Professional Documents

Culture Documents

QGX T Arn CS 00005

QGX T Arn CS 00005

Uploaded by

Omar Tocmo0 ratings0% found this document useful (0 votes)

23 views38 pagesOriginal Title

QGX-T-ARN-CS-00005

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views38 pagesQGX T Arn CS 00005

QGX T Arn CS 00005

Uploaded by

Omar TocmoCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 38

&

wv

oe

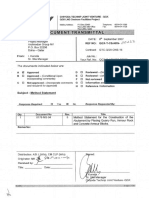

Issued by _Adel Monsef

| To _Mr.

‘The documents itemised below are for your aitention and action as indicated.

Isamu Kuroda

ARCHIRODON GROUP NV

‘CORPORATE MANAGEMENT SYSTEM

‘System Procedure CORP-SYS-02 Control of Dacuments and Data

=)

Document Transmittal

Project or Office

Ras Laffan, QATAR

0176 CLP Phase-4, Berth No. 5 Marine Works QG II LNG Onshore Facilities

Archirodon Construction (0) Co. S.A

Attn: Mr, Adel Monsef

. P.O, Box 22256, Doha,

7 Ras Laffan-Port Area

Qatar

Tel +974 4733353/7/8/9

Fax + 974 4733355

___ Position

Organisation _Chiyoda ~ Technip Joint Venture

Contract No.

Transmittal Ref, QGX-T-ARNI/CS-00005

Project Manager

Document Codes

‘MS Management system document ‘MA_| Material submittal

D_| Drawing © | Other Contract document ee

F_| Blectronie file R_| Report 1}

ft ation Codes i

1__ | Information, no response required R_| Review and retum comments |

C_| Construction or Use R2_ | Retum to originator after amendment

[“A™ [For approval, please reply

Tie ‘Document Code and Pile Reference * [Rev | Size | Cop | Action

n | |

Method Statement for the Construction | |

of the Abutment by Placing Quarry Run, | |

1 | MS | Armour Rock and Concrete Armour | 0176-MS-04 | 1 | Ad) 1 | A |

Blocks |

|

‘Remarks

5

Signature Date of Issue _04 January 2007

“Note: For an expithation of the references for management system documents, see Table 7.1

and Table 7.3 of this system procedure.

Document ref. CORP-SYS-02-P02 Rew.

ARCHIRODON CONSTRUCTION OVERSEAS CO. S. 4.

‘METHOD, Document Ref

statemenr | _orrenis.o__| Revision 1 | Page 10f10 | prea

PROJECT MANAGEMENT SYSTEM ES

CLP PHASE 4-BERTH 5, MARINE WORKS

QG IL LNG Onshore Facilities Project

At Ras Laffan,Qatar.

Method Statement

For the Construction of the Abutment by

Placing Quarry Run, Armour Rock and

Cencrete Armour Blocks

Issue Status & | Issued for approval.

Description

| Preparediy | Reviewed by | Approved by

Construction | ProjectQC | Project

Document. Rev Issue Date | Section ‘Section Manager

0176-MS-04 1 04 Jan. 2007 M. Wadie M. Khalil | A Monsef_

Appendix A 1 04 Jan. 2007 \

Appendix B 1 04 Jan. 2007 Re |

Appendix C 1 | 04 Jan. 2007 ay, I

Appendix D 1 | 04 Jan. 2007 Qt i

|AppendixE | 4 | 04 Jan. 2007

ARCHIRODON CONSTRUCTION (OVERSEAS) Co. SA

METHOD | Document Ref. io a

STATEMENT | __0176-MS-o4 |_| Revision” 1 Eeeanorin:

Construction of the Abutment by Piacing Quarry Ren, Armour Rock and Concrete Armour

