Professional Documents

Culture Documents

Flyer WEARSCANNER en

Uploaded by

hafiz_hayat_44190215Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flyer WEARSCANNER en

Uploaded by

hafiz_hayat_44190215Copyright:

Available Formats

WEARSCANNER®

Online particle size distribution counter

monitors wear debris in oil

• Recognizes bearing & gear teeth damage

• Avoids consequential damage

• Enhances the availability of the plant

Early recognition of bearing and gearbox damage with WEARSCANNER®

Several hundred liters of oil circulate sor that detects electrically conductive the detected particles observed during

within a gearbox. In large machines particles, counting them in real-time trend monitoring enable the early de-

and oil tanks it may even be several and classifying them by size according tection of progressive damage to gear

thousand. The function of the oil is to ISO 16232. The non-intrusive sen- teeth or roller bearings.

to lubricate, clean and cool. Contami- sor can be mounted upstream from WEARSCANNER® uses a new patented

nants in the oil are indicators of incipi- the bypass oil filter in large machines, method for detecting particles that is

ent damage. However, they can also for example. based on the eddy current principle

lead to premature failure by disrupting It automatically transfers the measured and works independently of oil tem-

the thin lubricating film in roller bear- data to the plant control system via perature, flow rate, viscosity, air and

ings, pumps, valves, crank shafts and ModBus and/or straight to the opera- water content and oil color (darken-

gear meshes. tor or service center via online CMS. ing). In this way, it is also able to detect

WEARSCANNER® is an intelligent sen- Changes in the quantity and size of very slow-moving particles.

Particle size classes according to ISO 16232

Size classes covered by WEARSCANNER®

Class

B C D E F G H I J K

Size 5 – 15µm 15 – 25µm 25 – 50µm 50 – 100µm 100 – 150µm 150 – 200µm 200 – 400µm 400 – 600µm 600 – 1000µm >1000µm

Fine (Class E - G) Standard (Class H - K)

© Copyright 2009 PRÜFTECHNIK AG – U.S. Pats. 7,441,356; 7,423,424 Other patents pending. – Printed in Germany VIB 9.110-22

How WEARSCANNER® works

WEARSCANNER® Class 3

Class 2

Size and distribution of particles

Class 1

Each peak represents a particle that flows The size categories – three in this case – are

through the sensor tube. configured for each particular situation.

The amplitude indicates the size of the The time resolution and scan rate can be

particle. selected.

The peaks are counted in set time inter- The sensitivity of the WEARSCANNER® can

General rule: The larger the particles, vals – and the number of peaks per time be adapted by adjusting the gain, power

the greater the damage. interval is transmitted via ModBus TCP. and filter to the machine application.

Technical details

Fitting dimensions Temperature range Maintenance

1/2“- other sizes available upon request -20°C – 80°C no moving parts, maintenance-free

Measuring method Signal processing Self-monitoring

eddy current, differential coil principle particle distribution counter with integral aver- integrated

Particles age determination and classification Leightning protection

ferritic or non-ferritic Display integrated

Particle size class LED 1: green = system ready, red = fault – LED 2: Casing material

up to 8 size classes can be set yellow = particles passing through, red = stainless steel 1.4308 (seawater-proof)

Flow velocity overload Dimensions

0.01 m/s – 5 m/s Interfaces 120 x 80 x 80 mm

Oil type TCP/IP, Ethernet Weight

mineral or synthetic Protocols 3.5 kg

Oil pressure Modbus TCP

max. 16 bar Power supply

24 V – 48 V

Visit us at www.pruftechnik.com

PRÜFTECHNIK

Condition Monitoring GmbH

Oskar-Messter-Str. 19-21

85737 Ismaning, Germany

Tel: +49 89 99 616-340

Fax: +49 89 99 616-300

eMail: diagnostic@pruftechnik.com

Productive maintenance technology

You might also like

- Michael Ungar - Working With Children and Youth With Complex Needs - 20 Skills To Build Resilience-Routledge (2014)Document222 pagesMichael Ungar - Working With Children and Youth With Complex Needs - 20 Skills To Build Resilience-Routledge (2014)Sølve StoknesNo ratings yet

