Professional Documents

Culture Documents

COR JN40000578 - TN1532 SDES-KLKOM GPB80D v1

Uploaded by

Kholis JaimonOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

COR JN40000578 - TN1532 SDES-KLKOM GPB80D v1

Uploaded by

Kholis JaimonCopyright:

Available Formats

PREPARED BY REVIEWED BY APPROVED BY

NAME: NAME: NAME:

KHOLIS JAIMON MOHD HUSNIZAR B ADNAN CHIN KEAN KHOON

DESIGNATION: DESIGNATION: DESIGNATION:

PROJECT ENGINEER PROJECT MANAGER DIRECTOR

DATE: DATE DATE:

27TH OCTOBER 2021 27TH OCTOBER 2021 27TH OCTOBER 2021

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 1 of 58

CLOSEOUT REPORT

CLIENT : SIME DARBY ENERGY SOLUTIONS

JOB START : 01ST OCTOBER 2021

JOB FINISHED : 24TH OCTOBER 2021

CUSTOMER REF : KLKOM GPB80D

JOB NUMBER : JN40000578/ TN1532

GENERATOR SPECIFICATIONS:

VOLTS : 11 kV THERMAL CLASSIFICATION

AMP. S : 476 A ARM : 155(F)

OUTPUT : 9063kVA FIELD : 155(F)

RPM : 1500 RPM

FREQUENCY : 50Hz BRUSHLESS EXCITER

EXCITATION VOLTS : 115 VOLTS : 75 V

FIELD AMP.S : 399 A AMP.S : 362 A

ARM. CONNECTION : STAR (Y) OUTPUT : 47 kVA

EXCITATION VOLTS : 110V TYPE : NTAKL

FIELD AMP.S : 8.8A SERIAL NO : 905566A50A

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 2 of 58

RE: OVERHAUL OF KLKOM GPB80D 9063kVA NISHISHIBA GENERATOR

SIME DARBY ENERGY SOLUTIONS had engaged Genturbo Industrial Sdn Bhd to perform generator overhaul work

for KLKOM GPB80D generator. Overhaul work was started on 1 st of October 2021 by removing the generator from

the GTG. After 5 days of removal work at site, generator was finally delivered to GTISB workshop.

For overhaul work, there are certain standard that was followed to ensure that the result is still within the range

of the standard. All standard use during overhaul work was list down in each result table. Apart from international

standard, a well calibrated measurement tools also plays a crucial role in each overhaul process as uncalibrated

measurements tool might give an inaccurate result which might lead to unnecessary rework.

Preliminary finding founds out the external of the generator was heavily contaminated with dust. Insulation

resistance and winding resistance were performed prior to generator disassembly work. Result was low even though

it is still within the acceptable range as per IEEE standard. Upon dismantling, it was found out that the internal part of

the generator was heavily contaminated with dust. Detailed work scope was listed down in Chapter 1.0.

1.0 SCOPE OF WORK CARRIED OUT

Below is the scope of work carried out on the generator at Genturbo Industrial Sdn Bhd workshop.

1. GENERAL WORK

a. Generator exterior had been visually inspected for any mechanical damage prior to disassembling

and delivery.

b. Generator parts had been cleaned with high pressure hot water jet.

c. Generator had been repainted prior to delivery.

d. New rubber gasket had been replaced.

2. MAIN STATOR

a. Insulation resistance and winding resistance test had been performed on the winding in room

temperature.

b. Winding had been inspected for any deformation and discoloration.

c. Stator core had been visually inspected.

d. Contamination on winding had been cleaned with degreaser and high-pressure hot water.

e. Oven baked at 130C for 16 hours.

f. Winding had undergone two times varnishing processed. It was oven baked to cure the varnish.

g. Partial discharge (PD) and Tan Delta (TD) test on stator winding was performed before and after

varnish (PERFORMED BY 3RD PARTY)

h. Electrical check on space heaters, sensors and current transformer (CT).

i. Borescope inspection on main stator winding.

3. EXCITER STATOR

a. Insulation resistance and winding resistance test had been performed on the winding in room

temperature.

b. Winding had been inspected for any deformation and discoloration.

c. Stator core had been visually inspected.

d. Contamination on winding had been cleaned with degreaser and high-pressure hot water.

e. Oven baked at 120C for 8 hours.

f. Revarnished with air-dry varnish.

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 3 of 58

4. PERMANENT MAGNET(PMG) STATOR

a. Insulation resistance and winding resistance test had been performed on the winding in room

temperature.

b. Winding had been inspected for any deformation and discoloration.

c. Stator core had been visually inspected.

d. Contamination on winding had been cleaned with degreaser and high-pressure hot water.

e. Oven baked at 120C for 8 hours.

f. Revarnished with air-dry varnish.

5. ROTOR

a. Visual inspection on rotor condition was performed.

b. Insulation resistance and winding resistance test was performed on main rotor and exciter rotor

winding.

c. Diode was removed. Polarity check and voltage drop test was performed on the diode.

d. Voltage drop test on main rotor winding was performed.

e. Cleaning of rotor using degreaser and high-pressure hot water.

f. Oven baked of rotor at 130C for 12 hours.

g. Rotor was varnished and cured inside oven.

h. Rotor was coated with red varnish after varnish had been cured.

i. Surface contact check, bearing clearance measurement, shaft run-out check, Non-Destructive Test

(NDT) and electrical continuity check between endshield and rotor was performed on rotor shaft.

6. BEARINGS

a. Visual inspection on the bearing was performed.

b. Bearing clearance check, Non-Destructive Test and plastic gauge check had been performed.

c. Mild polishing of bearing.

d. Electrical inspection on bearing sensors (RTD).

7. ASSEMBLY

a. Air gap between stator and rotor core on main stator, exciter stator and PMG stator was performed.

b. Bearing and seal clearance had been measured.

c. Insulation resistance and winding resistance test was performed on main stator after generator had

been fully assembled.

d. Generator was painted after assembly.

e. Shaft lock prior to delivery.

8. MISC. WORK

a. Refer to daily report for site activities.

b. Alignment between generator and gear box was performed.

c. Vibration check was performed during generator load test. Load test was performed from 0% and

increased with an interval of 25%. Vibration check was performed with each load increment.

d. All result was documented and compiled within this report.

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 4 of 58

2.0 PHOTO REFERENCE

Below is the photo taken during overhaul for your reference.

OVERHAUL PROCESS

2.1 DE view of the generator prior to disassembling. 2.2 DE view of generator prior to delivery.

2.3 NDE view of generator prior to disassembling. 2.4 NDE view of generator as delivered.

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 5 of 58

2.5 DE sleeve bearing as found 2.6 DE sleeve bearing as installed.

2.7 NDE sleeve bearing as found. 2.8 NDE sleeve bearing as installed.

2.9 DE winding overhang was contaminated with 2.10 DE winding overhang was varnished and coated

unknown particle. with red varnish. Aluminium tape was used to

detect any crack in the winding.

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 6 of 58

2.11 NDE winding was contaminated with unknown 2.12 NDE winding overhang was cleaned, varnished

particle and coated with red varnish.

2.13 PMG stator as found. 2.14 PMG stator after cleaning.

2.15 Exciter stator as found. 2.16 Cleaned exciter stator as installed.

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 7 of 58

2.17 Plastic gauge check was performed on DE 2.18 Plastic gauge check was performed prior to

bearing and bearing journal prior to generator installation of top half of the DE bearing during

disassembly. generator assembly.

2.19 Plastic gauge check was performed on NDE 2.20 Plastic gauge check was performed prior to

bearing and bearing journal prior to generator installation of top half of the NDE bearing during

disassembly. generator assembly.

