Professional Documents

Culture Documents

4239 AA DC 21U62RN018 IS02 - Checkprint

4239 AA DC 21U62RN018 IS02 - Checkprint

Uploaded by

amitOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4239 AA DC 21U62RN018 IS02 - Checkprint

4239 AA DC 21U62RN018 IS02 - Checkprint

Uploaded by

amitCopyright:

Available Formats

NOTES

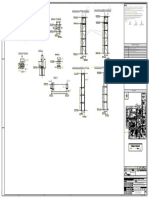

CN 01 CONSTRUCTION STAGES

FIRST PHASE - EXTENSION OF FOUNDATION AND ADDITION / REPLACEMENT OF BOLTS 1. PLANT DATUM H.P.P. EL.+100.000 CORRESPONDS TO EL.+15.550 METERS ABOVE THE LOW LOW WATER SPRING (LLWS).

1. ALL THE ADJOINING STRUCTURES / FACILITIES SHALL BE PROPERLY PROTECTED BEFORE STARTING THE 2. ALL DIMENSIONS ARE IN MILLIMETERS (UNLESS INDICATED OTHERWISE).

TN DEMOLITION WORK. EXISTING EQUIPMENT (IF ANY) SHALL BE REMOVED / DISMANTLED FROM POSITION.

EXISTING PLATFORM / PIPE SUPPORT (IF ANY) ABOVE PEDESTAL SHALL BE REMOVED / DISMANTLED.

3. ALL ELEVATIONS AND COORDINATES ARE IN METERS (UNLESS INDICATED OTHERWISE).

49° 01

4. DIMENSIONS AND DETAILS TO BE CROSS VERIFIED AND CONFIRMED FROM SITE.

2. EXISTING BOLTS, AFTER REMOVAL OF GROUT SHALL BE CUT AND FLUSHED WITH EXISTING TOC. 5. PRIOR TO THE EXECUTION OF WORKS DESCRIBED IN THIS DRAWING, THE SUB-CONTRACTOR HAS TO PREPARE A

EXISTING / DEMOLITION RECONSTRUCTION / MODIFICATION 3. EXISTING PAVING SHALL BE DEMOLISHED. EXISTING REINFORCEMENT BARS FOR PAVING SHALL BE METHOD STATEMENT OF DESCRIBED WORKS AND TAKE APPROVAL FROM CONTRACTOR / OWNER REPRESENTATIVES AT

STAGES 1 TO 5 STAGES 6 TO 23 TEMPORARILY BENT UPWARDS DURING SOIL EXCAVATION AND TREATED WITH CORROSION INHIBITOR SITE.

PUMP FOUNDATION PLAN PUMP FOUNDATION PLAN (AAA03AB21). 6. BEFORE STARTING THE DEMOLITION ACTIVITIES, SITE SHALL BE INSPECTED BY SUBCONTRACTOR AND CONTRACTOR’S

(SCALE 1:25) (SCALE 1:25) 4. EXISTING SUB-GRADE / SUB-BASE & SOIL SHALL BE EXCAVATED (ABA02AD01). REPRESENTATIVE TO IDENTIFY AND MARK ANY POSSIBLE ADDITIONAL ITEMS NOT SHOWN IN THE DRAWING TO BE

OLD VENDER DRAWING NOT AVAILABLE (****) BEFORE STARTING FOUNDATION CONSTRUCTION ACTIVITIES, SUBCONTRACTOR DEMOLISHED OR RELOCATED. PRIOR APPROVAL BY CONTRACTOR REPRESENTATIVE IS NECESSARY BEFORE

5. ANY UNDERGROUND UTILITIES IF FOUND DURING EXCAVATION SHALL BE TEMPORARILY SUPPORTED OR

TO VERIFY ON SITE THAT, GIVEN COORDINATES & TOG LEVELS IS IN ACCORDANCE TO RE-ROUTED AS PER INSTRUCTIONS FROM ENGINEER IN CHARGE. DEMOLITION OF THESE ITEMS.

EXISTING DISCHARGE LINE. 7. DURING PAVING DEMOLITION EXISTING SURROUNDING FOUNDATIONS SHALL BE PRESERVED.

RECONSTRUCTION (FOUNDATION ENLARGEMENT SIDE).

6. AS THE NEW BOLTS ARE LOCATED (SEE PLAN VIEW) NEAR THE REINFORCEMENT OF EXISTING 8. THE NEW REINFORCEMENT TO BE EMBEDDED USING EPOXY RESIN CAN BE LOCALLY ADJUSTED IN CASE IT CLASHES

OF FOUNDATION

WITH EXISTING REINFORCEMENT.

