Professional Documents

Culture Documents

Ultrasonics

Uploaded by

hafiz_hayat_441902150 ratings0% found this document useful (0 votes)

10 views10 pagesUltrasonics uses technology to detect sounds that are above the normal human hearing range of 20-20,000 Hz. An ultrasonic gun is needed to measure ultrasonic signals and convert them to audible frequencies displayed in decibels. Ultrasonics is useful for detecting air leaks, steam leaks, bearing problems, electrical faults, and other issues that produce ultrasonic frequencies. It can help find problems that produce noise but may be masked by ambient industrial noise.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentUltrasonics uses technology to detect sounds that are above the normal human hearing range of 20-20,000 Hz. An ultrasonic gun is needed to measure ultrasonic signals and convert them to audible frequencies displayed in decibels. Ultrasonics is useful for detecting air leaks, steam leaks, bearing problems, electrical faults, and other issues that produce ultrasonic frequencies. It can help find problems that produce noise but may be masked by ambient industrial noise.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views10 pagesUltrasonics

Uploaded by

hafiz_hayat_44190215Ultrasonics uses technology to detect sounds that are above the normal human hearing range of 20-20,000 Hz. An ultrasonic gun is needed to measure ultrasonic signals and convert them to audible frequencies displayed in decibels. Ultrasonics is useful for detecting air leaks, steam leaks, bearing problems, electrical faults, and other issues that produce ultrasonic frequencies. It can help find problems that produce noise but may be masked by ambient industrial noise.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 10

Reliability Engineering and Diagnostic Solutions

Ultrasonics

A technology that allows

us the hear what we

cannot audibly hear with

our human limitations

Reliability Engineering and Diagnostic Solutions

Ultrasonics

Cannot be measured with

standard CM tools, an

Ultrasonic Gun is required

to measure the signal and

then heterodyne the signal

to an audible one. The units

are displayed in dB

Reliability Engineering and Diagnostic Solutions

Frequency Ranges

• The human ear can only detect

sound in the sonic range 20

to 20,000 Hz

• Any sounds that are above the

humans hearing capabilities

are referred to as Ultrasonic

Subsonic Sonic Range Ultrasonic Range

Range

Reliability Engineering and Diagnostic Solutions

Ultrasonics

Excellent tool for finding Air leaks

Good tool for finding bearing problems,

lubrication issues can also be addressed

Good tool for finding steam leaks in

steam traps

Good in finding Electrical faults

Very good in finding flow related

problems in pipes and valves

Others

Reliability Engineering and Diagnostic Solutions

Some Ultrasonic Applications

Air Leaks

Steam Leaks

Mechanical Wear Detection

Lubrication Issues

Corona Discharge

Heat Exchangers

Vessels, and Closed Systems

(underground tanks)

Valves

Reliability Engineering and Diagnostic Solutions

Ultrasonics and Air Leaks

Air leaks are typically

found in the 40kHz

range

Huge cost to Industry,

a small leak over 1

year can cost

thousands of dollars

Plant noise can hide

audible noise

Reliability Engineering and Diagnostic Solutions

Faulty Steam Traps

Generate Ultrasonic

turbulence, valve

bounce and float

impacting

Another method that

may help in resolving

the problem is to

measure inlet and

outlet temperatures

Reliability Engineering and Diagnostic Solutions

Ultrasonics and Electrical problems

Commonly found in:

motor control

centers

breaker panels

power lines

connections

Insulation

breakdown

Improper or

broken connections

Reliability Engineering and Diagnostic Solutions

Ultrasonics and Bearings

A high percentage of

bearing fail due to

incorrect, insufficient

lubrication which

generate frequencies in

the 30kHz range,

Ultrasonics can help

detect this problem

Bearing impacts can

clearly be heard, and

dB levels trended

Reliability Engineering and Diagnostic Solutions

You might also like

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Pass Ultrasound Physics Exam Study Guide ReviewFrom EverandPass Ultrasound Physics Exam Study Guide ReviewRating: 4.5 out of 5 stars4.5/5 (2)

