Professional Documents

Culture Documents

Clisis 5

Uploaded by

fortroniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Clisis 5

Uploaded by

fortroniCopyright:

Available Formats

5 ROOM PRELIMINARY REQUIREMENTS

5.1 INTRODUCTION

The CLISIS remote tilting table can be installed in a room that has been officially

approved for the operation of radiological equipment of the same class.

In addition, proper operation of the unit can be achieved only if the environmental

characteristics specified in the following sections are strictly observed.

WARNING:

ENSURE THAT THE CONSTRUCTION AND LOAD CAPABILITY OF THE

FLOOR ARE SUFFICIENT FOR THE INSTALLATION OF THIS EQUIPMENT.

ENSURE THAT THE CENTRAL GROUND TERMINAL OF THE ROOM HAS A

RESISTANCE IN ACCORDANCE WITH THE REGULATIONS IN FORCE.

ENSURE THAT THE ROOM LINE INPUT IS PROTECTED BY MEANS OF A

DIFFERENTIAL BREAKER CALIBRATED FOR A MAXIMUM LEAKAGE

CURRENT OF 30mA.

ENSURE THAT THE ROOM EMERGENCY CIRCUIT IS PRESENT AND

DESIGNED IN ACCORDANCE WITH THE REGULATIONS IN FORCE.

FAILURE TO COMPLY WITH THIS WARNING MAY CAUSE SERIOUS OR

FATAL BODILY INJURY AND DEGRADE THE UNIT SAFETY LEVEL.

5.2 ACCESSORIES FOR INSTALLATION

In order to properly install the CLISIS remote tilting table, the use of special

accessories for the installation might be necessary. The accessories to be used

depend on the room constructions and should be ordered before the installation

starts.

CLISIS installation dollies Mecall p/n SXAA02

CLISIS over floor installation plate Mecall p/n SXAA03

CLISIS under floor installation plate Mecall p/n SXAA04

CLISIS SERVICE MANUAL Section 5 - pag. 1 / 24

5.3 ROOM REQUIREMENTS

The unit has been designed to operate in a room respecting the following

environmental conditions:

ENVIRONMENT TEMPERATURE from +15°C to +40°C

ENVIRONMENT HUMIDITY 80% non condensing

In addition to the above, the following rules must be observed:

1. The construction and load capability of the ceiling are sufficient for the

installation of the unit.

2. The floor is level or can be compensated.

3. Precautionary measures have been taken to prevent scatter radiation from

entering other rooms and/or hallways and that all exposed walls are lead-

lined.

In particular the Hospital physicians should approve the room layout before

the installation starts.

4. Sufficient consideration has been given to the room layout with respect to

minimum clearances between walls and the equipment as specified in the unit

manual.

5. Carefully evaluate the best fixation system to be use for the ceiling rails as

described in the following layout example.

6. It is a good practice to install an intercom system to ease the communication

between the patient and the medical staff.

WARNING: ROOM HEIGHT REQUIREMENTS

The minimum allowed room height, with standard 20 mm base spacer is 2550 mm as shown in the

following figure.

In case the unit must be installed using a different base spacer, the room minimum height

requirement must be increased of the same quantity.

CLISIS SERVICE MANUAL Section 5 - pag. 2 / 24

CLISIS SERVICE MANUAL Section 5 - pag. 3 / 24

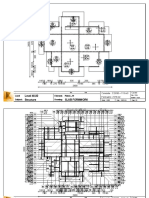

A typical room layout could be the following one:

4200

LEGEND:

1. CLISIS 90/20 TABLE

2 2. GENERATOR POWER CABINET

3. CLISIS OPERATIVE LIMIT

4. CONTROL DESK TABLE

5. CLISIS CONSOLE

6. ROOM POWER ELECTRICAL BOARD

7. ANTI-X GLASS 1200x800 (suggested)

8. 18" LCD MONITOR ON TROLLEY

4800

3

1 7

8

DOOR MICROSWITCH

4

RADIATION HAZARD LAMP

SP.

5 ROOM EMERGENCY SWITCH H=1700mm

6

Modifiche

Rev Data descrizione modifica Firma

scala Denominazione

offerta:

CLISIS INSTALLATION EXAMPLE del:

data

firma

OVER-FLOOR BASE PLATE SHEET 1 of 3

visto (LAYOUT)

disegno n° Rev

Via Negrelli, 55 LISSONE (ITALY)

Tel.(039)483.249-484.884-464.841 Fax 039/464819

4200

Cable exit for Clisis.

6mm thickness

removable floor cover.

"A" Detail

Cable exit

for cabinet FLOOR LEVEL

260

6

80

Totally inspectionable

Under Floor conduit.

4800

200

("A" Detail)

Cable exit for

Console.

N°2 WIRES Ø 1.0 TO ROOM ELECTRICAL BOARD

Cables exit for room power

electrical board.

N°1 Ø80 tube in wall or N°4 WIRES Ø 1.0 TO ROOM ELECTRICAL BOARD

SP.

external canalization.