Blocks

LIST OF CONTENTS

Page

1.0 Introduction. 3

2.0 Document Control... sec. 3

3.0 Health, Safety and the Environment

3.1 Health and Safety Hazards 3

3.2 Adverse Environmental Impacts 4

33 ‘Transportation. 4

34 ‘Communications. 4

3.5. Noise Monitoring. 5

3.6 Dust control...... 5

4.0 Resources

4.1 Equipment. 7 tees:

42 Personnel... 6

5.0 References. Pda ie 8

6.0 Methodology

61 Schedule of Work............. e seeeesenee, ~ 8B

6.2 Removal of Antifer Cubes from Land and from sea 8

6.3 Installation of screened quarry run 9

64 Installation of rubble material 9

6.5 Installation of armoured rock ... 9

6. Installation of conerete armoured cubes... 9

67 Placing of strctural fil 10

7.0 Quality Control... eo:

Appendices:

Appendix A Job Safety Analysis

Appendix B_ Environmental Impact Statement

Appendix Drawings

Appendix D Night Shift Procedure CORP-GEN-15 Rev. 1

Appendix E Abutment Construction Sequence Under Loading Platform Deck

ARCHIRODON CONSTRUCTION (OVERSEAS) Co. SA

METHOD | Document Ref.

STATEMENT | __0176-MS-04 Revision 1 Page 3 of 10

‘Construction of the Abutment by Placing Quarry Run, Armour Rock and Concrete Armour

Blocks

1.0 INTRODUCTION

L1. This document describes the methods to be implemented and resources to be utilised for the

removal of Antifer Armour Cubes, placing of screened quarry run (IT) 1-500 Kg covered by

armour rock 600-2,000 Kg and protected with a revetment of concrete armour cubes type I, IT

and Ii. A geotextile membrane will be installed-and a compacted structural fill will be placed

to give access to the loading platform. The steel casing of the first two rows of piles will be

protected by Timber Jacket before covering them with rocks and Armour Cubes.

1.2, This method statement and job safety analysis are hereby developed within these elements to

describe in more detail the methods used, the resources deployed and the controls put into

place to eliminate or mitigate safety hazards and adverse environmental impacts,

2.0 BOCUMENT CONTROL

2.1. This method statement is a controlled document as required by the system procedure Quality

Planning and issued in accordance with the system procedure Control of Documents and

Data.

2.2. The method statement is subject to amendment during the execution of the Works as a result

of periodic review and whenever circumstances require subject to CTJV approval. Revisions

will be issued in accordance with the system procedure Control of Documents and Data

whenever the main text changes or when an appendix is added or removed. Revised

appendices for substitution will be issued separately and, where appropriate, will include a

separate schedule of contents.

23. This document’s revision and appendix issue statas is shown in the Project Register of

Management System Documents, a copy of which may be obtained from the Project Office

upon request

3.0 HEALTH, SAFETY AND THE ENVIRONMENT

3.1 Health and Safety Hazards

3.1.1 As required by the Project Health & Safety Plan, the significant health and safety hazards of

this work have been analysed in accordance with the general procedure Hazard Analysis and

Environmental Impact Assessment and are listed below.

Security Hazard / Possible unauthorized access

Falling of personnel and equipment into the sea, drowning

Lifting hazard / Falling object

Noise level

Night time working

Exposure to concrete

Electrical hazards / Welding (working near or over water)

eoeceoe

ARCHIRODON CONSTRUCTION (OVERSEAS) Co. SA

METHOD Document Ref.

STATEMENT o176-ms-o4 | Revision 1 Page 4 of 10

Construction of the Abutment by Placing Quarry Run, Armour Rock and Conerefe Armour

Blocks |

3.1.2 Controls will be implemented to minimise these hazards as set out in the form Safery Hazard

Controi Programme included in Appendix A,

3.2 Adverse Environmental Impacts

3.21

3.2.2

As required by the Project Environmental Plan, the significant adverse environmental impacts

of this work have been analysed in accordance with the general procedure Hazard Analysis

and Environmental Impact Assessment and are listed below.