- NDT - Ultrasonice Test - Backwell Echo AttenuationDocument9 pagesNDT - Ultrasonice Test - Backwell Echo AttenuationAnand SinhaNo ratings yet

- Ultrasound Detection Predictive Maintenance For The MassesDocument5 pagesUltrasound Detection Predictive Maintenance For The MassesevelulahirNo ratings yet

- WL Ultrasonic TestingDocument8 pagesWL Ultrasonic TestingGanesh JadhavNo ratings yet

- Ultrasonic Testing (UT) Is A Family of NDT TechniquesDocument6 pagesUltrasonic Testing (UT) Is A Family of NDT TechniquesNaveenNo ratings yet

- UT Lesson6 08 12Document85 pagesUT Lesson6 08 12Gulfam HussainNo ratings yet

- Electrical Equipment Reliability With Ultrasound & InfraredDocument6 pagesElectrical Equipment Reliability With Ultrasound & InfraredAM KANo ratings yet

- Application Note Ultrasonic Weld TestingDocument12 pagesApplication Note Ultrasonic Weld Testingj_carloscoliveira5071No ratings yet

- Airborne & Structure-Borne Ultrasound As A Key Component of Predictive MaintenanceDocument27 pagesAirborne & Structure-Borne Ultrasound As A Key Component of Predictive MaintenanceSaliya RathnayakeNo ratings yet

- Cat Probes NDT Engl SonotecDocument58 pagesCat Probes NDT Engl SonotecamitNo ratings yet

- Guided Wave InspectionDocument1 pageGuided Wave InspectionJomer J SimpsonNo ratings yet

- MRI AcousticsDocument14 pagesMRI AcousticsQOBITNo ratings yet

- NFPA 70B and CSA Z463 Standards For Electrical MaintenanceDocument5 pagesNFPA 70B and CSA Z463 Standards For Electrical MaintenanceAM KANo ratings yet

- Baumer Catalogue-Ultrasonic CT EN 1305 11106734Document132 pagesBaumer Catalogue-Ultrasonic CT EN 1305 11106734Jarielson SantanaNo ratings yet

- Beginner - S Guide To Ultrasonic LTDocument3 pagesBeginner - S Guide To Ultrasonic LTRahul ChandrawarNo ratings yet

- Ultrasonic TestingDocument29 pagesUltrasonic TestingMeryL Ang100% (1)

- Twi Ut1Document45 pagesTwi Ut1Ahmed El GehaniNo ratings yet

- Non-Destructive Testing: Fabrication, Welding and Inspection Basics For Maintenance EngineerDocument6 pagesNon-Destructive Testing: Fabrication, Welding and Inspection Basics For Maintenance EngineerSusovan SensharmaNo ratings yet

- Acoustic Transducers and Measurement SystemsDocument66 pagesAcoustic Transducers and Measurement SystemsZippo NguyễnNo ratings yet

- Ultrasonic SensorDocument7 pagesUltrasonic SensorCLAS COACHINGNo ratings yet

- Ultrasonic SignalingDocument9 pagesUltrasonic Signalingsriananthakumar06No ratings yet

- Ultrasonic Testing PDFDocument163 pagesUltrasonic Testing PDFAlex Muresan100% (5)

- Ultrasonic Monitoring (A New Method For Condition Monitoring)Document4 pagesUltrasonic Monitoring (A New Method For Condition Monitoring)Ankur KumarNo ratings yet

- Fault Detection by Means of UL Passive Threat On BearingsDocument4 pagesFault Detection by Means of UL Passive Threat On BearingsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Decreasing Substation Failures With Ultrasound TechnologyDocument6 pagesDecreasing Substation Failures With Ultrasound TechnologyAnonymous Wu6FDjbNo ratings yet

