spray of acidified (pH 3 to 3.3) salt water solution, which

falls-out on to the specimens at a rate of 1.0 to 2.0ml/80cm²/hour, in a chamber

temperature of +35C.

Salt Spray - Chamber Temperature - 38°C; Saturator Temperature - 45°C

6.30 ISO 3769 Exposed to a continuous indirect spray of acidified (pH 3 to 3.3) salt water solution, which

falls-out on to the specimens at a rate of 1.0 to 2.0ml/80cm²/hour, in a chamber

temperature of +35C.

Salt Spray - Chamber Temperature - 35°C; Saturator Temperature - 45°C

6.31 ISO 7253

Exposed to a continuous indirect spray water, which falls-out on to the specimens at a

rate of 1.5 to 3.0ml/80cm²/hour, in a chamber temperature of +35C.

Salt Spray - Chamber Temperature - 35°C or 50°C; Saturator Temperature - 45°C or 60°C

6.32 ISO 9227 Exposed to a continuous indirect spray of acidified (pH 3.1 to 3.3) or neutral (pH 6.5 to 7.2)

salt water solution, which falls-out on to the specimens at a rate of 1.0 to

2.0ml/80cm²/hour, in a chamber temperature of +35C or 50C

Salt Spray - Chamber Temperature - 35°C; Saturator Temperature - 45°C

6.33 IEC 60068-2-11 Exposed to a continuous indirect spray of neutral (pH 6.5 to 7.2) salt water solution, which

falls-out on to the specimens at a rate of 1.0 to 2.0ml/80cm²/hour, in a chamber

temperature of +35C.

CM Envirosystems Pvt Ltd.Data Sheet |

Technical specifications are subject to change. 20-09-2019

CME/BO/04-00/02-00

Test Standard Annexure II

Compliance SST / CCT - SF

Salt Spray - Chamber Temperature - 35°C; Saturator Temperature - 45°C

6.34 JISH8502 M1 Exposed to a continuous indirect spray of neutral (pH 6.5 to 7.2) salt water solution, which

falls-out on to the specimens at a rate of 1.0 to 2.0ml/80cm²/hour, in a chamber

temperature of +35C.

Salt Spray - Chamber Temperature - 35°C; Saturator Temperature - 45°C

6.35 JISH8502 M2 Exposed to a continuous indirect spray of acidified (pH 3.1 to 3.3) salt water solution,

which falls-out on to the specimens at a rate of 1.0 to 2.0ml/80cm²/hour, in a chamber

temperature of +35C.

Salt Spray - Chamber Temperature - 50°C; Saturator Temperature - 60°C

6.36 JISH8502 M3 Acetic Acid Salt Spray Test, pH 3.1to 3.3, continuous indirect spray of acidified (pH 3.1to

3.3) salt water solution, which falls-out on to the specimens at a rate of 1.0 to

2.0ml/80cm²/hour, in a chamber temperature of +50C.

Salt Spray - Chamber Temperature - 35°C; Saturator Temperature - 45°C

6.37 JIS Z 2371

Exposed to a continuous indirect spray water, which falls-out on to the specimens at a rate

of 1.5 to 3.0ml/80cm²/hour, in a chamber temperature of +38C.

Salt Spray - Chamber Temperature - 35°C; Saturator Temperature - 45°C

6.38 MIL STD 202 Exposed to a continuous indirect spray of neutral (pH 6.5 to 7.2) salt water solution, which

falls-out on to the specimens at a rate of 0.5 to 3.0ml/80cm²/hour, in a chamber

temperature of +35C.

Salt Spray - Chamber Temperature - 35°C; Saturator Temperature - 45°C

6.39 Renault D171058 Exposed to a continuous indirect spray of neutral (pH 6.5 to 7.2) salt water solution, which

falls-out on to the specimens at a rate of 1.0 to 2.0ml/80cm²/hour, in a chamber

temperature of +35C.

