Professional Documents

Culture Documents

Internship Report on Housing Development Project

Uploaded by

Riyaad MandisaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Internship Report on Housing Development Project

Uploaded by

Riyaad MandisaCopyright:

Available Formats

INTERNSHIP FINAL REPORT

CHAPTER ONE

1. BACKGROUND OF ORGANIZATION

Introduction

The housing shortage is among one of the most critical problems of the Harari Regional State. As

per the study of Regional Government there is a shortage of 10000 houses. In addition to this the

quality of the available housing was very low.

The state of housing situation therefore impels the strong intervention to expand construction

and create capacity in this area .In addition to shortage of housing, the high rate of unemployment,

the low level of the construction sector, and etc. lie among the most critical problems of the

Region.

Therefore, the Harari Regional State has been drafted a strategy to avail land to housing

cooperatives, individual house builders and real estate developers. To this effect Harari Housing

Development Project Office [HHDPO] were established by the proclamation number 56/1998 of

the Harari Regional State. Its mission is to oversee the construction of 8,140 houses, and execute

the goals set for the coming 4-5 years. It has an organisational structure that corresponds to its

major tasks. Based upon these broad missions for the five years, justification, overall objective,

goals, major targets and principles regarding house transfer and its executions are stated as

follows.

1. Background Housing Development Project

Project office

office

1.1 Overview of the company

1.11 Vision

The vision of this project is to make a real difference to peoples’ lives by promoting sustainable

communities. By:

Promoting good practice in housing management, and

Supporting the delivery of quality housing in well-designed neighborhoods.

MURAD AND BEKA 1

INTERNSHIP FINAL REPORT

1.1.

1.1.2 Mission

Play a significant role in the construction sector.

Increase its organizational strength by recruiting professionals, who will have at their

disposal advanced, state of the art machineries.

Take an active part in the nation’s real estate development thus ensuring maximum

customer satisfaction.

To solve the housing problem of the region, to create essential conditions that enable

the construction of houses in the existing parts of the region and in expansion areas.

Reduce unemployment problems and improve income of the residents based on the

government’s housing development program; in particular expand micro and small

enterprises in metal and woodwork and in the production of construction materials

sectors and etc. with a view of expanding employment and improving income.

1.1.3 Overall Objective of the Organization

1. Step by step solve the deteriorating accommodation problem in the city and improve

the city residents’ living standard.

2. Renew and upgrade the slum areas and decaying parts of the city.

3. Reduce unemployment problems and improve income of the residents based on the

government’s housing development program; in particular expand micro and small

enterprises in metal and woodwork and in the production of construction materials

sectors and etc. with a view of expanding employment and improving income.

4. Strengthen the construction industry and improve the vocational training systems.

5. Ensure fair wealth creation and distribution by constructing houses for low-income

households and ensuring tenure security.

1.2 Main products and service of the company

1.2.1 Features and facilities of modern cultural houses

In achieving an attractive appearance and comfortable floor plan, combines

traditional and the best of today’s design.

MURAD AND BEKA 2

INTERNSHIP FINAL REPORT

The master suite has a study/bath, dressing and outer balcony.

The opening through the kitchen to the back yard provides a convenient pass

through for the service rooms.

Terrace on the top of traditional room provides extra recreation area.

The design compact, so that lot size can be controlled

Having three and more than three different bed room.

1.2.2 Features and Facilities of Modern Meeting Hall Center

Meeting Hall center having the best today design

It’s have VIP member sitting area at the top.

It is accommodate more than 80 parliament member.

It use for improve political system of the city.

It has basement use for storing material.

1.2.3 Features and Facilities of Modern Recreation Center

Recreation center having the best today design

It has sport court use for valley ball and basketball.

It has green area at the center of recreation area and terrace on the top.

It has basement use for steam bath and storing material.

1.3 Main customers/the end user of the company’s products

Government employers, rich farmer’s tenants of kebele houses

Households to be relocated from renewal areas

City residents who have a capacity to repay the cost of the houses.

one who is temporarily residing out of harari region on account of business, a study

or others (Most of all Diasporas included)

The applicant age must be Over 18years

MURAD AND BEKA 3

INTERNSHIP FINAL REPORT

CHAPTER TWO

2. MANAGEMENT, TRAINING AND EMPLOYS

2.1. How we gotten in to the company

Firstly, Madda Walabu University prepare a letter internship placement and given to the student

through our department after the completion of second semester of third year class schedule.

Taking the request letter, we have asked different construction companies and organization. All

these companies and organization which we asked were not allowed us to take part in their

organizations. But Harari 0housing development and government construction agency, accept

our request and give us confirmation. After the completion of first semester of fourth year we

have started our internship practice by attending in Harari housing development and government

construction agency.

Then we made a contact with General Manager of Harari housing development and government

construction agency and he had written a letter for us, to do our practical attachment (internship)

In Harari housing development and government construction agency. Next day we went site and

introduced to site engineer, site Forman and staff members. . After they oriented us about the

site and work tasks we officially started our internship practice.

2.2 Section of the company we have been working in

In the company we were assigned in the construction section which is responsible for supervision.

The construction section consists of a construction Engineer who is head of the construction

section. It also consists of site Engineer, surveyor, Forman, operators, sub store time keeper &

sub contract workers.

2.2.1 Main parties in construction project

I. (owner - it may be individual, government like our case, real-estate developers etc.

Client (owner)

They are the most important party who is active from inception to completion with duty of

Availability and cost of land

Location and accessibility

MURAD AND BEKA 4

INTERNSHIP FINAL REPORT

Price

Required infrastructure

Legal constraint

Site preparation (right of way)

II. Consultant- the main role of the consultant is to interpret the client’s project requirement

in to a specific design.

The consultant team shall,

Ascertain, interpret and formulate the client’s requirement in to understandable project

Assess client’s cost limit to decide on materials & the like

Prepare contract document

Supervise the project and constantly inform the client on the progress

Approve payment

III. Contractor- these are groups established mainly as commercial companies, that contract

to construct development project

Responsibility of contractors

Carry out full site investigation prior to submission of tender

Submit tender

Plan, program, control the construction process

Notify consultant about delay, discrepancies

Effect all payment to his employees, supplier, sub-contractors

Provide post occupancy repair & maintenance if required

Public sector agencies

Statutory Authorities – offer technical advices during design and construction in their respective

areas. E.g. fire authority thus early information to these authorities is required

Municipalities and government authorities- offer the basic land permit and building permit.

Financial institutions- like banks, insurance company or other investors that provide funding.

MURAD AND BEKA 5

INTERNSHIP FINAL REPORT

Board of Directors

General Manager

Plan, Community

Audit & Inspection

Communication &

Documentation

House

Transferring Administrating &

Contracts Purchasing &

Administration General Services

Administration Finance

& Materials

Quality Micro Enterprise

Administration

Home Transferring

General Services

Home Administration

Enterprise

Development Record & Human

Resource

Laboratory Capacity Building

Management

Enterprise

Budgeting Purchaser &

Supplier

Building Project Construction Construction

Finance Material Material

Administration Distribution Administration

Figure 1 work flow in the section

MURAD AND BEKA 6

INTERNSHIP FINAL REPORT

2.3 The work piece we have been executing

In our internship program our advisor on the site assigned us to do daily work dairy that is needed

to compute the efficiency of the day to day activities. But this work is done at the end of each day.

So we are free almost the whole day. Because of that we are used to see, on the morning time, the

works that are done before our arrival on the site for internship. So in this section we are going to

discuss not only about the work diary, but also about the things that we sew & asked. Some of the

things are about the foundation, takeoff sheet and some design assumptions taken on the design of

the building. Supervision of construction/project is the reason for the quality and sufficiency of

specified project. Duties and responsibility of supervision can be achieved to the desired result if

especially he/she applies to the given/recommended rules. These rules are available in the form of

check list.