- #NDT4 Ultrasonic TestingDocument108 pages#NDT4 Ultrasonic Testingnasrul haziqNo ratings yet

- Flyer bs30 Sonaphone SonotecDocument2 pagesFlyer bs30 Sonaphone SonotechufuentsNo ratings yet

- Ultrasonic TestingDocument44 pagesUltrasonic TestingQaisir MehmoodNo ratings yet

- Ultrasonic Wave Propagation 1Document16 pagesUltrasonic Wave Propagation 1Manikandan NatarajanNo ratings yet

- Nondestructive TestingDocument35 pagesNondestructive TestingabyNo ratings yet

- Intro To UltrasonicsDocument21 pagesIntro To UltrasonicsVaraGoudNo ratings yet

- Generation of Audible Sound With Ultrasonic Signals: A Technical Seminar Report OnDocument21 pagesGeneration of Audible Sound With Ultrasonic Signals: A Technical Seminar Report OnBhavana Reddy MettuNo ratings yet

- Introduction of NDT UltrasonicDocument8 pagesIntroduction of NDT Ultrasonicfarez77No ratings yet

- N&VGUIDELINES04 (Chap1)Document15 pagesN&VGUIDELINES04 (Chap1)Gao TeacherNo ratings yet

- A Guide To Understanding Partial Discharge Sensor ApplicationsDocument18 pagesA Guide To Understanding Partial Discharge Sensor Applicationssalemg82No ratings yet

- Ultrasonic Predictive MaintenanceDocument3 pagesUltrasonic Predictive MaintenanceJoe ExairNo ratings yet

- Sound Noise ControlDocument22 pagesSound Noise ControlMohamed TahounNo ratings yet

- Chapter 6 Safety Noise - wk11Document42 pagesChapter 6 Safety Noise - wk11Hairie AbangNo ratings yet

- Distance Measurement Using Ultrasonic SensorDocument68 pagesDistance Measurement Using Ultrasonic Sensorsaran52_ece0% (1)

- Laboratory4 ELECTIVE2Document7 pagesLaboratory4 ELECTIVE2Ed LozadaNo ratings yet

- EsII - Lec-Sound (II)Document31 pagesEsII - Lec-Sound (II)Hadiqa ChaudhryNo ratings yet

- Ultrasonic SensorDocument17 pagesUltrasonic Sensorjitenderthakur490No ratings yet

- Ultrasonics DemoDocument315 pagesUltrasonics Demozubairsarwar912100% (1)

- Ultrasonic Airborne Leak DetectorDocument1 pageUltrasonic Airborne Leak DetectorTonphong KaewkongkaNo ratings yet

- Noise Level StandardDocument14 pagesNoise Level StandardSyazwani NasirNo ratings yet

- Ultrasonic InspectionDocument20 pagesUltrasonic Inspectionabraham silva hernandezNo ratings yet

- HVAC NoiseDocument41 pagesHVAC Noisesp su100% (3)

- Safety Bulletin (Occupational Noise)Document2 pagesSafety Bulletin (Occupational Noise)ManZooR Ul HassaNNo ratings yet

- Ultrasound Condition Monitoring Ue v7 PDFDocument7 pagesUltrasound Condition Monitoring Ue v7 PDFsergio alejandro baldivieso orozcoNo ratings yet

- Non Destructive TestingDocument9 pagesNon Destructive TestingAhmed KhanNo ratings yet

- Ultrasonic Testing Slides 1Document47 pagesUltrasonic Testing Slides 1ngtchungNo ratings yet

- Ultrasonic Security SystemsDocument3 pagesUltrasonic Security SystemsLawrence GraingerNo ratings yet

- 48W-28871-0 EMI Diagnostics With MDODocument11 pages48W-28871-0 EMI Diagnostics With MDOAkshay SinghNo ratings yet

- ABCs of UltrasonicsDocument49 pagesABCs of Ultrasonicsshruthig29111988No ratings yet

