Professional Documents

Culture Documents

JobLogReport Sand AA

Uploaded by

Temitope BelloCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JobLogReport Sand AA

Uploaded by

Temitope BelloCopyright:

Available Formats

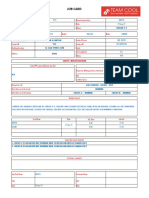

Field Ticket Number Field Ticket Date

JOB LOG

0000002 01-01-2000

Customer Well Name/ Well # Service Center

Papa field Services Kolo 01 West Africa Ltd

County/Parish Province/State NWA/Country

N/A Delta Nigeria

Lease/Unit Field/Block Land/Offshore

N/A Papa Land

Well Location API/UWI# Job Purpose Description

Lat: 3°26'49.636"N Long 5°34'31.964"E N/A PSL TCP SHOOT AND TEST-BOM

Well Type Fluid Type

Oil/Gas Brine

HES Employees Name Employees # Hours of Exposure

Wisdom Yorkor 566086 129.75

Emezie Elijah 548433 824.5

Victor Nweke 558447 824.5

Yahaya Hamed 658217 824.5

Proposed Start Date Proposed Start Time Crew Notification Crew Notification Crew Arrive At Shop Crew Arrive At Shop

01/01/2000 15:30 Date Time Date Time

24/08/2019 12:00 26/12/1999 07:30

Crew Leave At Shop Crew Leave At Shop Crew Arrive At Crew Arrive At Crew Required At Crew Required At

Date Time Location Date Location Time Loc. Date Loc. Time

26/12/1999 07:30 27/12/1999 15:30 27/12/1999 15:30

Crew Begin Wait Date Crew Begin Wait Crew End Wait Date Crew End Wait Time First Rig-Up Date First Rig-Up Time

N/A Time N/A N/A 15/09/2019 14:30

N/A

Last Rig-Down Last Rig-Down Time Crew Leave Location Crew Leave Location Shop To Shop Time Total Operating Time

27/12/1999 07:15 Date Time N/A 130.17

N/A N/A

Job Details

Event Description Event Date Event Time Remarks

Equipment Leave Shop 23/12/1999 11:15

Crew Leave Shop 26/12/1999 07:30

Arrive At Loc 27/12/1999 15:30 TCP personnel arrived for Kolo 1 perforate-and-test

operations. Rig on standby owing to contractual issues

between client and rig management.

Start Job 27/12/1999 16:50 PSL TCP SHOOT AND TEST-BOM

Other 27/12/1999 18:30 Spotted TCP gun basket, ancillary toolbox and radioactive

marker box.

Other 27/12/1999 19:00 Rig continued standby owing to contractual issues between

client and rig management. Rig also waiting on Surface Well

Test equipment.

Other 28/12/1999 08:15 Carried out offline quality checks on perforating guns, firing

heads and ancillary tools for perforating run on the Pre-Bima

sand.

Other 28/12/1999 20:00 Made up lift subs to perforating guns and pup joints, in

readiness for pick up.

Other 29/12/1999 11:15 Carried out system integration test with GR/CCL tool and

radioactive marker sub; established activity of radioactive

marker.

Other 30/12/1999 10:30 Confirmed real-time well parameters; Company Man

endorsed well data sheet.

Other 04/12/1999 14:45 Updated toolstring schematic and tally for perforating run on

the Pre-Brima sand.

Other 06/12/1999 17:15 Confirmed availability and compatibility of required cross-

ORION Version: 8.0 30/01/2000 06:52 AM Page 1 of 6

overs and handling gears (slips, clamps and elevators).

Other 06/12/1999 17:45 Rig continued waiting on arrival of Surface Well Test

equipment.

Other 07/01/2000 19:00 Discussed plan of action for perforate-and-test operation on

the Pre-Brima sand.

08/01/2000 13:30 Further discussed plan of action for perforate-and-test

operation on the Pre-Brima sand.

Other 09/01/2000 20:00 Reviewed pinning calculations for surface actuating pressures

for the back-up Time Delay Firer.

Other 10/01/2000 08:22 Further reviewed pinning calculations for surface actuating

pressures for the back-up Time Delay Firer.

Other 11/01/2000 15:43 First Source received Surface Well Test equipment for

perforate-and-test operation on the Pre-Bima sand.

Other 12/01/2000 10:30 First Source commenced rigging up and pressure testing

surface well test equipment.

Other 13/01/2000 12:20 Prepared firing bar.

