Professional Documents

Culture Documents

Study of Miyawaki Forest Method in Reducing Co Emission From Concrete Block Production Industry

Uploaded by

Ritesh MehtaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Study of Miyawaki Forest Method in Reducing Co Emission From Concrete Block Production Industry

Uploaded by

Ritesh MehtaCopyright:

Available Formats

International Journal of Research in Engineering and Science (IJRES)

ISSN (Online): 2320-9364, ISSN (Print): 2320-9356

www.ijres.org Volume 10 Issue 8 ǁ August 2022 ǁ PP. 622-630

Study of Miyawaki Forest Method in Reducing Co2

Emission from Concrete Block Production Industry

1

B. Praveen,B.E., 2Asst.prof. T.Sathieshkumar

Department of Civil Engineering,

Gnanamani College of Technology,

Tamil Nadu, India.

Abstract

Climate change is one of the major issues which the world is facing right now caused by the emission of harmful

Greenhouse gases such as carbon dioxide(CO2), chlorofluorocarbon(CFC), methane(CH4), etc. These harmful

gases are mainly generated from industrial activities, and from other anthropogenic activities. And this leads to

the increasing rate of carbon dioxide which will in turn leads to global warming. So it is very important to

determine the amount of carbon dioxide produced into the atmosphere. In past years many methods and

technologies have been introduced for reducing the rate of carbon dioxide. But studies on natural methods for

reducing CO2 emissions are limited. Miyawaki forest is one such method that involves planting trees per square

meter. This will reduce the temperature, air and noise pollution, etc. This project focuses on studying about

Miyawaki forest method for reducing CO2 emissions from industries. For the present study different industries

located in Trivandrum, Kerala will be considered. Finally, a cement concrete production industry was selected

for this project which is located in an urban area.

Keywords: 1. Miyawaki, 2. Greenhouse gas, 3. Concrete, 4. Industry.

----------------------------------------------------------------------------------------------------------------------------- ---------

Date of Submission: 18-08-2022 Date of acceptance: 02-09-2022

----------------------------------------------------------------------------------------------------------------------------- ----------

I. I INTRODUCTION

1.1 Miyawaki Forest / Miyawaki Method

Miyawaki is a technique pioneered by Japanese botanist Akira Miyawaki, that helps build dense, native

forests. The approach is supposed to ensure that plant growth is 10 times faster and the resulting plantation is 30

times denser than usual. It involves planting dozens of native species in the same area and becomes

maintenance-free after the first three years.

1.2 Miyawaki Process

The native trees of the region are identified and divided into four layers — shrub, sub-tree, tree, and

canopy.

The quality of soil is analyzed and biomass

which would help enhance the perforation capacity, water retention capacity, and nutrients in it, is

mixed with it.

A mound is built with the soil and the seeds are planted at a very high density — three to five saplings

per square meter.

The ground is covered with a thick layer of mulch.

Step 1: Determine the soil texture and quantify biomass

Soil texture helps determine water holding capacity, water infiltration, root perforation capacity, nutrient

retention, and erodibility. Check if the texture is sandy, loamy, or clayey. Perforator materials help to improve

perforation and allow roots to grow quickly. For this, we can use biomass that is spongy and dry in nature. The

husk is a by-product and is easily available at grain mills and animal feed stores. Other options include Rice

husk, wheat husk, corn husk (chipped), or groundnut shells (chipped).

Water retainer helps soil retain more moisture and water, as compared to its natural water retention capacity.

Natural materials such as coco-peat or dry sugarcane stalk can be used. A good test is to dip the material into the

water for some time, take it out and squeeze. If water oozes out during squeezing, then the material can be used

as a water retainer.

www.ijres.org 622 | Page

Study Of Miyawaki Forest Method In Reducing Co2 Emission From Concrete Block ..

Step 2: Select tree species for plantation

Make a database of all native species of your area. Identify its type (Evergreen, Deciduous, or Perennial),

advantages, maximum height, and assign layer. Check the native species sapling’s availability in the nursery,

their age, and sapling height. The ideal height is 60 to 80 centimeters. Major species: Choose five different

species to be the major forest species; these should be the species that you commonly find in your area. This will

constitute 40-50 percent of the number of trees in the forest. Supporting species – other common species of the

area will constitute 25-40 percent, and minor native species will make up the rest. Select tree species for

plantation shown in fig.4

Step 3: Design the forest

Master Plan: Identify the exact area for afforestation to procure materials and execute the project. The minimum

width of the project area should be 3 meters, but 4 meters is recommended.

