Professional Documents

Culture Documents

Plastik Boro

Uploaded by

asdsdasdCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Plastik Boro

Uploaded by

asdsdasdCopyright:

Available Formats

Synopsis Lipman Bottle Company, the leading bottle distribution company in Albany, New York

started distributing bottles of large bottle manufacturers on 1909. From then on, they started

to adapt to the changes in the bottling industry such as the use of plastics, which prove to be

profitable on their end. They grab the opportunity to distribute and print bottles with different

shapes and sizes for clients who liked the convenience of their dual services.

The energy consumed making a plastic bottle is significantly lesser than that of a plastic bottle.

Besides, due to the light weight of plastics, transportation charges are much lesser. Plastics can

also be recycled after use, which additionally brings down the costs. If a good plastic recycling

management system exists, the cost per bottle can be lowered significantly.

Using a plastic bottle for insulin is in fact a very good idea. Newer plastics such as COC’s can be

utilized so that they are able to overcome limitations of glass bottles. Previously, plastics were

being considered as a very unsafe material for use in the medical field. Doctors and specialists

were feeling safer to stick to the old glass containers.

Coca-Cola Company no use the recycle plastic in their bottles cause the plastic waste is

increasing ten times faster than recycling of plastic soda bottles and seriously effect health and

environment impacts. Coca-Cola Company Should uses the recycle plastic in their bottles to

reduce the increasing the plastic waste. Plastic waste can be reducing by recycling the plastic

bottle and produce new plastic bottle.

Glass has several advantages and disadvantages over plastic. One of the main advantages of

glass is that it is inert and non-degradable, and unlike plastics does not release any of its

components into the drug solution (chemical resistance). Insulin in glass bottles tends to have

a longer shelf-life compared to plastic.

We always buy plastic bottled products without knowing whether they are recyclable or not. In

fact, it is estimated that 80% of plastic bottles are not being recycled (Greenupgrader.com). A

nonrecyclable plastic bottle may last as long as 1000 years before it biodegrades completely

(Answers. com). Another notable fact is that 1 ton of recycled plastic bottles would save more

than 7.4 cubic yards of landfill (Earth911.com).

The technology to make 100% recycled-content plastic bottles has been available in the United

States since the U.S. Food and Drug Administration gave its approval in 1994 for food contact

applications. Coca-Cola Company is abandoning the decades old practice of packaging its soft

drinks in recycled content containers like aluminum cans and glass bottles in favor of non-

recycled plastic. Coca-Cola Company no use the PET in their bottles cause the plastic waste is

increasing ten times faster than recycling of plastic soda bottles.

Question: This is for my industrial design class. We have no lecture for this class at all. We just

have submitted a project at the end of the semester. I came up with this idea because one day

I broke my insulin bottle (I have diabetes). So I have a new idea of plastic insulin bottle instead

of glass bottle so the paper should include: Insulin is a hormone produced by the beta

cells of the Islets of Langerhans in the pancreas that helps in the metabolism of carbohydrates,

by converting glucose into glycogen.

Competitive advantage allows a company to be able to be more competitive than other

companies that have the same product or offer the same service. Riordan Manufacturing

manufactures plastic beverage containers, custom plastic parts, plastic fan parts and the major

customers of these plastic parts are automotive parts manufacturers, the Department of

Defense, bottling companies, aircraft manufacturers, and appliance manufacturers. These

items give them a competitive advantage over other companies as well as being able to

produce them for those that they produce them for.

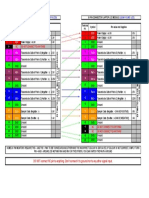

Break even prices for smaller size bottles, Albany Market Table 6. Break even prices for bigger

size bottles, Albany Market Table 7. Break even prices for smaller size bottles, New Jersey-New

York Market Table 8. Break even prices for bigger size bottles, New Jersey-New York Market

How did the Mr. Lipman’s goal of a 30% margin at capacity affect your price recommendation?

