Professional Documents

Culture Documents

Technical Data Sheet

Technical Data Sheet

Uploaded by

IVANCHUOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Data Sheet

Technical Data Sheet

Uploaded by

IVANCHUCopyright:

Available Formats

Technical Data Sheet

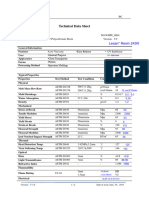

Alathon M4612

High Density Polyethylene

Product Description

Alathon M4612 is a copolymer that provides outstanding stress crack resistance and low temperature impact

strength. Typical applications include food containers, seat hinges, tube headers and parts requiring high ESCR.

Regulatory Status

For regulatory compliance information, see Alathon M4612 Product Stewardship Bulletin (PSB) and Safety Data

Sheet (SDS).

Status Commercial

Availability North America

Application Containers; Tube Headers

Market Rigid Packaging

Processing Method Injection Molding

Attribute High ESCR (Environmental Stress Cracking Resistance)

Nominal English Nominal SI

Typical Properties Value Units Value Units Test Method

Physical

Melt Flow Rate, (190 °C/2.16 kg) 1.2 g/10 min 1.2 g/10 min ASTM D1238

Density, (23 °C) 0.946 g/cm³ 0.946 g/cm³ ASTM D1505

Bulk Density 37-39 lb/ft³ 593-625 kg/m³ ASTM D1895

Spiral Flow 7.7 in 19.6 cm LYB Method

Mechanical

Flexural Modulus

(1% Secant) 135000 psi 931 MPa ASTM D790

(2% Secant) 112000 psi 772 MPa ASTM D790

Flexural Young's Modulus 146000 psi 1010 MPa ASTM D790

Tensile Modulus, (1% Secant) 92200 psi 636 MPa ASTM D638

Tensile Young's Modulus 117000 psi 807 MPa ASTM D638

Tensile Stress at Break, (23 °C) 3470 psi 23.9 MPa ASTM D638

Tensile Stress at Yield, (23 °C) 3350 psi 23.1 MPa ASTM D638

Tensile Elongation at Break, (23 °C) 550 % 550 % ASTM D638

Tensile Elongation at Yield, (23 °C) 12 % 12 % ASTM D638

Impact

Notched Izod Impact Strength, (23 °C) 1.4 ft-lb/in 74.7 J/m ASTM D256

Unnotched Impact Strength, (-18 °C) No Break No Break ASTM D4812

Hardness

Shore Hardness, (Shore D, max) 69 69 ASTM D2240

Thermal

Vicat Softening Temperature 255 °F 124 °C ASTM D1525

Low Temperature Brittleness, Fཥའ <-105 °F <-76 °C ASTM D746

Deflection Temperature Under Load, (66 psi,

144 °F 62 °C ASTM D648

Unannealed)

Melting Temperature 261.9 °F 127.7 °C ASTM D3418

LyondellBasell Alathon M4612

Technical Data Sheet Recipient Tracking #:

Date: 11/4/2022 Page 1 of 2 Request #: 4015605

Crystallization Temperature 235.8 °F 113.2 °C ASTM D3418

Notes

Conditions of Tensile Stress and Elongation values are: 50 mm/min, Type IV specimen.

Conditions of Flexural Modulus values are: 0.5 inches/min or 12.5 mm/min.

Conditions of Tensile Modulus values are: 50 mm/min, Type I Specimen.

Igepal® is a registered trademark of Rhodia.

Spiral Flow measures the number of inches of flow produced when molten resin is injected into a long, spiral

channel (0.0625" insert), at a constant injection pressure of 1000 psi with a melt temperature of 440 °F.

Deflection Temperature Under Load and Low Temperature Brittleness data are for control and development

work and are not intended for use in design or predicting performance at elevated or sub-ambient temperatures.

These are typical property values not to be construed as specification limits.

Processing Techniques

Specific recommendations for resin type and processing conditions can only be made when the end use,

required properties and fabrication equipment are known.

Company Information

For further information regarding the LyondellBasell company, please visit http://www.lyb.com/.

