Professional Documents

Culture Documents

Fabrication Verification Checklist

Uploaded by

Omar TocmoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fabrication Verification Checklist

Uploaded by

Omar TocmoCopyright:

Available Formats

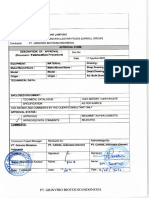

FABRICATION VERIFICATION CHECKLIST

ACCEPTED

ACTION DESCRIPTION RESULTS

YES NO

1 Material Inspection

1.1 Check / Review material certificate / delivery receipt.

1.2 Check material has no significant damage during delivery.

1.3 Check actual material specification as per approved drawings.

2 Steel Preparation

2.1 Check if material to be used is correct as per approved drawing.

2.2 Check if require material is readily available for withdrawal.

3 Material Marking and Cutting

3.1 Check latest drawing revision.

3.2 Ensure fabrication drawing is approved and signed.

3.3 Check layout / pattern /jigs

3.4 Check if correct material used.

3.5 Check if material tagging is correct as per drawing.

4 Drilling and Punching Holes

4.1 Check hole details

4.2 Check required holes as per latest drawing.

4.3 Check if hole diameter is correct.

5 Fit Up / Assembly

5.1 Check latest fabrication drawing

5.2 Check bevel geometry, Gap, tolerances, allignment, squareness

5.3 Check fit up preparation

5.4 Check measurement / layout

6 Dimensional Inspection

6.1 Check dimensional inspection report

7 Welding ( Visual Inspection Acceptance Criteria )

7.1 Crack Prohibition

7.2 Weld Base - Metal Fusion

7.3 Crater Cross Section

7.4 Weld Profiles

7.5 Undercut

7.6 Porosity

8 Cleaning / Surface Preparation

8.1 Ensure no tack weld / temporary weld / millscale.

8.2 No presence of rust scale, oil , grease

8.3 Dry surface, clean and smooth

8.4 No presence of chemical contaminants.

9 Blasting / Painting

9.1 Check paint specification is correct

9.2 Ensure even application of paint

9.3 Ensure require paint thickness is achieved

9.4 Ensure number of coating is followed.

9.5 Ensure that blasting finish requirement is achieved

10 Final Inspection

10.1 Check if Blasting / Painting Criteria is completed.

11 Piece Marking / Tagging

11.1 Check if tagging / marking is correct as per approved drawing.

11.2 Ensure that tagging / marking is understandable.

11.3 Ensure standard location of tagging is followed.

12 Packing and Delivery

12.1 Ensure packing will not damage finish surface.

12.2 Ensure proper packing material is used

Performed by: Noted By:

ROOS QA / QC Engineer / Date ROOS Production Head / Date

You might also like

- Quality Control Procedure SampleDocument12 pagesQuality Control Procedure Samplepocharquitecturaromania92% (50)

- SITE/10/20 Checklist for Screeding ProjectDocument5 pagesSITE/10/20 Checklist for Screeding ProjectAlphaNo ratings yet

- Case Laws IBBIDocument21 pagesCase Laws IBBIAbhinjoy PalNo ratings yet

- Brick&Bolt Quality Assessment System - QASCONDocument24 pagesBrick&Bolt Quality Assessment System - QASCONPulkit ChawlaNo ratings yet

- JIS G3452 PipeDocument0 pagesJIS G3452 PipefaridyeniNo ratings yet

- D3276-00 Standard Guide For Painting Inspectors (Metal Substrates)Document14 pagesD3276-00 Standard Guide For Painting Inspectors (Metal Substrates)kyeong cheol leeNo ratings yet

- Method Statement For Excavation and BackfillingDocument19 pagesMethod Statement For Excavation and BackfillingAbdullah AbdullahNo ratings yet

- Concrete Materials: Properties, Specifications, and TestingFrom EverandConcrete Materials: Properties, Specifications, and TestingRating: 4.5 out of 5 stars4.5/5 (5)