The consumer focus groups Pepsi used for this product coined the name the “CUBE” and it

stuck! Polyethylene terephthalate, or “PET plastic,” is a form of polyester used to make strong,

lightweight, shatter-resistant bottles for soft drinks, water, juice and other non-food products.

Bottles made from PET plastic, which are marked with the number one code on the or near the

bottle of the bottle, are recyclable into products including new containers, fiberfill for sleeping

bags and coats, fabric, carpet, auto parts, film and more.

Variable costs of bigger size bottles for Albany Market Table 3. Variable costs of smaller size

bottles for New York-New Jersey Market Table 4. Variable costs of bigger size bottles for New

York-New Jersey Market After which, we derived the break even prices for each combinations

and the recommended prices based on Mr. Lipman’s goal of 30% margin: Table 5.

If Coca-Cola Company still uses non-recycle plastic in their bottle, the plastic waste will keep

increasing and the raw material for producing plastic will decreasing. [Original source:

https://studycrumb.com/essay-typer]

You might also like

- Wedding Planning GuideDocument159 pagesWedding Planning GuideRituparna Majumder0% (1)

- Eco Design Packaging From The 3Ps To The 5RsDocument5 pagesEco Design Packaging From The 3Ps To The 5RsBertrandChovetNo ratings yet

- HACCP Plan With Flow Chart-1Document23 pagesHACCP Plan With Flow Chart-1Anonymous aZA07k8TXfNo ratings yet

- DC Booms Service Training OverviewDocument129 pagesDC Booms Service Training OverviewTamás Leményi100% (1)

- TRAIN Briefing - Revised Personal Income Tax RatesDocument73 pagesTRAIN Briefing - Revised Personal Income Tax RatesElizaFaithEcleoNo ratings yet

- CCST+Cybersecurity+Objecitve+Domain Cisco Final wCiscoLogoDocument3 pagesCCST+Cybersecurity+Objecitve+Domain Cisco Final wCiscoLogoQazi ZayadNo ratings yet

- Overview of The PET Plastic Recycling ProcessDocument7 pagesOverview of The PET Plastic Recycling ProcessGuntoro AliNo ratings yet

- EY - NASSCOM - M&A Trends and Outlook - Technology Services VF - 0Document35 pagesEY - NASSCOM - M&A Trends and Outlook - Technology Services VF - 0Tejas JosephNo ratings yet

- Guide to Waste Diversion: For Home and BusinessFrom EverandGuide to Waste Diversion: For Home and BusinessRating: 5 out of 5 stars5/5 (1)

- Plastic Bottle MachineDocument11 pagesPlastic Bottle MachineMelaku AssefaNo ratings yet

- The Rise of Disposable Coffee Cups and Efforts to Promote ReusablesDocument13 pagesThe Rise of Disposable Coffee Cups and Efforts to Promote ReusablesariaNo ratings yet

- Plastic Recycle SystemDocument13 pagesPlastic Recycle SystemTin Htut OoNo ratings yet

- Bio IPDocument25 pagesBio IPXaika Saldivar100% (3)

- The Importance of Plastic RecyclingDocument21 pagesThe Importance of Plastic Recyclingrhoby mendarosNo ratings yet

- Case Digest Basic Legal Ethics Subject FERDINAND A. CRUZ, Petitioner, vs. ALBERTO MINA, Et - Al., Respondents (G.R. No. 154207, 27 April 2007)Document3 pagesCase Digest Basic Legal Ethics Subject FERDINAND A. CRUZ, Petitioner, vs. ALBERTO MINA, Et - Al., Respondents (G.R. No. 154207, 27 April 2007)Grandeur P. G. GuerreroNo ratings yet

- OM Project ReportDocument6 pagesOM Project ReportMoiez AliNo ratings yet

- Benefits of PlasticsDocument5 pagesBenefits of PlasticsChessskaNo ratings yet

- Documentation On SustainabilityDocument29 pagesDocumentation On SustainabilityGurdeep BrarNo ratings yet

- Case Study SambalpurDocument2 pagesCase Study SambalpurMaheswari pandaNo ratings yet