X=5968.274

FOUNDATION, THE FOUNDATION SHALL BE FIRST DEMOLISHED ADEQUATELY WITHOUT DAMAGING THE

EXISTING REINFORCEMENT (ADA08AB02). 9. ANY DAMAGE TO THE EXISTING FOUNDATION DONE BY SUBCONTRACTOR DURING EQUIPMENT DISMANTLING SHALL BE

RECONSTRUCTED BY SUBCONTRACTOR.

(****)

200x137x885 DEEP EXISTING 7. ADDITIONAL REBAR SHALL BE ADDED BY CHEMICAL ANCHORING (ADA10BC01, ADA10AA02).

FOUNDATION TO BE DEMOLISHED OF FOUNDATION 200x250x885 DEEP CUT OUT TO BE 8. BEFORE POURING THE NEW CONCRETE, DEMOLISHED PART OF THE 10. ACCORDING TO SITE INSPECTION SURVEY, FOUNDATION IS IN GOOD CONDITION. NDT TEST IS DEEMED NOT NECESSARY.

ALONG WITH EXISTING BOLTS EXISTING REINFORCEMENT BARS TO BE 1220

X=5968.274 PRESERVED AND TREATED WITH POURED WITH CONCRETE. (TYP.) 11. ISOLATION JOINT IN CONCRETE SLAB ON GRADE SHALL BE FORMED WITH AN APPROVED BITUMEN IMPREGNATED

= = SURFACE SHALL BE TREATED WITH BONDING AGENT (ADA08AB02).

SURFACE PREPARATION 1220 CORROSION INHIBITOR FOR DETAIL REFER DETAIL ''A2/B2" FIBERBOARD. THE UPPER 20MM SHALL BE SEALED WITH AN APPROVED BITUMINOUS SEALANT RESISTANT TO

160 900 160

112.5

BY CHIPPING 9. CREATE POCKET FOR NEW ANCHOR BOLTS (ADA09BA01).

100

625 180 765 275 675 60 HYDROCARBONS, APPLIED STRICTLY IN ACCORDANCE WITH THE MANUFACTURER'S INSTRUCTIONS. THE JOINT FILLER

60 10. NEW PORTION OF FOUNDATION SHALL BE POURED WITH CONCRETE (ADA08AB02). SHALL BE FIXED FIRMLY TO THE FIRST PLACED CONCRETE BEFORE THE ADJOINING CONCRETE IS PLACED. THE

25

88

137

137

11. BITUMEN PAINT SHALL BE APPLIED ON THE EXTENDED NEW PORTION OF CONCRETE MUST BE THOROUGHLY COMPACTED ON BOTH SIDES OF THE EXPANSION JOINT. THE LOCATION OF

200

EXPANSION JOINTS SHALL BE AS SHOWN ON THE DRAWINGS WHERE REQUIRED BY DESIGN.

250

THE CONCRETE THAT IS EXPOSED.

265

12. ALL DIMENSIONS / COORDINATES / ELEVATIONS ARE BASED ON LASER SCAN DATA AND TO BE VERIFIED AT SITE BEFORE

280

12. EXCAVATED SIDES SHALL BE BACKFILLED AND COMPACTED (ACA05AM01)

165

350

665

200 200 OF EXISTING DISCHARGE OF NEW DISCHARGE

13. EXISTING REINFORCEMENT BARS FOR PAVING SHALL BE REPLACED IN THE ORIGINAL CONSTRUCTION ACTIVITIES.

Y=90441.477 200 TO BE ADOPTED BY PIPING

NEW GROUT TO BE POURED IN POSITION BEFORE POURING OF A NEW PAVING SHALL BE RESTORED (AEA08AG01) 13. BOF ELEVATION SHOWN IN THE DRAWING IS TENTATIVE DEPENDING ON DESIGN VERIFICATIONS. SITE TO ENSURE THAT,

Y=90441.477

255

825

860

(TYP.) ACTUAL DEPTH OF FOUNDATION SHALL BE EQUAL OR DEEPER THAN SPECIFIED ELEVATION TO PROCEED WITH GIVEN

255

SECOND PHASE DURING SKID

RECONSTRUCTION (ANCHOR BOLTS REPLACEMENT SIDE).

1000

1000

LEVELING MODIFICATIONS WORK. IN CASE OF SHALLOW FOUNDING DEPTH, SUBCONTRACTOR TO INFORM & TAKE CONCURRENCE

14. EXISTING FOUNDATION SHALL BE DEMOLISHED AT NEW BOLTS LOCATION, BY ADEQUATE METHOD TO FROM CIVIL DESIGN ENGINEER BEFORE PROCEEDING WITH GIVEN MODIFICATION.

(TYP.)

100

(TYP.)