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 8 of 58

2.21 Rotor condition after withdrawn from stator. 2.22 Rotor was cleaned, varnish and coated with red

Heavily contaminated with unknown particles. varnish prior to installation.

2.23 Exciter winding as found. 2.24 Exciter rotor was cleaned, varnish and coated

with red varnish prior to installation.

2.25 Diode as found (Positive ring) 2.26 Diode as installed.

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 9 of 58

2.27 Diode as found (Negative Ring) 2.28 Diode as installed.

2.29 Tubular heater as found. 2.30 Tubular heaters had been glass beads blasting

prior to installation.

2.31 NDT on DE bearing journal. 2.32 No surface crack was found on DE bearing

journal.

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 10 of 58

2.33 NDT on NDE bearing journal. 2.34 No surface crack was found on DE bearing

journal.

2.35 NDT on DE sleeve bearing (Bottom) 2.36 No surface crack was found on DE bottom halve

sleeve bearing. (Bottom)

2.37 NDT on DE sleeve bearing. (Top) 2.38 No crack was found on DE top halve sleeve

bearing

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 11 of 58

2.39 NDT on NDE sleeve bearing (Bot) 2.40 No crack was found on NDE bottom halve

sleeve bearing.

2.41 NDT test on NDE sleeve bearing (Top) 2.42 No crack was found on NDE top halve sleeve

bearing (Top)

2.43 Voltage drop test on main rotor winding. 2.44 Insulation of >50MΩ/250V between NDE rotor

shaft and generator body

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 12 of 58

2.45 Condition of DE bearing prior installation 2.46 Condition of DE bearing prior installation

(Bottom) (Top)

2.47 Condition of DE bearing prior installation 2.48 Condition of DE bearing prior installation

(Bottom) (Top)

2.49 Tangent Delta is being carried out on generator 2.50 Partial Discharge test is being carried out on

winding. generator winding.

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 13 of 58

2.51 NDE insulated labyrinth seal has been checked 2.52 DE insulated labyrinth seal has been checked and

and inspected prior installation. inspected prior installation

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 14 of 58

BORESCOPE PHOTO

BEFORE

2.53 Inner view of winding (DE) 2.54 Inner view of winding (DE)

2.55 Inner view of winding (DE) 2.56 Inner view of winding (DE)

2.57 Inner view of winding (DE) 2.58 Inner view of winding (NDE)

2.59 Inner view of winding (NDE) 2.60 Inner view of winding (NDE)

2.61 Inner view of winding (NDE) 2.62 Inner view of winding (NDE)

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 15 of 58

AFTER

2.63 Inner view of winding (DE) 2.64 Inner view of winding (DE)

2.65 Inner view of winding (DE) 2.66 Inner view of winding (DE)

2.67 Inner view of winding (DE) 2.68 Inner view of winding (NDE)

2.69 Inner view of winding (NDE) 2.70 Inner view of winding (NDE)

2.71 Inner view of winding (NDE) 2.72 Inner view of winding (NDE)

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 16 of 58

3.0 MECHANICAL REPORT

BEARING CLEARANCE

SLEEVE BEARING

(TOP HALF)

SLEEVE BEARING

(BOTTOM HALF)

DRIVE-END BEARING CLEARANCE

BEARING-OUTER (COUPLING SIDE) BEARING-INNER (ROTOR CORE SIDE)

B D

E

C

A

POINT MEASUREMENT (mm) POINT MEASUREMENT (mm)

A 220.29 D 220.35

B 220.30 E 220.35

C 220.29 F 220.35

I

G H

POINT MEASUREMENT (mm)

G 220.02

H 220.02

I 220.02

DE BEARING CLEARANCE

Maximum: 0.33mm

Minimum: 0.27mm

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 17 of 58

NON-DRIVE END BEARING CLEARANCE

BEARING-OUTER (EXCITER SIDE) BEARING-INNE R (ROTOR CORE SIDE)

B D E

C

A

POINT MEASUREMENT (mm) POINT MEASUREMENT (mm)

A 220.30 D 220.30

B 220.31 E 220.31

C 220.29 F 220.30

I

G H

POINT MEASUREMENT (mm)

G 220.02

H 220.02

I 220.02

NDE BEARING CLEARANCE:

Maximum:0.29mm

Minimum: 0.27mm

For the clearance of the sleeve bearing, there are no certain guidelines as of the period of generator overhaul. As a

guide, the following clearance was used.

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 18 of 58

By using the following tolerance extracted out from Alstom (Manufacturers), bearing tolerance were as follow

Minimum: +0.360mm

Maximum: +0.435mm

By taking the value calculated above, bearing clearance on DE and NDE are still within the acceptable range.

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 19 of 58

AXIAL ENDPLAY

X1 X2

OUTER INNER

(TOWARDS COUPLING FOR DE, (TOWARDS ROTOR CORE

TOWARDS PMG FOR NDE)

Y1 Y2

DE NDE

BEFORE (mm) AFTER (mm) BEFORE (mm) AFTER (mm)

X1 5.6 X1 6.8 X1 7.0 X1 6.3

X2 5.4 X2 4.2 X2 7.0 X2 7.7

Y1 5.6 Y1 6.8 Y1 7.0 Y1 6.3

Y2 5.4 Y2 4.2 Y2 7.0 Y2 7.2

SIDE CLEARANCE

U1 U2

OUTER

(TOWARDS COUPLING FOR DE, INNER

TOWARDS PMG FOR NDE) (TOWARDS ROTOR CORE

V1 V2

DE NDE

BEFORE AFTER (mm) BEFORE (mm) AFTER (mm)

U1 0.10 (9mm) U1 0.10 (23mm) U1 0.09 (12mm) U1 0.10 (30mm)

U2 0.10 (9mm) U2 0.10 (22mm) U2 0.10 (12mm) U2 0.10 (20mm)

V1 0.10 (12mm) V1 0.10 (23mm) V1 0.10 (12mm) V1 0.10 (23mm)

V2 1.10 (12mm) V2 0.10 (23mm) V2 0.10 (12mm V2 0.10 (22mm)

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 20 of 58

LABYRINTH SEAL CLEARANCE

INNER

(TOWARDS ROTOR CORE

2 3

1

OUTER

(TOWARDS COUPLING FOR DE,

TOWARDS PMG FOR NDE)

DE

SHAFT DIAMETER 260.02mm

FRONT VIEW LABYRINTH SEAL 1 (mm) LABYRINTH SEAL 2 (mm) LABYRINTH SEAL 3 (mm)

260.80 260.90 260.93

260.85 260.83 260.97

A C 260.86 260.91 260.93

B

MAX. CLEARANCEC 0.48mm MIN. CLEARANCE 0.39mm

NDE

SHAFT DIAMETER 260.02mm

FRONT VIEW LABYRINTH SEAL 1 (mm) LABYRINTH SEAL 2 (mm) LABYRINTH SEAL 3 (mm)

260.84 260.84 260.80

260.89 260.90 260.80

A C 260.86 260.87 260.92

B

MAX. CLEARANCEC 0.45 MIN. CLEARANCE 0.39mm

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 21 of 58

For the labyrinth seal clearance, there were no specific guidelines available except from manufacturers. By referring

to the guidelines mentioned in EASA Technical Manual, it is better to determine the labyrinth seal clearance from the

bearing clearance compared with shaft diameter. It mentioned that the labyrinth seal clearance should be 0.05mm to

0.10mm more than the bearing clearance.