Salt Spray - Chamber Temperature - 35°C or 50°C; Saturator Temperature - 45°C or 60°C

6.40 VOLVO STD 6011,102 Exposed to a continuous indirect spray of acidified (pH 3.1 to 3.3) or neutral (pH 6.5 to 7.2)

salt water solution, which falls-out on to the specimens at a rate of 1.0 to

2.0ml/80cm²/hour, in a chamber temperature of +35C or 50C

Salt Spray - Chamber Temperature - 35°C; Saturator Temperature - 45°C

6.41 VG 95 210 method 101C Exposed to a continuous indirect spray of neutral (pH 6.5 to 7.2) salt water solution, which

falls-out on to the specimens at a rate of 0.5 to 3.0ml/80cm²/hour, in a chamber

temperature of +35C.

Salt Spray - Chamber Temperature - 35°C; Saturator Temperature - 45°C

6.42 JAGUAR JNS 30.16.03 Exposed to a continuous indirect spray of neutral (pH 6.5 to 7.2) salt water solution, which

falls-out on to the specimens at a rate of 1.0 to 2.0ml/80cm²/hour, in a chamber

temperature of +35C.

Salt Spray - Chamber Temperature - 35°C; Saturator Temperature - 45°C

Exposed to a continuous indirect spray of neutral (pH 6.5 to 7.2) salt water solution, which

6.43 DEF STAN 1053 M36

falls-out on to the specimens at a rate of 1.0 to 2.0ml/80cm²/hour, in a chamber

temperature of +35C. daily for 8 periods of 10 minutes, at intervals of 50 minutes, with no

spray being applied during weekends

Salt Spray - Chamber Temperature - 35°C or 50°C; Saturator Temperature - 45°C or 60°C

BMW AA-0324 (AA-P

6.44

184) Exposed to a continuous indirect spray water, which falls-out on to the specimens at a

rate of 30 to 40ml/80cm²/24hours, in a chamber temperature of +35C or 50°C.

CM Envirosystems Pvt Ltd.Data Sheet |

Technical specifications are subject to change. 20-09-2019

CME/BO/04-00/02-00

Controller Annexure II

Specifications SST – SF

A digital temperature controller of 48x48mm size shall be used to control the temperature in

the test space.

The display shall be high contrast with LCDs displaying the process value in white and set

value in green.

7.1 Test Space Controller

Simple function keys shall be provided on the digital controller to change the set point.

PID based control shall be used for precise control of the set point. RTD Pt-100 sensor will

be used to connect this controller

A digital temperature controller of 48x48mm size shall be used to control the temperature in

the saturator.

The display shall be high contrast with LCDs displaying the process value in white and set

value in green.

7.2 Saturator Controller

Simple function keys shall be provided on the digital controller to change the set point.

PID based control shall be used for precise control of the set point. RTD Pt-100 sensor will

be used to connect this controller

DIN mounted safety controllers shall be provided in the electrical compartment to connect

the test space safety sensor and the saturator heater.

The display shall be high contrast with LCDs displaying the process value in white and set

7.3 Safety Controller value in green.

Simple function keys shall be provided on the digital controller to change the limit.

RTD Pt-100 sensor will be used to connect this controller

A cyclic timer of 48x48mm shall be used to set the intervals of spray.

7.4 Cyclic Timer

The display shall be red LED and simple functions keys shall be provided to change the

spray on/off time.

CM Envirosystems Pvt Ltd.Data Sheet |

Technical specifications are subject to change. 20-09-2019

You might also like

- SF 450 CCTDocument19 pagesSF 450 CCTSoup PongsakornNo ratings yet

- Technical Details - Ecology UnitsDocument4 pagesTechnical Details - Ecology Unitsprashant.jadhavNo ratings yet

- Dwg.20A+20B B-AHU-10Document8 pagesDwg.20A+20B B-AHU-10GengaNo ratings yet

- Commercial Unit Cooler:Cubic Type: F50HC 1806 E 7 N. Units: 1Document4 pagesCommercial Unit Cooler:Cubic Type: F50HC 1806 E 7 N. Units: 1Mario UrsuNo ratings yet

- Ahus Data For Ot ProjectDocument12 pagesAhus Data For Ot ProjectIrfan SiddiquiNo ratings yet