‘Waste and debris disposal

Pollution from equipment due to leakage or during refuelling

Pollution from the washing out of the concrete truck mixer

Pollution from hydraulic hose leakage / burst

Noise level

Controls will be implemented to minimise these adverse impacts, as set out in the form

Environmental Impact Statement included in Appendix B.

33 Transportation,

3.1.1 The transportation of all project materials such as the armoured rock, concrete blocks ete. to

Berth # 5 area will be by Sea via tug boats and barges.

3.1.2 The access for equipment and personnel to the working area, for Berth ff 5 area will be through

the existing temporary jetty at Archirodon site facilities inside Ras Laffan Port See appendix-

€. Also an alternative access to personnel will be through the roadway on the breakwater to

reach Berth # 5 area,

34 ‘Communications.

3.4.1 Marine Equipment will be provided with VHF station. They shall co-ordinate each other in VH

Frequency different than the one used at Ras Laffan Port in order not to interfere with their

operations. Communication between CTJV and Archirodon shall be held through mobile

telephones

sv | Company Title ChJ/Mobile No.

1 | RLIC Harbour Master nee ce

[2 [etsy | JeanPierre Tholozan | Construction Manager 5570327

] Marine Area

3 [CTV | Michael Khoury | a anager | _ 5895028

ARCHIROBON CONSTRUCTION (OVERSEAS) Co. SA

oe Document Ref) Revision 1 Page 5 of 10

STATEMENT O176-MS-04 = fee

Construction af the Abutment by Placing Quarry Run, Armour Rock and Concrete Armour

Blocks

4 | aRCO | Adel Monsef | Project Manager 5564892 |

5 | ARCO Maged Wadie Construction Manager 5856045 |

35 Noise monitoring.

3.5.1 Periodic noise monitoring will be carried during construction of Berth # 5.

3.5.2 Whenever noise level exceeds the 85 (Dba), all employees will be instructed to wear PPE,

(earplugs).

3.5.3 The noise level range produced by the construction equipment will be as follows:

Equipment “ion son

Floating crane 70-94

Mobile crane [Loader 7-102

‘Dump track ‘Less than 85

‘Generator / Welding set / Air a a

compressor |

3.6 Dust control.

3.6.1 Personnel exposed to dust shall wear dust masks,

4.0 RESOURCES

41 Equipment

4.1.1 The main equipment envisaged for the above works includes the following:

‘Table 4.1 Plant List

‘Equipment Make/Size i] Task

Jack-Hammer 1 | Demolishing of crown

wall and concrete road.

| Floating Crane Lima 2400/136 Tons | 1 | Removal and installation

| of rocks and concrete

| armour cubes

Mobile crane 30 Tons or bigger 1 | Removal and installation

concrete armour cubes.

ARCHIRODON CONSTRUCTION (OVERSEAS) Co. SA

~~ METHOD ~ Document Ref.

[ STATE ye Revision 1 Page 6 of 10

Construction of the Abutment by Placiag Quarry Run, Armour Rock and Concrete Armour

Blocks

T N

Equipment MakelStze . Task

‘Transport barge ~~ | Lesvosi3,Kriti2/1000 | 2 | Transport of rocks and

HEE capacity each concrete armour cuibes.

Land crawler crane Manitowoc 4100 /150 | 1 | Onshore handling of

[tons concrete armour cubes,

Ganiry Crane Casagrande/120 tons | 1 | Onshore handling of

concrete armour cubes. _|

Bump trucks 16 m3 4 | Loading of rocks

Excavator ‘Cat 330 oF equivalent | 2 | Loading and Placing of

rooks

Fug boats 1000 HP 2 | For Marine operations

el

4.1.2 Water, lubrication and fuel services, to above equipment will be provided from Archirodon

facilities at the temporary Project Lay down Area, located inside Ras Laffan Port.

4.1.3. Workshop services to equipment will be provided from the workshop facilities at the Project

Lay down Area, located inside Ras Laffan Port.