- Some Solutions To Enderton LogicDocument16 pagesSome Solutions To Enderton LogicJason100% (1)

- Cable Schedule - Instrument - Surfin - Malanpur-R0Document3 pagesCable Schedule - Instrument - Surfin - Malanpur-R0arunpandey1686No ratings yet

- CYPE 2021 + CYPE ArchitectureDocument15 pagesCYPE 2021 + CYPE ArchitectureHajar CypeMarocNo ratings yet

- Ultrasonic VegaDocument24 pagesUltrasonic VegaMAX PAYNENo ratings yet

- Ojt Evaluation Forms (Supervised Industry Training) SampleDocument5 pagesOjt Evaluation Forms (Supervised Industry Training) SampleJayJay Jimenez100% (3)

- 1910 - Handy Adhesion PDFDocument3 pages1910 - Handy Adhesion PDFMohamed NouzerNo ratings yet

- Andersen Cascade Impactor Thermo SciencetificDocument4 pagesAndersen Cascade Impactor Thermo SciencetificNguyễn Thị Mỹ Duyên100% (1)

- Unknown. Viscocamp Lauda 18s. Lauda GroupBrochure - ME - E - 12!10!02 - WebDocument68 pagesUnknown. Viscocamp Lauda 18s. Lauda GroupBrochure - ME - E - 12!10!02 - WebnashihaNo ratings yet

- Multiphase Level & Interface Measurement: Optimal Monitoring of Separation ProcessesDocument5 pagesMultiphase Level & Interface Measurement: Optimal Monitoring of Separation ProcessesSantiNo ratings yet

- Applications/Processing Guide: How To Use This Section The Resistive ElementDocument8 pagesApplications/Processing Guide: How To Use This Section The Resistive ElementNiyamathullahNo ratings yet

- Applications/Processing Guide: How To Use This Section The Resistive ElementDocument8 pagesApplications/Processing Guide: How To Use This Section The Resistive ElementCarlosAgustoPinedaSanchezNo ratings yet

- Viscosity Conversion ChartDocument2 pagesViscosity Conversion ChartRoberto Andrés Padilla Taylor100% (1)

- Capillary Viscometers Flyer E Web PDFDocument8 pagesCapillary Viscometers Flyer E Web PDFKristel ThomasNo ratings yet

- SVP - Product Brochure Well Test Package-3 Phase Separator LWWTDocument1 pageSVP - Product Brochure Well Test Package-3 Phase Separator LWWTMohd Reza MohsinNo ratings yet

- Sensores NDC SensDocument2 pagesSensores NDC Senstcontrols.projectNo ratings yet

- Service Case Study 1Document9 pagesService Case Study 1Gaurav ChauhanNo ratings yet

- Data Sheet: Elcometer 110 PATTI Adhesion TesterDocument2 pagesData Sheet: Elcometer 110 PATTI Adhesion TestertilanfernandoNo ratings yet

- Viscomaster EngDocument8 pagesViscomaster EngKumar VivekNo ratings yet

- HPGR Vega LsDocument24 pagesHPGR Vega LsLuis Kevin Talavera RojasNo ratings yet

- BS&W Thermo Measurement-DatasheetDocument4 pagesBS&W Thermo Measurement-DatasheetBEN ADEGBULUNo ratings yet

- 1D-miniLDV Brochure 201611 PDFDocument1 page1D-miniLDV Brochure 201611 PDFmanikandan RNo ratings yet

- Product Information: Vegaswing 51 Vegaswing 61 Vegaswing 63Document28 pagesProduct Information: Vegaswing 51 Vegaswing 61 Vegaswing 63muhammad tariqNo ratings yet

- BT Applications Oilgas RefineriesDocument20 pagesBT Applications Oilgas RefineriesFer NandoNo ratings yet