- Bouteille: Polyethelene Terephthalate (PET) Bottles As Material For BagsDocument1 pageBouteille: Polyethelene Terephthalate (PET) Bottles As Material For BagsJoshua TagayunaNo ratings yet

- Science Report TemplateDocument12 pagesScience Report TemplateGeorge CrosbyNo ratings yet

- All CHAPTERS GROUP2 PBSMDocument49 pagesAll CHAPTERS GROUP2 PBSMVillaquer Dominic P.No ratings yet

- Info Sheet: Recyclable Plastic BagsDocument2 pagesInfo Sheet: Recyclable Plastic Bagsemporio72No ratings yet

- LFDDDDDSCSCWDocument5 pagesLFDDDDDSCSCWSrikanth SaratchandranNo ratings yet

- Red Horse Beer The Rising Bottle of FiberDocument28 pagesRed Horse Beer The Rising Bottle of FiberPARIDA EGINGNo ratings yet

- Sustainable Packaging DissertationDocument6 pagesSustainable Packaging DissertationCollegePaperHelpCanada100% (1)

- Americans Choose Bottled Water But Ban Needed to Curb Plastic WasteDocument4 pagesAmericans Choose Bottled Water But Ban Needed to Curb Plastic WasteAnjana AgnihotriNo ratings yet

- Term Paper On Plastic RecyclingDocument6 pagesTerm Paper On Plastic Recyclingc5jbmre7100% (1)

- What Are The Problems Derived From DrinkingDocument2 pagesWhat Are The Problems Derived From DrinkingDaniela Villegas MNo ratings yet

- Increase Use of Biodegradable Plastics by 10Document18 pagesIncrease Use of Biodegradable Plastics by 10Anustha ChoudharyNo ratings yet

- Thesis Statement For Plastic BagsDocument4 pagesThesis Statement For Plastic Bagschristyhuntjackson100% (2)

- Truth About Glass Recycli: What Is Downcycling?Document16 pagesTruth About Glass Recycli: What Is Downcycling?artisingh3412No ratings yet

- Plastics 2Document56 pagesPlastics 2MaeChelle DoronillaNo ratings yet

- 122 RES - (09) BioplasticDocument19 pages122 RES - (09) BioplasticApril Jade RuizNo ratings yet

- Environmental Issues: Further InformationDocument3 pagesEnvironmental Issues: Further InformationEny IndahwatiNo ratings yet

- Envi Sci Group 7Document19 pagesEnvi Sci Group 7Marbas, Novie Dame E.No ratings yet

- Recycling Plastic: Complications & Limitations: Resin Codes Don't Equal RecyclabilityDocument2 pagesRecycling Plastic: Complications & Limitations: Resin Codes Don't Equal RecyclabilitySafar Al InseNo ratings yet

- BST ProjectDocument23 pagesBST ProjectSaloni AgrawalNo ratings yet

- The Best Way to Eliminate Plastic WasteDocument5 pagesThe Best Way to Eliminate Plastic WasteSrikanth ThanuNo ratings yet

- Research Paper On Recycling PlasticDocument5 pagesResearch Paper On Recycling Plasticoiotxmrhf100% (3)

- PlastikDocument4 pagesPlastikMarcellia CrenataNo ratings yet

- A Lifecycle Assessment of Plastic Bottles and Potential Policy ImplicationsDocument10 pagesA Lifecycle Assessment of Plastic Bottles and Potential Policy Implicationsehorces1948No ratings yet

- W4V24 Plastics V2016 HandoutDocument7 pagesW4V24 Plastics V2016 HandoutSaraCaballeroNo ratings yet

- Case Litehouse FoodsDocument3 pagesCase Litehouse FoodsSreeda PerikamanaNo ratings yet

- Company Environmental IssueDocument1 pageCompany Environmental IssueNoel John Paul AysonNo ratings yet

- Sustainable Packaging CompaniesDocument16 pagesSustainable Packaging CompaniesSamuel AngelusNo ratings yet

- CWC CWC: Overview of The PET Plastic Recycling ProcessDocument7 pagesCWC CWC: Overview of The PET Plastic Recycling ProcessAdmaw AnleyNo ratings yet

