Professional Documents

Culture Documents

5.1-2 GA-A-MK3-7149003-R0-r1

Uploaded by

Hung NguyenOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5.1-2 GA-A-MK3-7149003-R0-r1

Uploaded by

Hung NguyenCopyright:

Available Formats

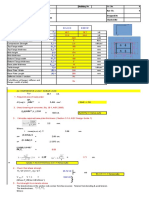

DESIGN CALCULATION FOR SHUTTER / GATE LEAF / STOPLOG ESTIMATION FORMAT NO.

-EF-LPG-CISG-A-102 / A-103-R0 DATED 1/11/2018

DATED : 11/3/2019 GATE SIZE 1500 1500 mm

CLIENT : JFE ENGINEERING CORPORATION, JAPAN LOCATION PUMP WELL CONNECTION GATE

PROJECT : HANOI CITY YEN XA SEWERAGE SYSTEM PROJECT TAG NO. ID NO. 11.3.4

REFERENCE DRG NO.

REVISION NO. & DATE

1 DESIGN DATA :

a) Width of opening = 1500 mm = 1.5 m

b) Height of opening = 1500 mm = 1.5 m

c) Design seating head = 4150 mm = 4.150 m

d) Seating Head on bottom rib = 4900 mm = 4.900 m

e) Design unseating head = 4150 mm = 4.150 m

f) Unseating Head on bottom rib = = 4900 mm = 4.900 m

2 MATERIAL SPECIFICATIONS AND PERMISSIBLE STRESSES :

Reference Documents : AWWA C-560 code of practice for Shutter.

Material used for manufacturing : = CI CLASS B / CI FG-220

The above selected material is used for skin plate, vertical stiffeners and horizontal stiffener of Shutter and have following strength :

Ultimate Tensile Strength TS = 220 Mpa

Ultimate Compressive Stress CS = 770 Mpa

Modulus of Elasticity E = 99,974 Mpa

Factor of Safety FS = 5.00

Allowable Stress = Strength / Factor of Safety

Allowable Tensile Stress = 44 Mpa

Allowable Compressive Stress = 154 Mpa

Based on the ratio of compressive to tensile strength of cast iron.

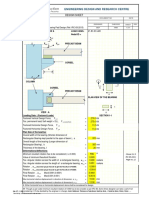

3 BOTTOM RIB STRENGTH AND DEFLECTION

The maximum stresses and the deflection are calculated based on the specified design head. The beam is simply supported with a uniform

water load at the bottom rib.

The "beam" is a composite shape made up of a plate and a trapezoidal rib. The anisotropic properties of cast iron are considered. See the

sketch for dimensions.

T

C TRAPEZOID = T + H - H(2B + A)/(3 (B + A)

C COMP = (C TRAPEZOID x A TRAPEZOID + CFLAT PLATE x A FLAT PLATE)/ TOTAL AREA UNSEATING PRESSURE

H

I FLAT PLATE = W x T3/12 SEATING PRESSURE

I TRAPEZOID = H3(B2 + 4 x B x A + A2)/(36 (B + A) H2

W

S1 = I COMP / CCOMP H3

S2 = I COMP / (H + T - CCOMP )

B A

I COMP DEFLECTION = (CCOMP - CFLAT PLATE)2 x A FLAT PLATE) + ITRAPEZOID + I FLAT PLATE

I COMP = (C TRAPEZOID-CCOMP )2 xA TRAPEZOID+(CCOMP-CFLAT PLATE)2 xA FLAT PLATE) +ITRAPEZOID + IFLAT PLATE

CCOMP

A B H W T H2 H3 Area "C" "I"

Plate 300.00 22.00 6600.00 11.00 266200

Rib 30.00 36.00 125.00 4125.00 82.61 5356297

Handling/Stem Hole 31.80 34.20 59.50 109.50 -1650.00 84.80 -343598.48

Composite 9075.00 30.13 14121298

* The stem hole or handling hole is a very small part of the overall beam. Although stresses are calculated based on the properties through

that section, the value for Moment of Inertia for deflection is based on a solid member.