SERIES WIRED TO ROOM ELECTRICAL BOARD

Modifiche

Rev Data descrizione modifica Firma

scala Denominazione

offerta:

CLISIS INSTALLATION EXAMPLE del:

data

firma

OVER-FLOOR BASE PLATE SHEET 2 of 3

visto (CABLE CONDUIT)

disegno n° Rev

Via Negrelli, 55 LISSONE (ITALY)

Tel.(039)483.249-484.884-464.841 Fax 039/464819

CLISIS SERVICE MANUAL Section 5 - pag. 4 / 24

4200

Place the overfloor plate so that the

15

cables exit is as shown in the drawing.

Cables exit 1250

350

1250

OVERFLOOR PLATE

AREA = 1.75mq

PLATE WEIGHT = 220Kg

4800

MAXIMUM LOAD = 1500Kg

MAXIMUM LOAD ON BOLTS = 300Kg

BOLTS M12x35 CL 8.8

"SLM12" ANCHORS - FISCHER

1400

SEE "C" DETAIL

"C" DETAIL

SP.

Modifiche

Rev Data descrizione modifica Firma

scala Denominazione

offerta:

CLISIS INSTALLATION EXAMPLE del:

data

firma

OVER-FLOOR BASE PLATE SHEET 3 of 3

visto (OVERFLOOR CLISIS PLATE FIXING)

disegno n° Rev

Via Negrelli, 55 LISSONE (ITALY)

Tel.(039)483.249-484.884-464.841 Fax 039/464819

4200

LEGEND:

1. CLISIS 90/20 TABLE

2. GENERATOR POWER CABINET

2

3. CLISIS OPERATIVE LIMIT

4. CONTROL DESK TABLE

5. CLISIS CONSOLE

6. ROOM POWER ELECTRICAL BOARD

7. ANTI-X GLASS 1200x800 (suggested)

4500

3 8. 18" LCD MONITOR ON TROLLEY

7

1

8

4

DOOR MICROSWITCH

SP. RADIATION HAZARD LAMP

5

ROOM EMERGENCY SWITCH H=1700mm

6

Modifiche

Rev Data descrizione modifica Firma

scala Denominazione offerta:

CLISIS INSTALLATION EXAMPLE del:

data

firma

UNDER-FLOOR BASE PLATE SHEET 1 of 3

visto (LAYOUT)

disegno n° Rev

Via Negrelli, 55 LISSONE (ITALY)

Tel.(039)483.249-484.884-464.841 Fax 039/464819

CLISIS SERVICE MANUAL Section 5 - pag. 5 / 24

4200

Cable exit for Clisis.

6mm thickness

removable floor cover.

"A" Detail

Cable exit for cabinet FLOOR LEVEL

260

6

80

Totally inspectionable

Under Floor conduit.

4500

("A" Detail)

200

Cable exit for

Console.

Cables exit for room power

electrical board. N°2 WIRES Ø 1.0 TO ROOM ELECTRICAL BOARD

N°1 Ø80 tube in wall or

SP.

external canalization. N°4 WIRES Ø 1.0 TO ROOM ELECTRICAL BOARD

SERIES WIRED TO ROOM ELECTRICAL BOARD

Modifiche

Rev Data descrizione modifica Firma

scala Denominazione

offerta:

CLISIS INSTALLATION EXAMPLE del:

data

firma

UNDER-FLOOR BASE PLATE SHEET 2 of 3

visto (CABLE CONDUIT)

disegno n° Rev

Via Negrelli, 55 LISSONE (ITALY)

Tel.(039)483.249-484.884-464.841 Fax 039/464819

4200

Clisis underfloor plate at

Place the underfloor plate so that the Room floor floor level fixed and covered Floor coating

Room floor

coating

cables exit is as shown in the drawing. coating with the same floor material. free zone.

Cables exit 1350

50

70

80

515

Clisis Support

Area.

Floor coating

890

free zone.

Clisis Support Area. "B" detail

Floor coating free zone.

890

UNDERFLOOR PLATE

SUPPORT AREA = 0.45mq

4500

515

PLATE WEIGHT = 70Kg

MAXIMUM LOAD = 1300Kg

MAXIMUM LOAD ON BOLTS = 300Kg

BOLTS M12x25 CL 8.8

SEE "B" DETAIL

SP.

Modifiche

Rev Data descrizione modifica Firma

scala Denominazione

offerta:

CLISIS INSTALLATION EXAMPLE del:

data

firma

UNDER-FLOOR BASE PLATE SHEET 3 of 3

visto (UNDERFLOOR CLISIS PLATE FIXING)

disegno n° Rev

Via Negrelli, 55 LISSONE (ITALY)

Tel.(039)483.249-484.884-464.841 Fax 039/464819

CLISIS SERVICE MANUAL Section 5 - pag. 6 / 24

5.4 SYSTEM CABLES

The CLISIS remote tilting table must be completed with a special set of cables that

allows the proper operation of the additional accessories.

Because each installation has its own typical layout, in this section are detailed the

lengths of the standard cables supplied with the systems, showing also the correct

way to route the cables.

In case during the design of the room layout, it is necessary to modify the standard

length of a group of cables, it is responsibility of the installer to clearly specify this

configuration change.