2.3.1Daily work diary

Like we have stated earlier the need of the daily work diary is to see the efficiency of the employees

& the daily laborers on each day. This helps the contractor to control every worker every day so

that they will stay on the track to finish the project on the specified time schedule.

The things that needs to be filled on the daily work diary are the date, the weather, staff on site,

labor force, progress of the project, works on hand, type of machineries used etc…. on the date

place we write the day, on the weather we write that days weather like sunny or rainy, on progress

of the project we state the works done on that day, by works on hand we mean works that are

transferred for the next day without being completed.

The main thing in doing the daily work diary is to record every single actions that held within the

site on that day. During our intern most of the time the things that are recorded on work diary are

Volume of concrete casted in m3

Weight of reinforcement bars used to reinforce beams, columns, solid slabs, ribbed

slab, and as a stirrup in kg (differentiating by their diameter)

Total area of formwork casted for slab, column, & beams in m2

Area of ribbed HCB placed in m2

2.4. The procedures we have been using while performing the task

MURAD AND BEKA 7

INTERNSHIP FINAL REPORT

We are not professional since we have no experience in site work. So we have taken the first step

to execute our task by referring theories which we have been learning in class and comparing it

with site work, presenting equations to different bodies to their respective field (one that give us

sufficient answer) and when risky work (mistake is observed) we inform to responsible body and

we discuss on that issue. We can say that we did our best to get what is expected to know and to

develop our practical skill during the internship program. We accomplished our task very well in

office and observe on site each and every step while they construct the building. Confidently

speaking we have work every assignment (work task) that our supervisor gave us and we were

good assisting him.

2.4.1 How good we have been in performing our task

Since working the daily work diary is a simple task we have been performing it without any

difficulties & without any confusion. This task is more of a recording work with simple

mathematical computation so we can say that we have done it accurately and neatly. But its better

if we discus about the construction held before we arrived at the site.

2.4.2 Challenges we have been faced and the measures taken

During the Internship we have faced these challenges:

Not having an experience on the construction sites.

Shortage of information in the drawings.

Lack of construction safety wears i.e. safety shoes, helmet, gloves, etc.

Difference in site and class technical terms.

2.4.3 Some of measures we have taken to overcome those challenges are:

We have learned the words they used by asking and trying to memorize each word. As

time progresses we was able to understand and respond to the words.

Through time information in the drawings is resolved when we engaged to work.

we have tried to use our own protective materials

MURAD AND BEKA 8

INTERNSHIP FINAL REPORT

CHAPTER THREE

3. OVERALL INTERNSHIP TRAININGS

3.1. Daily Technical duties that arise at the site

In this sub section of the report we have tried to present all trainings that we have experienced

during our internship period in the hoisting organization, harari housing development project

office. Our internship project in harari housing development project office focus on the

educational building project.

All the trainings and exposures which we have experienced during our internship regarding to

the educational building project are presented below. We have tried to summarize all the

training we got in two subgroups; site works and office works.

Regarding site works, we have got a chance to practically experience how major substructure and

superstructure get accomplished. I have summarized all trainings and exposures at site as follow:

current construction practice, supervision guidelines and site visits. On the other hand, office

works, we get trained on office works at construction site: quantity estimation, lesson and

experience on how different office works run and lesson on MS-project.

3.1.0. Site works

In this sub section we have tried to present our internship experience concerning daily site works. These

include the progress of the project from site clearance up to casting ground floor slab and upper basement

slab.

3.1.1. Substructure

Sub structure is one part of a structure which is found below the ground surface. It is used to

transfer load from super structure (i.e. the structural part which is found above the ground surface)

to the ground surface mainly soil mass or bed rock. In this stage of construction work the following

works are to be done at the site of the project:

3.1.1.1. Site clearance

MURAD AND BEKA 9

INTERNSHIP FINAL REPORT

Though we did not got the chance to see site clearance it’s carried out for removal of top soil (organic soil),

plants etc. to an average depth of 20-30cm with working space of 0.5 cm- 1m.

3.1.1.2. Bulk excavation

Bulk excavation is clearing of the upper soil after site clearance often to depth of FFL (floor finish level)

with recommended elevation reference on the design.

3.1.1.3. Setting out

Setting out is carried out using construction of profile board (batter board), which will serve as elevation

reference now onwards and location of pads are marked on ground (‘chekal’) to take step on pit

excavation. Profile (‘modiny’) is transferred using gomma (weha lek) from the pad that is located in highest

elevation compared to elevation of other pads.

Fig 2 setting out for school building

3.1.1.4. Pit excavation

It is the process of removing the top layer of the crest seeking for a sound material for placing of

footings to some depths. It also avoids the lateral movement of the structure. The depth

magnitude differs according to the properties of the superstructure, topography and the type of

the soil.

The excavation of foundation is executed 30cm wider on 4 faces of the foundations for working

space and the depth executed is 2m but some pits vary because of the boulder (The pit is dogged

up until hard and stiff soil strata acquired.). Therefore, the minimum depth for pits excavation is

50cm.

MURAD AND BEKA 10

INTERNSHIP FINAL REPORT

Excavation of foundation is a mechanical process and can be done using labor force and/or by

using excavation machineries. In this site Daily Labors are used to excavate foundation pits as

shown in the figure below.

Fig 3 pit excavation by man power

3.1.1.5. Trench excavation

Is executed for the construction of masonry work. it is excavated by taking 15cm working space

on both side by the concept of a worker can put his leg while constructing the masonry.

3.1.2. Structural work

3.1.2.1 Foundation

It is a part of the substructure which functions as the mediator in transferring the load superimposed by the

superstructure to the soil foundation. There are different types of footings. The selection would differ

depend up on various factors listed below:

The degree of exposure

The properties of the bearing soil

The area concurred by the footing

Environmental factors

The size of the building

Purpose of the building

Cost of the construction

MURAD AND BEKA 11

INTERNSHIP FINAL REPORT

Fig 4 Casting footing

Methodology (procedure for construction of footing)

5cm thick lean concrete is spread in the pit, erection of form work for the pad is followed

by placing pad reinforcements, checking the center and position of column using tumbi

(plum bob), rope (string) and tape measure, reinforcement for the foundation column is tied

to the base of footing reinforcement. After providing spacer for clear cover (50mm) it will

be ready to be casted.

3.1.2.2. Foundation column

Foundation column rise from footing and continue up to grade beam. Its purpose is to transfer all loads to

the foundation. The reinforcement of foundation column and the reinforcement of the footing pad have a

great connection as it’s shown in the above photo. When they cast footing pad they brace the foundation

column with yoke to prevent shifting of its center due to pressure of concrete and vibrator.

Methodology (procedure of construction)

Reinforcement of foundation column is placed with the consideration of overlap to the extending elevation

column. By tying Staffa (stirrup) and spacer for clear concrete cover. Cratchery ) is nailed and formwork

of elevation column is erected by keeping the alignment (verticality) checking with tumbi(tied on two

orthogonal side of column to check its deviation), after checking Center to center span length of

corresponding column, pouring height & tightness of form work concrete is casted till the lower base of

grade beam.

3.1.2.3 Masonry work

MURAD AND BEKA 12

INTERNSHIP FINAL REPORT

It is the building of structures from individual units laid in and bound together by mortar; it’s generally a

highly durable form of construction also depends on the quality of the material used, mortar and

workmanship. It is used for the construction retaining wall, septic tank and man hole. Mostly has

50cm thickness.

Methodology (procedure of construction)

The first step in masonry retaining wall construction is construction of its profile

which will guide the masons while construction.

Lay each course of stone masonry keeping the alignment, vertical and horizontal,

and mortar thickness.