- Appendix A - Specification For Fabrication and Erection of PipingDocument15 pagesAppendix A - Specification For Fabrication and Erection of PipingOmar TocmoNo ratings yet

- Pipe SupportsDocument18 pagesPipe SupportsOmar TocmoNo ratings yet

- FS2005 - Rev.4 Specification For Protective CoatingDocument67 pagesFS2005 - Rev.4 Specification For Protective CoatingRudolph Rednose100% (2)

- 0.ready Mix ConcreteDocument16 pages0.ready Mix ConcreteAguero AgueroNo ratings yet

- Itp Civil WorkDocument9 pagesItp Civil WorkChristian Albert Sinaga RumajarNo ratings yet

- Master Document Register for Majnoon ME&I ProjectDocument15 pagesMaster Document Register for Majnoon ME&I ProjectAbdullah Abdullah100% (1)

- Fire Water Demand PDFDocument28 pagesFire Water Demand PDFOmar TocmoNo ratings yet

- Cpccwf3002a Fix Floor Tiles LRDocument57 pagesCpccwf3002a Fix Floor Tiles LRFfdsfdsNo ratings yet

- Fabrication ProcedureDocument17 pagesFabrication Procedureanang Wahjudi100% (2)

- Piping Support DesignDocument27 pagesPiping Support DesignOmar TocmoNo ratings yet

- Steel Fabrication Method StatementDocument13 pagesSteel Fabrication Method StatementAfiq JamalNo ratings yet

- Duct Elbow Area PDFDocument14 pagesDuct Elbow Area PDFSakthi.pNo ratings yet

- HVAC Duct Installation ProcedureDocument17 pagesHVAC Duct Installation ProcedureResearcher100% (1)

- Field Civil Inspection & Test PlanDocument9 pagesField Civil Inspection & Test PlanChristian Albert Sinaga RumajarNo ratings yet

- Guide to Excavation and Fill Work MethodsDocument11 pagesGuide to Excavation and Fill Work Methods한상호No ratings yet

- Material Submittal For WPCDocument92 pagesMaterial Submittal For WPCdocument PlasmaNo ratings yet

- Approved Drawing - For Construction - T-257Document34 pagesApproved Drawing - For Construction - T-257Omar TocmoNo ratings yet

- Tank Vessel HandbookDocument76 pagesTank Vessel HandbooklsgmzNo ratings yet

- Fire and Gas Detection PhilosophyDocument22 pagesFire and Gas Detection PhilosophyOmar Tocmo100% (3)

- Tendon Grouting - VSLDocument46 pagesTendon Grouting - VSLIrshadYasinNo ratings yet

- Coating Insp ReferenceDocument13 pagesCoating Insp ReferenceDirno Zaidine100% (1)

- Tax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)Document1 pageTax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)Prànita Vailaya100% (1)

- Method Statement FOR Flooring: 10 M - T A&Bc EV - F & Mep WDocument8 pagesMethod Statement FOR Flooring: 10 M - T A&Bc EV - F & Mep WTariq KhattakNo ratings yet

- Support Rev-E8Document132 pagesSupport Rev-E8Omar TocmoNo ratings yet

- Design Standard for FRP StructuresDocument27 pagesDesign Standard for FRP Structuresjdiaz87No ratings yet

- Stainless Steel Tubes Dimensions, Tolerances and Conventional Masses Unit LengthDocument15 pagesStainless Steel Tubes Dimensions, Tolerances and Conventional Masses Unit LengthOctavio Cotillo LubiánNo ratings yet

- Nitrogen RejectionDocument7 pagesNitrogen RejectionOmar TocmoNo ratings yet

- 4 5827923419810760428Document250 pages4 5827923419810760428T M Santhosh KumarNo ratings yet

- Water Proofing Check List Fife RoadDocument3 pagesWater Proofing Check List Fife Road93 Fife ResidenciesNo ratings yet