PRESERVE EXISTING REINFORCEMENT, AS PER NEW BOLTS EMBEDMENT LENGTH REQUIREMENT

100

200

215 14. IN CASE OF HINDRANCE DUE TO SMALL PAVING SUPPORTS, SWITCH & INSTRUMENT SUPPORTS etc. CONSTRUCTION

215 PLUS 50MM. THE EXISTING CORRODED BOLTS SHALL BE CUT-OFF AND FLUSHED WITH EXISTING TOC. SUBCONTRACTOR CAN SUITABLY CHECK & DEMOLISH THESE PEDESTALS/SUPPORTS AFTER CONSULTING

1435

3375 (EXISTING FOUNDATION DIMENSION)

1 1 15. EXISTING REINFORCEMENT BARS SHALL BE PRESERVED AND TREATED WITH CORROSION INHIBITOR. CONTRACTOR'S RESPECTIVE DISCIPLINE ENGINEER AT SITE.

1 1

OF FOUNDATION

OF FOUNDATION

16. ADDITIONAL REBARS SHALL BE ADDED BY CHEMICAL ANCHORING (ADA10BC01, ADA10AA02). 15. CONSTRUCTION SUBCONTRACTOR TO SUITABLY DEVELOP THE REINFORCEMENT BBS FOR REQUIRED REBARS

1050

_ _ _ _

6 NOS. 17 DIA ANCHOR EXISTING BOLTS SECOND PHASE - NEW SKID INSTALLATION CONSIDERING SITE FEASIBILITY & CONCRETE CLEAR COVER AS SPECIFIED IN CONCRETE WORK GENERAL NOTE

(TYP.)

DRAWING 4239-AA-DX-00000005."

200

TO BE CUT AND FLUSHED WITH TOC. (CLV1)

(TYP.)

100

(ANCHOR BOLTS REPLACEMENT SIDE)

100

3400 (NEW SKID)

17. CONCRETE SURFACE SHALL BE TREATED WITH BONDING AGENT (ADA08AB02).

1000

1000

Y=90440.042 Y=90440.042

3375

3600

OF NEW SKID 18. NEW ANCHOR BOLTS/ POCKETS SHALL BE PLACED AT PROPOSED LOCATIONS AND

= =

==

250x200x350 DEEP EXISTING (****) FORMWORK SHALL BE PUT IN PLACE.

FOUNDATION TO BE DEMOLISHED

ALONG WITH EXISTING BOLTS 19. NEW PORTION OF FOUNDATION SHALL BE POURED WITH CONCRETE WITH APPROVED

MIX DESIGN TO AVOID SHRINKING (ADA08AB02).

200

200

20. EXCAVATED SIDES SHALL BE BACKFILLED AND COMPACTED (ACA05AM01)

1050

215x200x350 DEEP EXISTING 250 250

FOUNDATION TO BE DEMOLISHED 21. EXISTING REINFORCEMENT BARS FOR PAVING SHALL BE REPLACED IN THE ORIGINAL

ALONG WITH EXISTING BOLTS 215x200x350 DEEP CUT OUT TO BE POSITION BEFORE POURING OF A NEW PAVING. PAVING SHALL BE RESTORED (AEA08AG01)

POURED WITH CONCRETE. (TYP.) REFERENCE DRAWINGS:

900

250x200x350 DEEP CUT OUT TO BE

1000

(FOUNDATION ENLARGEMENT SIDE )

EXISTING GROUT TO BE FOR DETAIL REFER DETAIL ''A1/B1" POURED WITH CONCRETE. 4239-AA-DX-00000005 STANDARD DRAWING - CONCRETE GENERAL NOTES

2

1330

_

REMOVED AS PER DRAWING 22. INSTALLATION IN POCKET OF ANCHOR BOLTS (ADA11EB01).

100

NO. 4239-AA-DC-21U10RD030 1220x500x885 DEEP CUT OUT TO BOTH SIDE 4239-GG-VD-LG0362263P533001 GENERAL ARRANGEMENT DRAWING FOR FUEL OIL BLENDING (HGO) PUMP 63P533B

BE POURED WITH CONCRETE. 23. NEW GROUT SHALL BE POURED FOR SKID LEVELING (ADA12AB01). 4239-AA-DC-21U10RD030 REMOVAL OF EXISTING GROUT AND TOP OF FOUNDATION CHIPPING - AREA - OFFSITE

610

4239-AA-DA-2100N003 FOUNDATION LAYOUT CONSTRUCTION PLAN AREA 5 OFFSITE (PART-B)

388

25

200 200

500

100

1315

SURFACE PREPARATION 970 (NEW SKID)