Watering Plan: The water pipeline layout may need to be designed by an architect, based on the daily water

requirement for the area, backed by borewells and overhead tanks. The forest should be watered regularly for the

first 2-3 years.

Planning Project Execution: We also need to identify spaces such as the material/sapling/equipment storage

areas, site offices, and resting areas for laborers. There should also be approach roads to the afforestation area for

earthmover access, and to the materials/saplings storage areas for truck access, if the project area is large.

Step 4: Preparing the area

Site inspection: Visit the site to determine the feasibility and scope of the project. Take pictures of the site, and

confirm the availability of fencing, maintenance staff, running water, and sunlight. The site should get sunlight

for a minimum of 8-9 hours a day. No pipes/drains/wires or debris should be present in the area.

Removing debris and weeds: Weeds take away the nutrition of the soil and also restrict the movement of

materials and people. Hence they should be cleaned either manually or using a JCB/John Deere Tractor if the

area is huge. Ensure that the pulled-out weeds are disposed of away from the site; else they may re-grow.

Watering facility installation: There should be a main line with watering outlets for hoses, which can reach the

entire area of the forest. Watering should be done every day manually using a hosepipe with a shower and not by

drip irrigation, sprinklers, etc. The requirement is around 5 liters/sq meter per day.

Physical demarcation of areas: The areas should be marked (with limestone powder or wooden peg/rope) before

earthwork starts. Ensure that the marking of areas matches 100 percent with the master plan.

Making approach roads to marked areas: Clear weed growth, big stones, and boulders. The path could be of any

material (soil, sand, gravel, tar, etc.), but trucks/tractors should be able to use it.

Mound identification: The forests are usually created on 100 sq meter mounds, and each of these needs a serial

number in the order in which they will be created. Only after one mound is created and a plantation completed

on it, can the next mound be created.

Step 5: Plant the trees!

Mixing materials: Perforator, water retainer, and fertilizer, all without clumps, should be mixed. They should be

mixed in the exact ratio as was decided initially, for each mound.

Preparing the ground for plantation: Each forest is created on a 100 sqm mound. Using an earthmover machine,

first dig the earth to a depth of 1 meter on 100 sqm of land. Put half the earth back into the pit and spread it

www.ijres.org 623 | Page

Study Of Miyawaki Forest Method In Reducing Co2 Emission From Concrete Block ..

uniformly. This is to make the soil loose. Mix with the soil half the biomass prepared in the previous step. Then

put the remaining soil back into the pit and spread it uniformly. Now mix the remaining biomass with this soil

evenly. Afterward, shape the soil into a mound. In the Miyawaki method, all saplings will be planted together on

a mound, unlike conventional plantations where individual pits are dug up for each sapling.

Selecting trees for plantation: Place plants on the mound to create a multi-layered, natural forest. Try to group

plants that grow into different layers – shrub, subtree, tree, and canopy – in each sqm. Try not to place two trees

of the same kind next to each other; also, don’t follow a pattern while planting the trees. Try to maintain a

distance of 60 cm between saplings. The goal is to have a random, dense plantation of native tree species.

Plantation: To plant the tree, dig a small pit on the mound with a trowel, remove the root bag in which the plant

was growing, and gently place the plant in the pit. Level the soil outside gently around the stem of the plant, but

do not press or compact the soil. There should not be more than 8-10 people on a mound at a time, since the idea

is to plant on loose, aerated soil.

Support the plants with sticks: Saplings need support during the initial months so that they don’t droop or bend.

Insert support sticks into the soil close to the plant, without damaging the roots of the plant. For plants shorter

than 1 meter, use 1 meter-long bamboo sticks. For taller plants, use slightly thicker 2 - 2.5 meter-long bamboo

sticks. Tie the sticks to the plant stems using thin jute strings. Support sticks will be needed for at least every

alternate plant.

Mulching: Mulch should be evenly laid out on the soil, in a 5 - 7 inch layer. To ensure that the mulch stays on

the ground and does not fly around, it should be tied down with jute ropes. For this, bamboo pegs should be

nailed at the periphery of the forest. Tie the pegs to each other with rope, pressing down on the mulch. There

should be 30 pegs, each around 2 ft long, around every 100 sqm mound.

First watering: The first time, the forest should be watered for an hour. The minimum water requirement is 5

liters per sqm or 500 liters per 100 sqm mound.

Step 6: Look after the forest for three years

Monitoring: The forest should be monitored once in 1-2 months, to check if the targets have been achieved and

if any changes should be made to improve results. This should be done in the first 8-12 months. Count the

number of saplings that have survived, and record the data. The growth of selected species should also be

monitored.