Therefore, Moment of Inertia based on a section member I = 14121297.9

Moment of Inertia based on a solid member Is = 18638275.9

For Tensile Seating and Compressive Unseating S1= 468687.1

For Compressive Seating and Tensile Unseating S2= 120828.6

The compressive strength and modulus of elasticity are typical values taken from ASM Metals Handbook 9810.000

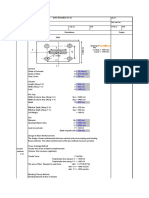

SEATING HEAD TENSILE STRESS

Tensile Stress = (Gate Width2 x Maximum Head x 9810 x W )/8/S1

= 8.65 Mpa

Allowable Tensile Stress = 44 Mpa

SEATING HEAD COMPRESSIVE STRESS

Compressive Stress = (Gate Width2 x Maximum Head x 9810 x W )/8/S2

= 33.57 Mpa

Allowable Compressive Stress = 154 Mpa

UNSEATING HEAD TENSILE STRESS

Tensile Stress = (Gate Width2 x Maximum Head x 9810 x W )/8/S2

= 33.57 Mpa

Allowable Tensile Stress = 44 Mpa

UNSEATING HEAD COMPRESSIVE STRESS

Compressive Stress = (Gate Width2 x Maximum Head x 9810 x W )/8/S1

= 8.65 Mpa

Allowable Compressive Stress = 154 Mpa

BEAM DEFLECTION AT MAXIMUM HEAD

Deflection = (Head on lowest rib x 9810 x beam width x5x width4 x 10^6/(384xExI)

= 0.510 mm

Allowable Deflection = Lesser value of span / 720 and 1.16 mm

= 1.160 mm

The deflection is calculated based on the 'I' and is therefore very conservative.

4 TYPICAL HORIZONTAL RIB STRENGTH AND DEFLECTION :WITHOUT STEM HOLE !

The maximum stresses and the deflection are calculated based on the specified design head. The beam is simply supported with a uniform

water load for the highest loaded rib (next to the bottom one).

H T H T

H2 ( if required)

H3 (if required)

W

W

B A UNSEATING PRESSURE B A UNSEATING PRESSURE

SEATING PRESSURE SEATING PRESSURE

CCOMP CCOMP

WITHOUT STEM HOLE ! WITH STEM HOLE !

C FLAT PLATE = T / 2

C TRAPEZOID = T + H - H(2B + A)/(3 (B + A)

C COMP = (C TRAPEZOID x A TRAPEZOID + CFLAT PLATE x A FLAT PLATE)/ TOTAL AREA

I FLAT PLATE = T x W3/12

I TRAPEZOID = H3(B2 + 4 x B x A + A2)/(36 (B + A)

S1 = I COMP / (H + T - CCOMP )

S2 = I COMP / CCOMP

I COMP DEFLECTION = (CCOMP -CFLAT PLATE)2 x A FLAT PLATE) + ITRAPEZOID + I FLAT PLATE

I COMP = (C TRAPEZOID - CCOMP )2 x A TRAPEZOID + (CFLAT PLATE -CCOMP)2 x A FLAT PLATE) + ITRAPEZOID + I FLAT PLATE

The "beam" is a composite shape made up of a plate and a trapezoidal rib. The anisotropic properties of cast iron are considered. See the

sketch for dimensions.

A B H W T H2 H3 area "C" "I"

Plate 300.00 22.00 6600.00000 11.000 266200.00

Rib 16.00 22.00 125.00 2375.000 81.211 3066748.9

Handling/Stem hole* 23.06 23.06 0.00 0.00 0.000 0.000 0.000

Composite 8975.000 29.579 11942441.4

* The stem hole or handling hole is a very small part of the overall beam. Although stresses are calculated based on the properties through

that section, the value for Moment of Inertia for deflection is based on a solid member.

Therefore, Moment of Inertia based on a section member I = 11942441.4

Moment of Inertia based on a solid member Is = 11942441.4

For Tensile Seating and Compressive Unseating S1= 403742.01

For Compressive Seating and Tensile Unseating S2= 101706.52

The compressive strength and modulus of elasticity are typical values taken from ASM Metals Handbook

SEATING HEAD TENSILE STRESS

Tensile Stress = (Gate Width2 x Maximum Head x 9810 x W )/8/S1

= 10 Mpa

Allowable Tensile Stress = 44 Mpa

SEATING HEAD COMPRESSIVE STRESS

Compressive Stress = (Gate Width2 x Maximum Head x 9810 x W )/8/S2

= 40 Mpa

Allowable compressive stress = = 154 Mpa

UNSEATING HEAD TENSILE STRESS

Tensile Stress = (Gate Width2 x Maximum Head x 9810 x W )/8/S2

= 40 Mpa

Allowable Tensile Stress = 44 Mpa

UNSEATING HEAD COMPRESSIVE STRESS

Compressive Stress = (Gate Width2 x Maximum Head x 9810 x W )/8/S1

= 10 Mpa

Allowable Compressive Stress = = 154 Mpa

BEAM DEFLECTION AT MAXIMUM HEAD

Deflection = (Head on lowest rib x 9810 x beam width x5x width4 x 10^6/(384xExI)

= 0.796 mm

Allowable Deflection = Lesser value of span / 720 and 1.16 mm

1.160 mm

The deflection is calculated based on the 'I' and is therefore very conservative.