In this section has been also added the system interconnection diagrams for the

most complete configuration supported by the CLISIS table. Such drawings show all

physical connections between the internal parts of the CLISIS remote tilting table

and the system itself with other accessories.

For additional information the installer must refer to section 7 of this manual.

WARNING:

Before starting the installation, it is necessary for the installer verify that all

accessories or interface cables are present and delivered in the lengths

defined during the room layout design phase.

CLISIS SERVICE MANUAL Section 5 - pag. 7 / 24

5.5 BASE PLATE INSTALLATION

The CLISIS remote tilting table must be fixed to the floor using three different methods:

Direct fixation of the unit base to the floor

This fixation method is allowed when the floor of the room is strong enough to bear the entire

system weight on the base surface as shown in the following figure:

70 70 70

N°8 CLISIS BASE

30 340 70 FIXATION

25

CLISIS BASE FIXING

LOADING AREA = 0.45mq

UNIT WEIGHT = 1100Kg

400

515

Clisis Base TOTAL LOAD = 1300Kg

MAXIMUM LOAD ON BOLTS = 300Kg

30 620

N°8 - Ø15 HOLES

890

CLISIS BASE FIXATION CLISIS BASE FIXATION

(W/O SPACER) (WITH SPACER)

1 1

3 3

2 2

13

13

FLOOR

FLOOR

NB: IF CONCRETE IS

4 CLASS Rc > 25N/mm 5 4

1 - N°1 SCREW TSCE UNI5933 CL10.9 M12X90

2 - N°1 WASHER Ø i 10.25 Ø e 30 5p.7 sv.90° 1 - N°1 SCREW TSCE UNI5933 CL10.9 M12X90

3 - CLISIS BASE 2 - N°1 WASHER Ø i 10.25 Ø e 30 5p.7 sv.90°

4 - N°1 BOSS FISCHER SLM 12 3 - CLISIS BASE

4 - 20mm SPACER (P/N = SXAA014)

5 - N°1 BOSS FISCHER SLM 12

IMPORTANT NOTICE:

It is responsibility of the installer to select the fixation method that grants the

correct unit anchoring in function of the constructive characteristics of the floor

itself.

In order to meet the requirements if the EN60601-1 regulation it is also necessary that the

installer interpose between the floor and the unit base the 20 mm spacer p/n SXAA014 as

shown in the previous figure.

CLISIS SERVICE MANUAL Section 5 - pag. 8 / 24

Use of the under floor installation plate p/n SXAA04

This the preferred fixation method to be used when the floor depth is enough to allow the

installation of the Mecall base plate SXAA04. In this case the base plate must be immured

into the floor as detailed in the following figure:

Clisis Support Area.

Floor coating free zone.

N°8 CLISIS BASE

890 80

FIXATION

10

80

UNDERFLOOR PLATE

515

1330

N°8 UNDERFLOOR PLATE

A M12 HOLES A LOADING AREA = 0.45mq

PLATE WEIGHT = 70Kg

TOTAL LOAD = 1300Kg

MAXIMUM LOAD ON BOLTS = 300Kg

50

1200

CLISIS BASE FIXATION

1

Clisis underfloor plate at floor 2 4

13

level fixed and covered with Floor coating

Room floor Room floor 3

the same floor material. free zone.

coating coating 5

FLOOR

15

50

80

1 - N°1 SCREW TCCE UNI5931 CL8.8 M12X35

2 - N°1 SPRING WASHER Ø 12

3 - N°2 PLAIN WASHER Ø 12

4 - CLISIS BASE

5 - OVER FLOOR PLATE

sez. A - A

IMPORTANT NOTICE:

It is responsibility of the installer to grant the correct anchoring of the base plate in

function of the constructive characteristics of the floor itself.

CLISIS SERVICE MANUAL Section 5 - pag. 9 / 24

In order to meet the requirements if the EN60601-1 regulation it is also necessary that the

installer interpose between the floor and the unit base the 20 mm spacer p/n SXAA014 as

shown in the following figure

Clisis Support Area.

Floor coating free zone.

N°8 CLISIS BASE 80

FIXATION

890

10

80

UNDERFLOOR PLATE

515

1330

N°8 UNDERFLOOR PLATE

A M12 HOLES A LOADING AREA = 0.45mq

PLATE WEIGHT = 70Kg

TOTAL LOAD = 1300Kg

MAXIMUM LOAD ON BOLTS = 300Kg

50

CLISIS BASE FIXATION

1200 1

2 4

13

Floor coating 3

Clisis underfloor plate at floor free zone.

level fixed and covered with 5

Room floor Room floor

the same floor material. 6

coating 20mm spacer coating

FLOOR

15

50

80

1 - N°1 SCREW TCCE UNI5931 CL8.8 M12X55

2 - N°1 SPRING WASHER Ø 12

3 - N°2 PLAIN WASHER Ø 12

4 - CLISIS BASE

5 - 20mm SPACER (P/N = SXAA014)