2260 100X100X350 125 125 LEGEND

100

112.5

BY CHIPPING POCKET = = 4#14 @200 INDICATES MODIFICATION

X=5967.824

1220x388x885 DEEP EXISTING NEW REBARS

450

525

525

FOUNDATION TO BE DEMOLISHED 10 NOS. 20 DIA NEW ANCHOR BOLTS

2_

12 DIA NEW

ALONG WITH EXISTING BOLTS BY VENDOR 1050

REBAR CONCRETE CHIPPING

OF NEW SKID

TO BE ADOPTED BY PIPING

OF NEW DISCHARGE

ABBREVIATIONS

CLV1 : REDUCTION OF ANCHOR BOLT ORIGINAL DIAMETER LESS THAN 2.00mm,

NO DAMAGE OF ANCHOR BOLTS AND NUT'S THREAD

CLV2 : REDUCTION OF ANCHOR BOLT ORIGINAL DIAMETER MORE THAN 2.00mm,

DAMAGE OF ANCHOR BOLTS AND NUT'S THREAD

CLV3 : ANY OTHER DAMAGE OF ANCHOR BOLTS AND NUT'S THREAD OR BENDING OF

EXISTING ANCHOR BOLTS

EXISTING / DEMOLITION RECONSTRUCTION / MODIFICATION RECONSTRUCTION / MODIFICATION

STAGES 1 TO 5 STAGES 6 TO 23

STAGES 6 TO 23

SECTION SECTION 2

SECTION 1 1

(SCALE 1:25) -

(SCALE 1:25) - (SCALE 1:25) -

(**) SUB-CONTRACTOR TO INFORM CONTRACTOR IN CASE (**) SUB-CONTRACTOR TO INFORM CONTRACTOR IN CASE

(**) SUB-CONTRACTOR TO INFORM CONTRACTOR IN CASE OF HIGHER PAVING THICKNESS.

OF HIGHER PAVING THICKNESS. OF HIGHER PAVING THICKNESS.

(***) FROM 3D MODEL (***) FROM 3D MODEL

(***) FROM 3D MODEL

(****) BEFORE STARTING FOUNDATION CONSTRUCTION ACTIVITIES, SUBCONTRACTOR

(****) BEFORE STARTING FOUNDATION CONSTRUCTION ACTIVITIES, SUBCONTRACTOR

TO VERIFY ON SITE THAT, GIVEN COORDINATES & TOG LEVELS IS IN ACCORDANCE TO

TO VERIFY ON SITE THAT, GIVEN COORDINATES & TOG LEVELS IS IN ACCORDANCE TO

EXISTING DISCHARGE LINE.

EXISTING DISCHARGE LINE.

JUST BEFORE POURING GROUTING CONCRETE SURFACE TO BE TREATED

EXISTING BOLTS TO BE CUT AND 1220 1220 WITH EPOXY BONDING AGENT LIKE

FLUSHED WITH TOC. CONCRETE SURFACE TO BE 500

P=80

215 845 160 NITOBOND EP OR EQUIVALENT

P=75

EXISTING GROUT TO BE REMOVED TREATED WITH EPOXY BONDING AGENT 30 THK. NEW GROUT TO BE POURED IN M20 NEW ANCHOR BOLTS 200 200 110

180 765 275 AS PER DRAWING NO. LIKE NITOBOND EP OR EQUIVALENT 160 900 160 30 THK. NEW GROUT TO BE POURED IN

SECOND PHASE DURING SKID LEVELING

40

SUPPLIED BY VENDOR (TYP.)

4239-AA-DC-21U10RD030 SECOND PHASE DURING SKID LEVELING

EL.+99.550 (***) EL.+99.540 (****)

75

EL.+99.510 (TOC) EL.+99.510 (TOC) EL.+99.540 (****) EL.+99.510 (TOC)

(TOG) (TOG) (TOG)

350

425

415

385

350

415

P=115

75

EL.+99.125 (***)TOP OF EXISTING PAVING EL.+99.125 (***)TOP OF EXISTING PAVING

100

150 (**)

150 (**)

925

915

150 (**)

685

100

915

75

500

350

350

100

EL.+98.625 (BOF) EL.+98.625 (BOF) 1

1 (TYP.) EL.+98.625 (BOF)

(REFER NOTE 13) (REFER NOTE 13) (REFER NOTE 13)

PAVING TO BE RESTORED 535

0.3MM THICK POLYTHENE 500(TYP.)

75

215x200x350 DEEP EXISTING FOUNDATION 50 THK EXISTING 20THK. ISOLATION JOINT (TYP.) (TYP.)