Maintenance: Water the forest with a hose pipe once a day. Keep the forest weed-free for the first 2-3 years.

Once the forest starts growing, weed growth will stop. Ensure that the plants stay straight, are not buried under

the mulch, and are only loosely tied to the support stick. Keep the forest clean, and free of plastic, paper, etc.

Maintain a proper drainage system so that water does not get accumulated anywhere in the forest. Do not build

bunds in the forest, as accumulated water can kill plant roots. The mortality rate of plants is usually 2-5 percent.

Mortality is to be checked only after 3-4 months of planting. Do not use any chemicals like pesticides or

inorganic fertilizers. If you notice pests, leave them undisturbed. The forest will slowly build its mechanism to

keep itself healthy. Mulching should be maintained for at least one year. The soil should be re-mulched with

time since dry soil is detrimental to forest health. Also, never remove organic matter like fallen leaves from the

forest floor, as it will kill good soil microbes. As the tree grows taller, longer support sticks may be needed so

that the tree shoot does not bend and become weak. Never cut or prune the forest as it could make the forest

weaker. Process Miyawaki method shown in fig.5

Fig.5 Process of Miyawaki method

www.ijres.org 624 | Page

Study Of Miyawaki Forest Method In Reducing Co2 Emission From Concrete Block ..

It has revolutionized the concept of urban afforestation by turning backyards into mini-forests. This method

includes planting trees (only native species) as close as possible in the same area which not only saves space, but

the planted saplings also support each other in growth and block sunlight from reaching the ground, thereby

preventing the growth of weed. The saplings become maintenance-free (self-sustainable) after the first three

years. The approach is supposed to ensure that plant growth is 10 times faster and the resulting plantation is 30

times denser than usual. Miyawaki method helps to create a forest in just 20 to 30 years, while conventional

methods take anywhere between 200 to 300 years.

1.3 Selection of Industry

For the present study, a site was selected from Trivandrum district, Kerala is Regional Nirmithi Kendra –

Concrete block production unit. The site was chosen in such a way that the rate of carbon emission is more.

Also to know the difference in carbon emission before and after implementing Miyawaki forest in that critical

area.

The total area of Industry = 1 acre 17.960 cent

Available area for project = 2750 sqm.

The site was represented as a critical area because the considered industry was having hollow block production

unit. Therefore the usage of cement content will be higher so the emission of carbon will also be higher.

www.ijres.org 625 | Page

Study Of Miyawaki Forest Method In Reducing Co2 Emission From Concrete Block ..

The site was chosen because the selected industry was located in an urban area surrounded by many residential

buildings in addition to that a hollow brick production unit is also functioning. Therefore the pollutants, as well

as carbon emitted, will be higher in this location compared to normally functioning industries. A large number of

hollow bricks made of cement are made per day. Due to the high usage of cement content, the emission of

carbon will be much higher.

After collecting the necessary data, such as how much hollow bricks are produced per day, total cement content

used per day, etc.. Using formulas from past research, the carbon emitted will be determined. After finding the

total carbon emission at the site, the soil condition will be checked for further implementation of the Miyawaki

forest.

The carbon emission will be determined after implementing the Miyawaki forest. The difference in carbon

emission can be found before and after implementing the Miyawaki forest to study the effectiveness of the

method in the reduction of carbon.

The data collected from the industry shows that there are mainly two machines used;

Concrete mixer machine

Concrete block-making machine

1.5 HP Motor pump etc.

These are working with electricity and hydraulic power. So that the CO2 emission from the machinery is not

indirect.

1.4 Implementation of Miyawaki forest

1.4.1 List of Trees – Industrial regions

In industrial areas, trees that may reduce noise and air pollution and act as a barrier against dust

should be used. Every piece of vacant land in these places needs to be planted with trees and other vegetation.

As per the research of the Kerala Bio-diversity Board, the list of trees that can be used in industrial regions is

given below;

Sl no. Scientific name English name

1. Artocarpus heterophyllus Jackfruit Tree

2. Mangifera indica Mango Tree

3. Hopea parviflora Iron wood of Malabar

4. Morinda coreia Indian Mulberry

5. Grewia tiliifolia Dhaman

6. Lagerstroemia reginae Queen's crepe-myrtle

7. Ailanthus triphysa Maharukh Tree

8. Saraca asoca Ashoka Tree

9. Garcinia gummi-gutta Malabar Tamarind

10. Butea monosperma Flame-of-the-Forest

11. Careya arborea Patana oak (Wild guava)

12. Pongamia pinnata Pongamia Tree

13. Syzygium cumini Jambul

14. Ficus religiosa Peepal tree

15. Ficus benghalensis Banyan tree

16. Azadirachta indica Neem

17. Mimusops elengi Spanish cherry (Medlar)

www.ijres.org 626 | Page

Study Of Miyawaki Forest Method In Reducing Co2 Emission From Concrete Block ..