6 - OVER FLOOR PLATE

sez. A - A

CLISIS SERVICE MANUAL Section 5 - pag. 10 / 24

Use of the over floor installation plate p/n SXAA03

This fixation method is recommended when the floor depth is not enough to allow the

installation of the under floor installation plate and/or the floor of the room is not strong

enough to bear the entire system weight laying on the table base. In this case the installer

must use the optional over floor installation plate p/n SXAA03 to distribute the weight on a

larger surface and to offer a better and easier fixation to the floor as detailed in the following

figure:

1400

50 OVERFLOOR PLATE

50 195 810

50

Clisis Base

N°8 FLOOR FIXATION

OVERFLOOR PLATE FIXING

1250

1150

N°8 - M12 HOLES

LOADING AREA = 1.75mq

N°8 CLISIS BASE PLATE WEIGHT = 220Kg

FIXATION TOTAL LOAD = 1500Kg

MAXIMUM LOAD ON BOLTS = 300Kg

50 1300 N°8 - Ø15 HOLES

OVER FLOOR PLATE FIXATION CLISIS BASE FIXATION

1 1

3 2 4

2

13

3

15

FLOOR 5

FLOOR

15

NB: IF CONCRETE IS

4 CLASS Rc > 25N/mm

1 - N°1 SCREW TCCE UNI5931 CL8.8 M12X35

2 - N°1 SPRING WASHER Ø 12

1 - N°1 SCREW TSCE UNI5933 CL10.9 M12X90 3 - N°2 PLAIN WASHER Ø 12

2 - N°1 WASHER Ø i 10.25 Ø e 30 5p.7 sv.90° 4 - CLISIS BASE

3 - OVER FLOOR PLATE 5 - OVER FLOOR PLATE

4 - N°1 BOSS FISCHER SLM 12

IMPORTANT NOTICE:

It is responsibility of the installer to grant the correct anchoring of the base plate in

function of the constructive characteristics of the floor itself.

CLISIS SERVICE MANUAL Section 5 - pag. 11 / 24

In order to meet the requirements if the EN60601-1 regulation it is also necessary that the

installer interpose between the floor and the unit base the 20 mm spacer p/n SXAA014 as

shown in the following figure

1400

50 OVERFLOOR PLATE

50 195 810

50

Clisis Base

N°8 FLOOR FIXATION

OVERFLOOR PLATE FIXING

1250

1150

N°8 - M12 HOLES

LOADING AREA = 1.75mq

N°8 CLISIS BASE PLATE WEIGHT = 220Kg

FIXATION TOTAL LOAD = 1500Kg

MAXIMUM LOAD ON BOLTS = 300Kg

50 1300 N°8 - Ø15 HOLES

OVER FLOOR PLATE FIXATION CLISIS BASE FIXATION

1

1

3 2 4

13

2

3

15

FLOOR 5

6

FLOOR

NB: IF CONCRETE IS

15

4 CLASS Rc > 25N/mm

1 - N°1 SCREW TCCE UNI5931 CL8.8 M12X55

1 - N°1 SCREW TSCE UNI5933 CL10.9 M12X90

2 - N°1 SPRING WASHER Ø 12

2 - N°1 WASHER Ø i 10.25 Ø e 30 5p.7 sv.90° 3 - N°2 PLAIN WASHER Ø 12

3 - OVER FLOOR PLATE 4 - CLISIS BASE

4 - N°1 BOSS FISCHER SLM 12 5 - 20mm SPACER (P/N = SXAA014)

6 - OVER FLOOR PLATE

CLISIS SERVICE MANUAL Section 5 - pag. 12 / 24

5.6 SYSTEM GROUNDING

All the control electronics of the CLISIS remote tilting table has the 0V grounded.

It is consequently clear that a grounding error in the installation or a ground

connection made with a cable of inadequate section may degrade both reliability

and safety level of the unit.

The following rules must be observed for a correct grounding:

1. Check that the central ground terminal in the examination room has the

characteristics specified in the safety norms of the country. In particular a

ground resistance lower than 2 is suggested.

2. Connect the CLISIS central ground terminal directly to the central ground

terminal of the power distribution box by means of a 4 mm² singe conductor

if the distance is less than 10 m. The cable section must be increased

proportionally in case of higher distances.

3. Connect all CLISIS ground internal cables only to the central ground terminal

of the unit located in the upper side of the power cabinet as shown in the

following figure. Make sure that the brass fixation screws has been properly

tightened

4. Do not add other ground connections that might involve sections of the

system, in order to avoid the possibility to cause ground loops.

CLISIS SERVICE MANUAL Section 5 - pag. 13 / 24

5.7 INPUT LINE AND EMERGENCY CIRCUIT

The CLISIS remote tilting table requires the connection to a single-phase line with

the following characteristics:

STANDARD INSULATION TRANSFORMER

Line Voltage 400V 3-phase

Line Voltage tolerance 10 % ( absolute max. rating )

Line frequency 50 Hz 60 Hz

Line frequency tolerance 2%

Stand-by power 1.000 VA

Peak power 4.000 VA

The standard configuration of the units includes the 400V 3-phase insulation

transformer. In case the line voltage is different from the standard one, the installer

refer to section 5.8 for further information.