By using the rules of thumb, the maximum and minimum clearance of the bearing should be as follow:

Maximum DE bearing clearance: 0.33mm

Tolerance for DE labyrinth seal: 0.38mm to 0.43mm

Maximum NDE bearing clearance: 0.29mm

Tolerance for NDE bearing labyrinth seal: 0.34 to 0.39

Labyrinth seal (bronze/brass) clearance guidelines (Extracted from EASA Technical Manual)

By comparing the maximum clearance of the labyrinth seal, it was out from the tolerance calculated. But, by referring

to the table above that was extracted from the EASA Technical Manual; for a shaft with a diameter of 191mm the

radial clearance is 0.31mm but for material other that brass/bronze may require more clearance. Hence, it can be

justified that the labyrinth seal clearance is still within the acceptable value.

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 22 of 58

SHAFT RADIAL RUN OUT CHECK

NDE BEARING JOURNAL

Ø 220mm

TIR: 0.00mm

DE BEARING JOURNAL

Ø 220mm

TIR: 0.00mm

COUPLING JOURNAL

Ø 180mm

TIR: 0.02mm

NDE

DE

REMARKS

1. The above T.I.R reading is acceptable as per ISO, DIN 42 955 Shaft Radial Run Out, Flange Coaxial Run and Plan

Parallelism Tolerances for rotating electrical machinery (Electric Motor)

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 23 of 58

AIR GAP CLEARANCE

MAIN ROTOR &

MAIN STATOR

EXCITER ROTOR &

EXCITER STATOR

PMG &

PMG STATOR

AIR GAP AIR GAP AIR GAP

PART POINT

PMG EXCITER MAIN STATOR

12

12 1.10mm 1.45mm DE: 14.00mm NDE:11.40mm

3 1.00mm 1.50mm DE: 14.20mm NDE:11.60mm

9 3

6 1.10mm 1.50mm DE: 14.15mm NDE:11.50mm

6

9 1.05mm 1.45mm DE: 14.00mm NDE:11.50mm

ROTOR & STATOR

UNBALANCED 5.88% 1.69% 0.80% 0.87%

REMARKS

As mentioned in chapter 2.12 Air Gap of Machines in EASA AR100 “The air gap of the machine should not vary from

the average by 5% for two-pole machines or 10% for other machines”. Hence it can be justified that the air gap is

within the acceptable range as per EASA AR100.

Measurements for mechanical work is as below:

Equipment Used Serial Number Calibration Due

Outside Micrometre S/N: 4946368215099 23RD AUG 2024

Inside Micrometre S/N: 4946368215099 23RD AUG 2024

Dial Gauge S/N: ATDZ35 23RD AUG 2024

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 24 of 58

4.0 ELECTRICAL REPORT

WINDING RESISTANCE TEST

MAIN STATOR

INSULATION RESISTANCE (BEFORE) VOLTAGE INJECTED:5kV TEMPERATURE:33.0C RELATIVE HUMIDITY: 64.1%

PHASE TO EARTH PHASE TO PHASE

PHASE 1 MIN 10 MIN PI PHASE 1 MIN 10 MIN PI

U-E (VW-G) 1.05 GΩ 1.94 GΩ 1.85 U-V (W-G) 7.50 GΩ 9.83 GΩ 1.31

V-E (UW-G) 1.13 GΩ 3.38 GΩ 2.99 U-W (V-G) 4.30 GΩ 8.17 GΩ 1.90

W-E (UV-G) 1.61 GΩ 9.25 GΩ 5.75 V-W (U-G) 6.80 GΩ 14.28 GΩ 2.10

INSULATION RESISTANCE (AFTER) VOLTAGE INJECTED:5kV TEMPERATURE: 30.4C RELATIVE HUMIDITY:65.8%

PHASE TO EARTH PHASE TO PHASE

PHASE 1 MIN 10 MIN PI PHASE 1 MIN 10 MIN PI

U-E (VW-G) 19.38 GΩ 38.95 GΩ 2.01 U-V (W-G) 31.22 90.85 2.91

V-E (UW-G) 21.35 GΩ 45.05 GΩ 2.11 U-W (V-G) 30.14 76.56 2.54

W-E (UV-G) 24.02 GΩ 53.08 GΩ 2.21 V-W (U-G) 36.79 90.87 2.47

WINDING RESISTANCE (BEFORE) WINDING RESISTANCE (AFTER)

TEMPERATURE 33.1C TEMPERATURE 30.4

PHASE RESISTANCE UNBALANCE PHASE RESISTANCE UNBALANCE

U-V 134.09 mΩ U-V 134.12 mΩ

U-W 134.12 mΩ 0.33% U-W 134.06 mΩ 0.05%

V-W 134.77 mΩ V-W 134.19 mΩ

REMARKS:

1. Due to the limitation of measuring equipment, winding resistance test was performed while the generator is

connected in Y (STAR).

2. From early result, it was suspected that the low reading is due to the present of conductive contaminant or

moisture penetration in the winding.

3. For insulation resistance the acceptable criteria as per IEEE Std 43-2013 is resistance should be >100MΩ and

the Polarization index should ≥2.

4. For winding resistance, the acceptable criteria as per IEEE Std 118-1978, resistance unbalance should be <2%.

5. From point 3 and 4, it can be justified that the result after overhauled work is within the acceptable limit.

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 25 of 58

MAIN ROTOR

INSULATION RESISTANCE (BEFORE) VOLTAGE INJECTED:250V TEMPERATURE:33.7C RELATIVE HUMIDITY:71.3%

PHASE TO EARTH

PHASE 1 MIN 10 MIN PI

+VE-E 0.01 MΩ 0.01 MΩ 1

INSULATION RESISTANCE (AFTER) VOLTAGE INJECTED:250V TEMPERATURE:31.2C RELATIVE HUMIDITY: 66.3%

PHASE TO EARTH

PHASE 1 MIN 10 MIN PI

+VE-E 6.18 GΩ 8.42 GΩ 1.36

VOLTAGE DROP TEST

TOTAL VOLTAGE INJECTED 60.3 V

WINDING 1 15.2V

1

WINDING 2 14.9V

4 2

WINDING 3 15.3V

3

WINDING 4 15.1V

REMARKS:

1. From early result, it was suspected that the low reading is due to the present of conductive contaminant or

moisture penetration in the winding.

2. For insulation resistance the acceptable criteria as per IEEE Std 43-2013 is resistance should be >100MΩ and

the Polarization index should ≥2. Based on this, it can be justified that the result after overhauled work is within

the acceptable criteria.

EXCITER STATOR

INSULATION RESISTANCE (BEFORE) VOLTAGE INJECTED: 500V TEMPERATURE :34.1C RELATIVE HUMIDITY:75.3%

PHASE TO EARTH

PHASE 1 MIN 10 MIN PI

F1-E 6.39 GΩ 7.35 GΩ 1.15

INSULATION RESISTANCE (AFTER) VOLTAGE INJECTED:500V TEMPERATURE: 30.8C RELATIVE HUMIDITY:66.1%

PHASE TO EARTH

PHASE 1 MIN 10 MIN PI

F1-E 29.2 GΩ 68.91 GΩ 2.36

REMARKS:

1. From early result, it was suspected that the low reading is due to the present of conductive contaminant or

moisture penetration in the winding.

2. For insulation resistance the acceptable criteria as per IEEE Std 43-2013 is resistance should be >100MΩ and

the Polarization index should ≥2. Based on this, it can be justified that the result after overhauled work is within

the acceptable criteria.