1.4.2 Trees by Layers

1.4.2.1 Canopy layer

This is the top layer of the Miyawaki forest. This layer contains trees above 40 feet in height.

A list of canopy layer trees is given below;

Sl Name of Trees – Canopy layer

no.

1. Sacred fig

2. Wild jack

3. Black varnish tree

4. Indian rosewood

5. Red Silk cotton tree

6. Blackboard tree, Devil’s tree

7. Bullet wood

8. Cinnamon

9. White teak

10. Strychnine tree

11. Malamanchadi

12. Yellow teak

13. Mango tree

14. Coral wood tree

15. Indian Coral, Tiger’s claw, Sunshine

16. tree

17. Fragrant ashok

18. Indian Gooseberry

19. Tree of heaven

20. Banyan tree

Jack fruit tree

1.4.2.2 Tree layer

This layer contains trees about 20 - 40 feet in height.

Sl Name of Trees – Tree layer

no.

1. Kanara nutmeg

2. Malabar ebony,Wild Mangosteen

3. Fragrant padre tree

4. Indian tulip tree

5. Beach Calophyllum

6. Red sandalwood

7. Rambutan

8. Rudraksham

9. Chikoo/Sapota

10. Bread fruit

11. Indian laurel

12. Bastard myrobalan

13. Panama tree

14. Indian beech

15. Tamarind

16. White cedar

17. White dammar

18. Malabar kino

19. Vediplavu

20. Karinthuvara

www.ijres.org 627 | Page

Study Of Miyawaki Forest Method In Reducing Co2 Emission From Concrete Block ..

1.4.2.3 Sub–tree layer

This layer contains trees about 6 - 12 feet in height.

Sl Name of Trees – Sub Tree layer

no.

1. Star fruit

2. Custard apple

3. Illipe butter tree

4. Powderpuff mangrove

5. Vegetable hummingbird

6. Sage leaved alangium

7. Wax apple, Java apple

8. White silk cotton

9. Cluster fig

10. Avocado

11. Dhaman

12. Sandalwood tree

13. Cacao tree

14. Dyer’s oleander

15. Burma Ironwood

16. Coffee

17. Mangosteen oil tree

18. Indian rock fig

19. Cashew nut

20. Kattuchamba

21. Drumstick

22. Neermulli

23. Sea Hibiscus

24. Garari

25. Pong Pong Tree

1.4.2.4 Shrub layer

This layer contains trees about 6 feet in height.

Sl Name of Trees – Shrub layer

no.

1. Malabar nut

2. Candle bush

3. Water hemp

4. Oleander

5. China rose

6. Lemon

7. Turkey berry

8. Confederate rose

9. East Indian screw tree

10. Cape jasmine

11. Citron

12. Lemon basil

13. Holy basil

14. Small knotweed

15. Horse wood, maggot killer

16. Chinese chaste tree

17. Curry tree

18. Ironwood tree

19. Rattle weed

20. Indian leadwort

21. Ceylon leadwort

22. Pagoda flower

23. Mountain sweet thorn

24. Pomelo

www.ijres.org 628 | Page

Study Of Miyawaki Forest Method In Reducing Co2 Emission From Concrete Block ..

25. Golden trumpet vine

26. Firecracker plant

27. Camphor Basil

II. RESULTS AND DISCUSSIONS

2.1 GENERAL

The results obtained for the present study are discussed in this section;

2.2 OBSERVATION

From the first phase of this project, as per the calculation, the average CO2 emission from the production of the

concrete block of the selected industry is approx. 0.004 kiloton per day.

Chemical composition of wood

The main component of the cell walls of trees is Cellulose (C6H10O5)n.

Carbon – 50%

Oxygen – 42%

Hydrogen – 6%

Nitrogen – 1%

Mineral matter - 1%

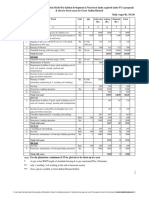

2.3 CALCULATION

CO2 Absorbs

1000 kg of tree = 100 % humidity

Therefore, Water content = 500 kg

Dry mass = 500 kg

47.5 % of Dry mass is Carbon = 500 x (47.5/100)

Dry mass of Carbon = 237.5 kg

As per the Molar mass ratios,

The molar mass of carbon = 12

The molar mass of oxygen = 16

Atomic mass of CO2 = 12+(16x2)

=44

1 kg of carbon will produce = 44/12

= 3.67 kg of CO2

CO2 absorbs 1000 kg of wood = 237.5 x 3.67

= 871.625 kg

CO2 absorbs 10 kg of wood = 871.625/1000

= 8.72 kg

As per the Miyawaki forest method, the Wood of the Canopy layer & tree layer becomes 15 kg and the Shrub

layer becomes 7 kg within 12 months. 3 to 5 trees and plants are planted by the Miyawaki method per square

meter. So, an average of 60 kg of wood is within a square meter.