You might also like

- AISC2005 Anchor Bolt5 Pin Connection NewDocument6 pagesAISC2005 Anchor Bolt5 Pin Connection NewThuyTranNo ratings yet

- AISC2005 Anchor Bolt5 Pin Connection NewDocument6 pagesAISC2005 Anchor Bolt5 Pin Connection NewThuyTranNo ratings yet

- Project Shabra C Location Al-AinDocument4 pagesProject Shabra C Location Al-AinHareesh KilaruNo ratings yet

- Manual: Engineering Calculation TemplateDocument8 pagesManual: Engineering Calculation TemplateHamiNo ratings yet

- Column Base Plate DesignDocument1 pageColumn Base Plate DesignBunkun15No ratings yet

- FinalDocument33 pagesFinalAnonymous sfkedkymNo ratings yet

- Anchor Bolt Design BP1Document29 pagesAnchor Bolt Design BP1satyakamNo ratings yet

- E TN CBD Aisc Asd89 008Document8 pagesE TN CBD Aisc Asd89 008Alvaro CalacioNo ratings yet

- Design Pad & Chimney Foundation1Document26 pagesDesign Pad & Chimney Foundation1Jule LobresNo ratings yet

- Base Plate Design-1 - J BoltDocument41 pagesBase Plate Design-1 - J BoltGautam PaulNo ratings yet

- Base Plate - IsMB 400Document6 pagesBase Plate - IsMB 400pandianNo ratings yet

- Davit CalculationDocument13 pagesDavit CalculationNiraj PandyaNo ratings yet

- Grit Tank WALL 6M LengthX3.5M Height DesignDocument10 pagesGrit Tank WALL 6M LengthX3.5M Height Designanurag pawarNo ratings yet

- 35M GRD Tower Design Report STCDocument10 pages35M GRD Tower Design Report STCEhtesham AliNo ratings yet

- Pole CalcDocument11 pagesPole CalcMia SaquingNo ratings yet

- Dokumen - Tips Design Pad Chimney Foundation1Document26 pagesDokumen - Tips Design Pad Chimney Foundation1Sharookhan ShajahanNo ratings yet

- Annexure - Bolt Torque CalculationDocument4 pagesAnnexure - Bolt Torque CalculationDarshan PanchalNo ratings yet

- 3 Splice-Ismb500 FinalDocument7 pages3 Splice-Ismb500 FinalAvishek DeyNo ratings yet

- 8.arch Main MemberDocument3 pages8.arch Main MembervibishnanNo ratings yet

- Steel End/Base Plate & Anchor Bolts Analysis & DesignDocument6 pagesSteel End/Base Plate & Anchor Bolts Analysis & DesignRey GonzalesNo ratings yet

- Baseplate-Kolom wf250Document79 pagesBaseplate-Kolom wf250Gary JonathanNo ratings yet

- 1 - SPLICE-WPB 700X300X204.5 - DraftDocument7 pages1 - SPLICE-WPB 700X300X204.5 - DraftAvishek DeyNo ratings yet

- Staircase Design FinalDocument18 pagesStaircase Design FinalSiddiqui RanaNo ratings yet

- Vertical Thrust - Upward 90Mm PipeDocument7 pagesVertical Thrust - Upward 90Mm PipeMukhlish AkhatarNo ratings yet

- Pad Footing 60M Kg. Air PanasDocument9 pagesPad Footing 60M Kg. Air PanasNurul SyafiqahNo ratings yet

- Calculation Sheet: 71197 Design For Pile Cap - Two Piles PP DJM MVLDocument3 pagesCalculation Sheet: 71197 Design For Pile Cap - Two Piles PP DJM MVLbhaskardharani50% (2)

- Steel End/Base Plate & Anchor Bolts Analysis & DesignDocument6 pagesSteel End/Base Plate & Anchor Bolts Analysis & DesignRey GonzalesNo ratings yet

- Base Plate Design As Per Is 800Document3 pagesBase Plate Design As Per Is 800K SrikanthNo ratings yet

- Retaining Wall - 8m With Traffic LoadDocument17 pagesRetaining Wall - 8m With Traffic LoadDev lamichhaneNo ratings yet

