Professional Documents

Culture Documents

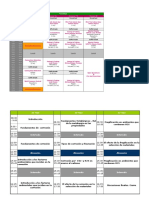

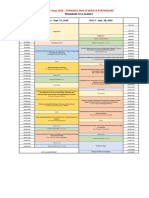

2 - Day Training Schedule For USG 900 V

Uploaded by

hafiz_hayat_441902150 ratings0% found this document useful (0 votes)

16 views1 pageOriginal Title

2 - day training schedule for USG 900 V

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views1 page2 - Day Training Schedule For USG 900 V

Uploaded by

hafiz_hayat_44190215Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

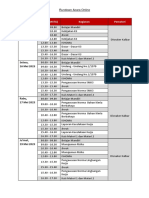

2 day training and machine inspection

USG 900 V, Com No 2.61/08486

Indorama Ventures Indonesia

Date Time Subjects Lecturer

Reiner

8.00 h – 9:15 h Introduction, safety

Kehrer

Main components and function of

9.15 h – 10:00 h the pellet production line USG 900 Class room

V.

Maintenance, cleaning and main

10:00 h – 10:30 h adjustments on USG 900 V based

on the operating manual. Part 1

10:30 h – 10:45 h Coffee break

Maintenance, cleaning and main

10.45 h – 11:15 h adjustments on USG 900 V based Class room

on the operating manual. Part 2

Influences on the pellet quality.

11:15 h - lunch Class room

Trouble shooting Part 1

12:00 h – 13:00 h Lunch

Influences on the pellet quality.

13:00 h – 15:30 h Class room

Trouble shooting Part 2

15:30 h – 15:45 h Coffee break

Main Alarms and failure messages

15:45 h – 16:45 h Class room

Trouble shooting

16:45 h - End Summary, questioning

End of first day

Disassembling, assembling and

8.00 h – 10:30 h main adjustments on a spare Workshop

cutting head M USG 900 V. Part 1

10:30 h – 10:45 h Coffee break

Disassembling, assembling and

10.45 h – lunch main adjustments on a spare Workshop

cutting head M USG 900 V. Part 2

12:00 h – 13:00 h Lunch

Inspection of the pellet production

13:00 h – 15:30 h At site

lines.

15:30 h – 15:45 h Coffee break

Inspection of the pellet production

15:45 h – 16:45 h On site

lines

16:45 - End Summary, questioning

End of the training

Automatik Plastics Machinery GmbH | Ostring 19 | 63762 Grossostheim | Germany

info@maag.com | Phone +49 6026 503 0 | Fax +49 6026 503 110 | www.maag.com

District Court Aschaffenburg HRB 10433 | VAT: DE815001158 | Managing Directors:Harald Zang, Maurizio Zaugg

You might also like

- Komatsu Forklift Training Rundown and MaintenanceDocument1 pageKomatsu Forklift Training Rundown and MaintenanceAmborsius SitorusNo ratings yet

- ICEER 2020-ProgramDocument2 pagesICEER 2020-ProgramNidia CaetanoNo ratings yet

- Welder Training & Certification Program OverviewDocument1 pageWelder Training & Certification Program OverviewSatish KeskarNo ratings yet

- NAPTIN Graduate Skills Programme BrochureDocument40 pagesNAPTIN Graduate Skills Programme BrochureEngr KushenscottNo ratings yet

- CMTI Product Innovation Event ScheduleDocument2 pagesCMTI Product Innovation Event SchedulegururajaNo ratings yet

- Invitation Letter AP 20200519 PDFDocument1 pageInvitation Letter AP 20200519 PDFAsrullahNo ratings yet

- Invitation Letter AP 20200519 PDFDocument1 pageInvitation Letter AP 20200519 PDFAsrullahNo ratings yet

- Live Line Tools - Testing TrainingDocument10 pagesLive Line Tools - Testing TrainingRavneel KaranNo ratings yet

- Final Program - Subsea WorkshopDocument2 pagesFinal Program - Subsea WorkshopLucas FernandoNo ratings yet

- Run Down Palm Oil MillDocument1 pageRun Down Palm Oil MillChandra Dwi PutraNo ratings yet

- First Week Oil & Gas Training ScheduleDocument2 pagesFirst Week Oil & Gas Training ScheduleEdgar AraujoNo ratings yet

- 1Document1 page1sam nacionNo ratings yet

- Final Announcement Konker IOA Bandung 2018Document33 pagesFinal Announcement Konker IOA Bandung 2018MutiaRahmatiaNo ratings yet

- Training Course On The Calibration of Weighbridges: (Draft Programme)Document2 pagesTraining Course On The Calibration of Weighbridges: (Draft Programme)Selyun E OnnajNo ratings yet

- DG Set Installation Guidelines Revised A-CheckDocument154 pagesDG Set Installation Guidelines Revised A-Checkram27_rajiNo ratings yet