4.14 All equipments shall be holding valid certificate from a third party inspector and shall be

subject to CTJV inspection.

42 Personnel - Responsibility — Work pattern,

4.2.1 The Construction Manager is responsible for the organization and coordination of the entire

work.

4.2.2 The Marine Superintendent will be in charge for the co-ordination of activities between the

project team and each of the vessels. He is responsible for instructing the Deck Foremen about

the requirements of the contract, including all restrictions, safety regulations, the work-scope

and time schedule. In addition, he will supervise vessel movements and be responsible for

related logistic matters. Onboard the vessels and equipment, each Deck Foreman will be in

charge of the staff and vessel operation. He will be instructed as per this MS to carry out this

activity.

42.3. The Safety Officers are responsible to assist the construction team to develop safe methods of

working and to monitor implementation of the controls put in place.

42.4 The PM is responsible for the management and co-ordination of all the sub-contractors and

concemed authorities, so as the works on the project will be carried out in a safe and

environmentally friendly way to meet contract requirements, in particular time and quality.

METHOD [Document Ref.

STATEMENT 0176-MS-04

ARCHIRODON CONSTRUCTION (OVERSEAS) Co. SA

Revision

1

Page 7 of 10 |

425

426

42.7

428

Blocks

Construction of the Abutment by Placing Quarry Run, Armour Rock and Concrete Armour

Construction activities will be carried on a 24-hours basis. Night Shift Procedure shall be

adopted. (Refer to Procedure CORP-GEN.-15 Rev. 1 included in Appendix D)

‘The activities will be coordinated closely between Archirodon and CTIV.

Each shift has total duration 12 hrs but actual working hours are 10 with a total break of 2 Hrs.

‘The manpower for this work includes the following:

Manpower Deployment Schedule

Deseription

‘Marine superintendent

Site Enginesr

Foreman,

Deck foreman

Surveyor

“Excavator operator

Grane operator

Dump truck driver I

‘Trailer operaior

Welders |

‘Transportation Foreman

‘Asst. transportation Foreman

Floating crane operator

Seamen

Tug boat operator

Labourers

Safety officer for each shift

af eof of | 83) v9f 19] =] | 19] on) 00} | 09) eo] oof =] 2

Divers

Note: Safety Officer shall be permanently on Barge.

ARCHIRODON CONSTRUCTION (OVERSEAS) Co. SA

METHOD Document Ref

STATEMENT or76-ms-o4 | Revision 1 Peeing

Construction of the Abutment by Placing Quarry Rum, Armour Rodi and Concrete Armour

Blocks

5.0 REFERENCES

© System procedure CORP-SYS-O1 Quality Planning

‘System procedure CORP-SYS-02 Control of Documents and Data

General procedure CORP-GEN-04 Procurement of Materials and Services

General procedure CORP-GEN-12 Hazard Analysis-and Environmental Impact

Assessment

General procedure CORP-GEN-15 “Requirements for Safe working at Night”

General procedure CORP- TEC - 02 “Control of Pollution”

General procedure CORP-TEC- 09° “Control of Marine Vessel Access”

General procedure CORP- TEC - 04 “Requirements for safe lifting by Crane”

Project procedure 0151-SP-Ol Control of Inspection and Testing

Project procedure 0151-SP-02 Control of Quality Records

Project plan 0151-PQP-01 Project Quality Plan

Project plan 0151-PSP-O1 Project Health, Safety &Security Plan

Project plan 0151-PEP-O1 Project Environmental Plan

CTIV procedure QGX/20/00/QA/SW/NA/O16 Welding Requirement at Site

CTIV procedure QGX/20/00/QA/PC/NA/002 Inspection Coordination Procedure (With

Subcontractor)