3.1.2.4. Grade beam

Is a component of building foundation (laid on masonry work) consists of reinforced concrete beam that

transmit loads from bearing wall in to spaced foundations. Also used for bracing (protect the horizontal

movement of individual footing (columns) due to the horizontal load). It is separated from the ground

floor with expansion joints (cheap wood) there for it does not transmit loads from ground floor it is assumed

that ground floor can resist the loads imposed on it using the ground as support hence it is in direct contact

with the ground. Grade beam reinforcement is placed on 5cm thick lean concrete that is laid on masonry

with provision of spacer & stirrup, after constructing the formwork concrete is casted.

3.1.2.5 Back fill, compaction and hard core

All internal back filling is done with approved material, if possible with material excavated on the site. It

should be well rammed and consolidated by adding waters as necessary to achieve the required compaction

by keeping moisture content to optimum.

Compaction is the process in which a stress applied to a soil causes to decrease density. It’s a

Vital part of the construction.

Hard core: is provided under the ground slab. It shall be sound approved stone of specified finishing

thickness The main purpose of hard core is to prevent the dampness from the soil penetrating and affecting

MURAD AND BEKA 13

INTERNSHIP FINAL REPORT

the floor slab through capillary action. 25cm thick hardcore work should be sound, well rammed and

consolidated with the top surface blinded with crushed masonry.

3.1.2.6 Ground floor

It is a plane horizontal structural element used to support live loads and transfer the loads to the supporting

ground.

Methodology (procedure of casting ground floor)

After backfill and compaction, hard core were provided under the slab

Then mesh(reinforcement for ground slab) is provided which is used to prevent crack

developed by settlement (consolidation of back fill material due to losing of moisture

content through time), temperature change, shrinkage, expansion and related factors.

Also cheap wood was placed around grade beam used as expansion join since ground slab

is not structural part of the building

Finally concrete is casted

3.1.3 Super structure work

3.1.3.1 Elevation column

Column is as structural part of a building which is a vertical member that support vertical, horizontal and

moments coming from the beam ,slab, stair and other member of the structure and transfer it to the sub

structure i.e. foundation.

Methodology (procedure of construction)

1. Krachery (bracing) will be prepared with a dimension of 2cm greater than the

dimension of the columns on each side.

2. The formwork will be inserted inside the krachery and then erected.

3. Use plumb bob and check vertical alignment.

MURAD AND BEKA 14

INTERNSHIP FINAL REPORT

4. Then the formwork will be fixed in position and the concrete will be filled the

formwork for the column has to wait at least 24 hours to be removed after casting.

When columns are cast, the air inside the voids of the concrete has to removed

(compaction) by a vibrator. In casting a column the concrete cover is maintained by a

device called spacer, which is small cubical molded cement with a wire which binds it

to the reinforcement

Fig 5 column work

Stirrup (Staffa)

They are provided to resist diagonal shear cracks and outward buckling in case of column, to tie

longitudinal bars, to improve ductility and Stirrups are required to be designed to carry shear above

the capacity of concrete.

Fig 6 column stirrup

Methodology (procedure of construction)

Same as foundation column since elevation column is higher concrete is poured through shutter to

height of 2m and the opening is closed by sliding the form work the rest height is poured at the

top. Pouring height is provided to prevent occurrence of segregation

MURAD AND BEKA 15

INTERNSHIP FINAL REPORT

3.1.3.2. Beams

It is a horizontal structural element that is capable of withstanding load primarily by resisting

bending. The bending force induced into the material of the beam as a result of the external loads,

own weight, span and external reactions to these loads.

Intermediate beam is used to carry slab and transfer the loads to the supporting columns. Beams

can be continuous, fixed or cantilever. In this site the beams has the same thickness with the slab

are called submerged beams. When a beam is subjected to loading, it develops tension zones so it

has to be reinforced. Also a beam subjected to shear stress can’t be overcome with increasing the

depth of the beam. This is because it is impractical to make beams too deep due to architectural

reasons and other reasons. Therefore stirrups are provided to take the shear stress. These are

horizontal load bearing members which are classified as either

Secondary beams which transmit floor loads to the main beams.

Main beams which transmit floor and secondary beam loads to the columns

Methodology (procedure of construction)

The construction of beam is the same as the case of column, but in this case the form work is set

up in the horizontal direction, while in the case of column it is laid vertical. The placing,

compacting, and curing are the same.

3.1.3.3. Slab

Slab is common structural elements of modern building that support its dead weight and loads

imposed on it by transferring them to beams or walls safely. In this site the slabs are two way-slabs

because the uniform distribution loads resist them primarily by bending about both the axis, it’s

known when the ratio of the long span to the short span is less than two.

MURAD AND BEKA 16

INTERNSHIP FINAL REPORT

Methodology (procedure of construction)

Ribbed slabs are built using precast beams, hollow concrete block (three cells), reinforcement

bars, and concrete. Here are some of the steps that I glance during construction of ribbed slabs.

Precast beams are spread over the false work and panel with 54cm interval

Over those precast beams HCBs are loaded across the crosection.

Use negative reinforcement bar to tie up the precast beam and beam.

The electrical and drainage installation are well fixed

Diameter six plain bar are distributed over the HCBs along and across and along the

section.

Concrete is filled, vibrated (in area of beam and solid slab), and cured.

Fig 7 slab work

3.1.3.4. Stair case

Stair are set of steps leading from one floor to another and are provided in building to afford a

means of communication between the various floors, steps arranged in series and placed in an

enclosure is called stair case. . Building law and safety matters, user concerns identification,

function and spatial experience, clarity and traffic flow as well as aesthetic concepts are determined

very early in the course of a basic design of stair case. On the main office building there are two

types of stairs

i. Two flight stairs (open newel half turn stairs) its direction is reversed by 180°

ii. Three flight stairs (open newel half turn stair) with quarter space landing

MURAD AND BEKA 17

INTERNSHIP FINAL REPORT

Fig 8 formwork of stair case and its casting

3.1.4. Concrete work

Concrete work includes selection of materials (its component) proportioning, mixing, placing,

compacting and curing. Since each step of concrete work has significant effect on its final product

to attain desired properties for fresh and hardened concrete the above procedures has to be carefully

carried out.

Concrete is a composite material composed of coarse granular material (aggregate or filler)

embedded in a hard matrix of material (cement or binder) that fills the space among the aggregate

particles and glues them together.

Compressive strength is well known property of concrete and has low resistance to tensile force to

overcome this property steel reinforcement which is high in tension and compression is introduced.

3.1.4.1. Ingredients of concrete and their selection

Cement

It is a material with adhesive and cohesive properties which make them capable of uniting or

bonding together fragments or particles of solid matter into a compact whole.

In our site PPC (Pozzolana Portland Cement) and OPC (Ordinary Portland Cement) are used. PPC

is different from OPC in its higher resistance to corrosion, reduces rate of hardening and lower

frost resistance. Cement is stored in a dry and well ventilated store, on a wooden floor raised

minimum 20cm. above the ground.

MURAD AND BEKA 18

INTERNSHIP FINAL REPORT

Aggregates

Aggregates are important constituents in concrete they generally occupy 65- 75% of the volume

of concrete hence due consideration should be given in their selection and proportion. In choosing

aggregate for in a particular concrete attention should be given to three important requirements:

Workability when fresh for which the size and gradation of the aggregate should be

such that undue labor in mixing and placing will not be required

Strength and durability when hardened for which the aggregate should:

- contain no impurities which adversely affect strength and durability

- be resistant to weathering reaction

- Does not go in to undesirable reaction with the cement

Economy meaning

it shall be available from local and easily accessible

well graded in order to minimize paste in consequent cement requirement

The aggregate used on the site is a product of national cement plc. Transported from dire dawa it

has basaltic nature with grain size of 1-4 cm. The silt content of the aggregate is checked whenever

necessary because high silt content can risk the structure under construction. The test that is usually

done for this purpose is jar test. The silt content of aggregate increases in rainy season. Because

silt materials are transported by rain water (flood) & accumulates in the aggregate. If the test

indicates that its silt content is high the aggregate will be changed or it will be washed.