CO2 absorbs per sq.m = 6 x 8.72kg

= 52.32 kg

Total number of days for production = 5 days x 12 months

= 60 days per year

Total emission of CO2 per year = 0.004 x 60

= 0.24 kiloton

Total absorption of CO2 per sq.m per year = 0.00005 kilotons.

The available area of the industry = 2750 m2

Total absorption of CO2 = 2750 x 0.00005 kiloton

= 0.138 kiloton.

This method can be reduced the 60 % of CO2 emission from the selected industry.

III. CONCLUSION

As per the calculation, the average CO2 emission from the production of a concrete block in the selected

industry is approx. 0.24 kiloton per year. As per the project, the absorption of CO 2 per sq.m is 52.32 kg by the

Miyawaki forest method. The total absorption of CO2 per year is about 0.138 kilotons. This means, by this

method 60 % of total CO2 emissions can be reduced within one year gradually.

www.ijres.org 629 | Page

Study Of Miyawaki Forest Method In Reducing Co2 Emission From Concrete Block ..

REFERENCES

[1]. Martins.T., et al. (2021) investigated the intertemporal relationships caused by the coal, oil, and natural gas consumption in the

carbon dioxide emission by the G7 countries from 1965 to 2018

[2]. Adeyemi AdesinaI, (2020) studied the increasing sustainability awareness has put the concrete industry in the spotlight to reduce its

carbon dioxide emissions.

[3]. Clara Manuel,(2020) investigated the gathering and highlighting of scientific data through the compilation of Existing Miyawaki

forests studies.

[4]. Miyawaki A (1992). Restoration of Evergreen Broad-leaved Forests in the Pacific Region. In: M.K. Wali (ed.). Ecosystem

Rehabilitation.

Author’s details

1

B.Praveen, B.E., Department of Civil Engineering, Gnanamani College of Technology, Tamil nadu, India,

praveenbalajivel@gmail.com.

2

Asst. Prof. T.Sathieshkumar, Department of Civil Engineering, Gnanamani College of Technology, Tamil nadu,

India, sathieshcvl@gmail.com.

www.ijres.org 630 | Page

You might also like

- Square Foot GardeningDocument259 pagesSquare Foot GardeningLuke Rohde100% (7)

- Landscaping GuideDocument8 pagesLandscaping Guidekokosmart007No ratings yet

- E BizhubProC6500 Troubleshooting Guide Ver1.0Document32 pagesE BizhubProC6500 Troubleshooting Guide Ver1.0k_krotNo ratings yet

- MODULE 1 Land PreparationDocument8 pagesMODULE 1 Land Preparationariolamarygrace08No ratings yet

- Manure in MalawiDocument7 pagesManure in Malawiluis ruperto flores100% (2)

- Final Design Dwgs Rolpa Slope StabilityDocument5 pagesFinal Design Dwgs Rolpa Slope StabilityPrakash Singh RawalNo ratings yet

- Hydroponics ManualDocument35 pagesHydroponics ManualAlecsa Robert50% (2)

- ProposalDocument14 pagesProposalShikhar Joshi100% (1)

- 2014 - Hamidi - Distinguished Ground Improvement Projects by Dynamic Compaction or Dynamic ReplacementDocument675 pages2014 - Hamidi - Distinguished Ground Improvement Projects by Dynamic Compaction or Dynamic ReplacementDavi Nowicki GieseNo ratings yet

- The Ultimate Permaculture Gardening for Beginners: Profitable gardening, #3From EverandThe Ultimate Permaculture Gardening for Beginners: Profitable gardening, #3No ratings yet

- Grade 7 CBC Complete Agriculture NotesDocument67 pagesGrade 7 CBC Complete Agriculture NotesRaphael Leyson100% (5)

- Perform Nursery OperationsDocument6 pagesPerform Nursery OperationsCcz Vitali Campus100% (3)

- DLL Grade 9-AFADocument15 pagesDLL Grade 9-AFATolentino Maganan LoryNo ratings yet

- Tree Planting Activity - NSTPDocument7 pagesTree Planting Activity - NSTPKenjy Louise CasiñoNo ratings yet