- Gantry Grider FinalDocument8 pagesGantry Grider Finalasvenk309No ratings yet

- Factored Reaction (W) Factored Tensile Force On The Plate W/2Document8 pagesFactored Reaction (W) Factored Tensile Force On The Plate W/2Sudhanshu Shekhar SinglaNo ratings yet

- Cantilever Beam Design - PipeDocument1 pageCantilever Beam Design - Pipeberylqz5878No ratings yet

- This Sheet Designs The Conductor Cone Guides Used in The MFP Jacket.Document3 pagesThis Sheet Designs The Conductor Cone Guides Used in The MFP Jacket.Thomas StephenNo ratings yet

- Blast Wall by Yield Line AnalysisDocument1 pageBlast Wall by Yield Line Analysisnazeer_mohdNo ratings yet

- Bearing DesignDocument24 pagesBearing DesignPrabhakaran KarunanithiNo ratings yet

- Vdocuments - MX - Rectangular Tank CalculationDocument53 pagesVdocuments - MX - Rectangular Tank Calculationrodel lauronNo ratings yet

- THAIOIL - BEAM TO COLUMN - END PLATE - BOLTED - 006 - Rev BDocument15 pagesTHAIOIL - BEAM TO COLUMN - END PLATE - BOLTED - 006 - Rev BCivil StructureNo ratings yet

- Larsen & Toubro Limited Ecc Division: Transformer Transportation On Solding Khad Bridge Design Review of PierDocument3 pagesLarsen & Toubro Limited Ecc Division: Transformer Transportation On Solding Khad Bridge Design Review of PiervibishnanNo ratings yet

- Calculation For Quick Opening Closure: Design ConditionDocument5 pagesCalculation For Quick Opening Closure: Design ConditionA.K.100% (3)

- Base Slab Design - RampDocument6 pagesBase Slab Design - RampSuresh Mahalingam100% (1)

- EA - Check of Anchorage Zone in Post Tension Slab ECP 203-2020 v1.0Document2 pagesEA - Check of Anchorage Zone in Post Tension Slab ECP 203-2020 v1.0S DuttaNo ratings yet

- Icr SpreadsheetDocument4 pagesIcr SpreadsheetTommy SidebottomNo ratings yet

- Casing Hanger Calculation PDFDocument3 pagesCasing Hanger Calculation PDFMinhaj AkbarNo ratings yet

- 5 PilecapDocument6 pages5 PilecapMaheshNo ratings yet

- Anchor Bolt-Pinned ConnectionDocument7 pagesAnchor Bolt-Pinned ConnectionThắngg TrịnhhNo ratings yet

- Appendix A11Document3 pagesAppendix A11Thomas StephenNo ratings yet

- Design of Pad & Chimney FoundationDocument26 pagesDesign of Pad & Chimney FoundationTulsi LakhaniNo ratings yet

- Design Sheet: View A Load Case= Nodal ID = α F F F Precast BeamDocument5 pagesDesign Sheet: View A Load Case= Nodal ID = α F F F Precast BeamGanesh PrabuNo ratings yet

- Steel Design - SAP 2000Document5 pagesSteel Design - SAP 2000Nayolle CoelhoNo ratings yet

- Lecture 1 - Axial Stress and Strain - 3Document26 pagesLecture 1 - Axial Stress and Strain - 3Alvin DeliroNo ratings yet

- Direction X and Y: Betaun Armadu II - 24Document5 pagesDirection X and Y: Betaun Armadu II - 24Anonymous fj1w85No ratings yet

- To Do - DS-H - Supporting Beam - W8X18 - W8X18Document15 pagesTo Do - DS-H - Supporting Beam - W8X18 - W8X18amitNo ratings yet

- Louvers 1Document7 pagesLouvers 1alex robinNo ratings yet

- Staircase Design With TEDDSDocument3 pagesStaircase Design With TEDDSAmadi HenryNo ratings yet

- To Do - DS - LRFD - Supporting Beam - W8X18 - W8X18Document15 pagesTo Do - DS - LRFD - Supporting Beam - W8X18 - W8X18amitNo ratings yet

- Raft 1Document19 pagesRaft 1Kushan Dhanushka NanayakkaraNo ratings yet

- Column ConnectionDocument14 pagesColumn Connectionabhi aroteNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Problemas Cap 4Document20 pagesProblemas Cap 4maria garridoNo ratings yet

- 06-SpiritAerosys Boshers PaperDocument28 pages06-SpiritAerosys Boshers PaperCan YörütenNo ratings yet

- Strength of Materials - MCQDocument11 pagesStrength of Materials - MCQsudheer92100% (2)

