Professional Documents

Culture Documents

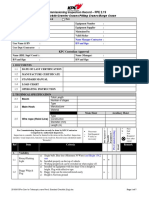

PTC Audit Checksheet 20220909

Uploaded by

yeucongnghemoiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PTC Audit Checksheet 20220909

Uploaded by

yeucongnghemoiCopyright:

Available Formats

[ PTC ]

■ Vendor : ■ Audit Date : ■ Auditor : Nguyễn

■ Audit Model : ■ Part Code :

Management standards and method Measurement Result Data

NO Inspection item Inspection details Quality issue Symptoms

Standards Method Cycle Sample 1 (First) Sample 2 (Middle) Sample 3 (Last)

※ Assembly hole inspecting Jig

- Is CTF/CTP inspection conducted by stand

CTF/CTP production? No size issue / Exterior First/interim/Final

① Management size . Check CTF/CTP inspection result by injection quality Product Inspection

by LOT

production LOT

※ Corner strength: 3kgf or more

- Is the quality of corner strength controlled by Lot?

Corner strength quality of corner

② verification

. Quality control for corner strength shall be

conducted

strength

Push-Pull gauge by LOT

- Is flash on gate area inspection conducted?

. 2021 : Front Direct structure applied,

Inspection for Flash on Attached Double sided Tape for cell comes off Flash inspection by

③ the front direct Gate when Flash occurs gate by LOT

area (Cell falls off/ Risk of damage)

Cell falls off/ Risk of

damage ※ Tape attaching area shall be washed with ethanol

- Is ethanol washing process to remove foreign

substance on the cell attaching Double sided Tape

area conducted? Ethanol washing by

④ . Use the cotton dipped in ethanol to wash

※ Ethanol code : 0204-006855

2 side tape attaching

area

by LOT

. Use 100% ethanol (No water mixed)

※ Tape attaching JIG shall be used

- Is JIG for attaching used in Double sided Tape

attaching? First/interim/Final

⑤ . Attach tape with JIG for attachment in order to Product Inspection

by LOT

Double sided Tape for prevent mis-attachment

cell attaching

After cell assembly,

Tape gets out of the

exterior surface and

absorbs foreign

substance (Pe Bag,

Cushion foreign

substance)

Double sided Tape for

cell attaching

Management standards and method Measurement Result Data

NO Inspection item Inspection details Quality

After issue

cell assembly, Symptoms

Tape gets out of the Standards Method Cycle Sample 1 (First) Sample 2 (Middle) Sample 3 (Last)

exterior surface and ※ Location of Tape attaching

absorbs foreign and Gap shall satisfy the management criteria

substance (Pe Bag, (See PLM work spec for detailed management standard by code)

Cushion foreign

substance)

- Does the gap in Tape attaching area follow the

work spec? First/interim/Final

⑥ . All work spec and management criteria by Codes

shall be satisfied

Product Inspection by LOT

※ See PLM work spec for detailed spec by inches

※ Keep initial/interim/final product by production process in

storage and write inspection result.

- Is quality management initial/interim/final product (Manage inspection result through Check Sheet)

conducted properly?

First/interim/Final First/interim/Final First/interim/Final

⑦ Product

. Keep initial/interim/final product by production

process in storage and manage according to

Product Product Inspection

by LOT

inspection item in check sheet?

※ UL restrictions shall be met

- Are UL Label properly attached and managed

according to its spec?

. Injection vendor achieves UL certificate &

standard injection label is attached UL restriction not

⑧ UL Label . UL restrictions: Resin vendors, Resin name, fire followed UL Label inspection by LOT

retardant grade

. VD) Management: Vendor name, part code,

production date and etc.

※ No remaining oil

(Conduct inspection with absorbing film)

- Is inspection with remaining oil absorbing film from Crack from flown remaining oil

⑨ Remaining Oil manafactured LOT conducted and check if Oil and

chemical solvent used follow the work instructions?

remaining oil and

screen issue

inspection with

absorbing film

by LOT

- Is the quality of the supplied goods secured?