© LyondellBasell Industries Holdings, B.V. 2018

Disclaimer

Information in this document is accurate to the best of our knowledge at the date of publication. The document is

designed to provide users general information for safe handling, use, processing, storage, transportation,

disposal and release and does not constitute any warranty or quality specification, either express or implied,

including any warranty of merchantability or fitness for any particular purpose. Users shall determine whether the

product is suitable for their use and can be used safely and legally.

In addition to any prohibitions of use specifically noted in this document, LyondellBasell may further prohibit or

restrict the sale of its products into certain applications. For further information, please contact a LyondellBasell

representative.

Trademarks

The Trademark referenced within the product name is owned or used by the LyondellBasell family of companies.

LyondellBasell Alathon M4612

Technical Data Sheet Recipient Tracking #:

Date: 11/4/2022 Page 2 of 2 Request #: 4015605

You might also like

- Concrete Design MixDocument15 pagesConcrete Design MixM HAFEEZ RAJANo ratings yet

- 8echapter08 SMDocument87 pages8echapter08 SMGermán González SilvaNo ratings yet

- Raft FoundationDocument12 pagesRaft Foundationurmiladhameliya9586% (7)

- (Civil Engineering Hydraulics) Robert H. J. Sellin B.SC., Ph.D. (Auth.) - Flow in Channels-Macmillan Education UK (1969) PDFDocument159 pages(Civil Engineering Hydraulics) Robert H. J. Sellin B.SC., Ph.D. (Auth.) - Flow in Channels-Macmillan Education UK (1969) PDFLuis David Lopez BuitragoNo ratings yet

- SPPWC (Green Book) 2009Document472 pagesSPPWC (Green Book) 2009cipele12100% (2)

- Plumbing TablesDocument3 pagesPlumbing TablesLeinad ColladoNo ratings yet

- Septic Tank DesignDocument3 pagesSeptic Tank DesignKara SignarNo ratings yet

- Building Utilities Plumbing Answer KeyDocument7 pagesBuilding Utilities Plumbing Answer KeyDessNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetIVANCHUNo ratings yet

- Hdpe Alathon H5520 EquistarDocument2 pagesHdpe Alathon H5520 EquistarEric Mahonri PereidaNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetLeductoan LeNo ratings yet

- Petrothene: Technical Data SheetDocument3 pagesPetrothene: Technical Data SheetEli DelgadoNo ratings yet

- Petrothene: Technical Data SheetDocument2 pagesPetrothene: Technical Data SheetJaime222No ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetihscribedNo ratings yet

- Lldpe Ga564189Document3 pagesLldpe Ga564189xy2zjgNo ratings yet

- Unival™ Dmdg-6200 NT 7: High Density Polyethylene ResinDocument3 pagesUnival™ Dmdg-6200 NT 7: High Density Polyethylene Resinyesenia flores rosadoNo ratings yet

- Technical Data Sheet - Original Hoop MaterialDocument2 pagesTechnical Data Sheet - Original Hoop MaterialMichelle Kozmik JirakNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetingindjorimaNo ratings yet

- NA9800000Document2 pagesNA9800000Noe floresNo ratings yet

- High Density Polyethylene Grade Used in Injection Molding Melt Index: 62 Density: 0.942Document2 pagesHigh Density Polyethylene Grade Used in Injection Molding Melt Index: 62 Density: 0.942Phung LucNo ratings yet

- PEADM5372Document2 pagesPEADM5372nicolas yoris marcoglieseNo ratings yet

- Spectrasyn™ 10: Polyalphaolefin (Pao) FluidDocument2 pagesSpectrasyn™ 10: Polyalphaolefin (Pao) FluidMaram YasserNo ratings yet

- Elite NG 5401BDocument3 pagesElite NG 5401BAbdo WalidNo ratings yet

- Technical Data Sheet - ASTM PDFDocument2 pagesTechnical Data Sheet - ASTM PDFnielNo ratings yet

- BCE111NPDocument3 pagesBCE111NPdignityymartNo ratings yet

- Elix ABS M220: Technical InformationDocument3 pagesElix ABS M220: Technical InformationDiegoTierradentroNo ratings yet

- 3812 ExceedDocument2 pages3812 ExceedJimmys GothiqueNo ratings yet

- SABIC PP 5703P Polypropylene Homopolymer For Injection MoldingDocument2 pagesSABIC PP 5703P Polypropylene Homopolymer For Injection MoldingMédi ChegmaNo ratings yet

