Professional Documents

Culture Documents

Ordering information for large flow meters

Uploaded by

j srisai sekharOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ordering information for large flow meters

Uploaded by

j srisai sekharCopyright:

Available Formats

manas

ORDERING INFORMATION

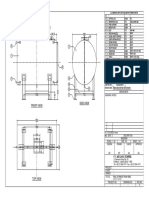

Table for Meter Dimensions MEGA-SROAT(mm) R

DN(mm) A B C FLOW METER SIZE

DN 400 : 16” DN 800 : 32”

400 600 325 600

DN 450 : 18” DN 900 : 36”

450 635 415 650 DN 500 : 20” DN 1000 : 40” a name that spells trust....

500 700 500 700 DN 600 : 24” DN 1200 : 48” AN ISO 9001: 2008 COMPANY

600 810 550 800 DN 700 : 28” DN 1400 : 56”

700 850 700 900 DN 750 : 30” DN 1600 : 64”

750

800

900

1000

910

1000

1085

1200

750

800

800

800

950

1000

1100

1200

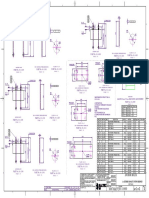

LINER MATERIAL

LN-01 : Hard Rubber

LN-02 : Soft Rubber

LN-03 : Neoprene Rubber

We Measure Flow

1200 1410 900 1400

1400 1600 1000 1400 ELECTRODE MATERIAL

EL-01 : SS316

1600 1840 1100 1600

EL-02 : SS316L

Note - EL-03 : HASTELLOY 'C

1. All dimensions are in mm.

2. Dimension ‘C’ is without earth rings. FLANGE /END CONNECTION STANDARDS

3. Dimensions are with terminal box. FCS-01 : AWWA : CLASS D

FCS-02 : ANSI : CLASS 150

FCS-03 :BS-10 : TABLE F-UPTO DN 600

FCS-04 : ANY OTHER

110 FLANGE MATERIAL

FM -01 : Carbon Steel

57 FM-02 : Mild Steel

FM-03 : Any Other

56

BODY MATERIAL

BM-01 : Mild Steel

BM-02 : SS304

A BM-03 : SS316

BM-04 : SS316L

FLOW TRANSMITTER TYPE

FTT- 01 : Blind

B FTT- 02 : With Display

C FLOW TRANSMITTER MOUTING

75 FT-01 : Integral

FT-02 : Remote (wall)

POWER SUPPLY

01 : 110 VAC ± 10%, 50 Hz

02 : 230 VAC ± 10%, 50Hz

Crownsp @ vsnl.com feb 2009-1000

DN 600 LN 02 EL 03 FCS 01 FM 01 BM 01 FTT02 FT02 02

Due to continuous development specifications are subject to change without prior notice.

manas microsystems pvt. ltd. R

REGD. OFFICE : ROW HOUSE NO. 5, PARVATI PARK, DATTAWADI, PUNE 411 030 BSI TM

WORKS : EL 54 ELECTRONIC ZONE, M.I.D.C. BHOSARI, PUNE 411 026. (INDIA)

TEL. : 020-27127044,27127047, 27127858 FAX : 020-27127045 QM 008

E-MAIL : mktg@manasmicro.com, manasmicro@yahoo.com

WEBSITE : www.manasmicro.com, www.flowmeterindia.in

Catalog No : Fc - FBE- 08

SERIES: MEGA SROAT AND SROAT 1000A / 1000 A+ l Measurement independent of un-dissolved solids. TRANSMITTER SROAT 1000A PLUS / SROAT 1000A TRANSMITTER : SROAT 1000 A plus

l Long lasting Ebonite rubber lining gives long life of sensor.