- PRO026 Float and Tape Brochure WebDocument6 pagesPRO026 Float and Tape Brochure WebRobert ArnoldNo ratings yet

- Smart - Ar-G2 (Ta Instruments) : Device Specifications Temperature Control GeometriesDocument1 pageSmart - Ar-G2 (Ta Instruments) : Device Specifications Temperature Control GeometriesArvind Kumar ChaurasiaNo ratings yet

- Act 87-88 Esp - Data PDFDocument12 pagesAct 87-88 Esp - Data PDFnaraNJORNo ratings yet

- ASTM D 2171 - 01 (Standard Test Method For Viscosity of Asphalts by Vacuum Capillary Viscometer)Document8 pagesASTM D 2171 - 01 (Standard Test Method For Viscosity of Asphalts by Vacuum Capillary Viscometer)Sudip MukhopadhyayNo ratings yet

- EN Level and Interface Measurement in Liquids VEGAFLEX 81 83 86Document24 pagesEN Level and Interface Measurement in Liquids VEGAFLEX 81 83 86Farhan YassarNo ratings yet

- Liquid Layers - Measuring Overall Level and Interface PointsDocument3 pagesLiquid Layers - Measuring Overall Level and Interface PointsBramJanssen76No ratings yet

- Spectro A Portable Kinematic Oil Analysis Solution For Field-Based UsersDocument6 pagesSpectro A Portable Kinematic Oil Analysis Solution For Field-Based UsersJose FarroNo ratings yet

- Which Water Permeance Test Should You Use ASTM E96 or F1249 GuideDocument8 pagesWhich Water Permeance Test Should You Use ASTM E96 or F1249 GuidepdinhNo ratings yet

- WP - Level Measurement 101 - GWR - FinalDocument2 pagesWP - Level Measurement 101 - GWR - FinalMohammed YusufNo ratings yet

- ABB Online Monitoring Transformer CoreSense HMDocument2 pagesABB Online Monitoring Transformer CoreSense HMAliyyus Sya'niNo ratings yet

- Guide 2 3Document32 pagesGuide 2 3ArgaNo ratings yet

- CemScanner EN PDFDocument5 pagesCemScanner EN PDFmhNo ratings yet

- Probador Bidireccional Smith MeterTM ProversDocument2 pagesProbador Bidireccional Smith MeterTM Proversboa144No ratings yet

- EPP 2042-03-19 Analogue CatDocument96 pagesEPP 2042-03-19 Analogue CatCalebNo ratings yet

- Vpac™Ii Is: Intrinsically Safe Through-Valve Loss Control InstrumentDocument2 pagesVpac™Ii Is: Intrinsically Safe Through-Valve Loss Control InstrumentXandré OSNo ratings yet

- Viscosystem Avs eDocument9 pagesViscosystem Avs eMohammed OuikhalfanNo ratings yet

- Industry Turbine Oil Siemens Steam Turbine Power Station ASIN5099UKDocument1 pageIndustry Turbine Oil Siemens Steam Turbine Power Station ASIN5099UKtaragian17No ratings yet

- Product Information: CapacitiveDocument16 pagesProduct Information: CapacitiveGlobal CHNo ratings yet

- Dual Packer Module PsDocument2 pagesDual Packer Module PsCARLOSELSOARESNo ratings yet

- Do More Automatically. Sustainably Save.: Wacker Neuson - All It Takes!Document2 pagesDo More Automatically. Sustainably Save.: Wacker Neuson - All It Takes!Molie1979No ratings yet

- Guide 2 3e 13939Document37 pagesGuide 2 3e 13939Hany El samadyNo ratings yet

- Civil Engineering Instrumentation For Infrastructure, Road & Highways, Building Material TestingDocument2 pagesCivil Engineering Instrumentation For Infrastructure, Road & Highways, Building Material TestingAimilNo ratings yet

- Spacer Dampers: For Effective Protection of Conductor BundlesDocument16 pagesSpacer Dampers: For Effective Protection of Conductor BundlesAndre Luis Fontes FerreiraNo ratings yet