Water

Water is an important ingredient of concrete as it actively participates in the chemical reaction with

cement. A popular yard stick to the suitability of water for mixing concrete is that

If water is fit for drinking then it fit for making concrete

It should be free from impurities such as suspended solids, silt, clay, acids, alkalis,

organic matters and dissolved salts.

MURAD AND BEKA 19

INTERNSHIP FINAL REPORT

Tests by the sense of smell, sight should reveal such impurities; however water of doubtful quality

should be submitted for laboratory analysis and test.

3.1.4.2 Mix proportion of concrete in our site

Mixing of concrete materials should be done thoroughly to ensure the uniform distribution of

materials in concrete mass. For practical concrete mix the cement, water and aggregate should be

so proportioned that the resulting concrete has the following properties:

i. When freshly mixed it is workable enough for economical and easy uniform

placement but not excessively fluid

ii. When hardened it possess strength and durability adequate to the purpose for which

it is intended

iii. It involves minimum cost consistent with acceptable quality

Volume batching is used in our site, to achieve the desired strength of concrete weight of cement

and size of boxes is changed. Here are some proportions

Concrete class Box size Number of cement (pcs) Mix

ratio

c-5 50x40x20 1 piece of cement (50 kg) ppc 1:4:6

c-20 50x40x20 1 piece of cement (50 kg) ppc 1:2:3

c-25 50x40x18 1 piece of cement (50 kg) ppc 1:2:3

c-30 50x40x16 1 piece of cement (50 kg) ppc 1:2:3

Table 3 mix proportion

NOTE: for different grade of concrete (c20, c25, c30) box ratio is the same but only with variation

of box depth.

For c25 concrete 360kg of cement is used per m3

For c30 concrete 400kg of cement is used per m3

MURAD AND BEKA 20

INTERNSHIP FINAL REPORT

3.1.4.3 Placement and compacting of concrete

In order to secure good hardened concrete, certain fundamental principles should be born in mind

in handling it when fresh. The best concrete mix can be easily damaged when a little mistake is

made on the way from the mixing place to forms. Therefore, each step in handling and transporting

should be carefully controlled. Segregation i.e. segregation of the coarse aggregate from the mortar

or of water from other ingredients, should be prevented. The equipment and method of handling

and transporting concrete should be selected according to

Amount of concrete involved

Size and type of construction

Location of batch plant

Relative cost

In our site they use crane to transport the concrete hence the slab is huge section that consumes

about 80m3 in the left section and 110m3 on the right section of a building. Using such machine

has advantage of

Maintain quality of fresh concrete (i.e. prevention of setting and protects from effect of

weather)

Reduction in man power

Quick casting (time efficient)

Compaction is one of important steps in concrete making, because the density, strength and

durability of concrete depend so much on it. The objective of compaction is to ensure an intimate

contact between the constituent materials and to illuminate air bubbles and to achieve maximum

density which leads to higher strength. It is done by vibrator. However proper and efficient

vibration is required in site some sections are over vibrated, and others are less vibrated in both

cases the concrete is subjected to segregation

3.1.4.4. Curing concrete

It is important that fresh concrete be kept moist for several days after placing. Moist is necessary

for proper hardening of concrete because chemical reaction that result in setting and hardening of

MURAD AND BEKA 21

INTERNSHIP FINAL REPORT

the paste takes place only in presence of water. In addition the loss of water by evaporation from

the time the concrete is mixed and placed is usually so rapid that if concrete dries out too quickly

by exposure to the sun and wind it will shrink. This early and usually rapid shrinkage will result

in tensile stresses that will lead to surface crack. In order to prevent such effects and to assure

attainment of strength the concrete is cured from day one after it is casted by spraying water and

spreading sand on the concrete. I.e. the use of sand is to reduce rate of evaporation and keep the

moist for longer time.

3.1.5. Reinforcement

Reinforcement bars are a rounded steel bars with different size provided to overcome concrete

weakness in tension and give additional compressive strength. All reinforcement bars are of the

specified quality and in accordance with the standard technical specification the bars should be

store in clean and dry area and also sheltered from rainfall. It should be reasonably free from

corrosion, rust and other impurities, such as grease, oil and other kind of dirt which affect the

strength of reinforcement. Different diameter of bars are used most of which fall between 8-20mm.

diameter 24mm bars were used for beams on critical section (large span without interior column

(7.2m) ).

3.1.6 Form work

Concrete is a plastic material when fresh hence it needs forms or molds until it sets and hardens.

The forms are generally made of either timber or steel. Before placing concrete the forms and

subgrade should be cleaned and moistened thoroughly specially in hot weather. In order to

prevent concrete from adhering to the surface forms should be thoroughly oiled.

Striping form work

Early striking of forms is generally desirable to permit quick re use, start curing as soon as

possible and allow repairs and surface treatment while the concrete is still green and condition

are favorable for good bond.

The time between casting of concrete and removal of the formwork depends mainly on the strength

development of the concrete and on the function of formwork. Provided the concrete strength is

MURAD AND BEKA 22

INTERNSHIP FINAL REPORT

confirmed by test on cubes stored under the same condition, formwork can be removed when the

cube strength is 50% of the nominal strength or twice the stress to which it will then be subjected

whichever is greater, provided such earlier removal will not result in unacceptable deflection such

as due to shrinkage and creep. As I observed in site some removal period of formworks are listed

below

For non-load bearing parts of formwork like sponda (side vertical forms for

beams),columns, walls, footings grade beams it is removed in -------24hrs

for intermediate beams and slab formwork strikes in ------- 21 days

3.1.7. Office work

In this sub section we have tried to explain our internship experience regarding office works.

This includes preparation of different take off sheets and preparation of re-bar schedule, we

have added typical takeoff sheet and re-bar schedule sheet.

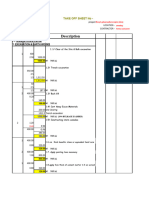

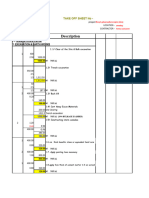

3.1.7.1 Takeoff sheet

It is the process of measuring quantities from detail drawing. It is used to calculate different

quantities like excavation, formwork, concrete, masonry and backfill. Takeoff sheet often has

the following format:

T D S Description T D S Description

Table 4.take off sheet

3.1.7.2. Re-bar schedule

It is used to record re-bar shape, dimension, number, position which is taken from structural

details. It helps us to prepare the work order with minimize wastage using 12m re-bar.

MURAD AND BEKA 23

INTERNSHIP FINAL REPORT

It is clear that the reinforcement bar is one of the essential units of a certain structural element

and for these reason it is important to determine the type and amount of steel required for a

certain project. The cost of reinforcements in the market is per kilogram, and also the sheets

are usually prepared in kg. A typical re-bar schedule has the following format:

S/ Description Shape Dia. Length x No of Wastag Remark

N e

(Location) (mm (mm) 12mba

) r

Table5. Re-bar schedule

3.2. Other responsibility that are given for us

These responsibility are given by the site engineer for us that is we are responsible for checking

the following listed work in proper method, b/c we assigned as site supervisor.

3.2.1 Pit Excavation

Check:-

The foundation drawings to correspond with the conditions on the site, if not

prepare a written report and submit to the designer immediately.

The coordinate points are carefully transferred to ground using plum bob

The excavation or foundation is executed 25 cm. wider on each side than the

thickness of the foundation wall as given in the standard technical specification.