- Building Check Sheet AuditDocument2 pagesBuilding Check Sheet Auditvicvic VICNo ratings yet

- TABLE OF CONTENTS of PenstockDocument2 pagesTABLE OF CONTENTS of PenstockMadhav Baral100% (1)

- Sample # 1Document3 pagesSample # 1Clarence Ferro100% (1)

- Manzo - Fabrication, Installation and Testing Specification For Pipes, Valves and EquipmentDocument20 pagesManzo - Fabrication, Installation and Testing Specification For Pipes, Valves and EquipmentSenzo NkwanyanaNo ratings yet

- Nilex HDPE Installation Manual PDFDocument19 pagesNilex HDPE Installation Manual PDFĐặng Thịnh NguyễnNo ratings yet

- Inspection and Test Plan of Steel StructureDocument2 pagesInspection and Test Plan of Steel StructureEd Fang100% (1)

- Method Statement For Application of Tiles WorksDocument19 pagesMethod Statement For Application of Tiles WorksHafiz M WaqasNo ratings yet

- 6.1. 2005 Rev5.1Document64 pages6.1. 2005 Rev5.1sumit kumarNo ratings yet

- 09 MaterialsDocument7 pages09 MaterialsMohamedNo ratings yet

- Description 1. Reinforcement: 1. Nomenclature of Item: 2. Structural Drawing No.: 3. Date of CastingDocument2 pagesDescription 1. Reinforcement: 1. Nomenclature of Item: 2. Structural Drawing No.: 3. Date of CastingjitendraNo ratings yet

- Approval Sheet For Concreting WorkDocument3 pagesApproval Sheet For Concreting WorkDushyantha JayawardenaNo ratings yet

- CQM Quality Preparatory SampleDocument5 pagesCQM Quality Preparatory Sampleabdalla el-saadaneyNo ratings yet

- Duct Insulation ChecklistDocument1 pageDuct Insulation ChecklistAnanthuNo ratings yet

- Design Alternative SteelDocument86 pagesDesign Alternative SteelViet Hung NguyenNo ratings yet

- 216-NR Consolidated 2020-07Document263 pages216-NR Consolidated 2020-07Dinar OjakNo ratings yet

- 3.welding Operation InstructionDocument20 pages3.welding Operation Instructionkinfegeta100% (1)

- 01 Vo-2 Specification (R) of Keel Wooden Block (r2)Document7 pages01 Vo-2 Specification (R) of Keel Wooden Block (r2)ssNo ratings yet

- Essential quality checks for building construction materials and RCC workDocument24 pagesEssential quality checks for building construction materials and RCC workKshitij ChaudhariNo ratings yet

- W42 Deck Sign Off Feb 7 2024 - MarconDocument2 pagesW42 Deck Sign Off Feb 7 2024 - Marconjpaal72No ratings yet

- Pipe Insulation ChecklistDocument1 pagePipe Insulation ChecklistAnanthuNo ratings yet

- Ducting ChecklistDocument1 pageDucting ChecklistAnanthuNo ratings yet

- Geonet Quality ManualDocument6 pagesGeonet Quality ManualCESAR_OVIEDOFNo ratings yet

- Specification For Requirements Common To All FabricationsDocument37 pagesSpecification For Requirements Common To All FabricationsPaul BainesNo ratings yet

- Fabrication Method StatementDocument13 pagesFabrication Method StatementTanveer PatilNo ratings yet

- Brick Masonry Project Inspection Batch Quality Acceptance RecordDocument4 pagesBrick Masonry Project Inspection Batch Quality Acceptance RecordAung Thit LwîñNo ratings yet

- Forming Head Procedure GuideDocument8 pagesForming Head Procedure GuideLuhur PrandikaNo ratings yet

- Linea Oblique Weatherboard Horizontal Technical Specification PDFDocument44 pagesLinea Oblique Weatherboard Horizontal Technical Specification PDFVaughn Joseph TarimanNo ratings yet