- PriyankaDocument2 pagesPriyankaSimran RajputNo ratings yet

- Core Topic 6Document35 pagesCore Topic 6api-252361076No ratings yet

- Green Marketing Definition and Examples in 40 CharactersDocument4 pagesGreen Marketing Definition and Examples in 40 CharactersInigoraniNo ratings yet

- The Problem and Its Background: According To The Earth Day Network For The End Plastic Pollution Campaign (2018)Document37 pagesThe Problem and Its Background: According To The Earth Day Network For The End Plastic Pollution Campaign (2018)Kaye VelascoNo ratings yet

- English 11 - Research Logs 1-8Document9 pagesEnglish 11 - Research Logs 1-8api-496615437No ratings yet

- Biodegradable Plastic Bags ManufacturingDocument15 pagesBiodegradable Plastic Bags ManufacturingAli AhmadNo ratings yet

- B2 Reading Test1Document2 pagesB2 Reading Test1Krisztina KatyinaNo ratings yet

- Case Study - NudgeDocument8 pagesCase Study - NudgeLinh Phan Thị MỹNo ratings yet

- Alternative To Plastic Waste Generation and ReuseDocument5 pagesAlternative To Plastic Waste Generation and ReuseBhoomika HollaNo ratings yet

- W4V24 Plastics V2016 HandoutDocument7 pagesW4V24 Plastics V2016 HandoutJessica KingNo ratings yet

- 162302how Much Should You Be Spending On Hazardous Waste Recycling?Document3 pages162302how Much Should You Be Spending On Hazardous Waste Recycling?zoriusxvsuNo ratings yet

- Project Profile On PET Bottles: Product Code (NIC Code) : 22203Document12 pagesProject Profile On PET Bottles: Product Code (NIC Code) : 22203Mr.vijay VaddiNo ratings yet

- Practica IndividualDocument2 pagesPractica IndividualARGENIS DIAZ MARTINEZNo ratings yet

- Lesson Proper For Week 14: Relationship of Business To EnvironmentDocument10 pagesLesson Proper For Week 14: Relationship of Business To EnvironmentMariathess MojicaNo ratings yet

- Sample Research Paper About RecyclingDocument6 pagesSample Research Paper About Recyclinggvzfmq91100% (1)

- Blue Template 1Document14 pagesBlue Template 1DugstupakNo ratings yet

- DavidDocument3 pagesDavidJuliana OchoaNo ratings yet

- CibilguarDocument1 pageCibilguarasdsdasdNo ratings yet

- Causes and Effects of Broken FamiliesDocument2 pagesCauses and Effects of Broken FamiliesasdsdasdNo ratings yet

- Fonk EiseDocument2 pagesFonk EiseasdsdasdNo ratings yet

- EndeigerpisiDocument3 pagesEndeigerpisiasdsdasdNo ratings yet

- KiborDocument3 pagesKiborasdsdasdNo ratings yet

- Electric Chair Executions: A Torturous and Inhumane MethodDocument3 pagesElectric Chair Executions: A Torturous and Inhumane MethodasdsdasdNo ratings yet

- GuaterslaiDocument2 pagesGuaterslaiasdsdasdNo ratings yet

- Control ADocument2 pagesControl AasdsdasdNo ratings yet

- FukbolDocument2 pagesFukbolasdsdasdNo ratings yet

- FounDocument2 pagesFounasdsdasdNo ratings yet

- Moder FamDocument2 pagesModer FamasdsdasdNo ratings yet

- Introduction to routers, switches, gateways and other networking devicesDocument2 pagesIntroduction to routers, switches, gateways and other networking devicesasdsdasdNo ratings yet

- Lohan Returns to Acting After Decade with Netflix's 'Falling for Christmas' Rom-ComDocument3 pagesLohan Returns to Acting After Decade with Netflix's 'Falling for Christmas' Rom-ComasdsdasdNo ratings yet