Other 14/01/2000 09:15 Prepared secondary explosive sub

Other 15/01/2000 11:15 Pinned Time Delay Firer with calculated 20 pins in the

presence of Etihad, NNPC and Frontier Exploration reps.

Other 15/01/2000 08:30 Rig management resolved contractual issues with

NNPC/Etihad; rig called off strike.

Other 15/01/2000 10:00 Reviewed plan of action for deploying TCP/DST assembly,

and for perforating and testing the Pre Brima sand (interval

13480ft – 13484ft).

Safety Meeting 15/01/2000 13:00 Held pre-job meeting prior to picking up and running in hole

perforate-and-test assembly.

Running In Hole 15/01/2000 14:30 Picked up 4ft-loaded 4-5/8’’ perforating gun, and made up the

bottom, back-up pressure-actuated firing head assembly to

gun hanging in elevators.

Running In Hole 15/01/2000 15:00 Replaced seals with new Viton seals, and made up drop-bar

pressure-assisted mechanical firing head to top of gun

suspended in rotary.

Running In Hole 15/01/2000 15:45 Made up and ran in hole three joints of 2-7/8’’ EUE pups, and

filled with 30ft-column of clean drill water.

Running In Hole 15/01/2000 16:00 Deployed shock absorber, Champ packer, Armada sampler

and the closed-ball valve Select Tester Valve assembly.

Running In Hole 15/01/2000 18:30 Continued tripping in hole with the Omni and RD circulating

valves.

Running In Hole 15/01/2000 20:50 Made and ran in hole the radioactive marker sub assembly.

Running In Hole 15/01/2000 21:30 Manually filled work string with cushion 8.33ppg water from

Select Tester Valve to surface.

Running In Hole 15/01/2000 21:45 Rigged up to cement unit for pressure test, flushed surface

lines until clean returns observed, and closed lotorc valve.

Running In Hole 15/01/2000 22:00 Pressure tested surface lines against closed lotorc valve to

5000psi for 10min. Good test.

Running In Hole 15/01/2000 22:15 Opened lotorc valve, and pressure tested against closed ball

of Select Tester Valve to 5000psi for 10min. Good test.

Running In Hole 15/01/2000 22:45 Continued deploying perforating assembly and DST assembly

on stands of 3-1/2’’ drill pipe and 5’’ drill pipe, manually

filling with cushion water every 5 stands.

Running In Hole 16/01/2000 07:30 Pressure tested after first 45 stands (at 5000ft) against Select

Tester Valve to 5000psi for 10 min. Good test.

Running In Hole 16/01/2000 07:55 Continued deploying perforating assembly and DST assembly

on stands of 3-1/2’’ drill pipe and 5’’ drill pipe, manually

ORION Version: 8.0 30/01/2000 06:52 AM Page 2 of 6

filling with cushion water every 5 stands.

Running In Hole 16/01/2000 17:00 Pressure tested at 10528ft against closed Select Tester Valve

to 5000psi for 10min. Good test.

Running In Hole 16/01/2000 17:30 Continued deploying perforating guns in hole on stands of

drill pipe.

Running In Hole 16/01/2000 21:00 Completed manual filling of stands of drillpipe to 12330.29ft,

and pressure tested against closed Select Tester Valve to

5000psi for 10min. Good test.

Running In Hole 16/01/2000 23:50 Completely ran approx. 1100ft of drill pipe dry to take

perforating guns to depth, creating desired underbalance of

800psi approx.

Other 17/01/2000 00:30 E-line rigged up for correlation, and ran in hole to locate

position of radioactive marker relative to top shot of

perforating gun.

Other 17/01/2000 06:45 E-line located radioactive marker 18ft shallower at 13066ft.

Other 17/01/2000 10:00 E-line completely pulled out of hole and rigged down.

Space Out 17/01/2000 10:30 Moved work string 18ft deeper to position gun accurately on

depth, as per e-line correlation.

Other 17/01/2000 11:15 E-line rigged up for a second correlation

Space Out 17/01/2000 15:30 Located radioactive marker rightfully at 13084ft; e-line pulled

out of hole.

Other 17/01/2000 16:30 Set Champ packer by making four right hand turns and

setting down 25000lbs.

Other 17/01/2000 17:00 Commenced rigging up flow head, coflexip hose and kill line;

and commenced pressure testing to 5500psi. Good test.