The foundation depth, width, line and levels to correspond the drawings.

The trench and pits to be clean from grass, bushes and pieces of wood.

3.2.2. Formwork Construction

Check: -

The bracing of formwork:-The form work must be strong enough to carry the load

imposed until the concrete is strong enough to carry itself and harden sufficiently.

MURAD AND BEKA 24

INTERNSHIP FINAL REPORT

Formworks have the right dimensions and are level and straight.

Before casting concrete, formworks have to be thoroughly cleaned out and free

from holes and dirt.

The top level of the formwork shall be at the same level as the top level of finished

concrete. If not define the top level of finished concrete on the formwork with

great accuracy.

3.2.3. Back Filling

Check:-

All organic materials, such as pieces of wood, roots, bushes and black cotton

soil are removed from all backfill material.

All the places where backfilling shall be executed are clean from grass, bushes

and pieces of wood.

Where pipes and electrical cables are in connection with the backfilling, the

work shall be executed very carefully, so they do not break or get damaged.

Each layer to be well rammed and consolidated with the addition of waters as

necessary to achieve the required compaction i.e. Keep moisture content to

optimum.

The maximum layer of fill for one time compaction does not exceed 20cm,

thickness in accordance with the standard technical specification.

3.2.4. Concrete

Check:-

All ingredients cement, aggregates and water are of the type and quality specified.

Cement in stored in a dry and well ventilated store, on a wooden floor raised minimum

20cm. above the ground.

Sand to be clear of impurities like dust mica & organic matter.

Coarse aggregate to be crushed basaltic stone or gravel of approved quality.

MURAD AND BEKA 25

INTERNSHIP FINAL REPORT

Coarse aggregate to be hard, dense, durable non-porous and uncoated rock

fragments.

Aggregates are stored on clear hard surface to prevent contamination by soil.

Water used for mixing concrete is clean and free from injurious amounts of oil, acids,

alkalis, organic materials.

3.2.4. Steel Reinforcement

Check:-

Steel reinforcement is stored in clean condition. It should be free from loose rust.

The dimension, length and shape of the reinforcement bars are according to the

drawings and specifications.

Bending of reinforcement bars is done with adequate bending tools but heat is strictly

not allowed for bending of reinforcement bars.

All bars with cracks or splits at the bend are not used for construction.

All reinforcement bars are clean and free from close rust, grease, oil, or tar and other

kind of dirt.

The reinforcement bars are placed in position according to the drawings, and firmly

bound together with mild steel wire(black wire), diameter 1.5mm in accordance with

the standard technical specification.

These blocks or spacers do not turn over when concrete is casted.

3.2.5. Stone Masonry

Check: -

The trench to be clean from grass, bushes and piece of woods

The stone has to be hard, sound, free from cracks and not weathered.

The stone masonry execution is with specified mortar and with well filled joints

The stone masonry during execution is kept free from solid and other kind of dirt

The mix proportion of mortar is correct

3.2.6. Hard Core

MURAD AND BEKA 26

INTERNSHIP FINAL REPORT

The main purpose of hard core is to prevent the dampness from the soil penetrating and affecting

the floor through capillary action.

Check:-

Stone for hard-core is sound and approved quality.

All stones in the hard-core are of approximately equal and recommended size.

All hard-core is wall rammed and consolidated with the top surface blinded with

crushed aggregate in accordance with the standard technical specification.

The placing of stones to result in minimum voids.

3.3. Benefits of the Internships

During our internship experience at HARARi HOUSING DEVELOPMENT PROJECT OFFICE we have

been benefited from the internship experience. During these four months of our internship

program we were able to bridge the gap between student life and professional life. This

internship program provided us a platform to introduce our self in professional field.

In the internship program we have gained benefits which helped us to explore our skills, qualities

and abilities. Since in our first practical experience everything done is new and interesting to me.

However within these four months we have been the opportunity to improve our practical skills,

theoretical knowledge, our interpersonal communication skills, team playing skills, leadership

skills and etc. and also have the opportunity to understand about the work ethics and gain a great

knowledge in entrepreneurship skills.

We get some benefit beside which we didn’t if we spent those four months in the class. Some of

the benefits are:

3.3.1. In terms of improving Practical Skills

This program gave us many opportunities to test and refine our skills. All in our learning years

our knowledge has been theoretical. This program has changed this and now we have developed

practical knowledge which helped us to build and improve our confidence.

MURAD AND BEKA 27

INTERNSHIP FINAL REPORT

The main aim of this internship program is to improve student practical skills by applying his /her

theoretical knowledge. During our internship program we get the following practical skill.

How to read, understand and interpret the structural and architectural drawing of

the building.

How to construct the building in limited space by using Steps during the

construction of different part of the building.

How to prepare formwork for different structure part of the building and checking

the alignment of formwork by using string and tumbi

How to check whether the columns deviate or not by using plum bobs (tumbi).

How to prepare (mix) different compressive strength of concrete and how to

place, compact, Cast and cure concrete

How to prepare different document in office such as takeoff sheet, rebar schedule,

bill of quantity, payment certificate, and cost breakdown.

How to control the quality of different material on site Knowing diameter of

reinforcement by inspection.

Understanding arrangements of bars in reinforcement detail drawing

3.3.2.In terms of upgrading theoretical knowledge

In addition to the practical skill this program helps us to strengthen our theoretical knowledge

and gain meaningful engineering experience to complement academic studies. The courses taken

were focused on theory. Since the practice depends first on theory, it was easy to work and

correlate the activities and enhance our understanding of constructing a building. Theoretical

knowledge is dependable on principles, logic and calculations.

This internship program provided us with the opportunity to expand our attitude, broadening

our intellectual knowledge and practical skills. The work I did was mostly related to structural

design we took specifically reinforced concrete. The lecture mainly discussed about two concepts

Analysis and Design of RC sections. We covered designs such as beam and one way slabs, column

MURAD AND BEKA 28

INTERNSHIP FINAL REPORT

and stair case. Here we got a chance to see the entire reinforcement placement on the truly tells

us for what purpose they placed. Finally when some problem arises at the site this create a

chance for us to something to say on it.

3.3.3. In terms of improving interpersonal communication skill

During the site work and office work we have been able to ask different kinds of people from all

walks of life. During these times we have gained confidence on how: -

to ask different questions

to make discussions

to answer questions when asked

To respond to superior and etc.

In the design office, we had been given the chance to talk and interview important people from

different sites. Through these interviews we have been able to talk to Resident Engineer. During

these interviews we had the opportunity to learn on the communication skills that we have been

striving for a long time.

3.3.4. In terms of improving team playing skills

Most of the tasks we completed were assigned as group duty. So most of the time we had to

work independently but at the same time together. While we were doing this different tasks,

ideas where rose and there were arguments between us. But at the end we agreed on acceptable

terms which we believe helped us share what we have in our mind. This thing helps us to develop

our team playing skills to some extent.

We have learned that as part of a team, an engineer should have to works with a positive attitude

within a group for the success of a project. An engineer must have good managerial and

organizational skills. Confident and enthusiastic engineers are able to succeed by gaining the trust

of co-workers.

Good team player possesses the following skill

Communicates constructively

MURAD AND BEKA 29

INTERNSHIP FINAL REPORT

Listens actively

Functions as an active participant

Shares openly and willingly

Cooperates and pitches in to help

Exhibits flexibility

Shows commitment to the team

Works as a problem-solver

Treats others in a respectful and supportive manner

3.3.5. In terms of leadership skills

We have seen how each worker is controlled and organized to perform its day to day activities.

Among all other managements we have seen that human resource management is the most

important one.

We have actually observed the method of controlling the working time and amount of work done

by each worker so that the work proceeds according to the work plan.