- Dwg.38 B-AHU-19Document4 pagesDwg.38 B-AHU-19GengaNo ratings yet

- LMS BOQ C-4 - BELDEN - Eib-Knx-CableDocument2 pagesLMS BOQ C-4 - BELDEN - Eib-Knx-Cablesiraj sNo ratings yet

- E) DSF1000 AlDocument5 pagesE) DSF1000 AlAgeng A. PooNo ratings yet

- Technical Data: Date Rev. Date Project ID Tracking Number Project Name AHU Name AHU ModelDocument3 pagesTechnical Data: Date Rev. Date Project ID Tracking Number Project Name AHU Name AHU ModelAiman AliNo ratings yet

- Technical Data: Date Rev. Date Project ID Tracking Number Project Name AHU Name AHU ModelDocument3 pagesTechnical Data: Date Rev. Date Project ID Tracking Number Project Name AHU Name AHU ModelAiman AliNo ratings yet

- E) DSF1300 Al1Document5 pagesE) DSF1300 Al1Ageng A. PooNo ratings yet

- Comparison Sheet For Third Party ReportsDocument190 pagesComparison Sheet For Third Party Reportsrafi khan nangyalNo ratings yet

- 01-1 Per PDFDocument6 pages01-1 Per PDFGeorge ProteasaNo ratings yet

- Dwg.24 B-AHU-14Document4 pagesDwg.24 B-AHU-14GengaNo ratings yet

- Date SheetsDocument3 pagesDate SheetsAnıl ÖztürkNo ratings yet

- Part Number: YE00819: Classic Original ClassicDocument2 pagesPart Number: YE00819: Classic Original ClassicYousif_AbdalhalimNo ratings yet

- Dwg.21 B-AHU-11Document3 pagesDwg.21 B-AHU-11GengaNo ratings yet

- Technical Details - MAHUDocument6 pagesTechnical Details - MAHUprashant.jadhavNo ratings yet

- Development of AerofoilDocument6 pagesDevelopment of Aerofoilvaisakp777No ratings yet

- Sprcompin 01Document4 pagesSprcompin 01bshahidhNo ratings yet

- SG 6.6-155 - Estimated Foundation Design T122.5-51ADocument4 pagesSG 6.6-155 - Estimated Foundation Design T122.5-51AJIMYJONNo ratings yet

- V-101 3 Phase SeparatorDocument1 pageV-101 3 Phase Separatorrandi martaNo ratings yet

- BBS-10-W8-DS-006 - C - Glycol Charcoal Filter DS PDFDocument1 pageBBS-10-W8-DS-006 - C - Glycol Charcoal Filter DS PDFAdianto RahmanNo ratings yet

- DOP CE EGGER Eurospan Mmex Rec301 ENDocument2 pagesDOP CE EGGER Eurospan Mmex Rec301 ENMateusz Latosiński LSD.STUDIO ✖No ratings yet

- LMR-240-UF AttenuationDocument2 pagesLMR-240-UF AttenuationVenu GopalNo ratings yet

- TAN HUE VIEN-Technical AHU-op2Document72 pagesTAN HUE VIEN-Technical AHU-op2Cao Son DuongNo ratings yet

- Final TestDocument15 pagesFinal TestSeptian FirdausNo ratings yet

- F27HC 46 e 7Document2 pagesF27HC 46 e 7วงศกร สิงห์เอี่ยมNo ratings yet

- L 4E5ATG (Specification)Document2 pagesL 4E5ATG (Specification)hanryNo ratings yet

- Hydraulic Analysis Report - B1 - INT-1Document17 pagesHydraulic Analysis Report - B1 - INT-1Dennis MendezNo ratings yet

- Características Tecnicas CablesDocument1 pageCaracterísticas Tecnicas CablesAnonymous 4kYNmixNo ratings yet

- Gas-Tight Premium Connection: 2.375 In. (60.33) 4.7 LBM/FT (6.99)Document1 pageGas-Tight Premium Connection: 2.375 In. (60.33) 4.7 LBM/FT (6.99)DiegoCaicedo1982No ratings yet

- 110-123-116 SettlementDocument52 pages110-123-116 Settlementraghav abudhabiNo ratings yet