INTRODUCTION : 1 Display(Optional) : 16 Character x 2line LCD for

l End connection flanges as per customer's Requirements. Common Specs. to both transmitters :

l Much better accuracy compared to other types of meters instantaneous flow rate and

Series MEGA SROAT is offering large sized electromagnetic cumulative flow.

in its class. 1. Type : Integral mounted [std.]

flow meters introduced by manas. The sizing ranges from 2 Pulse Output : 1 pulse per hour to 100,000

400mm diameter to 1600mm diameter. These flow meters are Remote Mounted pulses \ hour,

APPLICATIONS :

very accurate(Typically 0.5% of actual flow rate). Hard ebonite [on request] (Open collector 3 Wire),

rubber lining makes these meters suitable for measurement of

1)Extremely useful for large water supply schemes. 2. Min. Media Conductivity : 5 µs /cm [ for lower programmable.

Raw Water containing even abrasive sand and quartz particles, 3 Comm. Port : RS 232 or RS 485 with

mud etc. and still delivering long life. This Series is also suitable

conductivities consult

2) Suitable for Sewage measurements factory] MODBUS RTU compatible to

for sewage applications. serial printer.

3. Flow Velocity Range : 0.1 m/s to 10 m/s

3) Municipal water measurement schemes. 4 Data Logging : Up to 5000 readings can be

PRINCIPLE OF OPERATION: 4. Accuracy : ±0.5% of reading [at ref. stored on real time base.

conditions] between These readings can be

The MEGA SROAT series of electromagnetic flow meters work 100% to 10% of viewed latter using a

TECHNICAL SPECIFICATIONS:

on FARADAY'S LAW OF ELECTROMAGNETIC INDUCTION. It, calibrated range. keyboard or may be

in brief, states; “When a conductor moves within a magnetic ±0.75% of reading for printed.

A ) PRIMARY FLOW SENSOR : - Mega Sroat

field , voltage is induced in it which is proportional to the

flow rate between 10 to

velocity of conductor” TRANSMITTER : SROAT 1000 A

1. Meter Size : DN 400 to DN 1600 5% [refer accuracy graph]

In this case the conductor is flowing media. The equation is as 6. Ref. Conditions : Power supply nominal.

2. Media Pressure : PN 10 1. Signal Output : 4-20 mA dc isolated in max.

below: Temperature 27°c ± 2°c

600 ohms

E= B.v.d 7. Repeatability : ±0.2% of reading 2. Coil Excitation Frequency : 12.5Hz/6.25 Hz

3. Media Temperature : 0-80°C max

Where 8. Ambient Temperature : 0 - 50°c 3. Local Display : a) 3 ½ digit LCD calibrated

E = Induced voltage [proportional to velocity] 9. Temperature Drift : ±0.015% per °C max. in % or engineering units

4. Operating Ambient : 0 - 60 °C

B = Magnetic flux density 10. Humidity : 90 % R. H. max. non for flow rate indication

Temperature

v = Mean velocity of the media condensing b) 8 digit LCD non

d = Diameter of flow-sensor(distance between the sensing resettable type for totalised

5. Material of construction 11. Material of Housing : Al. Die cast.

electrodes) quantity.

12. Power Supply : 230 V ac/ 110 V ac

Pipe : SS 304 [ non magnetic ] 50 Hz/24 Vdc.

For a given size of flow tube & compatible amplifier the flux

Electrodes : SS 316/SS 316L/ or others as 13. Damping : Adjustable from 5 to 30 Secs.

density 'B' is constant, the distance between the electrodes is

: per compatibility with service 14. Cable Entries : 4 no. For remote amplifier

constant. Hence, the induced voltage is proportional to the

: liquid. 2 no. For integral amplifier

flowing media. Thus the meter can be calibrated in terms of

Liner : Hard Ebonite rubber ½” NPT / ½” BSP /

volumetric flow rate by knowing the cross-sectional area of the

Flanges : CS / SS 316 / SS 304 / SS 316 L PG11[Female]

tube.