If possible, it is also a good norm to apply the following rules for the line connection:

1. The input line must be totally independent from any other lines that might

create interference.

2. The main line cable is laid in conduit separate from the cable conduit.

3. The section of the line cables must be minimum 4.0 mm.

4. In case the input line characteristics does not match the requirements it is a

good practice to install a line conditioner.

The input line cable must be connected at the CLISIS power cabinet line terminals,

as detailed in the following figures.

CLISIS SERVICE MANUAL Section 5 - pag. 14 / 24

IMPORTANT NOTICE FOR THE INSTALLER:

The CLISIS line input must be protected by means of a safety switch, calibrated

for a maximum leakage current of 30 mA.

The input line can be disconnected from the unit turning in OFF position the line

switch mounted on the front panel of the power cabinet as shown in the following

figure:

The room power distribution box must be designed not only to meet the technical

requirements previously specified but also to comply with the requirements of the x-

ray generator and of the image processor (for more details see the related service

documentation). In particular, the general requirements of the room input line is:

Line Voltage 400V 3-phase

Line Voltage tolerance 10 % ( absolute max. rating )

Line frequency 50 Hz 60 Hz

Line frequency tolerance 2%

Power source impedance @ 400V 0.20

Line input reactive power 120 kVA

Line input active power 100 KW

Stand-by power 300 VA

Peak power 2.000 VA

THE ROOM POWER DISTRIBUTION CIRCUIT, DESCRIBED IN THE

FOLLOWING PAGES, MUST BE USED BY THE INSTALLER AS GUIDE LINE

FOR ANY SITE SPECIFIC DESIGN.

CLISIS SERVICE MANUAL Section 5 - pag. 15 / 24

The CLISIS remote tilting table is also equipped with two emergency switches

located on the control desk and SFD keyboard. Such switches can be used to

disable the room power circuit or simply power off the CLISIS table. The selection of

the modality must be done by the installer setting the position of the rotary switch

SW18 mounted on the CLISIS control board as detailed in the following figure:

In particular the available settings are:

Position1 Emergency switches by pass.

In this modality, the serial of the CLISIS emergency switches

contact is forced Normally Closed.

Position 2 Emergency switches external mode

In this modality, the serial of the CLISIS emergency switches

contacts is available at CN106.1 and CN106.2 terminals.

This contact should be wired in serial with the room emergency

circuit.

Position 3 Emergency switches internal mode

In this modality the CLISIS emergency switches, when activated,

power off only the table itself. In this case CN106.1 and CN106.2

terminals the can not be wired in serial with the room emergency

circuit.

In any dangerous situation, or in case a movement can not be stopped, the operator

must hit immediately one of these switches. The power circuit of the CLISIS table is

immediately switched off, but all other units will continue to operate normally.

The emergency switch must be re-enabled only if the operator is absolutely sure

that the danger condition has been removed.

CLISIS SERVICE MANUAL Section 5 - pag. 16 / 24

The emergency circuit of the room power distribution circuit must be connected to terminals

CN106.1 and CN106.2 of the CLISIS power cabinet as shown in the following figure:

IMPORTANT NOTICE:

THE CLISIS EMERGENCY CIRCUIT IS DESIGNED TO BE CONNECTED TO A 24V ac/dc

CIRCUIT WITH A MAXIMUM CURRENT FLOW OF 1A.

THE CONNECTION OF THE CN106.1 AND CN106.2 TERMINALS WITH AN HIGHER

VOLTAGE AND/OR CURRENT FLOW COULD PRODUCE SERIOUS FAULT OF THE

CLISIS CONTROL CIRCUITS

THE INSTALLER IS RESPONSIBLE FOR THE PROPER OPERATION OF THE

EMERGENCY SWITCH.

CLISIS SERVICE MANUAL Section 5 - pag. 17 / 24

CLISIS SERVICE MANUAL Section 5 - pag. 18 / 24

I F

R T I

E E

D

M

MA

TE

A

N

G S

EM Y

ENT S

CLISIS SERVICE MANUAL Section 5 - pag. 19 / 24

I F

R T I

E E

D

EM

MA

A

T

N

G S

EM Y

ENT S

CLISIS SERVICE MANUAL Section 5 - pag. 20 / 24

I F

R T I

E E

D

M

MA

TE

A

N

G S

EM Y

ENT S

CLISIS SERVICE MANUAL Section 5 - pag. 21 / 24

I F

R T I

E E

D

EM

MA

A

N

T

GE S

ME N T S Y

CLISIS SERVICE MANUAL Section 5 - pag. 22 / 24

I F

R T I

E E

D

MA

EM

A

T

N

G S

EM Y

ENT S

CLISIS SERVICE MANUAL Section 5 - pag. 23 / 24

5.8 INPUT LINE VOLTAGE SELECTION

The line voltage input can not be selected by installer. In fact the primary winding of

the CLISIS insulation transformer is voltage specific and can not be adapted.