Other 18/01/2000 04:15 Applied and held 1200psi in annulus to confirm Champ

packer sealing and to open Select Tester Valve.

Safety Meeting 18/01/2000 04:30 Held pre-job meeting to discuss lines of action to actuate

firing head and detonate perforating gun.

Other 18/01/2000 04:45 Rigged up acoustic shot detection device to stick-up of drill

pipe in rotary.

Initiate Firing Head 18/01/2000 04:55 Opened swab valve, dropped firing bar through work string,

and allowed to gravitate; closed swab valve.

Initiate Firing Head 18/01/2000 05:10 Observed very minimal indication of possible gun detonation

from recorded output of acoustic shot detection device

Other 18/01/2000 05:30 Opened well, and commenced monitoring well on choke

manifold. 0psi flowing tubing head pressure.

Other 18/01/2000 11:15 Bled off 1200psi held in annulus to close Select Tester Valve;

re-applied and held pressure (1300psi) in annulus to open

Select Tester Valve.

Other 18/01/2000 11:35 Client decided to fill up string completely with 8.33ppg water

and to attempt to carry out injectivity test in order to further

verify gun detonation.

Other 18/01/2000 11:50 Lined up to cement unit, and built up pressure to 1000psi in

work string. No pressure drop observed, indicative of no

injectivity.

Initiate Firing Head 18/01/2000 11:55 Built up pressure to optimum surface actuating pressure of

3500psi for the back-up pressure actuated Time Delay Firer,

held for one minute and bled off completely. Lost 1bbl,

indicative of possible open perfs.

Initiate Firing Head 18/01/2000 12:15 Built up pressure to maximum surface actuating pressure of

4100psi for the back-up pressure actuated Time Delay Firer,

held 4000psi for one minute and bled off completely. Lost

0.5bbl, indicative of possible open perfs.

Other 18/01/2000 13:15 Attempted to commence displacing well to diesel to create

larger underbalance and then monitor well for flow.

Other 18/01/2000 21:45 Attempted to cycle OMNI circulating valve to circulating

position in order to reverse circulate 9.3ppg brine and

ORION Version: 8.0 30/01/2000 06:52 AM Page 3 of 6

displace well to 6.9ppg diesel.

Other 18/01/2000 22:00 Observed a pressure spike of 4400 psi at the data acquisition

unit and annulus chart recorder monitor whilst the rig pump

gauge recorded 200psi.

Other 18/01/2000 22:15 Pressure spike of 4400psi from defective rig pump exceeded

pressure limits of all rupture discs in the string, resulting in

communication between annulus and work string.

Other 19/01/2000 09:00 Commenced rigging down flow head and surface well test

lines, owing to inability to proceed with well test operations.

Other 19/01/2000 10:30 Rigged down flow head and surface well test lines, owing to

inability to proceed with well test operations.

POOH 19/01/2000 14:15 Commenced pulling out of hole and racking back stands of

drill pipe above TCP/DST assembly.

POOH 20/01/2000 03:30 Pulled out of hole and laid down radioactive marker sub, RD

and OMNI circulating valves.

POOH 20/01/2000 04:15 Located ball valve of Select Tester Valve still in closed

position and firing bar settling on closed Select Tester Valve.

POOH 20/01/2000 04:25 Retrieved firing bar. Firing bar had a broken indent plug.

Safety Meeting 20/01/2000 06:00 Held safety meeting prior to continuing to pull out of hole

TCP assembly; discussed procedure for pulling out of hole

live gun.

POOH 20/01/2000 06:55 Pulled out of hole and laid down Mechanical Firing Head

assembly.

POOH 20/01/2000 07:15 Confirmed with infrared thermometer that gun temperature

was less than 225 deg F.

POOH 20/01/2000 07:50 Pulled out of hole perforating gun.

Other 20/01/2000 17:00 Concluded turn-around maintenance on TCP ancillary

equipment.

Other 20/01/2000 10:30 Measured lengths and dimensions of TCP/DST bottom hole

assembly for re-run perforate-and-test operation on first sand

of Pre-Bima.

Other 20/01/2000 14:45 Updated toolstring schematic and tally for second perforating

run on the Pre-Brima sand.

Other 20/01/2000 19:00 Discussed plan of action for second perforate-and-test run on

the Pre-Bima sand.

Other 20/01/2000 20:00 Reviewed pinning calculations for surface actuating pressures

for the back-up Time Delay Firer.