Coil Housing : CS (Polyurethene 15. Ingress Protection : IP-65

Painted ) / SS304/ SS 316

PRINCIPAL ADVANTAGES:

Earth Electrodes : SS 316/SS 316L / Hastalloy C /

or others

l Robust, rugged, welded steel/stainless steel construction

Body Material : CS / SS 316 / SS 304

withstanding to IP68.

6. Flange Standard : ANSI /BS/AWWA/Any other as

l Very much suitable for submerged or buried application.

per customer's Specs.

l No Pressure Drop across the sensor, being full bore FLOW RATE TABLE : Flow rate at v = 1m/s

7. Power Supply to : Pulsed DC

construction.

Field Coils DN m3/Hr. LPM LPS MLD DN m3/Hr. LPM LPS MLD

400 452.389 7539.816 125.664 10.8 800 1809.556 30159.26 502.654 43.429

450 572.555 9542.580 159.043 13.7 900 2290.219 38170.32 636.172 54.965

500 706.858 11780.960 196.349 16.9 1000 2827.431 47123.85 785.398 67.858

ERROR DIAGRAM 600 1017.875 16964.59 0 282.743 24.4 1200 4071.501 67858.34 1130.972 97.716

700 1385.441 23090.69 0 384.845 33.2 1400 5541.765 92362.75 1539.379 133.002

2.5

750 1590.430 26507.17 0 441.786 38.1 1600 7238.223 120637.1 2010.618 173.717

% ERROR OF ACTUAL FLOW

2.0

Sample Calculation for Velocity in flow Tube :

1.5

1.0 Pl. Refer the velocity Table where flow rates at 1 meter/sec. velocity through different sizes of flow meter are given. In general

through large size of meters the velocity taken is between 2 to 3 m/sec.

0.5

0 Given flow rate by customer :3000 m3/hr. (Say)

Expected Velocity through Flow meter : 2.5 m/sec.(Approximately)

- 0.5 Flow rate at 1 meter/sec. velocity : 3000/2.5=1200 m3/hr.

- 1.0 Referring Velocity table, DN700 is having 1385.441 m3/hr. flow rate at 1 m/sec. velocity.

We get velocity for given flow rate through DN700 : 3000/1385.441=2.165 m/sec.

- 1.5 This is suitable velocity. Thus in this case DN700 is suitable meter.

- 2.0

Alternately, Suppose the given line size is 800 NB. Flow rate is 3000 m3/Hr. Velocity through DN 800 flow meter,

- 2.5 V=3000m3/hr./1809.556 =1.658 m/s. Where, 1809.556 is the flow rate in m3/hr., specified for 1 meter velocity through DN800

0 10 20 30 40 50 60 70 80 90 100

meter as per the above velocity table.

FLOW AS PERCENTAGE OF RANGE

You might also like

- BTU Meter - Manas Microsystems Pvt. Ltd.Document2 pagesBTU Meter - Manas Microsystems Pvt. Ltd.manasNo ratings yet

- Sroat 1000-PlusDocument2 pagesSroat 1000-PlusVishnu PatidarNo ratings yet

- Material: SA-350 LF2 CL1 or CL2Document3 pagesMaterial: SA-350 LF2 CL1 or CL2Anonymous Ftxuwk1Ww5No ratings yet

- As Build Drawing: Cme RT Pole 6 M Site Name: Pondok Tjandra Site Id: Sda003Document36 pagesAs Build Drawing: Cme RT Pole 6 M Site Name: Pondok Tjandra Site Id: Sda003herry horasNo ratings yet

- Intake flow meter chamber planDocument1 pageIntake flow meter chamber plangawtomNo ratings yet

- SHOP DRAWING SECTIONDocument1 pageSHOP DRAWING SECTIONhungNo ratings yet

- Heat Exchanger 521.49Document1 pageHeat Exchanger 521.49dejanpecicNo ratings yet

- Technical Data SheetDocument13 pagesTechnical Data SheetRohit MEPNo ratings yet