- Paper Vending MachineDocument67 pagesPaper Vending MachineLawrenze Morales78% (9)

- Brochure Manual Nutrient Solutions For Greenhouse Crops Global en UsDocument94 pagesBrochure Manual Nutrient Solutions For Greenhouse Crops Global en UsirkhajuNo ratings yet

- How To Make A Mini Forest With Miyawaki MethodDocument7 pagesHow To Make A Mini Forest With Miyawaki MethodLuís Palma RodriguesNo ratings yet

- Tree Nursery How To PDFDocument6 pagesTree Nursery How To PDFpankaj suryaNo ratings yet

- For Establishment of Under The Grants-In-Aid For Greening India Scheme During The 10Th Plan PeriodDocument14 pagesFor Establishment of Under The Grants-In-Aid For Greening India Scheme During The 10Th Plan PeriodrupinderNo ratings yet

- Benzir - Speech 2Document3 pagesBenzir - Speech 2Benzir HussainNo ratings yet

- Tree Plantation: Various Techniques and Their ImportanceDocument10 pagesTree Plantation: Various Techniques and Their ImportanceDivyansh RajatNo ratings yet

- New Developments in The Giant Reed (Arundo Donax) and Bamboo Two Highly Productive Biomass Crops For Food, Fuel and FiberDocument2 pagesNew Developments in The Giant Reed (Arundo Donax) and Bamboo Two Highly Productive Biomass Crops For Food, Fuel and FiberKevin J. MillsNo ratings yet

- Report On Mulching Machine Sem 1Document17 pagesReport On Mulching Machine Sem 1Siddhesh Zirpe50% (2)

- Hole DiggerDocument67 pagesHole DiggerJeevan Landge PatilNo ratings yet

- Tree Nursery Establishment and Tree ManagementDocument17 pagesTree Nursery Establishment and Tree ManagementJulia Dela CruzNo ratings yet

- Community Development ProjectDocument19 pagesCommunity Development ProjectShivanshu PandeyNo ratings yet

- PlantationDocument71 pagesPlantationasaminew awokeNo ratings yet

- Tree Plantation in BangladeshDocument8 pagesTree Plantation in Bangladeshসুখী মানুষ50% (2)

- Forest TutorialDocument6 pagesForest TutorialMuddassarNo ratings yet

- Assignment 1 TKPDocument17 pagesAssignment 1 TKPJanatun Maqwa JemaliNo ratings yet

- IGBC Water ConservationDocument15 pagesIGBC Water ConservationVarsha KadapattiNo ratings yet

- AGSHqf 5 XYy 0 D M66 O4 Z191 LG D0 ZGW ML VCAcri Ig E4Document5 pagesAGSHqf 5 XYy 0 D M66 O4 Z191 LG D0 ZGW ML VCAcri Ig E4Gaddipati MohankrishnaNo ratings yet

- Midterm Exam - Bom01. p1Document4 pagesMidterm Exam - Bom01. p1Briann BarriosNo ratings yet

- Guidelines For Plantation in The Industrial Parks of TelanganaDocument23 pagesGuidelines For Plantation in The Industrial Parks of TelanganaswathiNo ratings yet

- TLE - 9 (HORTICULTURE) - q3 - CLAS1 - Land Clearing and Cultivation Practices and Procedures - v2 (FOR QA) - Liezl ArosioDocument11 pagesTLE - 9 (HORTICULTURE) - q3 - CLAS1 - Land Clearing and Cultivation Practices and Procedures - v2 (FOR QA) - Liezl ArosioGerlie VillameroNo ratings yet

- Pakistan Citrus Growers Nutrition HandbookDocument14 pagesPakistan Citrus Growers Nutrition Handbookkhan.hulk555No ratings yet

- Xeriscape: Considerations Commercial Status Implementation Issues GuidelinesDocument14 pagesXeriscape: Considerations Commercial Status Implementation Issues GuidelinesTarun MattaparthyNo ratings yet

- GB AssignmentDocument12 pagesGB AssignmentAvinash GudipatiNo ratings yet

- Chipped WoodDocument12 pagesChipped WoodVeganOrganicNetworkNo ratings yet

- Adopt A Plant CDPDocument11 pagesAdopt A Plant CDPAnil KumarNo ratings yet

- Module 4 - Forestry & Environment PDFDocument11 pagesModule 4 - Forestry & Environment PDFManoa Nagatalevu TupouNo ratings yet

- Guide To Artificial Perches For BirdsDocument9 pagesGuide To Artificial Perches For BirdsOmar RodriguezNo ratings yet