Other 20/01/2000 20:30 Pinned Time Delay Firer with calculated 20 pins in the

presence of Etihad, NNPC and Frontier Exploration reps.

Safety Meeting 21/01/2000 11:15 Held pre-job meeting prior to picking up and running in hole

perforate-and-test assembly.

Running In Hole 21/01/2000 12:15 Picked up back-up 4ft-loaded 4-5/8’’ perforating gun, and

made up the bottom, back-up pressure-actuated firing head

assembly to gun hanging in elevators.

Running In Hole 21/01/2000 12:25 Replaced seals with new Viton seals, and made up drop-bar

pressure-assisted mechanical firing head to top of gun

suspended in rotary.

Running In Hole 21/01/2000 12:45 Made up and ran in hole three joints of 2-7/8’’ EUE pups, and

filled with 30ft-column of clean drill water.

Running In Hole 21/01/2000 13:00 Deployed shock absorber, Champ packer and Big John Jar

Running In Hole 21/01/2000 13:10 Commenced waiting on redressing of Armada sampler.

Running In Hole 22/01/2000 00:30 Continued tripping in hole with rest of DST bottom hole

assembly. Select Tester Valve in lock-open position.

Running In Hole 22/01/2000 01:45 Made and ran in hole the radioactive marker sub assembly.

Running In Hole 22/01/2000 02:00 Commenced deploying perforating assembly on stands of

drillpipe

Running In Hole 22/01/2000 11:45 Deployed TCP/DST assembly past top of liner at 10526ft

ORION Version: 8.0 30/01/2000 06:52 AM Page 4 of 6

Running In Hole 22/01/2000 14:30 Completely deployed TCP/DST assembly to depth, according

to drillpipe tally.

Other 22/01/2000 15:15 E-line rigged up for correlation, and ran in hole to locate

position of radioactive marker relative to top shot of

perforating gun.

Other 22/01/2000 18:50 E-line located radioactive marker 17.5ft shallower at

13101.7ft.

Other 22/01/2000 21:15 E-line completely pulled out of hole and rigged down.

Space Out 22/01/2000 21:40 Moved work string 17.5ft deeper to position gun accurately

on depth, as per e-line correlation.

Other 22/01/2000 22:15 E-line rigged up for a second correlation

Other 23/01/2000 01:00 E-line got held up at 12480ft.

Other 23/01/2000 03:00 E-line pulled out of hole and rigged down.

Other 23/01/2000 03:30 Established circulation; circulated for 30 minutes at 100psi.

Other 23/01/2000 04:15 DST specialist commenced making several attempts to set

Champ packer; no success.

Other 23/01/2000 07:30 Reverse circulated; and DST specialist continued attempting

to set packer.

Other 23/01/2000 08:15 Packer set; tested packer backside to 1000psi for 10min.

Good test.

Other 23/01/2000 08:30 Commenced rigging up surface well test equipment.

Other 23/01/2000 11:55 Confirmed proper line up. Flushed lines.

Safety Meeting 23/01/2000 12:15 Held pre-job meeting to discuss lines of action to actuate

firing head and detonate perforating gun.

Other 23/01/2000 12:20 Rigged up acoustic shot detection device to stick-up of drill

pipe in rotary.

Other 23/01/2000 12:40 Opened Champ packer bypass.

Other 23/01/2000 12:50 Commenced displacing string to 6.9ppg diesel

Other 23/01/2019 13:27 Pumped 198bbl of diesel.

Initiate Firing Head 23/01/2000 15:34 Opened swab valve, dropped firing bar and allowed to

gravitate; closed swab valve.

Initiate Firing Head 23/01/2000 15:39 Got very positive indication of gun detonation at 5min from

time firing bar was dropped.

Other 23/01/2000 16:28 Opened well at choke manifold, and commenced unloading

diesel from string.

Other 24/01/2000 18:45 Shut in well on surface to allow 12-hour build-up of pressure.

Other 25/01/2000 06:25 Opened well at choke manifold, and continued to monitor

well.

Other 26/01/2000 11:00 Opened packer bypass; commenced reversing out diesel.

Other 26/01/2000 12:30 Commenced rigging down flow head and surface well test

lines

Other 26/01/2000 18:00 Ended reverse circulating and rigging down flow head.

POOH 26/01/2000 18:30 Commenced pulling out of hole stands of drill pipe

POOH 27/01/2000 03:45 Completely pulled out of hole stands of drill pipe.