CTIV procedure QGX/20/00/QA/PC/NA/020 QA/OC Requirements for Subcontractors

CTV specification for concrete material, mix and construction QGX/120/00

JCLIDBYNA/008,

© CTIV specification for lifting procedure QGX/120/00/S A/PC/NA/104

60 METHODOLOGY

6.1 Schedule of Work

6.1.1 Construction activities will be carried on a 24-hours basis, and each shift has total duration of

12 hrs but actual working hours will be for 10 hrs,

6.12 The activities will be coordinated closely between Archirodon and CTIV and port authorities,

6.1.3 Archirodon will adhere to RLC safety rules and regulations applicable in the port area

62 Removal of Antifer Cubes from Land and from sea

‘The removal of the Antifer Concrete Cubes will be executed from land for the upper Cubes. It

vill consist of a Mobile crane that will be standing on the edge of the access road on the

breakwater after the removal of the Crown Wall Blocks and will place the removed Cubes

temporary on the edge of the road on the existing rock protection. Cares will be taken to place

them in a safe way not to be broken so we can replace them in the tie in as indicated in

ARCHIRODON CONSTRUCTION (OVERSEAS) Co. SA

METHOD Document Ref, 7 a

STATEMENT 0176: MS-04 Revision 1 l Page 9 of 10

Construction of the Abutment by Placing Quarry Run, Armour Rock and Concrete Armour

Blocks

63

64

65

6.6

drawing No. QGX/27/74/MO/DR/PLI611. The tower and underwater cubes will be removed

by the use of a floating crane and the help of the divers” team. Stocks will be partially placed

on the slopes next to removed ones and on a supply barge and transported by sea to the

laydown atea where they will be properly stocked to be used later as the previous ones.

Installation of screened quarry ran

‘The screened quarry run will be transported to location by supply barges and placing of quarry

run will be by the use of a loader and direct dumping on the slopes to form the core of the

abutment. The surveying team will guide the fill by placing buoy on the edges and developing

the cross section to ensure the correct progress of the works. The slope will be formed by the

slope stability of the rock and the floating crane will assist for the correct formation of the

slopes at the required envelops. This operation will be for the fist 50 meters of the abutment.

For the remaining part where the piles are completed the floating crane will install the quarry

run with the use of a bucket or the scraper as the barge can not enter in between the piles up to

+0.0 elevation. Placing of quarry run from +0.0 up to final elevation will follow the

construction steps as per the attached COWT report ~appendix E (P.64036 ~dated 24/5/2006).

Insfallation of rubble material

At the front in the abutment a one meter layer of rubble material class H (2-20Kg) will be

placed by the use of floating orane. It will be protected by the atmour rocks, on which the

revetment of Concrete Armour Cubes will take place.

Installation of armoured rock

‘The Armour rock wilt be placed by pieces with the bucket of the floating crane using the

Global Positioning System according to drawing coordinates, The divers’ team will assist and

help the placing according to drawings requirement as indicated in Drawing

QGX/27/74/MO/DR/SV/620 for the first 50 meters of the abutment. For the remaining part

where the piles are completed the floating crane will install the armoured rock with the use of a

bucket up to +0.0 elevation. Placing of armoured rock from +0.0 up to final elevation will

follow the construction steps as per the attached COWI report-appendix E (P.64036 ~dated

24/5/2006).

Installation of concrete armoured cubes

Conotete Armour Cubes Type 1, II and II will be placed by the floating came using the Global

Positioning System and the help of the divers’ team for underwater placing and the rocks

placing superintendent for placing above water, according to required porosity for the first 50

meters of the abutment. Por the remaining part where the piles are completed the floating crane

will install the armoured cubes up to +0.0 elevation. Placing of armoured cubes from +0.0 up

‘to final elevation will follow the construction steps as per the attached COW] report ~appendix

E (P.64036 -dated 24/5/2006).