For effective leadership we understood that personal values like confidence, effective

communication and devotion are very important.

Here in our every place is occupied with the right person, this person has a responsibility so they

do their work effectively. Therefore no one give us a position to experience this thing which

means I didn’t get this benefit

Leadership is a skill to guide, control and monitor peoples.

3.3.6. In terms of understanding about work ethics related issue

Our supervisor was always advising us that we should be an ethical and responsible professional

for the future. He has been showing how to develop this good behavior during our stay on the site

with him. And also he told us lots of practical cases that related to work ethic that he could see

when he was working in different places.

MURAD AND BEKA 30

INTERNSHIP FINAL REPORT

We have been guided and obeyed by the rule and regulation of the company. Some of the work

ethics include;

Punctuality: - means keeping the companies work beginning and ending time and

to complete a given task within the given period.

Office disciplines: - in work place you don’t have to disturb the working

atmosphere. For example abstain from opening loud voice, loud music, songs and

things which disturb others workers working mood.

Reliability: - The worker should be qualified for the part he is supposed to

be performing . He/she must have appropriate skill and knowledge for the

task assigned

Honesty: - Regarding this value each worker regardless of its status should

abstain from bad behaviors such as cheating , bias , corruption etc..

Cooperation: - Each worker should interact and cooperate with each other

while working . That is because it is through such system problems could be

easily solved.

On our stay on the site we were very punctual, daily attendant of the work & responsible to our

profession. During this program we were developed our work ethics.

At the site we have been able to see different engineers in hierarchy work and lead the site

workers and the engineers under them. During these times we have been able to observe that

one should have great skills to be a leader. Among them: -

Good speaking ability.

To have the ability to listen to others.

To be decisive.

Good management skills.

To know the subject one is working on thoroughly.

And etc.

MURAD AND BEKA 31

INTERNSHIP FINAL REPORT

Generally, we can say we have gained the potential benefits by taking the Engineering Internship

Program from this perspective; we have gained a valuable lesson that transparency and

carefulness are two very important work ethics one needs to abide and live by.

3.3.7. In terms of entrepreneurship skills

This entrepreneurship has tended to start ventures hat on a specific skill have already developed

and knowledge that already acquired in certain occupation industry. Entrepreneurial skills helps

to success in today’s competitive market’s must possess basic skills necessary to enable to start

develop finance and market our own business enterprise. There are number of qualities and skills

need to have, including personal attributes business skills and management capability, self-

motivations skills, time management skills and administrative skills.

A. Self-motivation skills: to succeed in work, one must be self-start with cleared desired

goals in a mind’s must have confidence in myself and in our idea

B. Time management skill: ability to plan our day and manage time is particularly important

for our job.

C. Administration skills: these includes, self-worth, ability to control one’s life, self-

awareness, self-management/personality responsibility, transfer of learning, motivation,

team work, interpersonal communication, problem solving and creativity are some for

the important aspects.

3.4. Relevant research projects identified in the organization

Understanding site work from structural drawings and know what measures taken.

Effect of cart away material on future development.

Effect of using limited sample test for large site on the project.

Safety consideration in Ethiopia context in general.

Effect of unskilled labor and less quality material on the project.

MURAD AND BEKA 32

INTERNSHIP FINAL REPORT

CHAPTER FOUR

4. EVALUATION AND CRITIQUE

4.1 Goal of Internship

Internship program is practical skill that is scheduled by the ministry of education for the students

in different sector such as in engineering, health, teaching…etc. These helps for the students to

develop practical knowledge rather than theoretical knowledge. We were able to introduce ourself

with a very dynamic working environment. And in order to cope up with such environment, it was

expected that we improve our practical skills of solving engineering problems. Since the field of

engineering mostly comprises of field activities, it is obvious that we encounter problems that

needed to be solved on the spot and for that one requires the ability to analyze, assess and come

up with a solution that may solve the problem and greatly reduce the difficulties faced. We had the

chance to associate our self with some professionals and by doing so, we were able to ask practical

questions and demand explanation on the topic. During our routine site visits, we had the chance

to spend time with the construction workers.

These internship practice has its own value in our future work life as an experience to help us

after graduation to develop some confidence ,b/c for the future site works isn’t new for us and help

us to develop entrepreneurship skills, so we believe internship helps for all sector to countries

development and to be produce productive generation

4.2. Conclusion

The field practice has played a tremendous role in equipping, students with the practical

knowledge of understanding and implementing field exercises in civil engineering. It helped us

develop self-confidence and introduced us to the world of construction. It helps the student to

practically understand the theory they learned in the class. It also acquainted us with the

knowledge required to monitor construction sites.

On the site we worked we have tried to see the excavation, setting out, slab construction, beam

construction and other construction stages stated above. Foundation is the structure that

MURAD AND BEKA 33

INTERNSHIP FINAL REPORT

transfers load from the building to the soil underneath. And this is the part of the construction

work where high precision and control is necessary

The whole process beginning from the sub-surface investigation to the finalizing steps in the

construction of the foundation is basic and needs a little more care than do others. This is because

the minimum of mistakes made in the construction of the foundation may lead to a disastrous

collapse/ failure of the whole building. Therefore the processes and activities mentioned on the

report should be strictly followed and controlled.

4.3. Recommendation

The university should arrange some practical visit in some courses. Because it helps

the students to easy understand what they are learnt in laboratory and lecture class.

The university should determine, before the internship program the Department must

be given to the students the course of quantity surveying, Because it helps the students

to easy understand what they are learnt in lecture class and in the site.

Organizations and companies hosting the students don’t pay much attention to

students as well as the follow ups of the academic supervisors. This negligence affects

the motivation and work habit of the students I highly recommended the universities

and concerned bodies to make strict follow up on students by working in close

relationship with hosting organizations.

4.4. Our strength and area for improvement

One of our greatest strength we have achieved and have upgraded our theoretical

knowledge ever practically via internship program.

In our internship program we have gained much skills related to personal and

professional ethics. Ethics is an issue that has to be in consideration in working area.

The workers are with different behaviors as per their background .the personality of

every worker has its own significant on work.

MURAD AND BEKA 34

INTERNSHIP FINAL REPORT

REFERENCE

1. Company profile

2. Construction material text book

3. Other lecture materials

4. EBCS 2 (Ethiopian building code and standards), 1995

5. http://en.wikipedia.org/

MURAD AND BEKA 35

INTERNSHIP FINAL REPORT

APPENDIX

HHDPO ……………… Harari Housing Development Project Office

PPC…………………….Pozzolna Portland Cement

OPC……. .…………….Ordinary Portland Cement

HCB…………………….hallow concrete block

MWU…………………..madda walabu university

MURAD AND BEKA 36

You might also like

- 6012SSL - Project Management For Business AssignmentDocument11 pages6012SSL - Project Management For Business AssignmentThảo My TrươngNo ratings yet

- Compony Profile: Internship Report On Residential Building 2020-2021Document24 pagesCompony Profile: Internship Report On Residential Building 2020-2021Shain100% (3)

- Dokumen - Tips - Real Estate Business Plan in Kenya PDFDocument16 pagesDokumen - Tips - Real Estate Business Plan in Kenya PDFMark AmwayiNo ratings yet

- Construction Project Proposal: Proposed Two - Storey Residential House BuildingDocument12 pagesConstruction Project Proposal: Proposed Two - Storey Residential House BuildingMhelvinz Iso de Rosa100% (1)

- Boq of G-2 BuildingDocument26 pagesBoq of G-2 Buildingmalik mac80% (5)

- Collaboration Processes: Looking Inside the Black BoxDocument13 pagesCollaboration Processes: Looking Inside the Black Boxเข้าใจว่า น่าจะชื่อตุ้นNo ratings yet