- Rundown ToT Dan Workshop SMK Bakti IdhataDocument1 pageRundown ToT Dan Workshop SMK Bakti Idhataagasa hirosiNo ratings yet

- Value Investing Agenda: Registration to ValuationDocument1 pageValue Investing Agenda: Registration to ValuationCamilo Andres NoyNo ratings yet

- Agenda Trining FA Q4 2017 Zone3Document1 pageAgenda Trining FA Q4 2017 Zone3Aan GilangNo ratings yet

- Pin Seminar Agenda (24 - 25 July 2023)Document5 pagesPin Seminar Agenda (24 - 25 July 2023)Muhamad JemadiNo ratings yet

- Service Training Agenda ScheduleDocument1 pageService Training Agenda SchedulePutra Wira MerdekaNo ratings yet

- Horario Intensivo 2010 PigasDocument10 pagesHorario Intensivo 2010 PigasZugehy Escalante IsseleNo ratings yet

- Agenda Kerja Guru SkanekaDocument1 pageAgenda Kerja Guru SkanekaHadi Ma'rufNo ratings yet

- Program Activities OutlineDocument3 pagesProgram Activities OutlineMildred Compendio-BregildoNo ratings yet

- Rundown - Workshop Review STKP & Basic Safety Training ParaxylDocument12 pagesRundown - Workshop Review STKP & Basic Safety Training Paraxylorang suksesNo ratings yet

- Tentative Schedule For IWCF CourseDocument1 pageTentative Schedule For IWCF CourseManish TanejaNo ratings yet

- Rundown Kegiatan Training Implementasi Sistem BarcodeDocument1 pageRundown Kegiatan Training Implementasi Sistem BarcodeSiti SupriyatiNo ratings yet

- Jadwal Acara User Meeting SoloDocument1 pageJadwal Acara User Meeting Solobakti tyan baktiNo ratings yet

- ESCAP Meeting Focuses on Testing Agricultural MachineryDocument3 pagesESCAP Meeting Focuses on Testing Agricultural Machinery'ucha' SikumbangNo ratings yet

- SMK Negeri 1 Kademangan teaching scheduleDocument1 pageSMK Negeri 1 Kademangan teaching scheduleAfriiya DiiniNo ratings yet

- D4 Service Level II Mar 15-19 2013Document6 pagesD4 Service Level II Mar 15-19 2013agooNo ratings yet

- Chapter 3Document24 pagesChapter 3Yuji KojimaNo ratings yet

- 5th Channel Partner Service Seminar AgendaDocument10 pages5th Channel Partner Service Seminar AgendaRa'ad Elias ShomalyNo ratings yet

- Jadwal Pelatihan Petugas PL-KUMKM23Document4 pagesJadwal Pelatihan Petugas PL-KUMKM23Yuniar SinagaNo ratings yet

- Activity Matrix On RPMS ReOrientation - DistrictDocument2 pagesActivity Matrix On RPMS ReOrientation - Districtrey yuyNo ratings yet

- Laporan Akhir Pelatihan Scania R 580 1 2015Document15 pagesLaporan Akhir Pelatihan Scania R 580 1 2015Odading AjgbangetNo ratings yet

- Issct Processing Workshop 2014: Protea Hotel Hluhluwe, South AfricaDocument2 pagesIssct Processing Workshop 2014: Protea Hotel Hluhluwe, South AfricaAnkit Katiyar IshanNo ratings yet

- Rundown Acara Online - Rev5Document3 pagesRundown Acara Online - Rev5Muhamad MachrusNo ratings yet

- Endocryn System Blok 1 Smt.5 Jadwal Pembelajaran: Upacara Hari KemerdekaanDocument2 pagesEndocryn System Blok 1 Smt.5 Jadwal Pembelajaran: Upacara Hari Kemerdekaanvee3_moedzNo ratings yet

- Program: International GE LM6000, LM2500 & LM1600 User ConferenceDocument8 pagesProgram: International GE LM6000, LM2500 & LM1600 User ConferencePeter_Phee_341No ratings yet

- 1614591889IADC Well Sharp For Surface BOP Introductory LevelDocument3 pages1614591889IADC Well Sharp For Surface BOP Introductory LevelMahrouz MadoNo ratings yet

- Agenda - SRT Training - ChannelDocument7 pagesAgenda - SRT Training - ChannelPuneet KathuriaNo ratings yet

- Agenda SPIS Webinars - Draft03 01Document2 pagesAgenda SPIS Webinars - Draft03 01David lucasNo ratings yet

- Week 9Document3 pagesWeek 9Edwin ChristianNo ratings yet

- As3 PDFDocument2 pagesAs3 PDFSailaja PallaviNo ratings yet

- UMS - EFFECTS Training Rundown - Rev00Document2 pagesUMS - EFFECTS Training Rundown - Rev00Ilman IhzaNo ratings yet