POOH 27/01/2000 04:00 Laid down radioactive marker sub.

POOH 27/01/2000 05:15 Completely laid down DST assembly.

POOH 27/01/2000 06:30 Laid down pup joints and Balanced Isolation Tool.

POOH 27/01/2000 06:45 Laid down top mechanical firing head

POOH 27/01/2000 06:55 Picked gun all the way up rotary to visually confirm shots

fired as loaded

POOH 27/01/2000 07:15 Laid down spent perforating gun.

Other 27/01/2000 08:15 Rig installed shooting nipple. E-line rigged up and pressure-

tested dual pack-off. Good test.

Other 27/01/2000 11:40 E-line picked up and commenced running in hole 5.91’’ OD

gauge ring.

Other 27/01/2000 14:30 E-line experienced HUD at 10536ft (top of liner).

ORION Version: 8.0 30/01/2000 06:52 AM Page 5 of 6

Other 27/01/2000 17:48 E-line pulled out of hole and laid down BHA.

Other 27/01/2000 18:45 E-line picked up and commenced running in hole 5.72’’ OD

gauge ring.

Other 27/01/2000 20:20 E-line experienced HUD again at 10536ft (top of liner).

Other 27/01/2000 23:55 E-line pulled out of hole and laid down BHA.

Other 28/01/2000 01:50 E-line made up and shear-tested DPU. E-line made up plug

and commenced running in hole bridge plug.

Other 28/01/2000 12:45 E-line pulled out of hole plug and rigged down.

Other 28/01/2000 14:10 Rig commenced running in hole bit and scraper assembly.

Other 28/01/2000 22:00 Rig held up at about 7000ft with bit and scraper assembly;

attempted circulating – no success.

Other 29/01/2000 06:45 Rig continued bit and scraper run while awaiting arrival of

acid pickle and mechanical setting tool for bridge plug.

Other 30/01/2000 07:00 Rig continued bit and scraper run while awaiting arrival of

acid pickle and mechanical setting tool for bridge plug.

Other 30/01/2000 10:15 E-line commenced rigging up and pressure testing shooting

nipple.

ORION Version: 8.0 30/01/2000 06:52 AM Page 6 of 6

You might also like

- Document Tile: Field Ticket Document No:OS-GOCE-R001Document1 pageDocument Tile: Field Ticket Document No:OS-GOCE-R001MarcoNo ratings yet

- Permit Number P290-00-5713663 State Waiting For Verification Lifetime Expires OnDocument13 pagesPermit Number P290-00-5713663 State Waiting For Verification Lifetime Expires OnNaseemandson TeamNo ratings yet

- Job Debriefing Form: JDD NoDocument4 pagesJob Debriefing Form: JDD Notafhim rashidNo ratings yet

- Graña y Montero Petrolera: Lote IV Lomitos 13682 Orig CompletionDocument2 pagesGraña y Montero Petrolera: Lote IV Lomitos 13682 Orig CompletionErick OlanoNo ratings yet

- Ep Wells Daily Operations Report: Event SummaryDocument5 pagesEp Wells Daily Operations Report: Event Summarymohamed gadallahNo ratings yet

- Complete Iterinary Forms 2022Document5 pagesComplete Iterinary Forms 2022Yay DumaliNo ratings yet

- Cargo Documents - CH1Document5 pagesCargo Documents - CH1Daniel FigueroaNo ratings yet

- Production Call Sheet 1Document3 pagesProduction Call Sheet 1api-329256627No ratings yet

- Shipment Loading Tracking Report - 11.12.19Document1 pageShipment Loading Tracking Report - 11.12.19Faruque UddinNo ratings yet

- DBG Sland Offshore DPR - 13.01.2021-045Document2 pagesDBG Sland Offshore DPR - 13.01.2021-045Yussuf DirieNo ratings yet

- OCP - AKPPL Bitumen Rev.ADocument252 pagesOCP - AKPPL Bitumen Rev.ASumantrra Chattopadhyay100% (1)

- Speke South-1 Daily Operation Report 19-04-2008Document2 pagesSpeke South-1 Daily Operation Report 19-04-2008Hamed MasaodNo ratings yet

- Docs 2Document5 pagesDocs 2Chika PatricaNo ratings yet

- Cerro Verde Production Unit Expansion: Electrical Bill of Materials Per Operating Screen Document No. SN-100462-MD07Document3 pagesCerro Verde Production Unit Expansion: Electrical Bill of Materials Per Operating Screen Document No. SN-100462-MD07jhonNo ratings yet