- Gen Ed Answer Key (A)Document7 pagesGen Ed Answer Key (A)Antonette Escarpe TorcinoNo ratings yet

- 1992SGSDesignersGuidetoPowerProductsApplicationManual2Ed 1182713547Document1,298 pages1992SGSDesignersGuidetoPowerProductsApplicationManual2Ed 1182713547analog changeNo ratings yet

- Business Proposal Housing DevelopmentDocument7 pagesBusiness Proposal Housing DevelopmentEufrasia Dian A HarmanNo ratings yet

- ConstructionDocument36 pagesConstructionbhavesh jangidNo ratings yet

- Content 1: 5. Overall Internship Experience .. .... 14Document43 pagesContent 1: 5. Overall Internship Experience .. .... 14Loza TadeNo ratings yet

- KEBERDocument19 pagesKEBERgemechu100% (2)

- Engineering Economics Business Plan for Foundation Specialist Construction FirmDocument21 pagesEngineering Economics Business Plan for Foundation Specialist Construction FirmteweldeNo ratings yet

- Module IDocument23 pagesModule IJan Jan AnoNo ratings yet

- Responsibilities of Main Parties (Firms)Document2 pagesResponsibilities of Main Parties (Firms)dadimosNo ratings yet

- DL MGT 241 Module 1 TestDocument7 pagesDL MGT 241 Module 1 TestChristian AlaskaNo ratings yet

- Refi Term Paper MuheetDocument14 pagesRefi Term Paper Muheetkmj muheetNo ratings yet

- Etungo PosterDocument1 pageEtungo PosterLinusNo ratings yet

- Project Proposal DraftDocument18 pagesProject Proposal Draftcha100% (3)

- Backup of DIDER DORDocument52 pagesBackup of DIDER DORbiniammebrate9No ratings yet

- Real Estate ProjectDocument9 pagesReal Estate Projectproperty E World100% (1)

- BizPlan SampleDocument43 pagesBizPlan SampleJc LaoNo ratings yet

- Project ProposalDocument23 pagesProject ProposalEshetu Mathewos100% (1)

- Damo Dalacha Gamo pension proposalDocument30 pagesDamo Dalacha Gamo pension proposalalemayehu tariku100% (1)

- Internship Experience in Construction ProjectDocument28 pagesInternship Experience in Construction ProjectSurafel AbateNo ratings yet

- University of Gondar Institute of Technology Dep't of Civil EngineeringDocument43 pagesUniversity of Gondar Institute of Technology Dep't of Civil Engineeringbereket gNo ratings yet

- Principles of Construction ManagementDocument2 pagesPrinciples of Construction Managementexcelsior xNo ratings yet

- Construction Project Management GuideDocument22 pagesConstruction Project Management GuideDarshan M MNo ratings yet

- Miftah NuredinDocument19 pagesMiftah Nuredinhabtu tesemaNo ratings yet

- Construction Project Management AssignmentsDocument8 pagesConstruction Project Management Assignmentsexcelsior xNo ratings yet

- VSU Construction Methods and Project Management Module 1Document5 pagesVSU Construction Methods and Project Management Module 1Cotangent TwoPiNo ratings yet

- ND-Developers-Company Profile PDFDocument11 pagesND-Developers-Company Profile PDFÃvíňâšh Ř ŔäťhőďNo ratings yet

- Individual Assignment # 1: (CITATION WWW /L 16393)Document13 pagesIndividual Assignment # 1: (CITATION WWW /L 16393)Alexander Hurtado CubillosNo ratings yet

- Rdip Form A Comprehensive Project Profile Agency: LGU-Pio V. Corpus Sector: Infrastructure Development SectorDocument7 pagesRdip Form A Comprehensive Project Profile Agency: LGU-Pio V. Corpus Sector: Infrastructure Development SectorJay-ann CondorNo ratings yet

- Producing a Tender Table of ContentsDocument38 pagesProducing a Tender Table of ContentsMohamed Gheita50% (2)

- Thecnical ProposalDocument11 pagesThecnical ProposalfayoNo ratings yet

- Building Flood-Proof Homes in Nghe AnDocument16 pagesBuilding Flood-Proof Homes in Nghe AnNguyễn Ngọc TrúcNo ratings yet

- Project CharterDocument11 pagesProject CharterAFZAAlNo ratings yet

- Rural Regeneration and Development Fund Second Call 2019 Category 2 Application FormDocument16 pagesRural Regeneration and Development Fund Second Call 2019 Category 2 Application FormBasit QureshiNo ratings yet

- Training ExperiencesDocument16 pagesTraining ExperiencesScribdTranslationsNo ratings yet

- Cement ProjectDocument66 pagesCement Projectmesfin esheteNo ratings yet

- Cotabato State University Proposed Residential BuildingDocument12 pagesCotabato State University Proposed Residential BuildingJonaisa CasanguanNo ratings yet

- Rift Valley University Bishoftuu Campus Department of Accounting and Finance Project Analysis and EvaluationDocument15 pagesRift Valley University Bishoftuu Campus Department of Accounting and Finance Project Analysis and EvaluationDereje AberaNo ratings yet

- Luxury Apartments London Construction PlanDocument6 pagesLuxury Apartments London Construction PlanFelo ObaNo ratings yet

- 2023 - 10 - 29 - IGH1645 - Suran Dilina - Unit 504 - Task 02Document17 pages2023 - 10 - 29 - IGH1645 - Suran Dilina - Unit 504 - Task 02Akila DeemanthaNo ratings yet

- Financial Modeling and Analysis of 50 Flats Housing ProjectDocument27 pagesFinancial Modeling and Analysis of 50 Flats Housing Projecthemanth kumar100% (1)

- Post-Construction Services - Ensuring Buildings Function as DesignedDocument2 pagesPost-Construction Services - Ensuring Buildings Function as DesignedRey Dela PeñaNo ratings yet

- Theory BoarderDocument19 pagesTheory BoarderLoed Baruis SamsonNo ratings yet

- Arief Renaldi Wiwaha 17511246 (Exam Lo 1-2)Document3 pagesArief Renaldi Wiwaha 17511246 (Exam Lo 1-2)Arief RenaldiNo ratings yet

- Terms of Reference Environmental SpecialistDocument4 pagesTerms of Reference Environmental SpecialistnpgovlkNo ratings yet

- PETALING JAYA CITY COUNCIL BUILDING CONTROL PROCESSDocument65 pagesPETALING JAYA CITY COUNCIL BUILDING CONTROL PROCESSNurnazihahNo ratings yet

- Construction Company Profile and Project PlansDocument5 pagesConstruction Company Profile and Project PlansYonatanNo ratings yet

- Company Profile: - Name of The CompanyDocument41 pagesCompany Profile: - Name of The CompanyPreetham N ANo ratings yet

- Group 7 Project CharterDocument17 pagesGroup 7 Project CharterJian yiNo ratings yet

- Kenya construction industry actorsDocument11 pagesKenya construction industry actorsISAAC KIPSEREMNo ratings yet

- CE-Project-2-Project-ProposalDocument6 pagesCE-Project-2-Project-Proposalわたしは 由紀No ratings yet

- Arefin Properties LimitedDocument37 pagesArefin Properties LimitedReyad HossainNo ratings yet

- BPM101 - Chap 3 - R1Document34 pagesBPM101 - Chap 3 - R1jin ke maNo ratings yet

- C&M Partners Co. Profile As of JAN 2011Document33 pagesC&M Partners Co. Profile As of JAN 2011joseph_oseoNo ratings yet

- Sites and Services Scheme: The Basic PrinciplesDocument22 pagesSites and Services Scheme: The Basic PrinciplesMageshwarNo ratings yet

- Intern Report1Document40 pagesIntern Report1anteneh hailieNo ratings yet

- Housing - Interview QuestionsDocument5 pagesHousing - Interview QuestionsLeo M. SalibioNo ratings yet