SHEET (TYP.) NEW POLYTHENE SHEET

TO BE DEMOLISHED LEAN CONCRETE (TYP.) 3#14@100 (TYP) (SEE NOTE 11) 50 THK. EXISTING

50 THK LEAN CONCRETE (TYP) M20 NEW ANCHOR BOLTS EXCAVATED SIDES TO BE BACKFILLED

ANCHOR BOLT POCKET TO BE CREATED BY EXISTING REINFORCEMENT BARS TO BE ADDITIONAL REBARS AND COMPACTED TO 95% MDD LEAN CONCRETE

215x200x350 DEEP CUT OUT SUPPLIED BY VENDOR

150MM DIA X 350MM DEEP CORE CUTTING PRESERVED AND TREATED WITH 100x100x350 TO BE POURED WITH EMBEDDED IN CONCRETE WITH

TO BE POURED WITH EXISTING REINFORCEMENT

NEW PORTION OF FOUNDATION TO BE

NON-SHRINK GROUT HIT-HY-500R-V4 EPOXY RESIN PRICE CODE

AND INTERNAL CONCRETE CHIPPING INTO CORROSION INHIBITOR CONCRETE (TYP.) POURED WITH CONCRETE

WITH DRILL BIT OF NOMINAL

8#14

EXISTING FOUNDATION ADDITIONAL REBAR DIA 14 OR 16 mm (TYP.) PRICE CODES DESCRIPTION OF WORK

AAA03AB21 DEMOLITION OF REINFORCED PAVING CONCRETE

AAA03AD03 CHIPPING OF EXISTING RC WORK

ABA02AD01 LIMITED SECTION EXCAVATIONS BY HAND

ACA05AM01 BACKFILLING

AEA10AB01 SUPPLY, CUTTING, MACHINING AND INSTALLATION OF WIRE WELDED MESH

ADA08AA01 LEAN CONCRETE

ADA08AB02 CONCRETE FOR FOUNDATION

AEA08AG01 CONCRETE FOR PAVING

DETAIL DETAIL SECTION SECTION 3 ADA09AA01 STRAIGHT FORMWORK FOR CONCRETE FOUNDATIONS

A1 B1 2

(SCALE 1:10) - ADA09BA01 ANCHOR BOLT BOXES

(SCALE 1:10) - (SCALE 1:10) - (SCALE 1:10) -

ADA10AA02 SUPPLY AND INSTALLATION OF REBAR

SECTION FOR STAGES 6 TO 23

SECTION FOR STAGES 6 TO 23 CONCRETE SURFACE TO BE TREATED ADA10BC01 FIXING STEEL REBAR HILTI DRILL INTO EXISTING CONCRETE

(AS PER SHOWN EXISTING (IN CASE OF DIFFERENT EXISTING

WITH EPOXY BONDING AGENT LIKE

REINFORCEMENT ARRANGEMENT / CASE 1) REINFORCEMENT ARRANGEMENT / CASE 2) ADA11EB01 INSTALLATION IN EXISTING BOXES OF ANCHOR BOLTS

NITOBOND EP OR EQUIVALENT

M20 NEW ANCHOR BOLTS ADA12AB01 NON-SHRINK GROUT

290 125 250

SUPPLIED BY VENDOR ADA16AA01 THREE COATS OF OXIDIZED BITUMINOUS PAINT

(TYP.) 200

P=75

30 THK. NEW GROUT TO BE POURED IN

SECOND PHASE DURING SKID LEVELING

ADA16AB01 POLYETHYLENE SHEET

KEY PLAN (OFFSITE- AREA 5)

CN

75

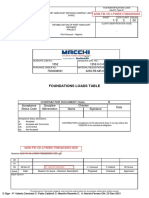

CONCRETE FOR FOUNDATION QUANTITY

.

49 Gr

44.1°

DRAWING LIMIT

X = 5656.210 DRAWING LIMIT

ROAD 1

290

Y = 90094.700

290

Y = 90430.820

75

TN

2#14@100 125 MATERIAL TOTAL QUANTITY [Cu. M]

TRACK 8

PW

215 125 215 125

FOR CONT. REFER DWG. NO. 4239-XX-DE-41000001

ADDITIONAL REBARS

2#14@100

200

0.121

350

FOUNDATION CONCRETE PW

52 TK 61 I X = 5722.955 X = 5722.955 52 TK 63 J 52 TK 63 H X = 5722.955 52 TK 61 H

ADDITIONAL REBARS

Y = 90472.045

ROAD 16

ROAD 14

01

Y = 90142.100

Y = 90235.050

Y = 90281.750

Y = 90350.565

52 P 549

NEW POWER STATION

(SOLAR TURBINE SITE)