In case the line voltage is different from 400V, it is necessary that the unit is factory

configured for the line ordering one of the following options:

220V ac INSULATION TRANSFORMER OPTION - ORDERING CODE: SXAA05

Line Voltage 220V 3-phase

Line Voltage tolerance 10 % ( abs. max. rating )

Line frequency 50 Hz 60 Hz

Line frequency tolerance 2%

Stand-by power 1.000 VA

Peak power 4.000 VA

380V ac INSULATION TRANSFORMER OPTION - ORDERING CODE: SXAA06

Line Voltage 380V 3-phase

Line Voltage tolerance 10 % (abs. max. rating )

Line frequency 50 Hz 60 Hz

Line frequency tolerance 2%

Stand-by power 1.000 VA

Peak power 4.000 VA

415V ac INSULATION TRANSFORMER OPTION - ORDERING CODE: SXAA07

Line Voltage 415V 3-phase

Line Voltage tolerance 10 % ( abs. max. rating )

Line frequency 50 Hz 60 Hz

Line frequency tolerance 2%

Stand-by power 1.000 VA

Peak power 4.000 VA

CLISIS SERVICE MANUAL Section 5 - pag. 24 / 24

You might also like

- DVD-VCR: Service ManualDocument135 pagesDVD-VCR: Service ManualJordi Mes Electro ElectriNo ratings yet

- C 315bee PDFDocument33 pagesC 315bee PDFagonzalo_367117079No ratings yet

- Transf Pad English TORREONDocument10 pagesTransf Pad English TORREONgeneubel rodriNo ratings yet

- LG DVD DS9313CPM (3829RHP038B)Document48 pagesLG DVD DS9313CPM (3829RHP038B)videosonNo ratings yet

- Nad M 55 Service Manual PDFDocument74 pagesNad M 55 Service Manual PDFSergey VissarionovNo ratings yet

- DTQ 2133SSFNDocument35 pagesDTQ 2133SSFNjosetantonioNo ratings yet

- CLISISINDEXDocument9 pagesCLISISINDEXfortroniNo ratings yet

- LG dv-8000Document65 pagesLG dv-8000ValeriiNo ratings yet

- Daewoo CM-101S DTH-21S7, DTH-21S8Document58 pagesDaewoo CM-101S DTH-21S7, DTH-21S8Marco Antonio100% (8)

- Manual Service MT1389seDocument28 pagesManual Service MT1389seR OneNo ratings yet

- SuperVent and SuperPro Instructions SPR JSC USDocument50 pagesSuperVent and SuperPro Instructions SPR JSC USLucas AlNo ratings yet

- Section 1: Product Safety Servicing Guidelines For Video Products Servicing PrecautionsDocument47 pagesSection 1: Product Safety Servicing Guidelines For Video Products Servicing PrecautionswittmaewNo ratings yet

- TCN001PEF0Document35 pagesTCN001PEF0Luis RugNo ratings yet

- DTQ-14Z5SC CH CN-001P PDFDocument35 pagesDTQ-14Z5SC CH CN-001P PDFSixto AgueroNo ratings yet

- Nad Electronics International: TorontoDocument49 pagesNad Electronics International: Torontoted.klonNo ratings yet

- Service Manual: Color TelevisionDocument58 pagesService Manual: Color TelevisionMarius-Ion AsandeiNo ratings yet

- Cn-201 Ab Diagrama DaewooDocument74 pagesCn-201 Ab Diagrama DaewooJairo PadronNo ratings yet

- CN201A ChassisDocument74 pagesCN201A ChassisgutierrezernestoNo ratings yet

- Aps2006 Rev0Document14 pagesAps2006 Rev0Martin Raynoldi GutierrezNo ratings yet

- Daewoo Dtq-14n2fc 20n2fc 20j2fc 20n3fc Chassis Cn-115iDocument43 pagesDaewoo Dtq-14n2fc 20n2fc 20j2fc 20n3fc Chassis Cn-115iFernandoSanchezNo ratings yet

- Elettromeccanica Colombo: Cast Resin TransformersDocument14 pagesElettromeccanica Colombo: Cast Resin TransformersHamilton GutierrezNo ratings yet

- C 320beeDocument19 pagesC 320beejolageNo ratings yet

- Network Blu-Ray Disc / DVD Home Theater System: Service ManualDocument151 pagesNetwork Blu-Ray Disc / DVD Home Theater System: Service ManualAlexNo ratings yet

- 3021 Mammography Siemens Planning GuideDocument11 pages3021 Mammography Siemens Planning GuideNahomi espinozaNo ratings yet

- Raised Access Floor Solutions Guide To Installation, Maintenance & UseDocument18 pagesRaised Access Floor Solutions Guide To Installation, Maintenance & UseAkicaNo ratings yet

- Winding and InsulationDocument6 pagesWinding and InsulationRatilal M JadavNo ratings yet

- Сигнализатор Потока Воздуха - vs5100 Om 12 RpDocument86 pagesСигнализатор Потока Воздуха - vs5100 Om 12 RpАлександрNo ratings yet

- Service Manual: Color TelevisionDocument54 pagesService Manual: Color Televisionlantanio007No ratings yet