- FLEX-03 2.6N - Datasheet - EnglishDocument2 pagesFLEX-03 2.6N - Datasheet - Englishedgars.sk.mrNo ratings yet

- IM10A (Globe Valves For LP&MP Service Ammonia)Document118 pagesIM10A (Globe Valves For LP&MP Service Ammonia)Gloria HamiltonNo ratings yet

- Technical Details - Ecology UnitDocument9 pagesTechnical Details - Ecology Unitprashant.jadhavNo ratings yet

- Verso S 20 X H PM - Ie5 - 1 - 4 - X F7 X X R1 C5 - 1 XDocument5 pagesVerso S 20 X H PM - Ie5 - 1 - 4 - X F7 X X R1 C5 - 1 XrkibNo ratings yet

- Tech - Clean Room at Kochi (REF - 11669)Document10 pagesTech - Clean Room at Kochi (REF - 11669)Anand VLNo ratings yet

- Description: Hivorex High Density Polyethylene General InformationDocument1 pageDescription: Hivorex High Density Polyethylene General InformationLuca GuadagnoNo ratings yet

- Paredes EstudioSamuel ScatteringDocument6 pagesParedes EstudioSamuel ScatteringStevens Amador MateusNo ratings yet

- Ecology Datasheet@T-11687 Rev 1-Jizan AirportDocument32 pagesEcology Datasheet@T-11687 Rev 1-Jizan Airportbasheer9No ratings yet

- Ebara JESX 2 Poles 60 en LDocument12 pagesEbara JESX 2 Poles 60 en LEduardo MercadoNo ratings yet

- F30HC 522 e 6Document2 pagesF30HC 522 e 6วงศกร สิงห์เอี่ยมNo ratings yet

- Product Summary: CZ-1030 Is A 30% Pitch Based Carbon Fiber Reinforced PPS Color: BlackDocument1 pageProduct Summary: CZ-1030 Is A 30% Pitch Based Carbon Fiber Reinforced PPS Color: BlackMark DingalNo ratings yet

- 1.0 General Plant Information: Existing Cement Mill Process Data SheetDocument6 pages1.0 General Plant Information: Existing Cement Mill Process Data SheetBùi Hắc HảiNo ratings yet

- 21-QN-003516-CH Technical Offer MSKPP OricaDocument4 pages21-QN-003516-CH Technical Offer MSKPP OricaArn Eduardo Solís TapiaNo ratings yet

- AHU Technical SelectionDocument5 pagesAHU Technical Selectionmohamed ghonemNo ratings yet

- Alex Thread Texti̇le - 110KW DHK PremiumDocument7 pagesAlex Thread Texti̇le - 110KW DHK PremiumMohmed Ashraf AhmedNo ratings yet

- Anderson Greenwood AGCO MM1 AEDocument4 pagesAnderson Greenwood AGCO MM1 AEMuhammad Moeed AlamNo ratings yet

- Specification Sheet: Description Uom ParameterDocument7 pagesSpecification Sheet: Description Uom ParameterMohammad IrfandiNo ratings yet

- Superfort 630-4 4.0 + 2.0 Betahete 800 Moulded Edges (1 X 220.0m) +GBDocument1 pageSuperfort 630-4 4.0 + 2.0 Betahete 800 Moulded Edges (1 X 220.0m) +GBIulian BarbuNo ratings yet

- Thermokey BFT 56368 P6AT - ULO Komore 232 ToneDocument9 pagesThermokey BFT 56368 P6AT - ULO Komore 232 ToneSladjan UgrenovicNo ratings yet

- Part Number: 9913: Low Loss 50 Ohm, RG8, #10Document3 pagesPart Number: 9913: Low Loss 50 Ohm, RG8, #10Priscilla Mora MadrigalNo ratings yet

- Uasar 10: 10 KN Advanced Niversal Testing AchineDocument3 pagesUasar 10: 10 KN Advanced Niversal Testing AchineBENAHMED HouariNo ratings yet

- Commercial Unit Cooler:Cubic Type: F30HC 622 E 7 N. Units: 1Document2 pagesCommercial Unit Cooler:Cubic Type: F30HC 622 E 7 N. Units: 1วงศกร สิงห์เอี่ยมNo ratings yet