- Expertip Tips Measuring Monitoring Wear Rate Forming FabricDocument5 pagesExpertip Tips Measuring Monitoring Wear Rate Forming FabricnotengofffNo ratings yet

- MV103 Brochure 0709Document2 pagesMV103 Brochure 0709kongbengNo ratings yet

- Para Consulta: Glass Capillary Kinematic ViscometersDocument25 pagesPara Consulta: Glass Capillary Kinematic ViscometersJUAN CARLOSNo ratings yet

- Radar: Liquid Level Sensor TechnologiesDocument7 pagesRadar: Liquid Level Sensor TechnologiesChen JeffryNo ratings yet

- CO Monitor 2Document2 pagesCO Monitor 2Naveed Ahmed Get-InfoNo ratings yet

- GK800 03 Volumetric Instruments eDocument42 pagesGK800 03 Volumetric Instruments eMaría AntoniaNo ratings yet

- CemScanner WEBDocument5 pagesCemScanner WEBYhaneNo ratings yet

- Mayer & CieDocument2 pagesMayer & CieYasir6732No ratings yet

- Cat Hvac en PDFDocument49 pagesCat Hvac en PDFThang TongNo ratings yet

- Euronorm 186-87Document4 pagesEuronorm 186-87Pedro OliveiraNo ratings yet

- TD OPTIWAVE6400 en 210426 4005812903 R03Document44 pagesTD OPTIWAVE6400 en 210426 4005812903 R03Ali GameelNo ratings yet

- TORNADO 431-038-08 - Digital - Torque - Testers - Brochure456Document12 pagesTORNADO 431-038-08 - Digital - Torque - Testers - Brochure456Ari FerdiantoNo ratings yet

- TA - VCS - SMEC Marine - 01Document4 pagesTA - VCS - SMEC Marine - 01RM HaroonNo ratings yet

- SecuritonDocument4 pagesSecuritonSuperhypoNo ratings yet

- Atago MasterDocument6 pagesAtago MasterIvan DiazNo ratings yet

- VISCOSITY Written ReportDocument6 pagesVISCOSITY Written ReporterizaNo ratings yet

- 2 - Day Training Schedule For USG 900 VDocument1 page2 - Day Training Schedule For USG 900 Vhafiz_hayat_44190215No ratings yet

- Main Components USG 900 VDocument13 pagesMain Components USG 900 Vhafiz_hayat_44190215No ratings yet

- Pellet Drier AERO 1000Document8 pagesPellet Drier AERO 1000hafiz_hayat_44190215No ratings yet

- MCI Quest2Document10 pagesMCI Quest2hafiz_hayat_44190215No ratings yet

- Alarm and Messages USG 900 VDocument27 pagesAlarm and Messages USG 900 Vhafiz_hayat_44190215No ratings yet

- UltrasonicsDocument10 pagesUltrasonicshafiz_hayat_44190215No ratings yet

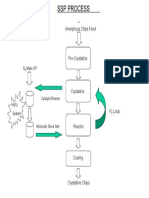

- SSP ProcessDocument1 pageSSP Processhafiz_hayat_44190215No ratings yet

- SHAFTALIGN 2-Page-Flyer DOC-21.300 09-09 enDocument2 pagesSHAFTALIGN 2-Page-Flyer DOC-21.300 09-09 enhafiz_hayat_44190215No ratings yet

- BalancingDocument15 pagesBalancinghafiz_hayat_44190215No ratings yet

- Vib IntroDocument32 pagesVib Introhafiz_hayat_44190215No ratings yet

- SHAFTALIGN Pocket-Guide DOC 2021.100 09-09 1.02 GDocument2 pagesSHAFTALIGN Pocket-Guide DOC 2021.100 09-09 1.02 Ghafiz_hayat_44190215No ratings yet

- Report Vibrasi Plant CP-2Document13 pagesReport Vibrasi Plant CP-2hafiz_hayat_44190215No ratings yet

- Piping Slurry ModelDocument1 pagePiping Slurry Modelhafiz_hayat_44190215No ratings yet