- Lennox DMS4 ManualDocument107 pagesLennox DMS4 ManualdwilhNo ratings yet

- AAMA 100-07 - Standard Practice For The Installation of Windows With Flanges or Mounting Fins in Wood Frame ConstructionDocument13 pagesAAMA 100-07 - Standard Practice For The Installation of Windows With Flanges or Mounting Fins in Wood Frame ConstructionjesoneliteNo ratings yet

- Tyco TY5522 TFP250 - 08 - 2022Document5 pagesTyco TY5522 TFP250 - 08 - 2022First LAstNo ratings yet

- Pdvsa: Engineering Design ManualDocument7 pagesPdvsa: Engineering Design ManualVicmar SuarezNo ratings yet

- Daewoo DTQ - 2130fssfm Chasis CN - 402fnDocument63 pagesDaewoo DTQ - 2130fssfm Chasis CN - 402fnHéctor AraujoNo ratings yet

- Daewoo DVQ - 13H1FCN Chassis CN - 081Document55 pagesDaewoo DVQ - 13H1FCN Chassis CN - 081Santiago MendezNo ratings yet

- Echnical Library: - Dtic Quality Inspected 8Document30 pagesEchnical Library: - Dtic Quality Inspected 8Grigor BabayanNo ratings yet

- Design and Fabrication of High Resistance Grounding System (Wye System, 600 Voltsor Below)Document7 pagesDesign and Fabrication of High Resistance Grounding System (Wye System, 600 Voltsor Below)danielNo ratings yet

- Tormax TX9200 Manual-1Document35 pagesTormax TX9200 Manual-1GhjNo ratings yet

- LG RC797T Service ManualDocument191 pagesLG RC797T Service ManualMike Adams100% (1)

- 4.06 Eh 10M Triple Combi BopDocument20 pages4.06 Eh 10M Triple Combi BopKerman BaezNo ratings yet

- CP-90 Operators ManualDocument54 pagesCP-90 Operators ManualCARL100% (1)

- Daewoo DTH-211F Chassis CM403FDocument64 pagesDaewoo DTH-211F Chassis CM403FDavid Argote BellidoNo ratings yet

- Daewoo Cn071 Chassis Dvq13h1fc TV-VCR SM OnlyDocument99 pagesDaewoo Cn071 Chassis Dvq13h1fc TV-VCR SM OnlyJose GuerreroNo ratings yet

- Daewoo Cn001m Chassis Dtq14p2 TV SMDocument75 pagesDaewoo Cn001m Chassis Dtq14p2 TV SMOxkar YetiNo ratings yet

- Daewoo Chassis CN 789s DTQ 29u9fs, 34z9fc CC 789m DTH 29u9fsaDocument38 pagesDaewoo Chassis CN 789s DTQ 29u9fs, 34z9fc CC 789m DTH 29u9fsalondon335No ratings yet

- NFPA 30 and Factory-Built Storage TanksDocument51 pagesNFPA 30 and Factory-Built Storage TanksLuis Ancalla GonzalesNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Radio Stations: Installation, Design and PracticeFrom EverandRadio Stations: Installation, Design and PracticeRating: 5 out of 5 stars5/5 (2)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Advanced Thermoforming: Methods, Machines and Materials, Applications and AutomationFrom EverandAdvanced Thermoforming: Methods, Machines and Materials, Applications and AutomationRating: 5 out of 5 stars5/5 (1)

- Distributed Process Control ReportFrom EverandDistributed Process Control ReportNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- Insulation Co-ordination in High-voltage Electric Power SystemsFrom EverandInsulation Co-ordination in High-voltage Electric Power SystemsRating: 4.5 out of 5 stars4.5/5 (5)

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- 09 Xray On - DisableDocument12 pages09 Xray On - DisablefortroniNo ratings yet

- Chapter 2Document73 pagesChapter 2fortroniNo ratings yet

- MAN015 - BetaHF - Service Manual Rev2Document53 pagesMAN015 - BetaHF - Service Manual Rev2fortroniNo ratings yet

- Zeta - ServiceDocument47 pagesZeta - ServicefortroniNo ratings yet

- MAN057 - BetaHF - User Manual - Eng Rev1Document47 pagesMAN057 - BetaHF - User Manual - Eng Rev1fortroniNo ratings yet

- Clisis 16Document10 pagesClisis 16fortroniNo ratings yet

- Chapter 1Document32 pagesChapter 1fortroniNo ratings yet

- WST - Technical ManualDocument43 pagesWST - Technical ManualfortroniNo ratings yet

- Chapter 3Document28 pagesChapter 3fortroniNo ratings yet

- Chapter 4Document17 pagesChapter 4fortroniNo ratings yet

- Clisis 6Document29 pagesClisis 6fortroniNo ratings yet

- Clisis 10Document49 pagesClisis 10fortroniNo ratings yet

- Clisis 15Document5 pagesClisis 15fortroniNo ratings yet

- Clisis 14Document18 pagesClisis 14fortroniNo ratings yet

- Clisis 11Document24 pagesClisis 11fortroniNo ratings yet

- Clisis 12Document30 pagesClisis 12fortroniNo ratings yet

- Clisis 13Document26 pagesClisis 13fortroniNo ratings yet

- Clisis 9Document15 pagesClisis 9fortroniNo ratings yet

- Clisis 7Document21 pagesClisis 7fortroniNo ratings yet

- Clisis 8Document18 pagesClisis 8fortroniNo ratings yet

- Clisis 2Document10 pagesClisis 2fortroniNo ratings yet

- Clisis 1Document14 pagesClisis 1fortroniNo ratings yet

- Technical Manual SIMPLY HP - ING - Sez.5 - AppendixDocument6 pagesTechnical Manual SIMPLY HP - ING - Sez.5 - AppendixfortroniNo ratings yet