- Power Generation Services Business Management System: Staff Request FormDocument1 pagePower Generation Services Business Management System: Staff Request FormPieter BezuidenhoutNo ratings yet

- Call Sheet 1Document3 pagesCall Sheet 1api-329256486No ratings yet

- Ep Wells Daily Operations Report: Event SummaryDocument5 pagesEp Wells Daily Operations Report: Event Summarymohamed gadallahNo ratings yet

- Daily ReportDocument4 pagesDaily ReportAhmedNo ratings yet

- Daily Report - Fiber Line #3 Date 17-02-2024Document2 pagesDaily Report - Fiber Line #3 Date 17-02-2024daniNo ratings yet

- TKCSML Sarsawa AbhinavDocument2 pagesTKCSML Sarsawa AbhinavlamrininosNo ratings yet

- 5g0302a DC Duri0985720190715rln12Document21 pages5g0302a DC Duri0985720190715rln12Ryan SinagaNo ratings yet

- Time Sheet Team Install Pump CEP UP Indramayu - SuryantoDocument1 pageTime Sheet Team Install Pump CEP UP Indramayu - SuryantoKukuh Perkasa WirayudaNo ratings yet

- Work Permit S CW 08299 2022Document2 pagesWork Permit S CW 08299 2022aliNo ratings yet

- R-HR-045 Call in Form NewDocument18 pagesR-HR-045 Call in Form NewATKNo ratings yet

- f75142368 ERECTION PROGRESS REPORT FOR Factory For Production of Reinforced SteelDocument6 pagesf75142368 ERECTION PROGRESS REPORT FOR Factory For Production of Reinforced SteelAbdulrahman AlkilaniNo ratings yet

- Appendix Daily Time Record October 23-27 WilliamDocument1 pageAppendix Daily Time Record October 23-27 WilliamLiam SerdeñaNo ratings yet

- Deobond Time SheetDocument2 pagesDeobond Time SheetKuldeep SharmaNo ratings yet

- Work ScheduleDocument1 pageWork ScheduleBinamra SNo ratings yet

- Foam Service Report: PT. Umega Maju BersamaDocument2 pagesFoam Service Report: PT. Umega Maju BersamaS Surya DharmaNo ratings yet

- Job List PSD PM8 TGL 14-15 Des 2020Document99 pagesJob List PSD PM8 TGL 14-15 Des 2020arief bayuNo ratings yet

- Po # 13049716 Continental EngDocument1 pagePo # 13049716 Continental EngAngel DelacruzNo ratings yet

- Cold Work Permit: Smg1 Flowline ProjectDocument2 pagesCold Work Permit: Smg1 Flowline Projectghazi kallelNo ratings yet

- Driver's LOGBOOKDocument156 pagesDriver's LOGBOOKVincent Joshua CruzNo ratings yet

- Drilling & Completion Summary - Ascending: Well Name: UNIVERSITY 3-33 6HDocument115 pagesDrilling & Completion Summary - Ascending: Well Name: UNIVERSITY 3-33 6HbmrhookerNo ratings yet

- Vertime Uthorization ORM: Project Name: WRM/105/SLA Project No.: 105/SLA Date: 03/04/2020Document1 pageVertime Uthorization ORM: Project Name: WRM/105/SLA Project No.: 105/SLA Date: 03/04/2020gkNo ratings yet

- OFFHN-4247,100 KvaDocument1 pageOFFHN-4247,100 KvaService CoatechNo ratings yet

- WorkPermitDetails 20 09 2023Document3 pagesWorkPermitDetails 20 09 2023gulamsafiNo ratings yet

- Chevron Bangladesh Drilling Morning Report: Date: 11/12/2013Document4 pagesChevron Bangladesh Drilling Morning Report: Date: 11/12/2013shuvo134No ratings yet

- Daily Photograph - Fiber Line #3 Date 9-02-2024Document1 pageDaily Photograph - Fiber Line #3 Date 9-02-2024daniNo ratings yet

- Network Change Request / New Mop Form: Open Other Ref NoDocument4 pagesNetwork Change Request / New Mop Form: Open Other Ref NoHassan Mody TotaNo ratings yet

- SP-2 - SAS - Incident RepairDocument2 pagesSP-2 - SAS - Incident RepairgeorgesNo ratings yet