- MEC302 Thermodynamics 04: University of Mumbai, B. E. (Mechanical Engineering), Rev 2016Document34 pagesMEC302 Thermodynamics 04: University of Mumbai, B. E. (Mechanical Engineering), Rev 2016BALAJI IKALENo ratings yet

- New Methodology For Calculating Damage Variables Evolution in Plastic Damage Model For RC StructuresDocument18 pagesNew Methodology For Calculating Damage Variables Evolution in Plastic Damage Model For RC Structuresno_milk_todayNo ratings yet

- Zone of Infulence For Tunnel Intersection1Document32 pagesZone of Infulence For Tunnel Intersection1roshansm1978No ratings yet

- ABE 51 Case StudyDocument5 pagesABE 51 Case StudyKimberly Jane MitraNo ratings yet

- HW5 ch6 2011x PDFDocument8 pagesHW5 ch6 2011x PDFMaryam Allayne AbastasNo ratings yet

- Indian Standard: Specification For Aluminium Conductors For Overhead Transmission PurposesDocument17 pagesIndian Standard: Specification For Aluminium Conductors For Overhead Transmission Purposesnitin369No ratings yet

- Model Question Paper - 3: Civil Engineering Exam InfoDocument10 pagesModel Question Paper - 3: Civil Engineering Exam InfoneerajakshaNo ratings yet

- Prediction of Elasto-Plastic Behavior of CRM CylinderDocument17 pagesPrediction of Elasto-Plastic Behavior of CRM CylinderDomnica StanciuNo ratings yet

- Physics Muster PDFDocument36 pagesPhysics Muster PDFMarlon FariaNo ratings yet

- Starch MD2020Document10 pagesStarch MD2020Poornima RNo ratings yet

- Influence of Different Additives On ColdDocument7 pagesInfluence of Different Additives On ColdMILON KUMAR HORENo ratings yet

- Quasi-Static Three-Point Beniding of Carbon Fiber Sandwich Beams With Square Honeycomb CoresDocument15 pagesQuasi-Static Three-Point Beniding of Carbon Fiber Sandwich Beams With Square Honeycomb CoresstaedtlerpNo ratings yet

- Ncert Physics Part - 2 11thDocument160 pagesNcert Physics Part - 2 11thvarunNo ratings yet

- 435R-95 Control of Deflection in Concrete StructuresDocument89 pages435R-95 Control of Deflection in Concrete StructuresIbrahim MNo ratings yet

- Deep Drawing Literature ReviewDocument37 pagesDeep Drawing Literature ReviewS T100% (3)

- Elastic Electronic Vibrational and Optical Properties of Filled Skutterudite Compound SrRu4As12 2020Document27 pagesElastic Electronic Vibrational and Optical Properties of Filled Skutterudite Compound SrRu4As12 2020ahlamNo ratings yet

- Comparison of Flexible Pavement PerformaDocument8 pagesComparison of Flexible Pavement PerformaHeriberto CastañedaNo ratings yet

- FMC - Novolastic Subsea Thermal Insulation - LOW RESDocument3 pagesFMC - Novolastic Subsea Thermal Insulation - LOW RESalphading50% (2)

- Short Term DeflectionDocument11 pagesShort Term DeflectionRikson TandelilinNo ratings yet

- Material Testing LabDocument79 pagesMaterial Testing LabBrijesh VermaNo ratings yet

- MF 04Document21 pagesMF 04Carlos De la CruzNo ratings yet

- Mechanics of Materials Lab 1-Zip Tie Tensile TestingDocument7 pagesMechanics of Materials Lab 1-Zip Tie Tensile TestingcoolshavaNo ratings yet

- Analysis of Strip Residual CurvaturesDocument9 pagesAnalysis of Strip Residual CurvaturesSachin JadhavNo ratings yet

- Stability of SpeedCore Walls Under Fire Loading Summary of Numerical AnalysesDocument13 pagesStability of SpeedCore Walls Under Fire Loading Summary of Numerical Analysesjackcan501No ratings yet

- Monocoque Racecar Frame - MacleishDocument17 pagesMonocoque Racecar Frame - MacleishRoberto PulinaNo ratings yet

- ASTM D6758-08 Standard Test Method For Measuring Stiffness and Apparent Modulus of Soil and Soil-Aggregate In-Place by Electro-Mechanical Method PDFDocument5 pagesASTM D6758-08 Standard Test Method For Measuring Stiffness and Apparent Modulus of Soil and Soil-Aggregate In-Place by Electro-Mechanical Method PDFgtddyNo ratings yet

- Exercises On Fracture MechanicsDocument33 pagesExercises On Fracture Mechanicsyaswanth199260% (5)