- Sizing Calculation FCVDocument3 pagesSizing Calculation FCVYawar QureshiNo ratings yet

- Drift Eliminators: Product ProfileDocument2 pagesDrift Eliminators: Product ProfileYohanes Joko TriyantoNo ratings yet

- Prime Geo 550H..Document1 pagePrime Geo 550H..wpacadaNo ratings yet

- Female Cordset: ADOAH040VAS0015E04Document3 pagesFemale Cordset: ADOAH040VAS0015E04Isnan DanangNo ratings yet

- Data Sheet GripsDocument23 pagesData Sheet GripsSoup PongsakornNo ratings yet

- Datasheet CDR Series Digital Crane ScalesDocument2 pagesDatasheet CDR Series Digital Crane ScalesSoup PongsakornNo ratings yet

- Datasheet in Series Fish and Game Linear Handheld ScalesDocument2 pagesDatasheet in Series Fish and Game Linear Handheld ScalesSoup PongsakornNo ratings yet

- Data Sheet GripsDocument23 pagesData Sheet GripsSoup PongsakornNo ratings yet

- c660m Leak and Seal Strength TesterDocument3 pagesc660m Leak and Seal Strength TesterSoup PongsakornNo ratings yet

- 5400 Solid Flange 1Document2 pages5400 Solid Flange 1Soup PongsakornNo ratings yet

- 2400 LC DS 1Document3 pages2400 LC DS 1Soup PongsakornNo ratings yet

- System Manual SEV 240Document79 pagesSystem Manual SEV 240Soup PongsakornNo ratings yet

- 2400HC DS 1Document3 pages2400HC DS 1Soup PongsakornNo ratings yet

- 1500 SLC DS-1Document2 pages1500 SLC DS-1Soup PongsakornNo ratings yet

- 505M1F (20210817)Document4 pages505M1F (20210817)Soup PongsakornNo ratings yet

- 1200 Standard DS 1Document3 pages1200 Standard DS 1Soup PongsakornNo ratings yet

- Leak TesterDocument52 pagesLeak TesterSoup PongsakornNo ratings yet

- No.183-BT (NEW) Ball TackDocument5 pagesNo.183-BT (NEW) Ball TackSoup PongsakornNo ratings yet

- RADWAG - Data - Sheet - Pue 7 1 32 HRP High Resolution ScaleDocument3 pagesRADWAG - Data - Sheet - Pue 7 1 32 HRP High Resolution ScaleSoup PongsakornNo ratings yet

- Color Fastness Rubbing Tester: FeatureDocument1 pageColor Fastness Rubbing Tester: FeatureSoup PongsakornNo ratings yet

- WTC Data Sheet ENDocument3 pagesWTC Data Sheet ENSoup PongsakornNo ratings yet

- Schopper Type Twist Counter: Feature SpecificationDocument1 pageSchopper Type Twist Counter: Feature SpecificationSoup PongsakornNo ratings yet

- Material Science UkDocument9 pagesMaterial Science UkSoup PongsakornNo ratings yet

- Gardner Type Washability Tester: FeatureDocument1 pageGardner Type Washability Tester: FeatureSoup PongsakornNo ratings yet

- WPTH Data Sheet ENDocument13 pagesWPTH Data Sheet ENSoup PongsakornNo ratings yet

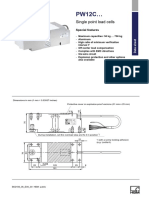

- PW12CDocument4 pagesPW12CSoup PongsakornNo ratings yet

- RADWAG - Data - Sheet - PM 35 c32 Q Precision BalanceDocument3 pagesRADWAG - Data - Sheet - PM 35 c32 Q Precision BalanceSoup PongsakornNo ratings yet

- RADWAG - Data - Sheet - Hy10 32 HRP High Resolution ScaleDocument3 pagesRADWAG - Data - Sheet - Hy10 32 HRP High Resolution ScaleSoup PongsakornNo ratings yet

- PW15BDocument6 pagesPW15BSoup PongsakornNo ratings yet

- Chatillon WT12 Series Crane Scales: FeaturesDocument2 pagesChatillon WT12 Series Crane Scales: FeaturesSoup PongsakornNo ratings yet