- Braskem CP 741 Blow Molding PolypropyleneDocument2 pagesBraskem CP 741 Blow Molding PolypropyleneRonaldo CamargoNo ratings yet

- Lexan Polycarbonate Embossed SheetDocument2 pagesLexan Polycarbonate Embossed SheetAmritraj CharlesNo ratings yet

- LLGA1810Document2 pagesLLGA1810KAKI BELANGNo ratings yet

- 400 00030953en Engage 8180 TdsDocument3 pages400 00030953en Engage 8180 TdsSIDDHARTH BHASNEYNo ratings yet

- High Density Polyethylene (HDPE Injection) : Technical Data SheetDocument1 pageHigh Density Polyethylene (HDPE Injection) : Technical Data SheetEleannys GarciasNo ratings yet

- Tds A1105 en 2017pdfpdfDocument2 pagesTds A1105 en 2017pdfpdfagungNo ratings yet

- 400 00285217en Hdpe 6200 TdsDocument2 pages400 00285217en Hdpe 6200 TdsOriana Gudiño GaliñoNo ratings yet

- 400 00030930en Engage 8003 TdsDocument4 pages400 00030930en Engage 8003 TdsManoharan SundaramNo ratings yet

- Alathon®: ApplicationsDocument2 pagesAlathon®: ApplicationsCarlos Revilla FloresNo ratings yet

- Wanhua PC Injection Moulding 20 Mfi Clarnate A1227Document2 pagesWanhua PC Injection Moulding 20 Mfi Clarnate A1227lucasNo ratings yet

- Tritan TX1001Document2 pagesTritan TX1001qiongyao cuiNo ratings yet

- NG30-02JBK - Next PolymersDocument4 pagesNG30-02JBK - Next PolymersdigiarkanandNo ratings yet

- TP Wanhua Clarnate A1227 Vs Lexan 243RDocument2 pagesTP Wanhua Clarnate A1227 Vs Lexan 243RMitja GorseNo ratings yet

- Sabic Hdpe B5429: High Density PolyethyleneDocument2 pagesSabic Hdpe B5429: High Density Polyethylenegetasew altasebNo ratings yet

- LG Chem TDS SP988 EnglishDocument1 pageLG Chem TDS SP988 EnglishSérgio BarbosaNo ratings yet

- DOWLEX™ 2038.68G: Polyethylene ResinDocument3 pagesDOWLEX™ 2038.68G: Polyethylene ResinJosé PalmaNo ratings yet

- ABS Sabic Cycolac MG94 Cust.cDocument5 pagesABS Sabic Cycolac MG94 Cust.cMurillo AraujoNo ratings yet

- Pao 100Document2 pagesPao 100Антон СтепураNo ratings yet

- Shear Flat SlabDocument1 pageShear Flat Slabadnan-651358No ratings yet

- Alathon: Technical Data SheetDocument3 pagesAlathon: Technical Data SheetJaime222No ratings yet

- SABIC Cycolac MG47FDocument3 pagesSABIC Cycolac MG47FChu ChuNo ratings yet

- SABIC® PP COPO - 412MK49 (MFR 45 DG - Min 2.16 KG)Document2 pagesSABIC® PP COPO - 412MK49 (MFR 45 DG - Min 2.16 KG)yang chinaNo ratings yet

- DOWLEX™ 2047G: Polyethylene ResinDocument3 pagesDOWLEX™ 2047G: Polyethylene Resinujang sukartaNo ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- PC Calibre Technical DataDocument4 pagesPC Calibre Technical DataMitja GorseNo ratings yet

- Achieve™ Advanced PP8285E1: Polypropylene Impact CopolymerDocument2 pagesAchieve™ Advanced PP8285E1: Polypropylene Impact CopolymermosesNo ratings yet

- Basell Hdpe Pe100 Pipe Alathon l4904Document3 pagesBasell Hdpe Pe100 Pipe Alathon l4904Josiola MariledoNo ratings yet