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 26 of 58

EXCITER ROTOR

INSULATION RESISTANCE (BEFORE) VOLTAGE INJECTED:250V TEMPERATURE: 33.8C RELATIVE HUMIDITY: 74.8%

PHASE TO EARTH

PHASE 1 MIN 10 MIN PI

U-E 3.45 GΩ 10.01 GΩ 2.90

INSULATION RESISTANCE (AFTER) VOLTAGE INJECTED: 250V TEMPERATURE:31.1C RELATIVE HUMIDITY:65.8%

PHASE TO EARTH

PHASE 1 MIN 10 MIN PI

U-E 51.5 GΩ 98.37 GΩ 1.91

WINDING RESISTANCE (BEFORE) WINDING RESISTANCE (AFTER)

TEMPERATURE 33.8C TEMPERATURE 30.4C

PHASE RESISTANCE UNBALANCE PHASE RESISTANCE UNBALANCE

U-V 5.765 mΩ U-V 5.835 mΩ

U-W 5.838 mΩ 0.77% U-W 5.791 mΩ 0.67%

V-W 5.826 mΩ V-W 5.864 mΩ

REMARKS:

1. Exciter rotor was internally connected in Y (STAR) connection, hence only 1 insulation reading was measured.

2. From early result, it was suspected that the low reading is due to the present of conductive contaminant or

moisture penetration in the winding.

3. For insulation resistance the acceptable criteria as per IEEE Std 43-2013 is resistance should be >100MΩ and

the Polarization index should ≥2.

4. For winding resistance, the acceptable criteria as per IEEE Std 118-1978, resistance unbalance should be <2%.

5. From point 3 and 4, it can be justified that the result after overhauled work is within the acceptable limit.

PERMANENT MAGNET STATOR

INSULATION RESISTANCE (BEFORE) VOLTAGE INJECTED: 500V TEMPERATURE:33.6C RELATIVE HUMIDITY:76.2%

PHASE TO EARTH

PHASE 1 MIN 10 MIN PI

U-E 169 MΩ 239 MΩ 1.41

INSULATION RESISTANCE (AFTER) VOLTAGE INJECTED: 500V TEMPERATURE:30.4C RELATIVE HUMIDITY: 65.4%

PHASE TO EARTH

PHASE 1 MIN 10 MIN PI

U-E 2.92 GΩ 14.9 GΩ 5.10

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 27 of 58

WINDING RESISTANCE (BEFORE) WINDING RESISTANCE (AFTER)

TEMPERATURE 33.4 C TEMPERATURE 30.3C

PHASE RESISTANCE UNBALANCE PHASE RESISTANCE UNBALANCE

U-V 0.4497 mΩ U-V 0.4999 mΩ

U-W 0.5008 mΩ 0.37% U-W 0.5011 mΩ 0.32%

V-W 0.4975 mΩ V-W 0.4981 mΩ

REMARKS:

1. Exciter rotor was internally connected in Y (STAR) connection, hence only 1 insulation reading was measured.

2. From early result, it was suspected that the low reading is due to the present of conductive contaminant or

moisture penetration in the winding.

3. For insulation resistance the acceptable criteria as per IEEE Std 43-2013 is resistance should be >100MΩ and

the Polarization index should ≥2.

4. For winding resistance, the acceptable criteria as per IEEE Std 118-1978, resistance unbalance should be <2%.

5. From point 3 and 4, it can be justified that the result after overhauled work is within the acceptable limit.

SENSOR ELECTRICAL CHECK

Temperature: 32.1°C

Diodes Voltage Drop Test

Voltage Injected: 1.5 V

Phase

U (Volt) V (Volt) W (Volt)

Direction

0.414 0.429 0.404

0.420 0.419 0.407

Forward

0.428 0.409 0.430

Diodes

0.410 0.425 0.426

0.422 0.409 0.403

0.424 0.419 0.402

0.426 0.406 0.416

Reverse

0.396 0.400 0.421

Diodes

0.409 0.381 0.417

0.421 0.416 0.418

Remarks

1. Each phase consists of 5 diodes for each direction. The 5 diodes were connected in parallel.

2. All diode in good condition

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 28 of 58

Sensor Temperature: 32.5°C

Type Resistance (Ω)

H1-H2 (OVERALL HEATERS READING) 66.0 Ω (IR TO GROUND @250v: 60.1 MΩ)

T1-T2 0.1

PT 100 (DE) 112.6

PT 100 (NDE) 112.1

PT100 (A1) 112.1

PT100 (A2) 112.5

PT100 (A3) 112.1

PT100 (A4; SPARE) 112.0

PT100 (A5; SPARE 112.1

PT100 (A6; SPARE 112.3

CURRENT TRANSFORMER (C1) 166.05

CURRENT TRANSFORMER (C2) 166.25

CURRENT TRANSFORMER (C3) 166.36

HEATER 1 (DE) 266.1

HEATER 2 (DE) 267.5

HEATER 3 (NDE) 265.3

HEATER 4 (NDE) 265.3

REMARKS

1. Measurement tools are as below:

Equipment Used Serial Number Calibration Due

Winding Resistance Meter 190814916 01ST SEPT 2023

Insulation Resistance Meter 201213734 21ST AUG 2023

Multimeter 201052118 22ND AUG 2024

2. PT100 temperature chart were as follows:

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 29 of 58

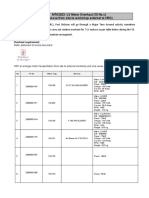

6.2 PARTIAL DISCHARGE AND TAN DELTA TEST

GST = Grounded Specimen Test

• Measures anything connected to ground

• Measures grounded insulation

• Describes the connection of the LV leads either connected to the ground point

(measured) or the guard point (not measured)

UST = Ungrounded Specimen Test

• Does not measure anything connected to the ground (Ground is

guarded)

• Measure ungrounded insulation

• Describes the connection of the LV leads either connected to the meter

(measured) or the ground point (not measured).

Figure 6.1 Schematic drawing of TD test

Test Energize Mode Injection (KV) Measure

1 U, V, W GST Tip-up Coverall

Figure 6.2 Schematic drawing of PD test

To date, there is no governing body or organization that has come up with an international

standard for the acceptance of partial discharge profile technology. As a rule of thumb and

based on manufacture guideline, the following guideline is used for condition acceptance.

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 30 of 58

PD Magnitude (QIEC/QWTD) Severity

Within ±25% Change Normal

> 25% Change Further Monitor

>50% Change Further Investigate

Table 3: PD Overall Guideline

Quality PD (Slot Section) nC PD (End winding)

Excellent <2 <2

Good < 4 to 5 < 4 to 5

Average 4 to 10 4 to 10

Acceptable ~ 10 ~ 15 to 20

Inspection Necessary > 15 > 20

Potential Problem > 20 > 50

Table 4: PD Table provided by PD Tech as a reference and should only be used as a

general guideline.

Description Limit

DF at 0.2Uo or 2kV 3.0%

DF per 0.2Uo to 1.0Uo 0.5%

Tipup (1.0Uo – 0.2Uo) 2.0%

Table 5: TD based on IEEE 286-2000 &IEC 60034-27-3

All defects identified in this report should be scheduled for rectification and the repaired areas.

This should be re-inspecting again after the works have been completed. All equipment should

be scheduled for another inspection within 12 months from this inspection or earlier, depending

upon their importance.