- AEV Force Test Stand Function: Nanbei Instrument LimitedDocument6 pagesAEV Force Test Stand Function: Nanbei Instrument LimitedSoup PongsakornNo ratings yet

- Peel Fixture For Yoghurt Pot Foil Seals: Capacity PackagingDocument2 pagesPeel Fixture For Yoghurt Pot Foil Seals: Capacity PackagingSoup PongsakornNo ratings yet

- 920-20601 GB Nk-9636a3Document0 pages920-20601 GB Nk-9636a3neeshakothari31No ratings yet

- Design01 Reablement ObservationDocument27 pagesDesign01 Reablement Observationapi-300643652No ratings yet

- Power HackSawDocument6 pagesPower HackSawMike Nichlos100% (2)

- Installation and Removal of High MastDocument3 pagesInstallation and Removal of High MastMohd Hafiz Muhamed100% (1)

- An A CodDocument14 pagesAn A Codapi-3708589No ratings yet

- 2001 ME Thesis PapersDocument53 pages2001 ME Thesis Papersazd1973No ratings yet

- R934C GB TB LMD 2012 07 - 7421 0Document8 pagesR934C GB TB LMD 2012 07 - 7421 0Ralf MaurerNo ratings yet

- AWS ConceptDocument1 pageAWS ConceptLotok TeaNo ratings yet

- Concurrent Programming in Java - LeaDocument2 pagesConcurrent Programming in Java - LeaSeanNo ratings yet

- Civl4333 STM-02Document6 pagesCivl4333 STM-02SamuelNo ratings yet

- Microelectronic CapsuleDocument20 pagesMicroelectronic CapsuleMouni BoomiReddyMounikaNo ratings yet

- Jinma 284 ManualDocument35 pagesJinma 284 ManualJuan Garcia100% (1)

- EG110 (Spring 2021) Exam #2 Pelayo MartinezDocument6 pagesEG110 (Spring 2021) Exam #2 Pelayo MartinezPelayo MartinezNo ratings yet

- Conn BrocDocument3 pagesConn BrocbenhealyNo ratings yet

- Nitto - MOS Pressure TestDocument6 pagesNitto - MOS Pressure TestNajwa AmirahNo ratings yet

- Feedback Control SystemDocument40 pagesFeedback Control SystemMuhammad SaeedNo ratings yet

- Gas Absorption PDFDocument93 pagesGas Absorption PDFIngeniería Industrias Alimentarias Itsm100% (1)

- TigerPMS CM63Document19 pagesTigerPMS CM63Mohamed BahaaNo ratings yet

- GRE Pipe Design GuideDocument36 pagesGRE Pipe Design GuideSandeep Bhatia100% (1)

- BS Stds For Elev EscDocument2 pagesBS Stds For Elev EscUmer FarooqNo ratings yet

- ReadMe NetDocument2 pagesReadMe NetMariano MartinezNo ratings yet

- Aw60 40leDocument2 pagesAw60 40leSnokeX100% (1)

- Slab Initial Sizing - ExampleDocument2 pagesSlab Initial Sizing - ExampleRafael CuaNo ratings yet

- C++ Cheat SheetDocument9 pagesC++ Cheat SheetAddele CruzNo ratings yet

- Advanced Electronic ComponentsDocument17 pagesAdvanced Electronic Componentsprem_chandranNo ratings yet

- Power Losses of Gear SystemsDocument11 pagesPower Losses of Gear Systemsarda akkayaNo ratings yet

- Envoy 500 Operator Training Manual (L7320, Rev. - ) Low ResDocument86 pagesEnvoy 500 Operator Training Manual (L7320, Rev. - ) Low ResALONSO GARCIA100% (1)

- 2019 - Chapter 31F Marine Oil Terminals 7Document1 page2019 - Chapter 31F Marine Oil Terminals 7sidhappy86No ratings yet

- Mec 100 Chapter 5 (Dimemsion & Unit)Document43 pagesMec 100 Chapter 5 (Dimemsion & Unit)Hisyammudin RoslanNo ratings yet