- SP 008 - Quality Standard For ISOFUSION V700 Glass CoatingsDocument5 pagesSP 008 - Quality Standard For ISOFUSION V700 Glass CoatingsAlexander RichardsonNo ratings yet

- Linea Oblique Weatherboard Vertical Technical SpecificationDocument40 pagesLinea Oblique Weatherboard Vertical Technical SpecificationVaughn Joseph TarimanNo ratings yet

- Yard Readiness Verification Check List BP2-YRV-002.Document5 pagesYard Readiness Verification Check List BP2-YRV-002.DHANEESH VELLILAPULLINo ratings yet

- Project Inspection ChecklistDocument1 pageProject Inspection ChecklistMohamed GamalNo ratings yet

- Materials and welding rules for inland shipsDocument212 pagesMaterials and welding rules for inland shipsNavalPRO Ingeniería NavalNo ratings yet

- Fabrication Procedure - ApprovedDocument12 pagesFabrication Procedure - ApprovedBidang Dalkon QAQCNo ratings yet

- Method Statement For Blasting and PaintingDocument11 pagesMethod Statement For Blasting and PaintingAbdullah Abdullah100% (2)

- Factory Inspections and Acceptance Tests: Guddu Barrage Rehabilitation Project Contract No.-SBIP/G2Document11 pagesFactory Inspections and Acceptance Tests: Guddu Barrage Rehabilitation Project Contract No.-SBIP/G2AmanNo ratings yet

- Method Statement For Surface Preparation, Blasting and PaintingDocument5 pagesMethod Statement For Surface Preparation, Blasting and PaintingPrasenjit DuttaNo ratings yet

- Crescent Dunes Solar Energy Project: Item Component Inspection/Test Sample - Notes Karrena QA/QC DocumentDocument25 pagesCrescent Dunes Solar Energy Project: Item Component Inspection/Test Sample - Notes Karrena QA/QC DocumentSleyda MunozNo ratings yet

- safety2Document17 pagessafety2Omar TocmoNo ratings yet

- Hvac Precommisioning ExecutionDocument13 pagesHvac Precommisioning ExecutionOmar TocmoNo ratings yet

- LR90STDDocument1 pageLR90STDOmar TocmoNo ratings yet

- Erection MethodologyDocument13 pagesErection MethodologyOmar TocmoNo ratings yet

- Pipe Welding ConsumablesDocument1 pagePipe Welding ConsumablesOmar TocmoNo ratings yet

- project specification for fire and gas systemDocument16 pagesproject specification for fire and gas systemOmar TocmoNo ratings yet

- Welding Procedure Specification for 904L Stainless SteelDocument1 pageWelding Procedure Specification for 904L Stainless SteelOmar TocmoNo ratings yet

- All New SpoolDocument3 pagesAll New SpoolOmar TocmoNo ratings yet

- Standard Pipe Sizes ME303-4.1.1Document5 pagesStandard Pipe Sizes ME303-4.1.1manashbdNo ratings yet

- SS304 304L Data SheetDocument2 pagesSS304 304L Data SheetPrakash KumarNo ratings yet

- FURNACESDocument40 pagesFURNACESOmar TocmoNo ratings yet

- EXCHANGERSDocument64 pagesEXCHANGERSOmar TocmoNo ratings yet

- QGX T CS CCS 00353Document22 pagesQGX T CS CCS 00353Omar TocmoNo ratings yet

- INSTRUMENTATIONDocument14 pagesINSTRUMENTATIONOmar TocmoNo ratings yet

- GS Chilling&liquefactionDocument6 pagesGS Chilling&liquefactionOmar TocmoNo ratings yet

- DRUMSDocument17 pagesDRUMSOmar TocmoNo ratings yet

- Piping Connection EquipmentDocument19 pagesPiping Connection EquipmentOmar TocmoNo ratings yet