6.2.1 INSULATION RESISTANCE CHECK

Pre-Test Pre-Test

Phase

(07/10/2021) (13/10/2021)

R-E 3.52G 19.7G

Y-E 6.21G 18.9G

B-E 3.14G 20.8G

R-Y 312M 41.7G

Y-B 416M 36.5G

B-R 7.43G 37.0G

Post Test Improve: PASS

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 31 of 58

6.2.3 TAN DELTA TEST

RED (PRE)

V test I meas. (mA) Frequency Cp (nF) DF (%) % Tip Up

1,270 38.968 97.2348 9.6492

2,540 77.983 97.2666 9.6903

3,810 116.79 *50.00 Hz 97.1114 9.6905 0.05

5,080 155.12 96.7386 9.6804

6,351 192.80 96.1710 9.6981

RED (POST)

V test I meas. (mA) Frequency Cp (nF) DF (%) % Tip Up

1,270 28.192 70.6559 0.4723

2,540 56.415 70.6973 0.5325

3,810 84.682 *50.00 Hz 70.7451 0.6068 0.43

5,080 113.06 70.8250 0.7198

6,351 141.62 70.9693 0.9026

YELLOW (PRE)

V test I meas. (mA) Frequency Cp (nF) DF (%) % Tip Up

1,270 38.910 97.0985 9.7148

2,540 77.871 97.1341 9.7690

3,810 116.58 *50.00 Hz 96.9344 9.7622 -0.03

5,080 154.85 96.5435 9.7157

6,351 192.39 95.9561 9.6886

YELLOW (POST)

V test I meas. (mA) Frequency Cp (nF) DF (%) % Tip Up

1,270 28.094 70.4183 0.4663

2,540 56.229 70.4565 0.5232

3,810 84.395 *50.00 Hz 70.5027 0.5955 0.45

5,080 112.67 70.5874 0.7161

6,351 141.18 70.7493 0.9138

BLUE (PRE)

V test I meas. (mA) Frequency Cp (nF) DF (%) % Tip Up

1,270 38.685 96.5558 9.6652

2,540 77.387 96.5327 9.6757

3,810 115.72 *50.00 Hz 96.2309 9.6174 -0.16

5,080 153.62 95.8183 9.5619

6,351 190.86 95.2125 9.5057

BLUE (POST))

V test I meas. (mA) Frequency Cp (nF) DF (%) % Tip Up

1,270 28.058 70.3193 0.4671

2,540 56.153 70.3569 0.5229

3,810 84.280 *50.00 Hz 70.4005 0.5930 0.44

5,080 112.49 70.4774 0.7067

6,351 140.95 70.6326 0.9035

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 32 of 58

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 33 of 58

6.2.4 PARTIAL DISCHARGE

(Pre-Test)

Divider Q IEC/ Q Avg

F Centre Factor Q WTD (noise) P Dis. Q Peak Q Avg

200 kHz 21.17 5.502 nC 44.17 pC 274.0 mW 15.40 nC 6.474 nC

500 kHz 17.60 5.958 nC 58.45 pC 535.4 mW 11.93 nC 5.137 nC

Red

2 MHz 37.40 3.897 nC 100.4 pC 273.9 mW 7.298 nC 4.231 nC

4 MHz 3.117 2.019 nC 108.6 pC 79.82 mW 2.737 nC 1.959 nC

6 MHz 2.967 1.167 nC 109.8 pC 72.63 mW 1.840 nC 1.181 nC

200 kHz 20.80 24.63 nC 32.37 pC 385.8 mW 54.26 nC 26.04 nC

500 kHz 17.28 24.78 nC 54.33 pC 572.5 mW 51.78 nC 24.84 nC

Yellow

2 MHz 40.56 2.298 nC 105.7 pC 95.61 mW 5.194 nC 2.521 nC

4 MHz 15.21 5.258 nC 104.7 pC 167.2 mW 8.999 nC 4.559 nC

6 MHz 52.85 20.15 nC 211.8 pC 563.7 mW 42.97 nC 20.64 nC

200 kHz 6.445 8.629 nC 36.64 pC 101.4 mW 16.54 nC 8.106 nC

500 kHz 5.251 5.063 nC 68.43 pC 171.7 mW 9.412 nC 4.569 nC

Blue

2 MHz 9.555 1.300 nC 97.36 pC 33.73 mW 2.423 nC 1.500 nC

4 MHz 8.961 1.711 nC 285.3 pC 41.09 mW 4.807 nC 1.778 nC

6 MHz 1.683 74.62 pC 119.8 pC 2.737 mW 171.3 pC 68.96 pC

(Post-Test)

Divider Q IEC/ QAvg

F Centre Factor Q WTD (noise) P Dis. Q Peak Q Avg

200 kHz 7.520 6.738 nC 44.17 pC 63.73 mW 10.11 nC 6.414 nC

500 kHz 4.249 2.362 nC 58.45 pC 95.32 mW 4.765 nC 2.573 nC

Red

2 MHz 0.666 131.7 pC 100.4 pC 40.49 mW 253.9 pC 134.3 pC

4 MHz 1.723 814.5 pC 108.6 pC 216.8 mW 1.025 nC 819.7 pC

6 MHz 12.25 532.7 pC 109.8 pC 110.9 mW 746.4 pC 491.6 pC

200 kHz 7.553 7.932 nC 32.37 pC 76.01 mW 14.75 nC 6.722 nC

500 kHz 4.258 6.766 nC 54.33 pC 108.5 mW 12.03 nC 6.160 nC

Yellow

2 MHz 0.691 1.296 nC 105.7 pC 41.29 mW 2.671 nC 1.187 nC

4 MHz 1.377 733.1 pC 104.7 pC 187.1 mW 1.862 nC 885.4 pC

6 MHz 10.75 514.5 pC 211.8 pC 108.0 mW 938.0 pC 500.6 pC

200 kHz 7.626 13.46 nC 36.64 pC 82.25 mW 24.13 nC 13.10 nC

500 kHz 4.504 9.355 nC 68.43 pC 115.0 mW 16.26 nC 8.686 nC

Blue

2 MHz 0.690 1.399 nC 97.36 pC 43.44 mW 2.679 nC 1.492 nC

4 MHz 1.587 938.3 pC 285.3 pC 216.1 mW 1.853 nC 874.1 pC

6 MHz 10.53 691.2 pC 119.8 pC 108.1 mW 1.136 nC 633.4 pC

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 34 of 58

PD Result Red Phase

(PRE)

PD Result Red Phase

(POST)

Fcentre = 200kHz, ∆F= 300kHz

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 35 of 58

PD Result Red Phase

(PRE)

PD Result Red Phase

(POST)

Fcentre = 500kHz, ∆F= 800kHz

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 36 of 58

PD Result Red Phase

(PRE)

PD Result Red Phase

(POST)

Fcentre = 2MHz, ∆F= 1MHz

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 37 of 58

PD Result Red Phase

(PRE)

PD Result Red Phase

(POST)

Fcentre = 4MHz, ∆F= 1MHz

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 38 of 58

PD Result Red Phase

(PRE)

PD Result Red Phase

(POST)

Fcentre = 6MHz, ∆F= 1MHz

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 39 of 58

PD Result Yellow Phase

(PRE)

PD Result Yellow Phase

(POST)

Fcentre = 200kHz, ∆F= 300kHz

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 40 of 58

PD Result Yellow Phase

(PRE)

PD Result Yellow Phase

(POST)

Fcentre = 500kHz, ∆F= 800kHz

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 41 of 58

PD Result Yellow Phase

(PRE)

PD Result Yellow Phase

(POST)

Fcentre = 2MHz, ∆F= 1MHz

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 42 of 58

PD Result Yellow Phase

(PRE)

PD Result Yellow Phase

(POST)

Fcentre = 4MHz, ∆F= 1MHz

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 43 of 58

PD Result Yellow Phase

(PRE)

PD Result Yellow Phase

(POST)

Fcentre = 6MHz, ∆F= 1MHz

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 44 of 58

PD Result Blue Phase

(PRE)

PD Result Blue Phase

(POST)

Fcentre = 200kHz, ∆F= 300kHz

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 45 of 58

PD Result Blue Phase

(PRE)

PD Result Blue Phase

(POST)

Fcentre = 500kHz, ∆F= 800kHz

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 46 of 58

PD Result Blue Phase

(PRE)

PD Result Blue Phase

(POST)

Fcentre = 2MHz, ∆F= 1MHz

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 47 of 58

PD Result Blue Phase

(PRE)

PD Result Blue Phase

(POST)

Fcentre = 4MHz, ∆F= 1MHz

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 48 of 58

PD Result Blue Phase

(PRE)

PD Result Blue Phase

(POST)

Fcentre = 6MHz, ∆F= 1MHz

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 49 of 58

6.2.5 SUMMARY

1. The PRPD pattern of this motor shows that the partial discharge activities occur at the first

and third quadrant of the 50Hz sinusoidal, which indicated the partial discharge may exists

in motor insulation.