ARCHIRODON CONSTRUCTION (OVERSEAS) Co, SA

6.7

10

7

72

73

METHOD Document Ref

STATEMENT. 0176-MS-04

Construction of the Abutment by Placing Quarry Run, Armour Rock and Concrete Armour

Blocks

Revision 1 Page 10 of 10 |

Placing of structural fl

‘The last portion of the abutment will have to be completed together with the loading platform

deck, small equipment and hand operation will be utilised for a portion of the work under the

concrete deck i.e. the Gunny Bags,

Geotextile membrane will be installed as per specification and according to manufacturer

recommendation.

Structural fill will be placed according to specs and will be compacted in layers as per

requirement including the sequence of tests.

QUALITY CONTROL

The construction and installation works will be surveyed and inspected in accordance with

IFC drawing, Project specifications and approved ITP’s,

All surveys, inspection and testing will be controlled by the project procedure Control of

Inspection and Testing.

Records generated by the inspections and tests will be controlled by the project procedure

Control of Quality Records.

~ END OF TEXT -

ARCEIRODON CONSTRUCTION (OVERSEAS) Co. SA

METHOD ‘Document Ref.

STATEMENT 0176-MS-04

‘See sections 2.2 & 23 for

Issue 1 | control of this appendix

(Construction of the Abutment by Placing Quarry Run, Armour Rockand

Conerete Armour Blocks

APPENDIX A

HAZARD CONTROL PROGRAM

Title

Reference

Rev.

Pee |

CTIV Job Safety Analysis Form

0176-MS-04 ISA

‘eunpaooit euOWLLOIALIS pue MBG 820) IRIED PU APO Ui Puno} aq UED syueWeINbe jLELILEUIAVS pUE (OV SpsAZOH ‘Adid) ABIES UO SUBIC

>uo oun ponoicde ose ysnus ysROKH feNsNpU APO UEKA‘SPUEZEY eoILLeYD 10 feots/ud ‘JeaBO}IG SONAL SEE OY} Jo KYB SION

“oN BNOHATEL AONSONBNS ATLO

pom oy Buguneas aojee ABH APLO UNPA YooUD LEA 6] 286% je LEU Ide0 BSHS APD o} Pevodss oxe suosiod Bu

“21292094840 syngode JostAadng "Uoq2=xP PUA BULAPISUED WHOM JON

Jeotes pue yearion of jsuuesieg sjoaug Josiuedng “uoweMba sO OHNE "HONK ONS ‘SBUNGBOONd AONZOWSN ® SNOLUGNOD ONIONYHO

I BUNGIOOUd LIWYSd WIOM APIO SHI NI STWLSG NUON SNOCUYZVH BOs CawINOae IWACwAd|

(i719) eanemaseiden asHs|

sano 6| (arto) mopuyusedng oundosia

seous Aes (¢| SEG. aime UES SueRT

worse ot | ~Gobeuiy SSH thom WopeTe1I09 1 TosIAedNg Gor Aq pouered) sfenouddy reUONIPRY|

1 ee

ors

2o0eieh 4D seus ysaung| ztoswuedns aor!

‘Bde NO¥INOO| 29% =) Jers ka vst|

unannindas gor WwHsN30| ‘iva eaaTeaBTS SaneR TSOAOTERS foUON,

‘siowioued BOF

=e ecaeecens

BPO|g MounY eyeIOuOD pus FOU INSUIY “Ung KAR Bulssid Pue SiSo|E] JejUy [PACUION pazKjeue Buieg Gor 30 SdKi|

yao 1 30vd aasiaza TI xen VWaryesi-s210 ON ¥SaWNN Sr)

a

20 (0) uonrnnsv05 wopouary = ap By =D

WHOS SISATWNY ALBAVS BOF {eae emcee

EqUOWIYDENY LOL/VN/OAMYS/OOIOZKOD

eT oBeg YSrrO'SIN-OZL0 “ON WSr

ua sonache wan sige ayes poze uo

ini canes wpa

rang 2scu ane panei 6

mua ewer span]

au asi tepone

asies sae wspasuy|

us. aH UPON

22.0) umenaco ronnie undod SISA TWH A13¥S Bor

vp Gebea

SEATS TI]