- Form CheckerDocument1 pageForm CheckerSigit Tri NugrohoNo ratings yet

- Job Debriefing Form: JDD NoDocument4 pagesJob Debriefing Form: JDD Notafhim rashidNo ratings yet

- 22 PDFDocument5 pages22 PDFvenkateshNo ratings yet

- Job Card-3173-Al Saad Sport Club-August-Chiller-2Document5 pagesJob Card-3173-Al Saad Sport Club-August-Chiller-2aditya rokkamNo ratings yet

- PAT Form - 614 CARMONADocument6 pagesPAT Form - 614 CARMONAJohn Kenedy Hernandez CasapaoNo ratings yet

- Demurrage CalculationsDocument1 pageDemurrage CalculationsJuan Ramón FuentesNo ratings yet

- Time Sheet Team Install Pump CEP UP Indramayu - AstomoDocument1 pageTime Sheet Team Install Pump CEP UP Indramayu - AstomoKukuh Perkasa WirayudaNo ratings yet

- Mss sp-85Document12 pagesMss sp-85Mhand AmsNo ratings yet

- SPB Abm IljinDocument25 pagesSPB Abm IljinBahri AdiNo ratings yet

- Informe Final Workover PLM-C7Document47 pagesInforme Final Workover PLM-C7Brian Barrón ChávezNo ratings yet

- HSE Incident Log 2022: SL Date (DD/Month/YYYY) Time of IncidentDocument134 pagesHSE Incident Log 2022: SL Date (DD/Month/YYYY) Time of IncidentIdris AdeniranNo ratings yet

- Action ItemsDocument13 pagesAction ItemsNonsoufo ezeNo ratings yet

- Pay KickstartDocument1 pagePay Kickstartyasin khanNo ratings yet

- Production Defective Material Report (DMR) Process Flow and Production Quality Data As of January, 2010Document8 pagesProduction Defective Material Report (DMR) Process Flow and Production Quality Data As of January, 2010santosh kumarNo ratings yet

- Concrete Curing LogDocument1 pageConcrete Curing Logzia50% (2)

- Workshop Shifting Estimation 2014Document15 pagesWorkshop Shifting Estimation 2014wahyuNo ratings yet

- Excavation Permit: Smg1 Flowline ProjectDocument2 pagesExcavation Permit: Smg1 Flowline Projectghazi kallelNo ratings yet

- f73994056 ERECTION PROGRESS REPORT FOR Gulf MallDocument5 pagesf73994056 ERECTION PROGRESS REPORT FOR Gulf MallAbdulrahman AlkilaniNo ratings yet

- Gas Reservoir SimulationDocument17 pagesGas Reservoir SimulationTemitope BelloNo ratings yet

- Porosity Resistity Tutorial QandADocument4 pagesPorosity Resistity Tutorial QandATemitope BelloNo ratings yet

- Curve FittingDocument20 pagesCurve FittingTemitope BelloNo ratings yet

- MDT InterpretationDocument11 pagesMDT InterpretationTemitope BelloNo ratings yet

- Defining The Reservoir ModelDocument23 pagesDefining The Reservoir ModelTemitope BelloNo ratings yet

- Well Data Summary ProgramDocument13 pagesWell Data Summary ProgramTemitope BelloNo ratings yet

- RDT AnalysisDocument7 pagesRDT AnalysisTemitope BelloNo ratings yet

- Oil Reserve DefinitionDocument32 pagesOil Reserve DefinitionTemitope BelloNo ratings yet

- Decline Model 2Document21 pagesDecline Model 2Temitope BelloNo ratings yet

- Overview of Drilling OperationDocument106 pagesOverview of Drilling OperationTemitope Bello100% (1)

- Partial Diff EquationsDocument32 pagesPartial Diff EquationsTemitope BelloNo ratings yet

- A - Rock Properties & SaturationDocument29 pagesA - Rock Properties & SaturationTemitope BelloNo ratings yet

- Reservoir ModelDocument133 pagesReservoir ModelTemitope Bello100% (1)

- Methane Production: - Methanogenesis Substrates / Pathways Isotopic Studies Hydrogen CyclingDocument36 pagesMethane Production: - Methanogenesis Substrates / Pathways Isotopic Studies Hydrogen CyclingTemitope BelloNo ratings yet

- Ordinary Diff EquationsDocument18 pagesOrdinary Diff EquationsTemitope BelloNo ratings yet