72 TK 581 X = 5759.811

1_ 1 2_ 2 PAVING CONCRETE QUANTITY 01

200

200

100

100

52 TK 63 K X = 5784.250 X = 5784.250 52 TK 63 I 52 TK 63 G X = 5784.250 52 TK 61 G

_ _ 20 THK. ISOLATION JOINT

75

X = 5807.330 ROAD 3

MATERIAL TOTAL QUANTITY [Cu. M] BASIN 4 SOUTH BASIN 4 NORTH

S/S D

215 52 P 511A/ B 01 X = 5850.630

Y = 90430.670

52 TK 01 F

X = 5837.410

52 TK 01 E

CONCRETE FOR PAVING 0.515

52 P 512A/ B

52 P 513A/ B

52 TK 01 D 52 TK 01 C

X = 5850.630 X = 5850.630

FOR CONT. REFER DWG. NO. 4239-XX-DE-21000001

EMBEDDED WITH HILTI

ROAD 5

TRACK 2

X = 5854.610

EMBEDDED WITH HILTI

FOR CONT. REFER DWG. NO. 4239-XX-DE-41000001

Y = 90598.810

Y = 90630.310

01 BASIN 1

01 52 P 508 A/B/C 56 P 505

HIT-RE-500- V4 EPOXY RESIN

51 P 531A/ B

685

52 P 509 A/ B 52 P 510A/ B

56 P 501A/B/C

HIT-RE-500- V4 EPOXY RESIN

Y = 90142.100

Y = 90142.100

52 TK 61 M 52 TK 61 L 01

X = 5885.000

X = 5890.250

WITH DRILL BIT OF NOMINAL

52 TK 02 D 52 TK 02 C

ROAD 4

ROAD 12

56 P 506

ROAD 8

52 TK 57 I 52 TK 59 H 01

WITH DRILL BIT OF NOMINAL

Y = 90478.415

Y = 90508.715

TRACK 8

52 TK 57 K 52 TK 59 F 56 P 507

DEMOLITION OF REINFORCED PAVING

01

52 TK 57 P X = 5711.525 52 TK 57 M X = 5711.525 X = 5711.525

DIA. 18mm (TYP.)

ROAD 18

X = 5916.540

EMBEDDED WITH HILTI

56 P 502A/ B

DIA. 18mm (TYP.)

X = 5921.910 56 P 503A/ B

TRACK 6

56 P 504

Y = 90360.325

51 TK 01 D

51 TK 01 C

Y = 90227.225

Y = 90258.935

Y = 90303.935

52 TK 61 K 52 TK 61 J BASIN 1

BASIN 2

HIT-RE-500- V4 EPOXY RESIN

CONCRETE QUANTITY 52 TK 57 N X = 5959.175 52 TK 57 L X = 5959.175 X = 5959.175 52 TK 59 E

TRACK 4

WITH DRILL BIT OF NOMINAL 63 P 533 S/S 15

A

3650 S/S B

2#14@100 ADDITIONAL REBARS

B

3#14@100 ADDITIONAL REBARS

Y = 90000.000

EXISTING S/S

Y = 90668.520

C 3700

52 TK 57 J 72 P 545 72 TK 580 X = 5975.984

52 TK 57 H 52 TK 59 G A 3360

B 2450

72 P 544 2450 01

DIA 18mm (TYP.)

X = 5980.174

Y = 90442.297

Y = 90465.040

BASIN 5 SOUTH BASIN 5 NORTH BASIN 5 NORTH

01

EXISTING REINFORCEMENT EXISTING REINFORCEMENT MATERIAL TOTAL QUANTITY [Cu. M] FOR CONT. REFER DWG. NO. 4239-XX-DE-41000002

50 P 534 A/B/C

50 P 539 A 01

ROAD 7

X = 6000.000

S/S C

X = 6019.150

FOR CONT. REFER DWG. NO. 4239-XX-DE-21000002

Y = 90094.640

FOR CONT. REFER

Y = 90430.820

50 P 539 B

01 TRACK 9 DWG. NO. 4239-XX-DE-21000001

Y = 90616.479

PAVING CONCRETE 0.515

50 P 539 C

50 P 539 D/E

PAVING TO BE RESTORED

50 TK 01 L X = 6055.925 50 TK 01 J X = 6055.925 50 TK 01 H X = 6055.925

NEW POLYTHENE SHEET 63P533B

Y = 90142.100

Y = 90252.275

Y = 90345.875

75

1 EXCAVATED SIDES TO BE BACKFILLED DEMOLITION OF REINFORCED 50 TK 01 K X = 6110.925 50 TK 01 I X = 6110.925 50 TK 01 G X = 6110.925

X = 6099.388

1 AND COMPACTED TO 95% MDD

FOR CONT. REFER DWG. NO. 4239-XX-DE-21000001

Y = 90094.790

NEW PORTION OF FOUNDATION TO BE

FOUNDATION CONCRETE QUANTITY X = 6152.160

FOR CONT. REFER DWG. NO. 4239-XX-DE-41000002

BASIN 6 SOUTH BASIN 6 NORTH

ROAD 11

500(TYP.)