- DoW LDPE 2685GDocument4 pagesDoW LDPE 2685Gtariquekhan143No ratings yet

- Dow Elite 5401G TDSDocument3 pagesDow Elite 5401G TDSAli RazuNo ratings yet

- SABIC® HDPE - M200056 - Global - Technical - Data - SheetDocument2 pagesSABIC® HDPE - M200056 - Global - Technical - Data - SheetAhmed Elgazar100% (1)

- Engage 7467Document2 pagesEngage 7467RomDipaNo ratings yet

- UHMW-PE Tivar 1000Document2 pagesUHMW-PE Tivar 1000centurion2988No ratings yet

- Technical Data Sheet ADFLEX F 500Document2 pagesTechnical Data Sheet ADFLEX F 500leftpowtaNo ratings yet

- Tds Infinam RG 7100 LDocument2 pagesTds Infinam RG 7100 LKacperNo ratings yet

- TDS Infinam ST 6100 LDocument5 pagesTDS Infinam ST 6100 LKacperNo ratings yet

- Ultramid A205fDocument3 pagesUltramid A205fSATHISH KUMAR SNo ratings yet

- Industrial VisitDocument10 pagesIndustrial VisitBilal Nawaz KiyaniNo ratings yet

- Civil Highway Network System ReportDocument30 pagesCivil Highway Network System Reportsayali patilNo ratings yet

- Summarized Catalogue 4Document104 pagesSummarized Catalogue 4Israel RogersNo ratings yet

- 44flow Through PipesDocument42 pages44flow Through PipesVenkata RamanaNo ratings yet

- ME466 Computational Fluid DynamicsDocument2 pagesME466 Computational Fluid DynamicsAkhi SankarNo ratings yet

- Ex 2 Déclaration de PerformanceDocument2 pagesEx 2 Déclaration de PerformanceLevasseurNo ratings yet

- Yadav 2020Document26 pagesYadav 2020ahmadalsaiahNo ratings yet

- C2-Mallemala Studio Acmv PPT-23.12.2019Document10 pagesC2-Mallemala Studio Acmv PPT-23.12.2019Raju KsnNo ratings yet

- Biaxialflexureand Axial Load Interaction in Short Rectangular Reinforced Concrete ColumnsDocument12 pagesBiaxialflexureand Axial Load Interaction in Short Rectangular Reinforced Concrete ColumnscarlosfernandoNo ratings yet

- Calc Sheet F1 Simple Aci 314Document62 pagesCalc Sheet F1 Simple Aci 314م.عمرو عبداللهNo ratings yet

- Preboard 1 - SEDC (Nov 2022)Document6 pagesPreboard 1 - SEDC (Nov 2022)Fleight VandollinNo ratings yet

- Seattle City LightDocument6 pagesSeattle City Lightfasih_baqai4252No ratings yet

- TimberDocument80 pagesTimberYooganNo ratings yet

- Euler Equation Fluid Dynamics PDFDocument2 pagesEuler Equation Fluid Dynamics PDFDianaNo ratings yet

- XJTLU - Steelwork CW - Portal Frame (2019-20)Document3 pagesXJTLU - Steelwork CW - Portal Frame (2019-20)FanisNo ratings yet

- बासाटारी मुखियाको चौपारी तल घुम्तीको प्रतिक्ष्यालय निर्माणDocument7 pagesबासाटारी मुखियाको चौपारी तल घुम्तीको प्रतिक्ष्यालय निर्माणHaree BhattaraiNo ratings yet

- Review Topic 4Document51 pagesReview Topic 4AlteaAlNo ratings yet

- Clay GroutingDocument10 pagesClay GroutingSabari PrasanthNo ratings yet

- (Estimation and Costing)Document26 pages(Estimation and Costing)Diksha GuptaNo ratings yet

- MOU Part 7 - July - 2019Document208 pagesMOU Part 7 - July - 2019thomas1313No ratings yet

- Sulphate Resisting Cement Product Data SheetDocument3 pagesSulphate Resisting Cement Product Data SheetAnoop Kumar SharmaNo ratings yet

- Chapter 6-1 DESIGN OF SHORT COLUMNS 3 1 2022Document53 pagesChapter 6-1 DESIGN OF SHORT COLUMNS 3 1 2022sajjad.ghazai2001No ratings yet