- Gas Processing and ConditioningDocument31 pagesGas Processing and ConditioningTemitope Bello100% (1)

- Unitization and Hydrocarbon Field DevelopmentDocument125 pagesUnitization and Hydrocarbon Field DevelopmentTemitope BelloNo ratings yet

- How Drugs Work - Basic Pharmacology For Healthcare ProfessionalsDocument19 pagesHow Drugs Work - Basic Pharmacology For Healthcare ProfessionalsSebastián Pérez GuerraNo ratings yet

- Roleplayer: The Accused Enchanted ItemsDocument68 pagesRoleplayer: The Accused Enchanted ItemsBarbie Turic100% (1)

- ME Eng 8 Q1 0101 - SG - African History and LiteratureDocument13 pagesME Eng 8 Q1 0101 - SG - African History and Literaturerosary bersanoNo ratings yet

- Biological Beneficiation of Kaolin: A Review On Iron RemovalDocument8 pagesBiological Beneficiation of Kaolin: A Review On Iron RemovalValentin GnoumouNo ratings yet

- RTDM Admin Guide PDFDocument498 pagesRTDM Admin Guide PDFtemp100% (2)

- Acute Coronary SyndromeDocument30 pagesAcute Coronary SyndromeEndar EszterNo ratings yet

- B.SC BOTANY Semester 5-6 Syllabus June 2013Document33 pagesB.SC BOTANY Semester 5-6 Syllabus June 2013Barnali DuttaNo ratings yet

- Mcom Sem 4 Project FinalDocument70 pagesMcom Sem 4 Project Finallaxmi iyer75% (4)

- Technology Management 1Document38 pagesTechnology Management 1Anu NileshNo ratings yet

- BMOM5203 Full Version Study GuideDocument57 pagesBMOM5203 Full Version Study GuideZaid ChelseaNo ratings yet

- 3 ALCE Insulators 12R03.1Document12 pages3 ALCE Insulators 12R03.1Amílcar Duarte100% (1)

- 2SB817 - 2SD1047 PDFDocument4 pages2SB817 - 2SD1047 PDFisaiasvaNo ratings yet

- .Urp 203 Note 2022 - 1642405559000Document6 pages.Urp 203 Note 2022 - 1642405559000Farouk SalehNo ratings yet

- Famous Russian PianoDocument10 pagesFamous Russian PianoClara-Schumann-198550% (2)

- Guidelines For SKPMG2 TSSP - Draft For Consultation 10.10.17Document5 pagesGuidelines For SKPMG2 TSSP - Draft For Consultation 10.10.17zqhnazNo ratings yet

- Project Scheduling and TrackingDocument47 pagesProject Scheduling and TrackingArun VinodhNo ratings yet

- Chapter 2 ProblemsDocument6 pagesChapter 2 ProblemsYour MaterialsNo ratings yet

- Dtu Placement BrouchureDocument25 pagesDtu Placement BrouchureAbhishek KumarNo ratings yet

- Working Capital in YamahaDocument64 pagesWorking Capital in YamahaRenu Jindal50% (2)

- 5c3f1a8b262ec7a Ek PDFDocument5 pages5c3f1a8b262ec7a Ek PDFIsmet HizyoluNo ratings yet

- Pe 03 - Course ModuleDocument42 pagesPe 03 - Course ModuleMARIEL ASINo ratings yet

- Hamstring - WikipediaDocument21 pagesHamstring - WikipediaOmar MarwanNo ratings yet

- Playful Homeschool Planner - FULLDocument13 pagesPlayful Homeschool Planner - FULLamandalecuyer88No ratings yet

- Organizational ConflictDocument22 pagesOrganizational ConflictTannya AlexandraNo ratings yet

- Digital MetersDocument47 pagesDigital MetersherovhungNo ratings yet

- RSA - Brand - Guidelines - 2019 2Document79 pagesRSA - Brand - Guidelines - 2019 2Gigi's DelightNo ratings yet

- CT SizingDocument62 pagesCT SizingMohamed TalebNo ratings yet

- User Manual For Speed Control of BLDC Motor Using DspicDocument12 pagesUser Manual For Speed Control of BLDC Motor Using DspicTrung TrựcNo ratings yet

- Dalasa Jibat MijenaDocument24 pagesDalasa Jibat MijenaBelex ManNo ratings yet

- Global Geo Reviewer MidtermDocument29 pagesGlobal Geo Reviewer Midtermbusinesslangto5No ratings yet