- Alternative Techniques For Removing Trees and BushesDocument73 pagesAlternative Techniques For Removing Trees and BushesjimborenoNo ratings yet

- Kakerenge-Bibbo-Buwambo RoadDocument6 pagesKakerenge-Bibbo-Buwambo RoadBrian MatovuNo ratings yet

- Treatment Using Lab Sacle Reed Bed Using Phragmitis AustralisDocument8 pagesTreatment Using Lab Sacle Reed Bed Using Phragmitis AustralisAlvaro Bonfante PoloNo ratings yet

- Wadz Notes q4 - Clean Up On Completion of Nursery WorkDocument28 pagesWadz Notes q4 - Clean Up On Completion of Nursery WorkEdward YagoNo ratings yet

- CDP HarshitDocument12 pagesCDP Harshitpersonal computerNo ratings yet

- Plantation EstablishmentDocument65 pagesPlantation Establishmentjoshua nomusNo ratings yet

- Social Issues and EnvironmentDocument9 pagesSocial Issues and Environmentdellaishere03No ratings yet

- Unit-4 Social Issues & Environment Sustainable DevelopmentDocument9 pagesUnit-4 Social Issues & Environment Sustainable DevelopmentdhanushNo ratings yet

- Ap 10 Compensatory Afforestation PDFDocument4 pagesAp 10 Compensatory Afforestation PDFRaja VishnudasNo ratings yet

- Hydroponics I: Lesson 3Document19 pagesHydroponics I: Lesson 3Bashar DaoudNo ratings yet

- PlantationDocument23 pagesPlantationasaminew awokeNo ratings yet

- Module 1Document83 pagesModule 1Panfilo MaglasangNo ratings yet

- Presentation Science Group 4Document15 pagesPresentation Science Group 4Yuan OlvisNo ratings yet

- Intensive Moringa Oleifera Cultivation in The North of SenegalDocument7 pagesIntensive Moringa Oleifera Cultivation in The North of SenegalFarhat DurraniNo ratings yet

- Guias 801-2 EnviromentDocument4 pagesGuias 801-2 EnviromentlcastellanosNo ratings yet

- Kanyogoga-Senge RoadDocument5 pagesKanyogoga-Senge RoadBrian MatovuNo ratings yet

- Design Considerations For An Engineered PDFDocument7 pagesDesign Considerations For An Engineered PDFBrian chunguliNo ratings yet

- Nadep MethodDocument8 pagesNadep MethodSandeep_AjmireNo ratings yet

- My Technoguide For Ampalaya Production Part 1Document39 pagesMy Technoguide For Ampalaya Production Part 1haroldlacaba67% (3)

- PDF DocumentDocument20 pagesPDF DocumentJoan Orcino AndayaNo ratings yet

- Busakya-Galamba-Jjagala RoadDocument6 pagesBusakya-Galamba-Jjagala RoadBrian MatovuNo ratings yet

- Souvick ChakrabortyDocument13 pagesSouvick ChakrabortyManas ChowdhuryNo ratings yet

- JC Excellente Christian Academy Inc.: TOPIC: Soil Resources InstructionDocument4 pagesJC Excellente Christian Academy Inc.: TOPIC: Soil Resources InstructionJi PaoNo ratings yet

- E-Tappal and E-File Training Presentation V 1.0Document29 pagesE-Tappal and E-File Training Presentation V 1.0Ritesh MehtaNo ratings yet

- Lion Corridor AreaDocument2 pagesLion Corridor AreaRitesh MehtaNo ratings yet

- Fca GR For Non CADocument2 pagesFca GR For Non CARitesh MehtaNo ratings yet

- CA Model For Habitat DevlopmentDocument2 pagesCA Model For Habitat DevlopmentRitesh MehtaNo ratings yet

- Annexure 31Document1 pageAnnexure 31Ritesh MehtaNo ratings yet

- Geo Refrence Map: LegendDocument1 pageGeo Refrence Map: LegendRitesh MehtaNo ratings yet

- Non Forest Land Declaration No AppliedDocument1 pageNon Forest Land Declaration No AppliedRitesh MehtaNo ratings yet

- Compensatory Affore Scheme Model3Document2 pagesCompensatory Affore Scheme Model3Ritesh MehtaNo ratings yet

- Handbook of FC Act, Rules & Guidelines, 2019Document133 pagesHandbook of FC Act, Rules & Guidelines, 2019SunitaNo ratings yet

- FCA Check ListDocument7 pagesFCA Check ListRitesh MehtaNo ratings yet

- FCA Proposals Model 3Document1 pageFCA Proposals Model 3Ritesh MehtaNo ratings yet