- SagrodDocument1 pageSagrodfarouqi fazaNo ratings yet

- SagrodDocument2 pagesSagrodWayanArtanaNo ratings yet

- Window SchedDocument1 pageWindow SchedTARA TAYLOR RAINENo ratings yet

- Thermax Limited: DMF - Design SummaryDocument14 pagesThermax Limited: DMF - Design SummaryRohit MEPNo ratings yet

- CVS ValvulasDocument20 pagesCVS ValvulasDaniel AcostaNo ratings yet

- Bản vẽ bình 3000L - DVADocument1 pageBản vẽ bình 3000L - DVANhật Quang PhạmNo ratings yet

- 14 KawakiproductDocument6 pages14 KawakiproductAkif DinçNo ratings yet

- Column & Footing DetailsDocument1 pageColumn & Footing DetailsBryan PaviaNo ratings yet

- Consumbles List Section Wise.Document9 pagesConsumbles List Section Wise.engineeringNo ratings yet

- SF1521 60070 2S - PDDDocument1 pageSF1521 60070 2S - PDDpayoseNo ratings yet

- Hdpe 81aDocument1 pageHdpe 81aAli RaheemNo ratings yet

- 4PileCapDesign - Bending Theory Method PDFDocument2 pages4PileCapDesign - Bending Theory Method PDFisholaoladimejiNo ratings yet

- Pdf&rendition 1Document6 pagesPdf&rendition 1alif mapajayaNo ratings yet

- Base Frame 01 ModelDocument1 pageBase Frame 01 ModelMohammed Saleem Syed KhaderNo ratings yet

- Compressed Air Receiiver: SR SeriesDocument2 pagesCompressed Air Receiiver: SR SeriesSuresh NathNo ratings yet

- Client: Project: Estimate No: Contract No: Sheet No: C06-C6/1Document7 pagesClient: Project: Estimate No: Contract No: Sheet No: C06-C6/1Krish ChandNo ratings yet

- FST001000LG Std-ModelDocument1 pageFST001000LG Std-ModelaryitoNo ratings yet

- Welder'S Qualification Test CertificateDocument1 pageWelder'S Qualification Test CertificateLHYT NTUANo ratings yet

- API2000Document3 pagesAPI2000DharaniNo ratings yet

- PRIMA POWER 301GB - Aug2013 - Ep - Technical - DataDocument2 pagesPRIMA POWER 301GB - Aug2013 - Ep - Technical - DataTantaouiNo ratings yet

- Mathcad - C06-C8 PDFDocument7 pagesMathcad - C06-C8 PDFKrish ChandNo ratings yet

- Base NH BussmannDocument7 pagesBase NH BussmannMiguel Guillermo Zelaya DamianNo ratings yet

- NH AccessoriesDocument12 pagesNH AccessoriesYordanis CeballoNo ratings yet

- UO - 041 BD Sockets & Spanners 1x2700 - 2018-09-17Document12 pagesUO - 041 BD Sockets & Spanners 1x2700 - 2018-09-17johnNo ratings yet

- Comparison - 18-01-2024Document4 pagesComparison - 18-01-2024ashish.itbhuNo ratings yet

- Jacket Tech PackDocument11 pagesJacket Tech PackĐỗ Hải ĐăngNo ratings yet

- Zeron 100Document2 pagesZeron 100NAVANEETHNo ratings yet

- M-Sec-09 - Rev-ADocument1 pageM-Sec-09 - Rev-AhungNo ratings yet

- Schedule of Slabs Reinforcement Details Level 4500Document1 pageSchedule of Slabs Reinforcement Details Level 4500vinujohnpanickerNo ratings yet

- C1-F1 Detail Plan View: 0.4x0.5 20mm 0.3x0.4 20mm 3 2 4 4 3 2 4 4 3 2 4 4Document1 pageC1-F1 Detail Plan View: 0.4x0.5 20mm 0.3x0.4 20mm 3 2 4 4 3 2 4 4 3 2 4 4Lyka AnchetaNo ratings yet