- Industrial Disputes Act1947 Cases: By: Anil Ashish Topno ROLL NO: 12003 Retail Management 2 YearDocument15 pagesIndustrial Disputes Act1947 Cases: By: Anil Ashish Topno ROLL NO: 12003 Retail Management 2 YearAnil Ashish Topno100% (1)

- PH and ORP Systems: Reliable in Pure Water Treatment ApplicationsDocument10 pagesPH and ORP Systems: Reliable in Pure Water Treatment ApplicationsmateusT850No ratings yet

- 01 04 2018Document55 pages01 04 2018sagarNo ratings yet

- Assessment E - Contract - LaundryDocument5 pagesAssessment E - Contract - LaundrySiddhartha BhusalNo ratings yet

- Practice Questions SheetDocument4 pagesPractice Questions Sheetsaif hasanNo ratings yet

- Crime MappingDocument13 pagesCrime MappingRea Claire QuimnoNo ratings yet

- Architecture Design Planning Undergraduate Postgraduate Guide 2018Document52 pagesArchitecture Design Planning Undergraduate Postgraduate Guide 2018Jack LinNo ratings yet

- Melissas ResumeDocument2 pagesMelissas Resumeapi-329595263No ratings yet

- Improving Control Valve PerformanceDocument5 pagesImproving Control Valve PerformanceBramJanssen76No ratings yet

- SL 70953 Liebert Gxt5 Lithium Ion 1 3kva I 230v Ups User GuideDocument70 pagesSL 70953 Liebert Gxt5 Lithium Ion 1 3kva I 230v Ups User Guidepetermaroko69No ratings yet

- CPS Fitting Stations by County - 22 - 0817Document33 pagesCPS Fitting Stations by County - 22 - 0817Melissa R.No ratings yet

- Pro & Contra Hydropower: AdvantagesDocument16 pagesPro & Contra Hydropower: AdvantagesbarukomkssNo ratings yet

- Casio fx-82MSDocument49 pagesCasio fx-82MSPéter GedeNo ratings yet

- Con Law Koppelman HugeDocument203 pagesCon Law Koppelman HugemrstudynowNo ratings yet

- GTA Liberty City Stories CheatsDocument6 pagesGTA Liberty City Stories CheatsHubbak KhanNo ratings yet

- Student Counseling Management System Project DocumentationDocument4 pagesStudent Counseling Management System Project DocumentationShylandra BhanuNo ratings yet

- MPS LTD Valuation ReportDocument1 pageMPS LTD Valuation ReportSiddharth ShahNo ratings yet

- Chapter 09 SolutionsDocument43 pagesChapter 09 SolutionsDwightLidstromNo ratings yet

- Lect 04Document22 pagesLect 04Beam MoonNo ratings yet

- Rtcclient Tool Quick Guide: Date Jan. 25, 2011Document3 pagesRtcclient Tool Quick Guide: Date Jan. 25, 2011curzNo ratings yet

- File System ImplementationDocument35 pagesFile System ImplementationSát Thủ Vô TìnhNo ratings yet

- Illegitimate Child's Right to Support from FatherDocument1 pageIllegitimate Child's Right to Support from FatherrickmortyNo ratings yet

- Right To Self OrganizationDocument7 pagesRight To Self OrganizationSALMAN JOHAYRNo ratings yet

- Human Behavior in OrganizationDocument85 pagesHuman Behavior in OrganizationNeric Ico Magleo100% (1)

- Legend Sheet P&ID For As-Built - Drafting On 20210722-5Document1 pageLegend Sheet P&ID For As-Built - Drafting On 20210722-5Ludi D. LunarNo ratings yet

- Rule 88 Case Digest #2 Santos vs. Manarang Facts: Don Lucas de Ocampo Died On November 18, 1906Document1 pageRule 88 Case Digest #2 Santos vs. Manarang Facts: Don Lucas de Ocampo Died On November 18, 1906Diane Dee YaneeNo ratings yet