- Catalog About ProbeDocument42 pagesCatalog About ProbeMonica CarrollNo ratings yet

- Physical Principles of UtzDocument44 pagesPhysical Principles of UtzRalph RichardNo ratings yet

- Defining Sound FieldsDocument10 pagesDefining Sound FieldshahahahahaNo ratings yet

- Operational Amplifier Noise: Techniques and Tips for Analyzing and Reducing NoiseFrom EverandOperational Amplifier Noise: Techniques and Tips for Analyzing and Reducing NoiseRating: 5 out of 5 stars5/5 (1)

- The Physics and Technology of Diagnostic Ultrasound: A Practitioner's Guide (Second Edition)From EverandThe Physics and Technology of Diagnostic Ultrasound: A Practitioner's Guide (Second Edition)No ratings yet

- Pellet Drier AERO 1000Document8 pagesPellet Drier AERO 1000hafiz_hayat_44190215No ratings yet

- 2 - Day Training Schedule For USG 900 VDocument1 page2 - Day Training Schedule For USG 900 Vhafiz_hayat_44190215No ratings yet

- Main Components USG 900 VDocument13 pagesMain Components USG 900 Vhafiz_hayat_44190215No ratings yet

- MCI Quest2Document10 pagesMCI Quest2hafiz_hayat_44190215No ratings yet

- Alarm and Messages USG 900 VDocument27 pagesAlarm and Messages USG 900 Vhafiz_hayat_44190215No ratings yet

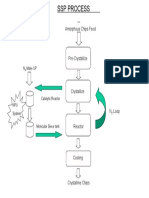

- SSP ProcessDocument1 pageSSP Processhafiz_hayat_44190215No ratings yet

- SHAFTALIGN Pocket-Guide DOC 2021.100 09-09 1.02 GDocument2 pagesSHAFTALIGN Pocket-Guide DOC 2021.100 09-09 1.02 Ghafiz_hayat_44190215No ratings yet

- BalancingDocument15 pagesBalancinghafiz_hayat_44190215No ratings yet

- Vib IntroDocument32 pagesVib Introhafiz_hayat_44190215No ratings yet

- SHAFTALIGN 2-Page-Flyer DOC-21.300 09-09 enDocument2 pagesSHAFTALIGN 2-Page-Flyer DOC-21.300 09-09 enhafiz_hayat_44190215No ratings yet

- Flyer WEARSCANNER enDocument2 pagesFlyer WEARSCANNER enhafiz_hayat_44190215No ratings yet

- Piping Slurry ModelDocument1 pagePiping Slurry Modelhafiz_hayat_44190215No ratings yet

- Shaft For CBP Cp-1-ModelDocument1 pageShaft For CBP Cp-1-Modelhafiz_hayat_44190215No ratings yet

- Report Vibrasi Plant CP-2Document13 pagesReport Vibrasi Plant CP-2hafiz_hayat_44190215No ratings yet

- Elektor 308Document57 pagesElektor 308Pablo DanielNo ratings yet

- Consolidate Data From Multiple Worksheets Into A Summary Worksheet in ExcelDocument10 pagesConsolidate Data From Multiple Worksheets Into A Summary Worksheet in ExcelThomas WongNo ratings yet

- Contractor Performance Evaluation Report FormDocument10 pagesContractor Performance Evaluation Report FormxonstanceNo ratings yet

- Subject Outline: 41889 Application Development in The iOS EnvironmentDocument10 pagesSubject Outline: 41889 Application Development in The iOS EnvironmentmjNo ratings yet

- Functions and Their CurvesDocument25 pagesFunctions and Their CurvesamafcomputersNo ratings yet

- Modeling Kinematic Devices in Simcenter Motion For... - Siemens PLM Community - 379752Document13 pagesModeling Kinematic Devices in Simcenter Motion For... - Siemens PLM Community - 379752anupNo ratings yet