Stacking/packing for - No Damage on parts mixed ※Secure supply truck quality Secure supply truck

⑩ truck (Wrapping) - Record Code-No & amount, Lot-No in parts detail

- No sealing and tear in Wrapping

material/Foreign

substance

(Damade, details, Wrapping) quality by LOT

(Foreign substance/dust prevention)

You might also like

- Understanding and Servicing Alarm SystemsFrom EverandUnderstanding and Servicing Alarm SystemsRating: 1 out of 5 stars1/5 (1)

- Overhead Crane Inspection ProceduresDocument5 pagesOverhead Crane Inspection ProceduresRonniNo ratings yet

- Settlement Agreement NFL, Rams, St. LouisDocument4 pagesSettlement Agreement NFL, Rams, St. LouisKSDK100% (1)

- Acacia School Development Plan Proposal v4Document40 pagesAcacia School Development Plan Proposal v4Tim EburneNo ratings yet

- Inspection Procedure: Grillon LanyardDocument5 pagesInspection Procedure: Grillon LanyardUlviyye ElesgerovaNo ratings yet

- Impressed Current CP Quality Control and Inspection Report FormDocument1 pageImpressed Current CP Quality Control and Inspection Report FormBiswasNo ratings yet

- Verif EPI GRIGRI Procedure enDocument3 pagesVerif EPI GRIGRI Procedure eninternetNo ratings yet

- 2.1. - Chantaplex-Technical Specification Fenolico Negro 18 MM 23-12-2021Document1 page2.1. - Chantaplex-Technical Specification Fenolico Negro 18 MM 23-12-2021Thais Yulisa Huamani HilarioNo ratings yet

- Chantaplex-Technical Specification Fenolico Negro 18 MM 23-12-2021Document1 pageChantaplex-Technical Specification Fenolico Negro 18 MM 23-12-2021Thais Yulisa Huamani HilarioNo ratings yet

- Inspection and Maintenance of Drill PipeDocument39 pagesInspection and Maintenance of Drill PipeinsaanNo ratings yet

- Point Multipoint PON Testing - enDocument10 pagesPoint Multipoint PON Testing - enMalleswar YallambhotlaNo ratings yet

- Checks and Maintenance AM120iC-12LDocument16 pagesChecks and Maintenance AM120iC-12LDaniel GarciaNo ratings yet

- 2305-0-18456-Po 14523644Document2 pages2305-0-18456-Po 14523644Alfonso LopezNo ratings yet

- Cur Soar Condicion A Do AutoDocument37 pagesCur Soar Condicion A Do AutoFabio Adriana FláviaNo ratings yet

- 1-A4-IWAPS 20191017 TEL Hiromitsu Maejima Final HandoutDocument30 pages1-A4-IWAPS 20191017 TEL Hiromitsu Maejima Final Handout富美徐No ratings yet

- Trial Run of Motor and Panels - 26.04.2019 - FinalDocument7 pagesTrial Run of Motor and Panels - 26.04.2019 - FinalChiranjit BhattacharjeeNo ratings yet

- Non Destructive Testing: Principal Features of The Main NDT MethodsDocument48 pagesNon Destructive Testing: Principal Features of The Main NDT MethodsdayalramNo ratings yet

- CDR212868 U625 Inop 7-30-2021Document32 pagesCDR212868 U625 Inop 7-30-2021Gustavo ArriolaNo ratings yet

- Inspection and Maintenance of Drillpipe E-BookDocument39 pagesInspection and Maintenance of Drillpipe E-BookPhan Trong HuanNo ratings yet

- Ijin ListrikDocument1 pageIjin ListrikBayu Rengga CendymardanaNo ratings yet

- Bael CHP Crane ReportDocument4 pagesBael CHP Crane ReportYonten WangchukNo ratings yet

- Foreign material presence Chefsen 10142344-108KLF V3Document13 pagesForeign material presence Chefsen 10142344-108KLF V3g.cuachaNo ratings yet

- Report Sample - Pre-Shipment Inspection-ThermometerDocument30 pagesReport Sample - Pre-Shipment Inspection-ThermometerCarlosSánchezNo ratings yet

- Gen Spider - : Robot For Turbine Generator InspectionDocument2 pagesGen Spider - : Robot For Turbine Generator InspectionLeandro AriasNo ratings yet

- B737 NG 600-7-8 9 BBJ Cockpit Guide Compacn (19!7!10) PDFDocument604 pagesB737 NG 600-7-8 9 BBJ Cockpit Guide Compacn (19!7!10) PDFMe Keen100% (1)

- Exterior Inspection B737-800Document14 pagesExterior Inspection B737-800Me KeenNo ratings yet

- LK 6. Engine Management System Vehicle Data: BBPP MPV BMTI/Automotive Reskilling & Upskilling 2020Document5 pagesLK 6. Engine Management System Vehicle Data: BBPP MPV BMTI/Automotive Reskilling & Upskilling 2020murti sapto wahyudiNo ratings yet

- Work Instruction: Item Inspection Characteristics Defect Limit Sample No. 1Document4 pagesWork Instruction: Item Inspection Characteristics Defect Limit Sample No. 1Đỗ Thành NhươngNo ratings yet