- Teaa Case Study-JzDocument85 pagesTeaa Case Study-JzKota BalaNo ratings yet

- Interiam Payment No. Drainege Ditch Lot - 1 East Hararge Zone Health OfficeDocument1 pageInteriam Payment No. Drainege Ditch Lot - 1 East Hararge Zone Health OfficeRiyaad MandisaNo ratings yet

- Lelo TiyDocument38 pagesLelo TiyRiyaad MandisaNo ratings yet

- Agreemant Contract Documenet 2015 AsphaltDocument168 pagesAgreemant Contract Documenet 2015 AsphaltRiyaad MandisaNo ratings yet

- Interiam Payment No. Drainege Ditch Lot - 1 East Hararge Zone Health OfficeDocument1 pageInteriam Payment No. Drainege Ditch Lot - 1 East Hararge Zone Health OfficeRiyaad MandisaNo ratings yet

- SamiDocument29 pagesSamiRiyaad MandisaNo ratings yet

- Ahmeeed QeeyraaDocument15 pagesAhmeeed QeeyraaRiyaad MandisaNo ratings yet

- Pay Cobil Lot-8Document8 pagesPay Cobil Lot-8Riyaad MandisaNo ratings yet

- Pay Cobil Lot-3Document37 pagesPay Cobil Lot-3Riyaad MandisaNo ratings yet

- Py Cobil 5Document8 pagesPy Cobil 5Riyaad MandisaNo ratings yet

- Amir PyDocument1 pageAmir PyRiyaad MandisaNo ratings yet

- Pay Cobil Lot-4 - NewDocument39 pagesPay Cobil Lot-4 - NewRiyaad MandisaNo ratings yet

- Design Manual for Ethiopia's Low-Volume Rural RoadsDocument45 pagesDesign Manual for Ethiopia's Low-Volume Rural RoadsMichael Kazi100% (1)

- Pymant Booyyii Lo 1 2014Document43 pagesPymant Booyyii Lo 1 2014Riyaad MandisaNo ratings yet

- Standards or NorMS With COST BREakdown AnalysisDocument65 pagesStandards or NorMS With COST BREakdown AnalysisRiyaad MandisaNo ratings yet

- Pymant Booyyii Lo 3 2014Document41 pagesPymant Booyyii Lo 3 2014Riyaad MandisaNo ratings yet

- Jimma, EthiopiaDocument51 pagesJimma, EthiopiaRiyaad MandisaNo ratings yet

- Holostic MyDocument30 pagesHolostic MyRiyaad MandisaNo ratings yet

- 111Document1 page111Riyaad MandisaNo ratings yet

- Form of Selected TopicsDocument1 pageForm of Selected TopicsRiyaad MandisaNo ratings yet

- CertificateDocument1 pageCertificateRiyaad MandisaNo ratings yet

- Data UsmeDocument1 pageData UsmeRiyaad MandisaNo ratings yet

- QubsaDocument20 pagesQubsaRiyaad MandisaNo ratings yet

- Application LetDocument5 pagesApplication LetRiyaad MandisaNo ratings yet

- Tell Me and I'll Forget, Show Me and I May Remember, Involve Me and I'll Understand.Document25 pagesTell Me and I'll Forget, Show Me and I May Remember, Involve Me and I'll Understand.Riyaad MandisaNo ratings yet

- Geometric Design ManualDocument240 pagesGeometric Design ManualRiyaad MandisaNo ratings yet

- Data UsmeDocument1 pageData UsmeRiyaad MandisaNo ratings yet

- Manpower Schedule: Month 2 No YEAR (G.C) 2022 Month 1Document1 pageManpower Schedule: Month 2 No YEAR (G.C) 2022 Month 1Riyaad MandisaNo ratings yet

- Month 2 Activities YEAR (G.C) 2022 Month 1Document1 pageMonth 2 Activities YEAR (G.C) 2022 Month 1Riyaad MandisaNo ratings yet

- Textiles and Clothing SustaninabilityDocument134 pagesTextiles and Clothing Sustaninabilitydike100% (1)

- Ras Abu Aboud Stadium Daily Report 040 (20190613)Document4 pagesRas Abu Aboud Stadium Daily Report 040 (20190613)tuan50% (2)

- 1 Proforma of Allotment LetterDocument32 pages1 Proforma of Allotment LetterGovind SandhaNo ratings yet

- GLOBAL GAME AFK IN THE ZOMBIE APOCALYPSE GAME Chapter 201-250Document201 pagesGLOBAL GAME AFK IN THE ZOMBIE APOCALYPSE GAME Chapter 201-250ganesh sarikondaNo ratings yet

- EU Food Label GuidanceDocument99 pagesEU Food Label GuidanceMunteanu CristianNo ratings yet

- Cse Reviewer - MathDocument58 pagesCse Reviewer - MathLyne LerinNo ratings yet

- SteelsDocument72 pagesSteelsLLNo ratings yet

- Rajagiri Public School Unit Test PhysicsDocument3 pagesRajagiri Public School Unit Test PhysicsNITHINKJOSEPHNo ratings yet

- QRP Yu1lm SDR-RX TXDocument299 pagesQRP Yu1lm SDR-RX TXD BNo ratings yet

- Zenopus ClassicDocument32 pagesZenopus Classicserenity42No ratings yet

- Unit 4 Early HumansDocument8 pagesUnit 4 Early HumansSepfira ReztikaNo ratings yet

- Girbau STI-54 STI-77 Parts ManualDocument74 pagesGirbau STI-54 STI-77 Parts Manualrpm14sheratonbsasNo ratings yet

- Eutelsat 12 West A Satellite FootprintDocument2 pagesEutelsat 12 West A Satellite FootprintSkybrokersNo ratings yet

- 07 IRIS NV PCB OtherDocument15 pages07 IRIS NV PCB OtherArnaldo cordovaNo ratings yet

- Gem EscortingDocument7 pagesGem Escortingsuman sutharNo ratings yet

- RCS England Trainees Guide To A Quality Improvement Project 2021Document17 pagesRCS England Trainees Guide To A Quality Improvement Project 2021Wee K WeiNo ratings yet

- FCV585 FCV620 Operator's Manual G 1-7-11Document57 pagesFCV585 FCV620 Operator's Manual G 1-7-11Katia QuispeNo ratings yet

- Cadence Monte Carlo Simulation TutorialDocument51 pagesCadence Monte Carlo Simulation Tutorialkuomatt100% (1)

- Bosch EBike Product Catalogue MY2021 enDocument92 pagesBosch EBike Product Catalogue MY2021 enIvanNo ratings yet

- Introduction To The Philosophy of The Human PersonDocument14 pagesIntroduction To The Philosophy of The Human PersonDan Niel50% (2)

- The Image of The CityDocument17 pagesThe Image of The CityMay Rose ParagasNo ratings yet

- Atlas MothDocument1 pageAtlas Mothlililala92No ratings yet

- vCloudPoint Sharing Computing Solution Data Sheet PDFDocument8 pagesvCloudPoint Sharing Computing Solution Data Sheet PDFkus satria dNo ratings yet

- EE 102 Cabric Final Spring08 o Id15Document10 pagesEE 102 Cabric Final Spring08 o Id15Anonymous TbHpFLKNo ratings yet

- The Picture of Dorian GrayDocument137 pagesThe Picture of Dorian GrayАнгелаС.No ratings yet

- AABB Accredited DNA Testing FacilitiesDocument2 pagesAABB Accredited DNA Testing Facilitiesjosueduran75No ratings yet

- Differences in Left Ventricular and Left Atrial FuDocument10 pagesDifferences in Left Ventricular and Left Atrial FueugeniaNo ratings yet