2. Tan Delta value (%DF) is still within limit, less than 3 %. The overall capacitance changes

and leakage current for this motor still within limit 5%. Below is the summary chart show the

charge value surveyed at 500kHZ.

3. PD detected is LOW. PD pattern indicate void discharge based on after service.

4. Recommended to monitor within 12-month time to observe the increment on the TD and

PD value.

5. During the pre-survey, there is abnormal detected, an electrical sparking can be seemed at

the winding insulation. The condition of the generator is dirty and contaminate. The

generator undergone overhaul and re-vanishing.

6. After generator compete servicing. Testing shown no abnormal, and no sparking sound

detected. TD and PD value drop. Insulation resistance value increase

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 50 of 58

7.0 ALIGNMENT REPORT

7.1 PRE-ALIGNMENT

Before generator mounting bolt was loosened, alignment check was performed between generator and GB. Alignment

reading as follow:

Figure 5.1 Pre-alignment data was collected as a reference

7.2 ALIGNMENT AFTER OVERHAUL

After generator was skid back to its original place, coupling spacer was installed. The distance was set to 554.4mm

by using calibrated inside micrometre. This value is still within the tolerance which is +0.6mm.

Figure 5.2 Setting end-to-end distance between generator and GB

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 51 of 58

Prior to alignment work, generator soft foot was measured. Result is as follow:

Figure 5.3 Soft foot check of generator

After generator soft foot had been rectified by adding 0.1mm thickness of shim, alignment work was then

performed between generator and GB. Alignment reading is as follows:

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 52 of 58

Figure 5.4 Final alignment result was verified & approved by KGA and KLKOM representative

Tolerance for the generator are as follows

Figure 5.5 Tolerance for generator alignment

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 53 of 58

To avoid over tighten of the fastener, all the fasteners supplied by client were properly tightened with a

calibrated torque wrench. The torque value set was 35 Nm and still within the range as per Figure 5.5. New nut was

use on the spacer and was supplied by client as per Figure 5.6.

Figure 5.6 New self lock nut

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 54 of 58

6.0 VIBRATION REPORT

Vibration data collection was performed once before GTG shut down and 5 times during testing. 3 point was marked

on the generator for data collection to ensure the data is consistent. Vibration point were as follow

VERTICAL VERTICAL

AXIAL AXIAL

HORIZONTAL HORIZONTAL

DRIVE END NON- DRIVE END

Figure 6.1 Vibration point (DE) Figure 6.2 Vibration point (NDE)

6.1 BEFORE OVERHAUL

Vibration data was acquired before GTG completely shut down. Data were as follows:

Point Drive End (mm/s) Non-Drive End (mm/s)

Horizontal 0.93 1.11

Vertical 1.07 0.81

Axial 1.02 0.96

6.2 AFTER OVERHAUL

Vibration check was performed during generator is connected to loadbank system. Load sequence was performed

from 0% and increased with an interval of 25%. Vibration check was performed with each load increment.

6.2.1 0% LOAD (WITH EXCITATION)

LOAD N/A

Point Drive End (mm/s) Non-Drive End (mm/s)

Horizontal 0.78 0.77

Vertical 0.66 0.52

Axial 1.09 0.56

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 55 of 58

6.2.2 (≈)25% LOAD

LOAD 1700kW

Point Drive End (mm/s) Non-Drive End (mm/s)

Horizontal 0.78 0.62

Vertical 0.55 0.47

Axial 0.68 0.58

6.2.3 (≈)50% LOAD

LOAD 3250kW

Point Drive End (mm/s) Non-Drive End (mm/s)

Horizontal 0.72 0.61

Vertical 0.68 0.46

Axial 0.73 0.94

6.2.4 (≈)75% LOAD

LOAD 4850kW

Point Drive End (mm/s) Non-Drive End (mm/s)

Horizontal 0.76 0.68

Vertical 0.68 0.38

Axial 0.66 0.41

6.2.5 (≈)100% LOAD

LOAD 6500kW

Point Drive End (mm/s) Non-Drive End (mm/s)

Horizontal 0.78 0.89

Vertical 0.81 0.33

Axial 0.81 0.51

REMARKS:

1. Overall vibration level is within ISO 10816-3 standard satisfactory limit.

2. Measurement tools are as below:

Equipment Used Serial Number Calibration Due

VIBRATION METER 628683 24TH AUG 2024

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 56 of 58

7.0 CONCLUSION

In order to achieve optimum and best work quality, Genturbo has adopted multiple sources of international standard

as a benchmark and guideline of every electrical and mechanical test carried out. Obviously, the generator test result

and performance has drastically improved after serial of quality control in place.

8.0 EXECUTIVE SUMMARY

In today’s modern and forward-thinking world, Facilities Management is a crucial part of the business. As such,

maintenance either planned, preventive or scheduled plays an important role in the facilities management in order to

develop a benchmark and keep track the machine performance as the parts in rotating machine will undergo wear and

tear that may require attention. Hence it is highly recommended Sime Darby Energy Solution and KLK Oleomas fully

utilizes the information and test result in this report for future preventive and predictive scheduled activities.

9.0 WARRANTY

This Nishishiba made generator, Serial Number 905566A50A is covered by our standard warranty as follows

1. 6-months warranty from the date of GTG package is successfully loaded. The warranty

covered against failure due to workmanship or material used and the generator is strictly

to comply with schedule maintenance recommended by OEM

We believe we have informed you sufficiently for the work scope/repair mentioned above. Should you require further

assistance or information on this matter, please do not hesitate to contact us.

By signing off this document, I acknowledge that By signing off this document, I acknowledge that

GENTURBO INDUSTRIAL SDN BHD have delivered GENTURBO INDUSTRIAL SDN BHD have delivered

all the work mentioned in this report. all the work mentioned in this report.

NAME: NAME:

DESIGNATION: DESIGNATION:

COMPANY: SIME DARBY ENERGY SOLUTIONS S/B COMPANY: KL-KEPONG OLEOMAS SDN BHD

DATE: DATE:

*This report is intended solely for the information and use of SIME DARBY ENERGY SOLUTIONS AND KL-KEPONG

OLEOMAS and is not intended to be and should not be used by anyone other than these specified parties.