Y = 90208.000

01

52 P 504 A/ B

52 TK 51 F

300 POURED WITH CONCRETE MATERIAL TOTAL QUANTITY [Cu. M]

HORTON

SPHERE

X = 6178.900

AVENUE B

52 TK 51 G 52 TK 51 E

X = 6197.500

(TYP.) FOUNDATION CONCRETE 0.121

ROAD 12

Y = 90375.825

Y = 90353.295

8#12

Y = 90332.000

DETAIL DETAIL EMBEDDED IN CONCRETE WITH

Y = 90430.820

A1 B1 ADDITIONAL REBARS 01

Y = 90392.023

FGL EL. 99.350

(SCALE 1:10) - (SCALE 1:10) -

HIT-HY-500R-V4 EPOXY RESIN

WITH DRILL BIT OF NOMINAL 4#12 @ 200 GROUT QUANTITY FOR CONT. REFER

DWG. NO. 4239-XX-DE-41000002

DIA 14 OR 16 mm (TYP.) ADDITIONAL REBARS MATERIAL TOTAL QUANTITY [Cu. M]

(AS PER SHOWN EXISTING (IN CASE OF DIFFERENT EXISTING 8#12 50 THK. NEW LEAN CONCRETE GROUT 0.299

am

REINFORCEMENT ARRANGEMENT / CASE 1) REINFORCEMENT ARRANGEMENT / CASE 2) ADDITIONAL REBAR N.Nik

FIXING STEEL REBARS 02 17.Nov.2022 IFC - ISSUE FOR CONSTRUCTION N.NIKAM K.Pachgade A.Frigerio

3_ 3_ INTO EXISTING CONCRETE REBARS FOR FOUNDATION QUANTITY 01

00

30.Sept.2022

27.JULY.2022

IFA - ISSUE FOR APPROVAL

IFA - ISSUE FOR APPROVAL

S.PATIL

A.Sawant

K.Pachgade

V.Rama Rao

A.Frigerio

A.Frigerio

MATERIAL TOTAL QUANTITY [NOS.] MATERIAL TOTAL QUANTITY [Kg.] Issue Date Reason for Issue - Revision Description Prepared Checked Approved

60 200 EXISTING REINFORCEMENT EXISTING REINFORCEMENT 9 (FOR DETAILS -A1, SECTION-1) 7.405 (FOR DETAILS -A1, SECTION-1)

REBARS REBARS

Digital signature

60 200 REBARS 6 (FOR DETAILS -B1, SECTION-2) REBARS 5.663 (FOR DETAILS -B1, SECTION-2)

AUTHORIZED FOR CONSTRUCTION

REBARS 12 (FOR DETAILS -A2) REBARS 11.034 (FOR DETAILS -A2)

REBARS 8 (FOR DETAILS -B2, SECTION-3) REBARS 8.324 (FOR DETAILS -B2, SECTION-3) DATE INITIAL SIGNATURE

REBARS 12 (FOR DETAILS -A3) REBARS 13.705 (FOR DETAILS -A3) 17.Nov.2022 O.OJU (Civil Dep.DL)

250

250

2#14@100 ADDITIONAL REBARS 12 (FOR DETAILS -B3, SECTION-4) REBARS 12.922 (FOR DETAILS -B3, SECTION-4)

REBARS TECNIMONT IDENTIFICATION CODE

REHABILITATION OF

325

325

Job-EC-Type-N°

CONDITION OF EXISTING FOUNDATION

PORT HARCOURT 4239-AA-DC-21U62RN018

EMBEDDED WITH HILTI EMBEDDED WITH HILTI PHASE DESCRIPTION CONCLUSION REFINERY PROJECT

125

125

DOC. CLASS. ISSUE

HIT-RE-500- V4 EPOXY RESIN HIT-RE-500- V4 EPOXY RESIN (Port Harcourt - Nigeria) 1 02

WITH DRILL BIT OF NOMINAL WITH DRILL BIT OF NOMINAL BEFORE CHIPPING 1. SURFACE DETERIORATION AND DISCOLORATION OF CONCRETE SURFACE DUE TO THE EXISTING FOUNDATION IS DEEMED ACCEPTABLE

DIA. 18mm (TYP.) DIA. 18mm (TYP.) OF EXISTING GROUT EXPOSURE TO ENVIRONMENTAL FACTORS AND OIL SPILLS OBSERVED. THROUGH COSMETIC REPAIR, ACCORDING TO CLIENT IDENTIFICATION CODE

2. SLIGHT DAMAGE ON THE CONCRETE FOUNDATION OBSERVED. PROJECT SPECIFICATION 4239-AA-SG-00000007. PORT HARCOURT

REFINING COMPANY

LIMITED (PHRC)

3

_ 3

_ AFTER CHIPPING

OF EXISTING GROUT (****) (****) TITLE

CONCRETE DRAWING

AFTER DEMOLITION

ACTIVITIES SHOWN IN THIS (****) (****) ANCHOR BOLT REPLACEMENT FOR

DRAWING

NOTE :- (****) MEANT FOR : "TO BE FILLED BY CONTRACTOR'S REPRESENTATIVE"