- Electrical Hotwork - Pipe ListDocument1 pageElectrical Hotwork - Pipe ListEka SaputraNo ratings yet

- JK Paper Launders Annexure-1Document1 pageJK Paper Launders Annexure-1kasvikrajNo ratings yet

- 1.9.2.5 AMP 22 Data Sheet - 2021Document2 pages1.9.2.5 AMP 22 Data Sheet - 2021Carlos FreireNo ratings yet

- Compliance SheetDocument1 pageCompliance Sheetkhadeerabk7925No ratings yet

- CO2 Fire Suppression System Component Data SheetsDocument19 pagesCO2 Fire Suppression System Component Data SheetsLaxmanDungraniNo ratings yet

- Ballast Calculations 01Document1 pageBallast Calculations 01Yudi DarmawanNo ratings yet

- Anchor Bolts: SCALE 1: 20 SCALE 1: 20 Scale 1: 5Document1 pageAnchor Bolts: SCALE 1: 20 SCALE 1: 20 Scale 1: 5pstechnical_43312697No ratings yet

- Ga Drawing of 125a PDB Panel 06-10-18-ModelDocument1 pageGa Drawing of 125a PDB Panel 06-10-18-ModelNareshkumar SarojNo ratings yet

- UltraFlow 2500-Ultrasonic Flow Meter Data SheetDocument4 pagesUltraFlow 2500-Ultrasonic Flow Meter Data SheetwaseemshahkhanNo ratings yet

- Calplas CatalogueDocument59 pagesCalplas CatalogueMorris MorrisonNo ratings yet

- Double Flanged Butterfly Valve F 012-K1 Double Flanged Butterfly Valve F 012-K1 Double Flanged Butterfly Valve F 012-K1Document6 pagesDouble Flanged Butterfly Valve F 012-K1 Double Flanged Butterfly Valve F 012-K1 Double Flanged Butterfly Valve F 012-K1Bobbie RuckNo ratings yet

- SBBV - Rnav Anlol 1a Rwy 08 - Sid - 20191107Document1 pageSBBV - Rnav Anlol 1a Rwy 08 - Sid - 20191107Rafael GeraldoNo ratings yet

- Mat 1140 For SuppliersDocument3 pagesMat 1140 For SupplierskarthimeenaNo ratings yet

- Daftar Gambar Rencana Rumah Tipe 36/72Document27 pagesDaftar Gambar Rencana Rumah Tipe 36/72Gilang dasa putra Pamungkas sNo ratings yet

- Atc Fire Panel - 2Document12 pagesAtc Fire Panel - 2Shubhajit ChakrabortyNo ratings yet

- APT001-D-DWG-ME-001 - Drawing Production Separator (V-100A-B-C) - 0 - IFBDocument2 pagesAPT001-D-DWG-ME-001 - Drawing Production Separator (V-100A-B-C) - 0 - IFBRoy RahadianNo ratings yet

- Forging CatalogueDocument27 pagesForging CatalogueTháiSơnTrầnNo ratings yet

- M-Sec-08 - Rev-ADocument1 pageM-Sec-08 - Rev-AhungNo ratings yet

- Catalog & Cable Ladder System GuideDocument8 pagesCatalog & Cable Ladder System GuidefjbetaNo ratings yet

- Drain DrawingDocument1 pageDrain DrawingUmesh Kumar100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- M.Tech Cyber Security Course Structure Y18Document2 pagesM.Tech Cyber Security Course Structure Y18j srisai sekharNo ratings yet

- Manual MEGA SROAT Ver 0 0Document46 pagesManual MEGA SROAT Ver 0 0j srisai sekharNo ratings yet

- Appgecet 2020 Detailed NotificationDocument6 pagesAppgecet 2020 Detailed Notificationj srisai sekharNo ratings yet