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 57 of 58

*THIS PAGE IS INTENTIONALLY LEFT BLANK

GENTURBO INDUSTRIAL SDN. BHD. (COMPANY NO: 1223590-X)

No 12 Jalan Sungai Batu 11/KU6, Kawasan Perindustrian Sungai Puloh, Klang 42100, Selangor Darul Ehsan. Malaysia.

www.genturbo.com.my

Tel: +6019-271 1766 / +603-3290 3799 Page 58 of 58

You might also like

- 0 WD951 EM610 00079 Rev 0 Operation and Maintenance Manuals For CranesDocument421 pages0 WD951 EM610 00079 Rev 0 Operation and Maintenance Manuals For Cranesrastkonemanjic100% (1)

- TM 10-3920-675-23-1 RTCH RT 240Document1,356 pagesTM 10-3920-675-23-1 RTCH RT 240Advocate100% (1)

- (TOYOTA) Manual de Taller Diagrama Electrico Toyota Corolla 1998 InglesDocument205 pages(TOYOTA) Manual de Taller Diagrama Electrico Toyota Corolla 1998 InglesFernandoSuarezChapperNo ratings yet

- Sarawak Work Permit Process-Flow (6 & 12 Months) : No Time Frame 180 Working Days 3 Working DaysDocument1 pageSarawak Work Permit Process-Flow (6 & 12 Months) : No Time Frame 180 Working Days 3 Working DaysRamLooNo ratings yet

- NTPC Limited: (A Government of India Enterprise)Document11 pagesNTPC Limited: (A Government of India Enterprise)Amit VijayvargiyaNo ratings yet

- Safety Comittee Report: Company Logo and Name Time Date VenueDocument2 pagesSafety Comittee Report: Company Logo and Name Time Date VenueHiren MahetaNo ratings yet

- QC Inspector CVDocument31 pagesQC Inspector CVBaraneedharanNo ratings yet

- Gnanagonda K Marthande: Hydraulic and Mechanical MaintenanceDocument3 pagesGnanagonda K Marthande: Hydraulic and Mechanical MaintenanceMarthandeNo ratings yet

- Techint Engenharia E Construção S.A.: Eneva Parnaiba V - Bottoming CycleDocument63 pagesTechint Engenharia E Construção S.A.: Eneva Parnaiba V - Bottoming Cycletatiana araujoNo ratings yet

- Schemersal OmronDocument6 pagesSchemersal Omronedi susantoNo ratings yet

- S0442 GPS L XXX SP 0005 - 0 - Specification For Piping Fabrication and InstallationDocument42 pagesS0442 GPS L XXX SP 0005 - 0 - Specification For Piping Fabrication and InstallationThành TrịnhNo ratings yet

- Mini Belt Grinder Project Jounal 4Document3 pagesMini Belt Grinder Project Jounal 41DS19ME136-Shivam KumarNo ratings yet

- Qa-Qc, Piping, Welding, Inspector CVDocument7 pagesQa-Qc, Piping, Welding, Inspector CVFirmansyah JailaniNo ratings yet

- TCR Arabia Company LTD: P.O BOX:3422 DAMAM 31471 (KSA)Document2 pagesTCR Arabia Company LTD: P.O BOX:3422 DAMAM 31471 (KSA)Ronel John Rodriguez CustodioNo ratings yet

- Company Introduction - Quadrant EngineeringDocument32 pagesCompany Introduction - Quadrant EngineeringMitul Patel100% (1)

- CORR-CON INSPECTION SERVICES COATING PROCEDURE TEST REPORTDocument4 pagesCORR-CON INSPECTION SERVICES COATING PROCEDURE TEST REPORTArun Prasad100% (1)

- BLR-LKO Flight TicketDocument2 pagesBLR-LKO Flight Ticketabhishek tiwariNo ratings yet

- Pipe Fitter CVDocument10 pagesPipe Fitter CVDOSAPATY VEDANAYAKAMNo ratings yet

- Updated ALOK RESUME PDFDocument4 pagesUpdated ALOK RESUME PDFALOK KUMARNo ratings yet

- A537 - 0500 - 1 - ENQ - REV0Power TransformerDocument155 pagesA537 - 0500 - 1 - ENQ - REV0Power TransformerRitaban R. BanerjeeNo ratings yet

- C Sec cp1Document212 pagesC Sec cp1Piyush BishnoiNo ratings yet

- Procedure For Ultrasonic Testing Dated 29-09-06Document22 pagesProcedure For Ultrasonic Testing Dated 29-09-06ravi00098No ratings yet

- Specs Interactive ExhibitsDocument528 pagesSpecs Interactive ExhibitsKerim AyNo ratings yet

- Ts Tpsodl Gi WireDocument1 pageTs Tpsodl Gi WireJainco Transmission LimitedNo ratings yet

- MO - NO. H11/504: Manufacturing Instructions MHKXTLS607X5Document1 pageMO - NO. H11/504: Manufacturing Instructions MHKXTLS607X5maruti_gbNo ratings yet

- Evaluation of Service Failure of Three Phase Induction Motor Using Failure Mode and Effects Analysis (FMEA)Document17 pagesEvaluation of Service Failure of Three Phase Induction Motor Using Failure Mode and Effects Analysis (FMEA)CHINEDU CHIEJINENo ratings yet

- Payslip:: Petrofac International LTDDocument1 pagePayslip:: Petrofac International LTDRakesh PatelNo ratings yet

- Electrical Insulation and Thermal Measurements For Motors and Drives AnDocument4 pagesElectrical Insulation and Thermal Measurements For Motors and Drives Anmu_ignoreNo ratings yet

- D'CosmixDocument60 pagesD'Cosmixjones32No ratings yet

- Format For Purchase Order DataDocument16 pagesFormat For Purchase Order Datakamal haiderNo ratings yet

- Attachment 17 Contractors Qualification SystemDocument9 pagesAttachment 17 Contractors Qualification SystemMohammad AshpakNo ratings yet

- QA/QC Inspection Checklist: Design Coordinates, Inc. CP No. - Vector ThreeDocument2 pagesQA/QC Inspection Checklist: Design Coordinates, Inc. CP No. - Vector ThreeNon Etabas GadnatamNo ratings yet

- Low Voltage Motor Insulation SystemDocument2 pagesLow Voltage Motor Insulation SystemzdrahalNo ratings yet

- Godrej Powder Coating ReportDocument1 pageGodrej Powder Coating Reportjames.anitNo ratings yet

- Project Completion Report - PAUTDocument2 pagesProject Completion Report - PAUTVelosi PMTNo ratings yet

- 5-6. Overhauling of TGS & CGS JSA HADEED MODULE A-BDocument8 pages5-6. Overhauling of TGS & CGS JSA HADEED MODULE A-Bammar mughalNo ratings yet

- Tender Document 1491902624Document20 pagesTender Document 1491902624Anshuman AgrawalNo ratings yet

- Gas Turbine - Compressor AlignmentDocument2 pagesGas Turbine - Compressor AlignmentNazmiNo ratings yet

- Dynasty 200 DXUser ManualDocument98 pagesDynasty 200 DXUser ManualBill100% (1)

- Mechanical hub assembly reportDocument56 pagesMechanical hub assembly reportsankey11286No ratings yet

- 429 & 430 - Weld RegrindingDocument2 pages429 & 430 - Weld RegrindingAbhishek ShuklaNo ratings yet

- Pt. Bayer Motor 3.7 KWDocument20 pagesPt. Bayer Motor 3.7 KWhamzah naoreyNo ratings yet

- Attachmnet#8 Rotor Air SystemDocument3 pagesAttachmnet#8 Rotor Air SystemzhangNo ratings yet

- Examination For Grant of Certificate of Proficiency (Cop) As Boiler Operation Engineer (Boe) Under TheDocument3 pagesExamination For Grant of Certificate of Proficiency (Cop) As Boiler Operation Engineer (Boe) Under TheVinothNo ratings yet

- APGENCO Proposal For ORG WP On 13-12-23 PDFDocument6 pagesAPGENCO Proposal For ORG WP On 13-12-23 PDFSun NyNo ratings yet

- PCS-9691 - X - Instruction Manual - EN - Overseas General - X - R1.00Document290 pagesPCS-9691 - X - Instruction Manual - EN - Overseas General - X - R1.00ahmadokkyNo ratings yet

- 43 - Checklist of Pumps For Monthly PMDocument6 pages43 - Checklist of Pumps For Monthly PMSiraj AhmedNo ratings yet

- Process Design Basis Rev ADocument49 pagesProcess Design Basis Rev Agharsallah mounaNo ratings yet

- PRICING INSTRUCTIONS RESPONSEDocument82 pagesPRICING INSTRUCTIONS RESPONSESatish KapoorNo ratings yet