- CMPak 4G - 4T4R Upgrade and 4T6S - Sector Split Verification - 21!02!2019 - 4361 - CDocument10 pagesCMPak 4G - 4T4R Upgrade and 4T6S - Sector Split Verification - 21!02!2019 - 4361 - CFalconkhanNo ratings yet

- Verif Epi Protraxion Procedure enDocument4 pagesVerif Epi Protraxion Procedure eninternetNo ratings yet

- CBC AuditDocument4 pagesCBC Auditfrenz2kiranNo ratings yet

- SOP Mobile Crane-Rev.1Document7 pagesSOP Mobile Crane-Rev.1RonniNo ratings yet

- (IQC) LG (67) - G3-1214 - Grille Assembly Discharge - Detailed Inspection ProcedureDocument15 pages(IQC) LG (67) - G3-1214 - Grille Assembly Discharge - Detailed Inspection ProcedureAnonymous Lta32Ta9No ratings yet

- Check List Blasting & Painting Inspection Tools: Tripatra-Samsung ConsortiumDocument1 pageCheck List Blasting & Painting Inspection Tools: Tripatra-Samsung ConsortiumHeri FebriyantoNo ratings yet

- Mobilink Project On Site Swap SOPDocument17 pagesMobilink Project On Site Swap SOPAung Min Soe100% (1)

- DWG Insulator PolymerDocument60 pagesDWG Insulator Polymerbagja wigunaNo ratings yet

- 2305-0-18453-Po 14521828Document2 pages2305-0-18453-Po 14521828Alfonso LopezNo ratings yet

- Mẫu báo cáo nghiệm thu khởi động máyDocument13 pagesMẫu báo cáo nghiệm thu khởi động máyduccanh98.hustNo ratings yet

- National Highways Authority of IndiaDocument1 pageNational Highways Authority of IndiajitendraNo ratings yet

- Telescopic Mobile/Crawler Cranes/Pilling Cranes/Barge Crane: Pre-Commissioning Inspection Record - FPE 2.19Document7 pagesTelescopic Mobile/Crawler Cranes/Pilling Cranes/Barge Crane: Pre-Commissioning Inspection Record - FPE 2.19arie.febryanNo ratings yet

- Magnetic Level GaugeDocument20 pagesMagnetic Level Gaugeمحمد رمضانNo ratings yet

- Jensen Vm9213Document40 pagesJensen Vm9213boroda2410No ratings yet

- En13032 1 2004ac 2005Document67 pagesEn13032 1 2004ac 2005bishoyNo ratings yet

- IRIS NV Elevator Maintenance Manual SectionsDocument12 pagesIRIS NV Elevator Maintenance Manual SectionsAndiosoNo ratings yet

- Drilling String InspectionDocument7 pagesDrilling String Inspectionrais ridha100% (2)

- Q-MAP (Ver - 5) - EngDocument20 pagesQ-MAP (Ver - 5) - EngyeucongnghemoiNo ratings yet

- 26071-JO-HSE-PMOB-007 Portable Generator R001Document1 page26071-JO-HSE-PMOB-007 Portable Generator R001dea tiaraNo ratings yet

- 2018-Poster Evaluation of The Tightness of A Closed System Needleless Connector Qimono VygonDocument1 page2018-Poster Evaluation of The Tightness of A Closed System Needleless Connector Qimono VygonmochkurniawanNo ratings yet

- Process and Product Audit Check ListDocument5 pagesProcess and Product Audit Check ListRudrappa VeerabhadrappaNo ratings yet

- Pre-Shipment Inspection: Product PhotoDocument35 pagesPre-Shipment Inspection: Product Photo123456No ratings yet

- Ongoing Road Inspection ReportDocument13 pagesOngoing Road Inspection ReportARTI PALEKARNo ratings yet

- FMEA Analysis of Rear Wiper AssemblyDocument1 pageFMEA Analysis of Rear Wiper AssemblySridhar DineshNo ratings yet

- Megger Test FormDocument1 pageMegger Test FormJHON CHRISTOPHER CENTINONo ratings yet

- Quantum Performance Report: 0 Base Unit ModuleDocument9 pagesQuantum Performance Report: 0 Base Unit ModuleMasih TukaranNo ratings yet

- Image StabilizationDocument3 pagesImage StabilizationDiego CNo ratings yet

- (IQC) LG (67) - G3-1213 - Decor Assembly - Detailed Inspection ProcedureDocument10 pages(IQC) LG (67) - G3-1213 - Decor Assembly - Detailed Inspection ProcedureAnonymous Lta32Ta9No ratings yet

- National Highways Authority of IndiaDocument1 pageNational Highways Authority of IndiajitendraNo ratings yet