- Renolit Alkorplan 00414 15mm + Lacquer enDocument2 pagesRenolit Alkorplan 00414 15mm + Lacquer enIngénieur CivilNo ratings yet

- Psych 2220 Exam 2 Review GuideDocument12 pagesPsych 2220 Exam 2 Review GuideSalil MahajanNo ratings yet

- 16 Drive ShaftDocument18 pages16 Drive ShaftTecnoCar Services SDRNo ratings yet

- 714U0101 Rev 12 - Blastmate III Operator ManualDocument90 pages714U0101 Rev 12 - Blastmate III Operator ManualAbel Palomino gilNo ratings yet

- Marcom WG 165: Design and Maintenance of Container Terminal Pavements (2015)Document5 pagesMarcom WG 165: Design and Maintenance of Container Terminal Pavements (2015)MNo ratings yet

- Java Programming Set 1Document5 pagesJava Programming Set 1MagarsaaNo ratings yet

- TDS Nycogrease GN43 4E3Document1 pageTDS Nycogrease GN43 4E3Salvador AdamoNo ratings yet

- Scholarships SINGA 2023-06-21-PSDocument116 pagesScholarships SINGA 2023-06-21-PSS RNo ratings yet

- Virtualized Data Center and Cloud Infrastructure Planning and DesignDocument3 pagesVirtualized Data Center and Cloud Infrastructure Planning and Designmayank10yadav_741026No ratings yet

- Engine MechanicalDocument42 pagesEngine MechanicalDavit OmegaNo ratings yet

- EN Komplett Set Active Sound Mit Sound Booster Audi A6 A7 4GDocument18 pagesEN Komplett Set Active Sound Mit Sound Booster Audi A6 A7 4GIstván PatakiNo ratings yet

- A StarDocument8 pagesA StarAlineNo ratings yet

- Marshmallow Readthedocs Io en 2.x LineDocument125 pagesMarshmallow Readthedocs Io en 2.x LineGilbert LoyogoyNo ratings yet

- How To Submit Shipping Instruction: New Interface - Easily & SeamlesslyDocument7 pagesHow To Submit Shipping Instruction: New Interface - Easily & SeamlesslyvNo ratings yet

- Overloud Gems: User ManualDocument49 pagesOverloud Gems: User ManualRossi ZengNo ratings yet

- CATALog Đ NG H Đo Lưu Lư NG SteamDocument60 pagesCATALog Đ NG H Đo Lưu Lư NG SteamHoàng Thiện PhạmNo ratings yet

- Functional Description: Spicer Off-HighwayDocument13 pagesFunctional Description: Spicer Off-HighwayАнатолій Гуменюк100% (4)

- CT042-3-1-IDB-Week 10Document42 pagesCT042-3-1-IDB-Week 10小垃圾No ratings yet

- Snas Idp 2023-2028Document80 pagesSnas Idp 2023-2028cmcarreonNo ratings yet

- Line Protection SIPROTEC 7SA8, 7SD8, 7SL8, 7VK87, 7SJ86: SIPROTEC 5 For Every Application and RequirementDocument8 pagesLine Protection SIPROTEC 7SA8, 7SD8, 7SL8, 7VK87, 7SJ86: SIPROTEC 5 For Every Application and RequirementArun KumarNo ratings yet

- Flexible Air-Jet Tooling For Vibratory Bowl FeederDocument198 pagesFlexible Air-Jet Tooling For Vibratory Bowl Feederayari med aliNo ratings yet

- Jeppview For Windows: List of Pages in This Trip KitDocument87 pagesJeppview For Windows: List of Pages in This Trip KitAugustin PNo ratings yet

- Sae J1708 2004 (En)Document16 pagesSae J1708 2004 (En)Oh No PotatoNo ratings yet

- Låtlo R/0F: - SubjectiveDocument11 pagesLåtlo R/0F: - SubjectiveAnil BasnetNo ratings yet