- CLISISINDEXDocument9 pagesCLISISINDEXfortroniNo ratings yet

- Technical Manual SIMPLY HP - ING - Sez.4 - AdjustementsDocument9 pagesTechnical Manual SIMPLY HP - ING - Sez.4 - AdjustementsfortroniNo ratings yet

- Tech eDocument302 pagesTech efortroni100% (1)

- Technical Manual SIMPLY HP - ING - Sez.0 - IndexDocument2 pagesTechnical Manual SIMPLY HP - ING - Sez.0 - Indexfortroni0% (1)

- Non-Incendive - Nec: Quantum™ Rotary Control MonitorsDocument8 pagesNon-Incendive - Nec: Quantum™ Rotary Control MonitorsLeo RojasNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityfeyayel988No ratings yet

- Safety Report Weekly 1st - Project TMCT 9-15 2023 (Week 2)Document19 pagesSafety Report Weekly 1st - Project TMCT 9-15 2023 (Week 2)Ahmad FikriNo ratings yet

- 60ton Capacity Pitless Type (B)Document1 page60ton Capacity Pitless Type (B)Star Arjun75% (4)

- Cie 132Document4 pagesCie 132Arjie RecarialNo ratings yet

- Iguzzini MaxiWoody - GBDocument5 pagesIguzzini MaxiWoody - GBadityyNo ratings yet

- Autodesk Robot Structural Analysis Professional 2014Document5 pagesAutodesk Robot Structural Analysis Professional 2014tovarNo ratings yet

- Gcu 10 Manual enDocument11 pagesGcu 10 Manual enGhassan ABO ALINo ratings yet

- 90.main SwithboardDocument33 pages90.main SwithboardManh DoanNo ratings yet

- Revised Full Wave RectifierDocument28 pagesRevised Full Wave RectifierSiddhartha SatyakamaNo ratings yet

- PDR IntroductionDocument16 pagesPDR IntroductionRachna patelNo ratings yet

- 1-10 PT Fuse Failure RelayDocument4 pages1-10 PT Fuse Failure RelaymaheshNo ratings yet

- Electrical Safety SWPDocument12 pagesElectrical Safety SWPRavikant PandeyNo ratings yet

- Spare Parts Catalogue A - 1 FX 960Document33 pagesSpare Parts Catalogue A - 1 FX 960dechetoNo ratings yet

- Building Code Vocabulary 1Document9 pagesBuilding Code Vocabulary 1Josua MenisNo ratings yet

- BOQ - Mod - Soro - 20 01 2023Document8 pagesBOQ - Mod - Soro - 20 01 2023Saurabh PandeyNo ratings yet

- Card Reader Wiring Addendum: Cables For Card ReadersDocument1 pageCard Reader Wiring Addendum: Cables For Card ReadersAnonymous MDkp0hnb3lNo ratings yet

- KL-500 10603Document3 pagesKL-500 10603mohamed ShabaanNo ratings yet

- EatonDocument101 pagesEatonrajpre1213No ratings yet

- Wastegate Turbocharger Operation DiagnosticDocument6 pagesWastegate Turbocharger Operation DiagnosticHamilton MirandaNo ratings yet

- Er.B.Santhosh Kumar, M.E., (PH.D)Document9 pagesEr.B.Santhosh Kumar, M.E., (PH.D)Santhosh KumarNo ratings yet

- Energy Saving HRC Fuse-Links: Blade Type HN 63 A - 800 A Cylindrical Type HF 2 A - 63 ADocument8 pagesEnergy Saving HRC Fuse-Links: Blade Type HN 63 A - 800 A Cylindrical Type HF 2 A - 63 AprekNo ratings yet

- Electrical Power Cable Engineering - HTMLDocument4 pagesElectrical Power Cable Engineering - HTMLceragonNo ratings yet

- STW1000 ManualDocument14 pagesSTW1000 ManualralucapNo ratings yet

- Ultrasonic Rodent Repellent Panel - ManualDocument3 pagesUltrasonic Rodent Repellent Panel - ManualraviNo ratings yet

- YSB23-0136 Bailee #4U ShowHouseDocument2 pagesYSB23-0136 Bailee #4U ShowHouseLiesa StoneNo ratings yet

- SWGR Technical DataDocument5 pagesSWGR Technical Datadaniel.cabasa2577No ratings yet

- Abb Flyer Diode ThyristorDocument2 pagesAbb Flyer Diode ThyristorHusejin Mehmedović100% (1)

- R1100RT Elec DiagramDocument3 pagesR1100RT Elec DiagramDanijel Denial Kurinčič100% (3)