- High Efficiency RF and Microwave Solid State Power AmplifiersFrom EverandHigh Efficiency RF and Microwave Solid State Power AmplifiersRating: 1 out of 5 stars1/5 (1)

- Automotive Actuators and EVAP System TestingFrom EverandAutomotive Actuators and EVAP System TestingRating: 4.5 out of 5 stars4.5/5 (4)

- Guide supplier data registration in G-SRMDocument24 pagesGuide supplier data registration in G-SRMyeucongnghemoiNo ratings yet

- Regulations for Exterior Defects Standard (RevisedDocument43 pagesRegulations for Exterior Defects Standard (RevisedyeucongnghemoiNo ratings yet

- Q-MAP (Ver - 5) - EngDocument20 pagesQ-MAP (Ver - 5) - EngyeucongnghemoiNo ratings yet

- MTC audit data analysisDocument2 pagesMTC audit data analysisyeucongnghemoiNo ratings yet

- HelmenthsDocument38 pagesHelmenthsKarwanNo ratings yet

- Admin Upload Food Processing Industry in India August 2013Document31 pagesAdmin Upload Food Processing Industry in India August 2013pv1977No ratings yet

- Action PlanDocument3 pagesAction PlanMaki BalisiNo ratings yet

- Catalogo Tecnico Toyota BT Staxio P Series SPE120 200Document4 pagesCatalogo Tecnico Toyota BT Staxio P Series SPE120 200Asesor ComercialNo ratings yet

- Well Construction Journal - May/June 2014Document28 pagesWell Construction Journal - May/June 2014Venture PublishingNo ratings yet

- Tall Buildings Case Studies of John Hancock Centre and Sears TowerDocument75 pagesTall Buildings Case Studies of John Hancock Centre and Sears TowerShanikAromgottilNo ratings yet

- Computerized Scholarship Monitoring SystemDocument11 pagesComputerized Scholarship Monitoring SystemCharles VegasNo ratings yet

- Recorder SongsDocument15 pagesRecorder SongsBich LeNo ratings yet

- Construction Contract SummaryDocument2 pagesConstruction Contract SummaryKerwin LeonidaNo ratings yet

- About The Rosary of Our LadyDocument2 pagesAbout The Rosary of Our LadyINONG235No ratings yet

- Kaynes Presention - BMDDocument18 pagesKaynes Presention - BMDArvind NangareNo ratings yet

- Corporate Finance I - Lecture 7bDocument20 pagesCorporate Finance I - Lecture 7bSandra BempongNo ratings yet

- Four Modes of DeliveryDocument21 pagesFour Modes of DeliveryRyan AbellaNo ratings yet

- SCHNEIDER NABCEP PV Resource Guide 10 4 16 W PDFDocument174 pagesSCHNEIDER NABCEP PV Resource Guide 10 4 16 W PDFbacuoc.nguyen356100% (1)

- Effect of Smell in Space PerceptionDocument8 pagesEffect of Smell in Space PerceptionApoorva KalraNo ratings yet

- Nick & Sammy - Baby You Love Me (Bass Tab)Document6 pagesNick & Sammy - Baby You Love Me (Bass Tab)Martin MalenfantNo ratings yet

- Chapter 4 Literature ReviewDocument5 pagesChapter 4 Literature ReviewAzhar Mahmood MahmoodNo ratings yet

- Module 9 PresentationDocument28 pagesModule 9 PresentationJerico CastilloNo ratings yet

- Kinsey Crimes and ConsequencesDocument370 pagesKinsey Crimes and ConsequencesMirela ZahNo ratings yet

- 4g 6 Traits Writing Rubric StudentDocument3 pages4g 6 Traits Writing Rubric Studentapi-295344358No ratings yet

- Telecom Business Information System AbstractDocument5 pagesTelecom Business Information System AbstractTelika RamuNo ratings yet

- EN Flower Valley Shawl by Joanna GrzelakDocument20 pagesEN Flower Valley Shawl by Joanna GrzelaklunajakovNo ratings yet

- P3am 7642 enDocument205 pagesP3am 7642 enAmine SEMRANINo ratings yet

- Shot List TemplateDocument2 pagesShot List Templateapi-525636391No ratings yet

- Renaissance Political CultureDocument28 pagesRenaissance Political CultureRuben K. JusteNo ratings yet

- At MCQ Salogsacol Auditing Theory Multiple ChoiceDocument32 pagesAt MCQ Salogsacol Auditing Theory Multiple Choicealmira garciaNo ratings yet

- Hand Soap CDCDocument2 pagesHand Soap CDCswesty100% (1)