- Digital Signal ProcessorDocument10 pagesDigital Signal ProcessorRitesh MehtaNo ratings yet

- Fca GR For Non CADocument2 pagesFca GR For Non CARitesh MehtaNo ratings yet

- City PlantationDocument1 pageCity PlantationRitesh MehtaNo ratings yet

- Bharuch JambusarDocument1 pageBharuch JambusarRitesh MehtaNo ratings yet

- Anti-Theft Security For Car Audios PDFDocument1 pageAnti-Theft Security For Car Audios PDFShrivlsi RamNo ratings yet

- Relay BasicsDocument13 pagesRelay BasicsHumayun AhsanNo ratings yet

- 06 Intel 8086 ArchitectureDocument28 pages06 Intel 8086 ArchitectureRisheena BeegumNo ratings yet

- Charalambous 2013Document6 pagesCharalambous 2013Rifat SaufiNo ratings yet

- Factors Affecting Crop Production: Pite U. Banayag, L.AgrDocument81 pagesFactors Affecting Crop Production: Pite U. Banayag, L.AgrFaqihuddin SP0% (1)

- Final Bulletin 77Document57 pagesFinal Bulletin 77Vaibhav DhayeNo ratings yet

- Chapter - 9 IrrigationDocument17 pagesChapter - 9 IrrigationrahulNo ratings yet

- East African: Naturally NurturedDocument32 pagesEast African: Naturally NurturedMercyNo ratings yet

- Bsi BS en Iso 16387 - 2014Document34 pagesBsi BS en Iso 16387 - 2014alferedNo ratings yet

- Design of RE WallDocument29 pagesDesign of RE WallraghuramammavajjalaNo ratings yet

- Soil Mineralogy With Environmental Applications (1) - Páginas-484-540Document57 pagesSoil Mineralogy With Environmental Applications (1) - Páginas-484-540Suane SouzaNo ratings yet

- Genetic Erosion, Drought Tolerance and Genotype by Environmentinteractionofdurum Wheat (Triticum TurgidumDocument205 pagesGenetic Erosion, Drought Tolerance and Genotype by Environmentinteractionofdurum Wheat (Triticum Turgidumyohanes eshetuNo ratings yet

- 2011 Deformation and Consolidation Around Encased Stone ColumnsDocument9 pages2011 Deformation and Consolidation Around Encased Stone ColumnsS R Kumar KonathalaNo ratings yet

- Cbse Class 10 Science Notes Chapter 16 Sustainable Management of Natural ResourceDocument5 pagesCbse Class 10 Science Notes Chapter 16 Sustainable Management of Natural ResourceRajnesh vanavarajanNo ratings yet

- Vila Thik UlamDocument42 pagesVila Thik UlamRuban DanielNo ratings yet

- TOOLSDocument4 pagesTOOLSNikkita Bartolome0% (1)

- Scientific American - Carbonic Acid Gas To Fertilize The AirDocument4 pagesScientific American - Carbonic Acid Gas To Fertilize The AirJesus LopezNo ratings yet

- Velcon Aviation Fuel Filter Cartridges ManualDocument2 pagesVelcon Aviation Fuel Filter Cartridges ManualAbdul BasitNo ratings yet

- Report 4Document52 pagesReport 4Deo DoktorNo ratings yet

- Permaculture Design For Land For LifeDocument39 pagesPermaculture Design For Land For LifeGaspar NorbertNo ratings yet

- GRE-Verbal Behind The Scenes 2014Document174 pagesGRE-Verbal Behind The Scenes 2014radrajithNo ratings yet

- Subgrade Strengthening of Roads On Black Cotton Soil Using Quarry DustDocument3 pagesSubgrade Strengthening of Roads On Black Cotton Soil Using Quarry DustVENKATESH POONDRUNo ratings yet

- Social Studies Notes Pack 2 - 2020Document46 pagesSocial Studies Notes Pack 2 - 2020Michael ChipashaNo ratings yet

- Tanda Thermal Power 04aug09 PDFDocument189 pagesTanda Thermal Power 04aug09 PDFGeetanjalivkNo ratings yet

- Scratch Programming For TeensDocument9 pagesScratch Programming For TeensPraveen KumarNo ratings yet

- Human-Induced Threats To Bio-Diversity in North-East India With Special Reference To MajuliDocument10 pagesHuman-Induced Threats To Bio-Diversity in North-East India With Special Reference To MajuliIJBSS,ISSN:2319-2968No ratings yet

- Karnal Gazeetter 1892Document314 pagesKarnal Gazeetter 1892Parveen Kumar100% (3)