- HES Training AgendaDocument1 pageHES Training AgendaShojib khanNo ratings yet

- LCM Webinar Schedule 6-DaysDocument3 pagesLCM Webinar Schedule 6-DaysAngelo AmayNo ratings yet

- Jadwal Pelatihan Online POM PertambanganDocument1 pageJadwal Pelatihan Online POM PertambanganFebrianto PatabangNo ratings yet

- Jadwal Training Robot PDFDocument2 pagesJadwal Training Robot PDFuser freeNo ratings yet

- PAT Workshops Help DCs and Auditors Understand AmendmentsDocument1 pagePAT Workshops Help DCs and Auditors Understand AmendmentsPunit BakulbhaiNo ratings yet

- Design Problem and SolutionDocument37 pagesDesign Problem and SolutionChristian M. MortelNo ratings yet

- TimetableDocument1 pageTimetableBOAZ MEDIANo ratings yet

- Rev Jadwal OLDP Batch 2Document1 pageRev Jadwal OLDP Batch 2retty sNo ratings yet

- Over The Road Engine Service TrainingDocument318 pagesOver The Road Engine Service Trainingibrahem100% (3)

- Jadwal Kuliah Sem IVDocument2 pagesJadwal Kuliah Sem IVNobel KurniadiNo ratings yet

- Updated Agenda NK Dist Meeting 2023Document4 pagesUpdated Agenda NK Dist Meeting 2023Minh Thư from BETESENo ratings yet

- Draft Minute To Minute Program - GTPP Visit by Chairman & Directors On 22-10-2020 To 24-10-2020Document3 pagesDraft Minute To Minute Program - GTPP Visit by Chairman & Directors On 22-10-2020 To 24-10-2020Sumit OmarNo ratings yet

- Redimix FluxDocument15 pagesRedimix FluxVinodh KannaNo ratings yet

- Main components of the pellet production line USG 900 VDocument13 pagesMain components of the pellet production line USG 900 Vhafiz_hayat_44190215No ratings yet

- Pellet Drier AERO 1000Document8 pagesPellet Drier AERO 1000hafiz_hayat_44190215No ratings yet

- Control panel alarms and messages for pelletizing systemDocument27 pagesControl panel alarms and messages for pelletizing systemhafiz_hayat_44190215No ratings yet

- UltrasonicsDocument10 pagesUltrasonicshafiz_hayat_44190215No ratings yet

- MCI Quest2Document10 pagesMCI Quest2hafiz_hayat_44190215No ratings yet

- Laser AlignmentDocument13 pagesLaser Alignmenthafiz_hayat_44190215No ratings yet

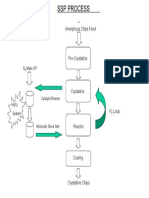

- SSP process overview: Amorphous to crystalline chipsDocument1 pageSSP process overview: Amorphous to crystalline chipshafiz_hayat_44190215No ratings yet

- Automatik Pelletizing SeminarsDocument2 pagesAutomatik Pelletizing Seminarshafiz_hayat_44190215No ratings yet

- SHAFTALIGN 2-Page-Flyer DOC-21.300 09-09 enDocument2 pagesSHAFTALIGN 2-Page-Flyer DOC-21.300 09-09 enhafiz_hayat_44190215No ratings yet

- Vibration Analysis FundamentalsDocument32 pagesVibration Analysis Fundamentalshafiz_hayat_44190215No ratings yet

- SHAFTALIGN Operating-Instructions DOC 21.200 12-09 1.02 G2Document148 pagesSHAFTALIGN Operating-Instructions DOC 21.200 12-09 1.02 G2hafiz_hayat_44190215No ratings yet

- 5 Why Template by HafizDocument2 pages5 Why Template by Hafizhafiz_hayat_44190215No ratings yet

- SHAFTALIGN Pocket-Guide DOC 2021.100 09-09 1.02 GDocument2 pagesSHAFTALIGN Pocket-Guide DOC 2021.100 09-09 1.02 Ghafiz_hayat_44190215No ratings yet

- BalancingDocument15 pagesBalancinghafiz_hayat_44190215No ratings yet

- Flyer WEARSCANNER enDocument2 pagesFlyer WEARSCANNER enhafiz_hayat_44190215No ratings yet

- BottomDocument1 pageBottomhafiz_hayat_44190215No ratings yet

- UpperDocument1 pageUpperhafiz_hayat_44190215No ratings yet

- PT I ND RAMA VENTURESDocument1 pagePT I ND RAMA VENTUREShafiz_hayat_44190215No ratings yet

- Report Vibrasi Plant CP-2Document13 pagesReport Vibrasi Plant CP-2hafiz_hayat_44190215No ratings yet