- Week 1: Familiarization With Rational Rose or Umbrello: 1. BrowserDocument4 pagesWeek 1: Familiarization With Rational Rose or Umbrello: 1. BrowserrkNo ratings yet

- ATM System DesignDocument13 pagesATM System Designj srisai sekharNo ratings yet

- Government of Andhra Pradesh A.P.State Council of Higher Education Appgcet-2020 (AdmissionsDocument9 pagesGovernment of Andhra Pradesh A.P.State Council of Higher Education Appgcet-2020 (Admissionsj srisai sekharNo ratings yet

- A Simple Explanation of The IoTDocument3 pagesA Simple Explanation of The IoTj srisai sekharNo ratings yet

- ABSTRACTDocument7 pagesABSTRACTj srisai sekharNo ratings yet

- Pgecet-2020-Helpline CentersDocument1 pagePgecet-2020-Helpline Centersj srisai sekharNo ratings yet

- CACHEDocument1 pageCACHEj srisai sekharNo ratings yet

- Social Engineering: The Art of Social HackingDocument23 pagesSocial Engineering: The Art of Social HackingLuja HawhsukNo ratings yet

- Hidden Secrets Behind The ImagesDocument14 pagesHidden Secrets Behind The Imagesj srisai sekharNo ratings yet

- Wms Req 05Document2 pagesWms Req 05j srisai sekharNo ratings yet

- A Simple Explanation of The IoTDocument3 pagesA Simple Explanation of The IoTj srisai sekharNo ratings yet

- TimetableDocument3 pagesTimetablej srisai sekharNo ratings yet

- Cache PDFDocument1 pageCache PDFj srisai sekharNo ratings yet

- Image Based Steganography Using LSB Insertion TechniqueDocument23 pagesImage Based Steganography Using LSB Insertion TechniquePranitha Kuchipudi50% (2)

- Work ProcedureDocument1 pageWork Procedurej srisai sekharNo ratings yet

- 8690 Ig6uiwjDocument12 pages8690 Ig6uiwjRamees ARNo ratings yet

- Introduction To ComputersDocument3 pagesIntroduction To Computersj srisai sekharNo ratings yet

- K&SDocument21 pagesK&Sj srisai sekharNo ratings yet

- The Medium Accesscontrol SublayerDocument69 pagesThe Medium Accesscontrol Sublayerj srisai sekharNo ratings yet

- Getting StartedDocument1 pageGetting Startedj srisai sekharNo ratings yet

- User ManualDocument9 pagesUser Manualj srisai sekharNo ratings yet

- Sync, share, and access files from any device with Google DriveDocument1 pageSync, share, and access files from any device with Google DriveErmirLekaNo ratings yet

- Practical-Electronics-1967-12 Spring Line ReverbDocument7 pagesPractical-Electronics-1967-12 Spring Line ReverbJohan TaalanderwijsNo ratings yet

- Instruction Manual Mode D'Emploi Manual de Instrucciones: Register OnlineDocument20 pagesInstruction Manual Mode D'Emploi Manual de Instrucciones: Register OnlineLauraNo ratings yet

- CS 4001: Probability and StatisticsDocument13 pagesCS 4001: Probability and StatisticsDinesh NaraharisettiNo ratings yet

- Chapter 5 - Analog Integrated Circuit Design by John ChomaDocument95 pagesChapter 5 - Analog Integrated Circuit Design by John ChomaAriana Ribeiro LameirinhasNo ratings yet

- Principal of Industrial Instrumentation CompressDocument573 pagesPrincipal of Industrial Instrumentation CompressRatnesh PandeyNo ratings yet

- NavDocument202 pagesNavfcoespinosa100% (1)

- Measurement and Instrumentation Theory and Application 2nd Edition Morris Solutions ManualDocument45 pagesMeasurement and Instrumentation Theory and Application 2nd Edition Morris Solutions Manualelmerhelenb7446100% (22)