euatoy osundns worary

‘nuns ewen vpn

ayo ase wopstay

using oie vant]

veg downey uoronony

mms aula won|

est woos 35H woven

euae4 oars won

09 (0) uononnsuoD | verona

ng ono sn payrsta| Lz

pnb pur ous 6

samnyes yauones| &

peusiin » euvessepaunooun| $2

Wao’ SISATUNY ALBz¥S BOF

VsM-0-SWr9Zi070N wer

my Aan paueag yo wonessy

‘Sda18 ALIAILOY|

Isva 40 3ONaNDAS|

BE 2

ve 2B

vorso-snvesio ven ver

Aunnoe oxoge ours ‘Ayanoe onoge oies Aunnoe enoge owes

Aynnse enoge ewes Ayanoe onoge owes ‘Ayange enoge owes

Aynnoe enoge ewes Auanoe onoge owes ‘Ayagoe onoge sues

Ayanoe enoge ewes: Ayanoe enoge owes: Ayagoe enoge owes:

el toy pey Ga]

areapeneexannerel| g

sporpamoaves name»

‘Saas ALIALOV]

o1sva 4o 3ONaND aS)

0 0} wonannste9 verenon bos sisi ALaavS Gor

ARCHIRODON CONSTRUCTION (OVERSEAS) Co. SA

[METHOD Document Ref. fa

STATEMENT 0176-MS-04

1

‘See sections 2.2 & 2.3 for

control of this appendix

|

Construction of the Abutment by Placing Quary Run, Armour Rock and Concrete

Armour Blocks

APPENDIX B

ENVIRONMENTAL IMPACT

STATEMENT

Titte Reference Rex. | Pages

Environmental impact Assessment

0176-MS-04

|

—_

& ARCHIRODON oROUP NY a

cones MANAGED SYSTEM

Fcc Petre CORDON? Hand tas cn ronment pt sesame

Environmental Impact Statement

Project _0176— Berth # 5 — Marine Works

SECTION A- WORK ANALYSIS

PartAi NameofCompany _Archirodon Construction (Overseas) Co. S.A.

Date Prepared _03/01/2007 Bocument Ref. _0176-MS-04

‘Name of Supervisor in Charge _Maged Wad

Numbers and Disciplines of Personnel Carrying Out the Task _1

Workshop / Transport / General Construction Skilled Labour

Part A2 Scope of Work Removing Amtifer blocks and placing Quarry ran, Armour mock

and Concrete Armour Blacks.

Part A3 Sequence of the Work and Significant Potential Adverse Environmental Impacts

| Activity 1 Removal of Antifer Cubes from Land and from sea.

Impact ~OiFleakage’ spillage from the mobile crane and floating erane barge. —

Activity 2 “Installation of screened quarry run

Impact Oil spillage/Leakage from tho mobile crane and Flosting crane barge.

| Activity 3 Installation of rubble material,

Impact ~Oil spillage/Leakage from the mobile crane and Floating crane barge.

Activity 4 Installation of armoured rock.

Activity 5 Installation of concrete armoured cubes.

Impact ~Oil spillage/L.eakage from the mobile crane and Floating crane bar;

Activity 6 “Installation of structural fill

Impact ~ Oil spillage/Leakage from the mobile crane and Flo:

Part A4 Details of Equipment to be Used

Cranes _Floating Crane barge, Mobile crane

Plant Dump trucks, Transport barges, Crane barge, Excavator, Loaders , Flat barges and Tug

Boats. EEE

_Lifting Tackle - Only 3” party certifi

tion lifting tackle will beused

Portable Equipment Survey instruments, Diesel Welders, Oxy-Acy cutting set, Light Tower,

Hand Tools.