- RubberDocument1 pageRubberhafiz_hayat_44190215No ratings yet

- Piping Slurry ModelDocument1 pagePiping Slurry Modelhafiz_hayat_44190215No ratings yet

- Brkarc 2011Document261 pagesBrkarc 2011jramongvNo ratings yet

- UCO Bank - Green Pin Generation Using UCO Mobile BDocument1 pageUCO Bank - Green Pin Generation Using UCO Mobile Bsunny kumarNo ratings yet

- Understanding Youth Unemployment and EducationDocument2 pagesUnderstanding Youth Unemployment and EducationIsha GargNo ratings yet

- Low power PLL FM stereo demodulator ICDocument8 pagesLow power PLL FM stereo demodulator ICSunardi WicaksonoNo ratings yet

- Edureka Data Science Masters Program CurriculumDocument41 pagesEdureka Data Science Masters Program CurriculumMeenal Luther NhürNo ratings yet

- Salvo RtosDocument30 pagesSalvo RtosNgô ĐạtNo ratings yet

- Mighty Press Hat PressDocument9 pagesMighty Press Hat PressJudy NeenaNo ratings yet

- Over Current Relay Types and ApplicationsDocument11 pagesOver Current Relay Types and ApplicationskishansaiNo ratings yet

- Ican Export V1.0-GBDocument112 pagesIcan Export V1.0-GBhakim BGNo ratings yet

- Tech and Human DignityDocument7 pagesTech and Human Dignityrosemariegalindo70No ratings yet

- In RomerDocument3 pagesIn RomerAmiteshNo ratings yet

- Manasa Panda Accelerant SoftwareDocument33 pagesManasa Panda Accelerant SoftwarePankaj SinghNo ratings yet

- Kobelco Crawler Crane Ck1200 1f Cke1100 1f Shop Manual S5gk00004ze03Document20 pagesKobelco Crawler Crane Ck1200 1f Cke1100 1f Shop Manual S5gk00004ze03scott100% (29)

- Oilcon Mark 6M: Technical ManualDocument177 pagesOilcon Mark 6M: Technical ManualParminder singh parmar100% (1)

- Blueridge Multi Zone Service Manual PDFDocument108 pagesBlueridge Multi Zone Service Manual PDFMatthew SalceNo ratings yet

- Jeep WK Grand Cherokee Section 08O RestraintsDocument490 pagesJeep WK Grand Cherokee Section 08O RestraintsParaskevas Stav100% (5)

- ATG Commerce - Intercepting PipelineDocument1 pageATG Commerce - Intercepting PipelineAmit Kumar LakraNo ratings yet

- Fault Codes and Scania Engine ParametersDocument8 pagesFault Codes and Scania Engine Parametersmirko coppini100% (1)

- WSMP 2022 - TD - MecadDocument15 pagesWSMP 2022 - TD - Mecadamirul rofiqNo ratings yet

- TARGA DVD hc5100x PDFDocument37 pagesTARGA DVD hc5100x PDFLeandro EzquerraNo ratings yet

- Standard GIS Guidelines for Transmission ProjectsDocument52 pagesStandard GIS Guidelines for Transmission ProjectsNauman Habib KhanNo ratings yet

- Endurance TestDocument2 pagesEndurance TestSatyaNo ratings yet

- 12 Volt Hydraulic Pump Mte 4850 PDFDocument1 page12 Volt Hydraulic Pump Mte 4850 PDFpurnomo100% (1)

- XPON POE ONT V2820D 1G3FPS Datasheet V2.0 ENDocument2 pagesXPON POE ONT V2820D 1G3FPS Datasheet V2.0 ENDamian RattalinoNo ratings yet

- Strategic Management at Infosys (Business Strategy)Document19 pagesStrategic Management at Infosys (Business Strategy)Madhusudan22No ratings yet

- STP (200kld) - Technical Datasheet 17.02.23Document150 pagesSTP (200kld) - Technical Datasheet 17.02.23Rajender Chamoli100% (1)

- Mobile App Marketing and Moneti - Alex GenadinikDocument54 pagesMobile App Marketing and Moneti - Alex GenadinikTài Nguyễn Anh100% (3)

- Doosan g424 Gasoline LP Engine g424 LP Engine G20e 3 G25e 3 g30 Service ManualDocument10 pagesDoosan g424 Gasoline LP Engine g424 LP Engine G20e 3 G25e 3 g30 Service Manualsam98% (43)

- Computerized Portable EMI Drill Pipe Inspection System Dual-FunctionDocument2 pagesComputerized Portable EMI Drill Pipe Inspection System Dual-FunctionYodilson Sanchez100% (1)

- Serv7106 V09N02 TXTDocument44 pagesServ7106 V09N02 TXTmario saavedra tarazonaNo ratings yet