- Piping SupervisorDocument12 pagesPiping SupervisorShakeel ahmadNo ratings yet

- Low and Medium Voltage Motor Repair Shop Selection GuidelineDocument10 pagesLow and Medium Voltage Motor Repair Shop Selection GuidelineGunadevan ChandrasekaranNo ratings yet

- 1.0 - M S Chilled Water PipeDocument13 pages1.0 - M S Chilled Water Pipe721917114 47No ratings yet

- Durag DR290 Installion and Operation PDFDocument54 pagesDurag DR290 Installion and Operation PDFFernando MelgarNo ratings yet

- Area Handover FormDocument1 pageArea Handover FormsivagaaneshNo ratings yet

- Board Resolution TemplateDocument1 pageBoard Resolution TemplatePranjwal SrivastavaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name Daterohitbhat2345No ratings yet

- Delivery OrderDocument3 pagesDelivery OrderAnonymous qVyuk2IRkNo ratings yet

- Alignment 1 PDFDocument2 pagesAlignment 1 PDFmayureshrmahajanNo ratings yet

- KOC Ratqa Lower Fars Heavy Oil Project AdvancesDocument6 pagesKOC Ratqa Lower Fars Heavy Oil Project Advancessalman KhanNo ratings yet

- ZUBAIR OIL FIELD DEVELOPMENT PROJECT MANAGEMENT OF NON-CONFORMITYDocument16 pagesZUBAIR OIL FIELD DEVELOPMENT PROJECT MANAGEMENT OF NON-CONFORMITYAbdullah AbdullahNo ratings yet

- GEN6001A GDC KLIA Inspection Report Generator - DraftDocument20 pagesGEN6001A GDC KLIA Inspection Report Generator - DraftRashid Al JaowadNo ratings yet

- Master Drawing of Battery Chargers o & M ManualsDocument216 pagesMaster Drawing of Battery Chargers o & M Manualsnitesh100% (1)

- Unbalance CalculationDocument1 pageUnbalance CalculationKholis JaimonNo ratings yet

- (D) MTA2023ElectricalLVMotorServices 20221213023552.378 XDocument2 pages(D) MTA2023ElectricalLVMotorServices 20221213023552.378 XKholis JaimonNo ratings yet

- Core Loss TestDocument2 pagesCore Loss TestKholis JaimonNo ratings yet

- Motor Overhaul SOP-DRSSBDocument51 pagesMotor Overhaul SOP-DRSSBKholis JaimonNo ratings yet

- Initial Report JN1142 4KW Submersible Pump-Southern Edible OilDocument9 pagesInitial Report JN1142 4KW Submersible Pump-Southern Edible OilKholis JaimonNo ratings yet

- Initial Report JN1142 4KW Submersible Pump-Southern Edible OilDocument9 pagesInitial Report JN1142 4KW Submersible Pump-Southern Edible OilKholis JaimonNo ratings yet

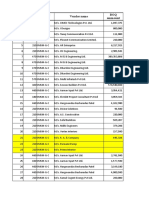

- MOTOR SERVICING WORK RECORD SUMMARYDocument9 pagesMOTOR SERVICING WORK RECORD SUMMARYKholis JaimonNo ratings yet

- Motor Test Report SummaryDocument15 pagesMotor Test Report SummaryKholis JaimonNo ratings yet

- Pod HandlerDocument13 pagesPod HandlerASWINNo ratings yet

- Diffusion Impurity Diffusion TechniquesDocument26 pagesDiffusion Impurity Diffusion TechniquesAshish JhaNo ratings yet

- Evaluation, Design Estimation & Costing of Bus DuctsDocument27 pagesEvaluation, Design Estimation & Costing of Bus Ductssedianpo100% (1)

- Mapua EE101-1L Exp 1Document3 pagesMapua EE101-1L Exp 1Bob Laurence CaridadNo ratings yet

- 1468816857summer Vacation HomeworkDocument16 pages1468816857summer Vacation Homeworkkaran girdharNo ratings yet

- Microwave Devices: Dr. Ahmed ShakerDocument57 pagesMicrowave Devices: Dr. Ahmed ShakerjaneaustnNo ratings yet

- Assignment No 11 of Applied Physics TanzeelDocument10 pagesAssignment No 11 of Applied Physics TanzeelAmeer JaanNo ratings yet

- Diode Electronic ComponentDocument10 pagesDiode Electronic ComponentEphraem RobinNo ratings yet

- FIITJEE SAMPLE PAPER FOR CLASS 7 (Paper 2Document21 pagesFIITJEE SAMPLE PAPER FOR CLASS 7 (Paper 2Abishek ThiyagarajanNo ratings yet

- Engine Cooling Fan Rav 4 2001 2002Document11 pagesEngine Cooling Fan Rav 4 2001 2002mattkidoNo ratings yet

- Rolling Resistance For Bycyle TiresDocument64 pagesRolling Resistance For Bycyle Tiresadrian fasaNo ratings yet

- Synchronous Servo Motor For Screw Drives (Direct Drive For Threaded Nut)Document20 pagesSynchronous Servo Motor For Screw Drives (Direct Drive For Threaded Nut)markokocNo ratings yet

- Naiz Hy1z-24v PDFDocument3 pagesNaiz Hy1z-24v PDFfroilan ochoaNo ratings yet

- CT Sizing Calculation of 11kV System-Rev0-Ver3Document91 pagesCT Sizing Calculation of 11kV System-Rev0-Ver3yasararafat190% (10)

- 1 PDFDocument62 pages1 PDFSIVAKAMI50% (2)

- Fossum J.G., Trivedi V.P. - Fundamentals of Ultra-Thin-Body MOSFETs and FinFETs-Cambridge University Press (2013) PDFDocument228 pagesFossum J.G., Trivedi V.P. - Fundamentals of Ultra-Thin-Body MOSFETs and FinFETs-Cambridge University Press (2013) PDFNelson José Rodríguez Sierra100% (1)

- EN - Op.2 - EEE EXP4 - Semi Conductors - LecturesDocument82 pagesEN - Op.2 - EEE EXP4 - Semi Conductors - LecturesImmaculee BITWAGEBWA VERONIQUENo ratings yet

- Ix & X Physics Formula SheetDocument24 pagesIx & X Physics Formula Sheetकुलदीप गणेशराव आढेNo ratings yet

- 2.1 Review QuestionsDocument10 pages2.1 Review QuestionsdanNo ratings yet

- VDS-30V P-Channel MOSFETDocument5 pagesVDS-30V P-Channel MOSFETElisabeth BaraNo ratings yet

- Tech Ref For Garmin NMEA2k enDocument42 pagesTech Ref For Garmin NMEA2k enAlara UrgunNo ratings yet

- Mechanic (Refrigeration & Air-Conditioner) (Semester Pattern)Document33 pagesMechanic (Refrigeration & Air-Conditioner) (Semester Pattern)swami061009No ratings yet

- Injection Control Pressure Sensor (ICP) : REF REFDocument2 pagesInjection Control Pressure Sensor (ICP) : REF REFgerardoespadasNo ratings yet

- Basic Electrical Theory Study Sheet (v3.1)Document1 pageBasic Electrical Theory Study Sheet (v3.1)Rick GouldNo ratings yet

- PN Junction Formation and Barrier PotentialDocument9 pagesPN Junction Formation and Barrier PotentialchristlllNo ratings yet

- PAC F88 E 150HP Product Reference SheetDocument11 pagesPAC F88 E 150HP Product Reference SheetAntonio VelázquezNo ratings yet

- ResistanceDocument18 pagesResistancegzb012No ratings yet

- Catalog WefatermDocument55 pagesCatalog WefatermAlin NicolaeNo ratings yet