& ARCHIRODON GROUP NV

CORPORATE MANAGEMENT SYSTEM

°F ene Proosire CORP-GEN-12 Hazan Analysis end Ersronmental InpactAsesonert

Environmental Impact Statement

Part AS Check List Response delete mapplicable responses Response

1 Hazardous materials No | 9 Dust pollution No

2 Material storage No | 10 Gilpollution Yes

3 Waste disposal No | 11 Chemical pollution No

4 Toxic waste No | 12. Emergency contingency plan Yes

5 Hazardous waste No | 13 Erosion No |

6 Biological waste No | 14 Turbidity No |

7 Chemical waste No | 15 Sedimentation No

8 Noise No | 16 Training required Yes

Part AG Provide further information if Yes to any of the above, or as necessary

10. Oil pollution from mobile crane and floating crane should there be any leakages.

12. Emergency Contingency Methods will be spill trays & Plastic sheets placed under

Machinery. A Contingency plan will be placed on site.

16. Training for the Workforce on Environmental aspects for site construction personnel.

‘Environmental Contingency plan, Prevention of oil Spills & Ground Contamination,

Reduction & minimising noise levels & proper Waste Disposal.

‘Note T Taentify any Material Sajety Data Sheets in Part A7

Note 2 Provide details of any third parties involved, e.g. scaffolders, electricians etc.

Part A7 List the name of each attachment and the number of pages

_______ Pages

‘pages

= pages

pages

= =: pages

Total number of pages including this Environmental Impact Statement pages

Part A8_Roview and approval a ie

‘ABa Prepared Name _Reda Tawfik Company _Archirodon.

Position _ Section Engineer Signature we Geared Date _ 03/01/2007

— Company Archirodon

‘ware Date 03/01/2007

‘ABe Approved Name _Maged Wadie ‘Company _Archirodon 7

Construction Manager Signature \ Loy Date _03/01/2007

Part A9 This Environmental Impact Statement has been communicated to and understood by all

personnel associated with the task.

Approved Name _Adel Monsef __ Compyny _Archirodon

Project Manager Signature __ Date _03/01/2007

Position _HSES. $.H.

Document Ref, 0176-MS-04

CAO COPLENAD-aHOO fos wtstunsocy

jordin porain = ce

roveduay a1q829I01 = ba

e

joedut oyesopous = eq oedutt yeueysqns= zg ped ajqurajormn = Tq __-sopoo waLASSesSE YSN

ee OF

L = 6

anne ef oH 8

i _ L

H a — 9

s

0 ‘Seis [oO Jo WANS dip UT aan Kpwes 16y SATUg SURI HURCOY amp pIoq Wo Idey 9q OF Ty iuoUTTEATION THIS |“

¥ ‘To Furbysay ayy TeIMOS oF ouesD sip TOU IoaUS SHSH|T jo BuNpwaNAs [sex dupe BuMesy | €

¥ air ait Tur aIOjoq aues9 oMp fo woRDdsuy |Z

¥ “i ranBar ace SenwOG puw aur GOUT aah Jo SOuHUATTAEAT| |

ae ‘yore up sompay 03 sauNSKOWA TOMO

eainseayy [OnUe) at0;q ISTH

- es ot

zizlzlcizlele HH MOULOIAUE pup puey on Aunnod sue FupeOY pur aubs9 ongoUT wos oBeye—] HO | |

ayaa tots oN Sysen 9 PEA 10 OAL soamseapy yoxq0} ax0jeq soudusy peyUIUINIO.NAN asIaApY IOwSYTUTIS

Looz/To/eo ete

wag WO pu I

ue] mioxy seqng seyHUY Jo eAOURY T “ON AUANOW PO-SW-9LIO. JPA MUNDO,

STUMSVAW IOMLNOS GNV LNGASSASSY MSRI- d NOLLOTS

juawayeag jedwy [oNOUITOAAN

susossy rod ponouno st ue seiRDty pareny Z1-NE AOD amPAOOAE

IWALSAS INAAEOWNVI ALVAOAHOO .

’AN dNOWO NOTOWHONY wy

eA0u CCE NGraIOD fos masND9g

yoodun yorum

You might also like