- An11425 Lna DesignDocument25 pagesAn11425 Lna DesignRaul LunaNo ratings yet

- Specifications: Product DescriptionDocument2 pagesSpecifications: Product DescriptionsanachNo ratings yet

- Tda7265 (30W+30W)Document18 pagesTda7265 (30W+30W)ShiguMiku TheyNo ratings yet

- SM36 Aa34Document40 pagesSM36 Aa34jackcastelNo ratings yet

- Gainsil-GS8722-SR C157708Document18 pagesGainsil-GS8722-SR C157708ikhsanaeNo ratings yet

- BPHEL 144 (English)Document96 pagesBPHEL 144 (English)JIJOMON O RNo ratings yet

- "Grid-Tie" FX and VFX Inverter/Charger: Outback Power SystemsDocument55 pages"Grid-Tie" FX and VFX Inverter/Charger: Outback Power SystemsalfredohdnNo ratings yet

- IOT Based Wireless Patient Health Monitoring Using LabVIEW & SensorsDocument16 pagesIOT Based Wireless Patient Health Monitoring Using LabVIEW & Sensorssreeharsha koduruNo ratings yet

- Sistem KontrolDocument20 pagesSistem KontrolJohann Sjbt100% (4)

- Mitsu Mitsubishi CNC FaultsDocument2 pagesMitsu Mitsubishi CNC FaultsVladimirAgeevNo ratings yet

- Index: Installation ManualDocument50 pagesIndex: Installation ManualSami Vehmas88% (8)

- IC6701 May 18 With KeyDocument14 pagesIC6701 May 18 With KeyAnonymous yO7rcec6vuNo ratings yet

- INC221 Lecture6 Transistor Biasing Circuit - ToDocument14 pagesINC221 Lecture6 Transistor Biasing Circuit - ToidatscribdNo ratings yet

- Multiple Choice Questions (MCQ) Unit: 1 Part-A: 15 Questions (Each 1 Mark)Document37 pagesMultiple Choice Questions (MCQ) Unit: 1 Part-A: 15 Questions (Each 1 Mark)DINESH KUMAR DRAVIDAMANINo ratings yet

- RTN XMC ODU Hardware Description (V100 - 18)Document81 pagesRTN XMC ODU Hardware Description (V100 - 18)George Loui FuentesNo ratings yet

- Application Manual: PWM Switching Regulator Controller IC TK11840LDocument15 pagesApplication Manual: PWM Switching Regulator Controller IC TK11840Lgilberto gutierrezNo ratings yet

- Didactic Katalog 07 en MonitorDocument316 pagesDidactic Katalog 07 en MonitorDavid ValderramaNo ratings yet

- Multi-Phase PWM Controller For CPU Core Power Supply: Features General DescriptionDocument14 pagesMulti-Phase PWM Controller For CPU Core Power Supply: Features General DescriptionFreddy ArmstrongNo ratings yet

- ATX Power Supply Modification Symmetric 2X30V DC DC Converter Circuit sg3525 - Electronics Projects Circuits PDFDocument1 pageATX Power Supply Modification Symmetric 2X30V DC DC Converter Circuit sg3525 - Electronics Projects Circuits PDFStefan CorneaNo ratings yet

- Pico System Some Issues (Alignment and Timing Control)Document37 pagesPico System Some Issues (Alignment and Timing Control)Anang SunandarNo ratings yet

- Parametric Amplification With TransistorsDocument2 pagesParametric Amplification With TransistorsdudulemarcNo ratings yet

- 3 DOF Helicopter - User ManualDocument23 pages3 DOF Helicopter - User ManualMurilloMaganNo ratings yet

- Type QD75MH Positioning Module Type QD75MH Positioning ModuleDocument834 pagesType QD75MH Positioning Module Type QD75MH Positioning Modulerammu2001100% (1)