- BiarDocument3 pagesBiarasdsdasdNo ratings yet

- Marker inDocument4 pagesMarker inasdsdasdNo ratings yet

- MausDocument2 pagesMausasdsdasdNo ratings yet

- TeibolDocument2 pagesTeibolasdsdasdNo ratings yet

- Nody D 23 01248 PDFDocument70 pagesNody D 23 01248 PDFLegis FloyenNo ratings yet

- Etextbook 978 0078025884 Accounting Information Systems 4th EditionDocument61 pagesEtextbook 978 0078025884 Accounting Information Systems 4th Editionmark.dame383100% (48)

- OptiLobe Rotary Lobe PumpDocument4 pagesOptiLobe Rotary Lobe PumpRemus-Mihai GheorghitaNo ratings yet

- Safety and Quality of Health Care System in IndiaDocument18 pagesSafety and Quality of Health Care System in IndiaKNOWLEDGE FeedNo ratings yet

- Nurses' Documentation of Falls Prevention in A Patient Centred Care Plan in A Medical WardDocument6 pagesNurses' Documentation of Falls Prevention in A Patient Centred Care Plan in A Medical WardJAY LORRAINE PALACATNo ratings yet

- Manual ZappyDocument9 pagesManual Zappyapi-45129352No ratings yet

- MSCL PipeDocument9 pagesMSCL PipeAhmad Zakwan Asmad100% (1)

- Unit 8 Grammar Short Test 1 A+B Impulse 2Document1 pageUnit 8 Grammar Short Test 1 A+B Impulse 2karpiarzagnieszka1No ratings yet

- G.princy Xii - CommerceDocument21 pagesG.princy Xii - CommerceEvanglin .gNo ratings yet

- SE John Deere 6020 Series Filter Overview and Capacities 6120 6120L 6220 6220L 6320 6320L 6420 6420L 6520L NOV20Document2 pagesSE John Deere 6020 Series Filter Overview and Capacities 6120 6120L 6220 6220L 6320 6320L 6420 6420L 6520L NOV20marianNo ratings yet

- Upliftment of Recto AveDocument6 pagesUpliftment of Recto AveFrance CortezanoNo ratings yet

- Data Protection Act (DPA)Document14 pagesData Protection Act (DPA)Crypto SavageNo ratings yet

- An Improved TS Algorithm For Loss-Minimum Reconfiguration in Large-Scale Distribution SystemsDocument10 pagesAn Improved TS Algorithm For Loss-Minimum Reconfiguration in Large-Scale Distribution Systemsapi-3697505No ratings yet

- Analysis and Design of BeamsDocument12 pagesAnalysis and Design of BeamsHasanain AlmusawiNo ratings yet

- Rapidcure: Corrosion Management Products Rapidcure UwDocument1 pageRapidcure: Corrosion Management Products Rapidcure UwHeramb TrifaleyNo ratings yet

- Engine Tune-UpDocument43 pagesEngine Tune-UpЮра ПетренкоNo ratings yet

- ABB Surge Arrester POLIM-H SD - Data Sheet 1HC0075860 E02 ABDocument4 pagesABB Surge Arrester POLIM-H SD - Data Sheet 1HC0075860 E02 ABHan HuangNo ratings yet

- LCD PinoutsDocument1 pageLCD PinoutsPablo Daniel MagallanNo ratings yet

- Crestron Teams HardeningDocument20 pagesCrestron Teams HardeningmanishNo ratings yet

- International Journal of Plasticity: Dong Phill Jang, Piemaan Fazily, Jeong Whan YoonDocument17 pagesInternational Journal of Plasticity: Dong Phill Jang, Piemaan Fazily, Jeong Whan YoonGURUDAS KARNo ratings yet

- Sap AbapDocument7 pagesSap Abapidrees aliNo ratings yet

- Mechatronic Project Progress Report W3Document5 pagesMechatronic Project Progress Report W3Hariz IzzuddinNo ratings yet

- Impact On Cocoon Quality Improvement.1Document10 pagesImpact On Cocoon Quality Improvement.1Naveen NtrNo ratings yet