FOUNDATION PUMP 63P533B - OFFSITE- AREA 5 SCALE

1:25 / 1:10

ORIG. SIZE

A0

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Motion & UnitsDocument2 pagesMotion & UnitsamitNo ratings yet

- House Rent - March 2023Document1 pageHouse Rent - March 2023amitNo ratings yet

- Tax InvoiceDocument1 pageTax InvoiceamitNo ratings yet

- To Do - DS-H - Supporting Beam - W8X18 - W8X18Document15 pagesTo Do - DS-H - Supporting Beam - W8X18 - W8X18amitNo ratings yet

- House Rent Jan2023Document1 pageHouse Rent Jan2023amitNo ratings yet

- Table For Value Entry - OldDocument10 pagesTable For Value Entry - OldamitNo ratings yet

- 4124 Ai Du 21110S006S01 Is01 - CheckprintDocument1 page4124 Ai Du 21110S006S01 Is01 - CheckprintamitNo ratings yet

- House Rent - Feb 2023Document1 pageHouse Rent - Feb 2023amitNo ratings yet

- 4124 Ai Du 21130i002s01 Is01 - RevisedDocument1 page4124 Ai Du 21130i002s01 Is01 - RevisedamitNo ratings yet

- 4124 Aa DC 21710S001S05 Is03 - CheckprintDocument1 page4124 Aa DC 21710S001S05 Is03 - CheckprintamitNo ratings yet

- To Do - DS - LRFD - Supporting Beam - W8X18 - W8X18Document15 pagesTo Do - DS - LRFD - Supporting Beam - W8X18 - W8X18amitNo ratings yet

- Pages From 4355-AI-DX-00000017 - DSDocument2 pagesPages From 4355-AI-DX-00000017 - DSamitNo ratings yet

- 4124 Aa DC 21110L106S01 Is02 - CheckprintDocument1 page4124 Aa DC 21110L106S01 Is02 - CheckprintamitNo ratings yet

- 4124 AA DC 21130I002S01 IS01 - CheckprintDocument1 page4124 AA DC 21130I002S01 IS01 - CheckprintamitNo ratings yet

- 4124-Ai-Du-21130i002s01-Is01 (2) - CheckprintDocument1 page4124-Ai-Du-21130i002s01-Is01 (2) - CheckprintamitNo ratings yet

- 4124 AI CS 217101001S11 - CommentedDocument143 pages4124 AI CS 217101001S11 - CommentedamitNo ratings yet

- 4124-Aa-Dc-21130i002s01-Is01 - Final CheckprintDocument1 page4124-Aa-Dc-21130i002s01-Is01 - Final CheckprintamitNo ratings yet

- 4239-AA-DC-21U50RN005-IS00 - TCM Check 021122Document1 page4239-AA-DC-21U50RN005-IS00 - TCM Check 021122amitNo ratings yet

- 4124 Aa DC 21710S001S03 Is03 - CheckprintDocument1 page4124 Aa DC 21710S001S03 Is03 - CheckprintamitNo ratings yet

- 4124 Ai Du 21710020VS01 Is03 - CheckprintDocument1 page4124 Ai Du 21710020VS01 Is03 - CheckprintamitNo ratings yet

- Calculation Note - 1710-EQ20VDocument10 pagesCalculation Note - 1710-EQ20VamitNo ratings yet

- 4124 Aa CS 21710V020S01Document24 pages4124 Aa CS 21710V020S01amitNo ratings yet

- 4239-AA-DC-41U52RN001-IS01 - CheckprintDocument1 page4239-AA-DC-41U52RN001-IS01 - CheckprintamitNo ratings yet

- 4239 C AA DC 41U52RN004 IS01 - CheckprintDocument1 page4239 C AA DC 41U52RN004 IS01 - CheckprintamitNo ratings yet

- 71u63-Eq63p533b 01Document8 pages71u63-Eq63p533b 01amitNo ratings yet

- 4239 AA DC 41U52RN003 IS01 - CheckprintDocument1 page4239 AA DC 41U52RN003 IS01 - CheckprintamitNo ratings yet

- 4239-C-AA-DC-41U52RN004-IS00Document1 page4239-C-AA-DC-41U52RN004-IS00amitNo ratings yet

- D 70 1320 553 Boiler Foundation Reinforcement Details 0079Document1 pageD 70 1320 553 Boiler Foundation Reinforcement Details 0079amitNo ratings yet

- SECT."K-K": Port Harcourt Refinery Project Rehabilitation ofDocument1 pageSECT."K-K": Port Harcourt Refinery Project Rehabilitation ofamitNo ratings yet

- 4239-FB-VD-LF9859170B0203003: Foundations Loads TableDocument3 pages4239-FB-VD-LF9859170B0203003: Foundations Loads TableamitNo ratings yet