- Shaft For CBP Cp-1-ModelDocument1 pageShaft For CBP Cp-1-Modelhafiz_hayat_44190215No ratings yet

- (Database Management Systems) : Biag, Marvin, B. BSIT - 202 September 6 2019Document7 pages(Database Management Systems) : Biag, Marvin, B. BSIT - 202 September 6 2019Marcos JeremyNo ratings yet

- BIO122 - CHAPTER 7 Part 1Document53 pagesBIO122 - CHAPTER 7 Part 1lili100% (1)

- Vacon NX, Non-Regenerative Front End FI9 UD01217B PDFDocument48 pagesVacon NX, Non-Regenerative Front End FI9 UD01217B PDFSilvian IonescuNo ratings yet

- Organic Logo-Faq enDocument6 pagesOrganic Logo-Faq enjcnavarro_No ratings yet

- AURTTA104 - Assessment 2 Practical Demonstration Tasks - V3Document16 pagesAURTTA104 - Assessment 2 Practical Demonstration Tasks - V3muhammaduzairNo ratings yet

- CM011l E01 Exp.3 DeJuanDocument3 pagesCM011l E01 Exp.3 DeJuanJarell De JuanNo ratings yet

- Project BAGETS Wok Plan and Budget SIPDocument4 pagesProject BAGETS Wok Plan and Budget SIPMaia AlvarezNo ratings yet

- Contract 1 ProjectDocument21 pagesContract 1 ProjectAditi BanerjeeNo ratings yet

- Historical Roots of The "Whitening" of BrazilDocument23 pagesHistorical Roots of The "Whitening" of BrazilFernandoMascarenhasNo ratings yet

- IJISRT23JUL645Document11 pagesIJISRT23JUL645International Journal of Innovative Science and Research TechnologyNo ratings yet

- BS EN 50483-6-2009 EnglishDocument27 pagesBS EN 50483-6-2009 EnglishДмитро Денис100% (2)

- End Points SubrogadosDocument3 pagesEnd Points SubrogadosAgustina AndradeNo ratings yet

- Pricelist 1Document8 pagesPricelist 1ChinangNo ratings yet

- Bhagwan Mahavir College of Architecture: Topic: Lacing, Batteneing, BracingDocument14 pagesBhagwan Mahavir College of Architecture: Topic: Lacing, Batteneing, BracingJai MenDparaNo ratings yet

- What Is Public RelationsDocument52 pagesWhat Is Public RelationsMarwa MoussaNo ratings yet

- Defenders of The Empire v1.4Document13 pagesDefenders of The Empire v1.4Iker Antolín MedinaNo ratings yet

- Chapter 3 PayrollDocument5 pagesChapter 3 PayrollPheng Tiosen100% (2)

- Re BuyerDocument20 pagesRe BuyerElias OjuokNo ratings yet

- General Mathematics SS3 2ND Term SchemeDocument2 pagesGeneral Mathematics SS3 2ND Term Schemesam kaluNo ratings yet

- English 2 Q3 Week 7 DLLDocument7 pagesEnglish 2 Q3 Week 7 DLLEste R A BulaonNo ratings yet

- 1013CCJ - T3 2019 - Assessment 2 - CompleteDocument5 pages1013CCJ - T3 2019 - Assessment 2 - CompleteGeorgie FriedrichsNo ratings yet

- CompTIA A+ Lesson 3 Understanding, PATA, SATA, SCSIDocument8 pagesCompTIA A+ Lesson 3 Understanding, PATA, SATA, SCSIAli Ghalehban - علی قلعه بانNo ratings yet

- System of Linear Equation and ApplicationDocument32 pagesSystem of Linear Equation and Applicationihsaanbava0% (1)

- The Making of A Scientist Class 10Document2 pagesThe Making of A Scientist Class 10abhigna.ravikumarNo ratings yet

- English ID Student S Book 1 - 015Document1 pageEnglish ID Student S Book 1 - 015Williams RoldanNo ratings yet