Professional Documents

Culture Documents

Rwanda Underpass

Uploaded by

Engineeri TadiyosCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rwanda Underpass

Uploaded by

Engineeri TadiyosCopyright:

Available Formats

Addis Ababa City Roads Authority

SUB-SURFACE INVESTIGATION

AND FOUNDATION

RECOMMENDATION REPORT

FOR

Bole-Meskel Square Road

(At Rwanda Embassy Junction)

JUNE 2008

P.O.BOX 62668 Tel. 391065/391733/391617/395955/391499 Fax 391230, 391617

E-mail: sava.eng@telecom.net.et/saba,eng@telecom.net.et

Addis Ababa, Ethiopia

Addis Ababa City Roads Authority

Bole-Meskel Square Road, Rwanda Embassy Junction

TABLE OF CONTENTS

Page

1. INTRODUCTION .................................................................. 1

1.1 Background .................................................................................... 1

1.2 Location .......................................................................................... 1

1.3 Regional and Site Geology.............................................................. 2

1.3.1 Regional Geology ..................................................... 2

1.3.2 Site Geology............................................................. 2

2. METHODOLOGY .................................................................. 4

2.1 Drilling ............................................................................................ 4

2.2 Testing and Sampling..................................................................... 4

2.2.1 Field Testing ............................................................ 4

2.2.2 Sampling ................................................................. 4

3. GEOTECHNICAL CHARACTERISTICS................................... 6

4. FOUNDATION RECOMMENDATION ...................................... 8

5. CONCLUSION .................................................................... 16

APPENDICES

Appendix 1: Borehole Logs

Appendix 2: Borehole Locations

Appendix 3: Geological Cross Section

Appendix 4: Laboratory Test Results

Appendix 5: Core Boxes Photograph

Geotechnical Investigation and Foundation Recommendation Report

SABA Engineering Plc.

Addis Ababa City Roads Authority

Bole-Meskel Square Road, Rwanda Embassy Junction

1. INTRODUCTION

1.1 Background

As per the request made by the client (i.e. Eng. Zewdie Eskinder & Co. Plc) for

Geotechnical Investigation and Foundation Recommendation works for Bole Ring

Road Round About to Meskel Square Road Design and supervision, SABA

Engineering PLC has executed a geotechnical investigation work by drilling eight

exploratory boreholes to a maximum depth of 15.75m at Rwanda Embassy Junction

at the proposed locations shown on the attached site plan (Appendix 2).

The objective of this investigation was to:

• Determine the type and extent of geological formations;

• Investigate the presence of ground water and identification of its level if

encountered;

• Determine the engineering properties of the layers constituting the sub-

surface geology of the site.

The field investigation was conducted from May 25 to June 03, 2008.

Accordingly, the general and particular geology of the site and the methodologies

employed are described and the investigation and tests used to study the engineering

properties of the subsurface strata including analysis and interpretations of results are

discussed. Finally, recommendation is given with regard to the bearing layer, bearing

depth, allowable bearing pressure and suitable type of foundation.

1.2 Location

The new overpass structure is located at Rwanda Embassy area having several

supporting piers. Representative eight supporting pier structure positions were

selected by the client and one borehole was drilled at each location to various depths

below NGL till a confidential foundation bearing layer was identified. The

coordinates and elevations of boreholes measured using hand-held GPS and the

depths drilled are tabulated as follows:

Borehole Easting Northing Elevation Depth

(m)

BH-D 0475587 0993901 2315 9.00

BH-E 0475585 0993859 2313 7.00

BH-F 0475600 0993822 2312 15.75

BH-G 0475593 0993803 2312 12.00

BH-H 0475598 0993751 2314 8.60

BH-I 0475593 0993691 2312 9.00

BH-J 0475594 0993724 2313 9.10

BH-K 0475600 0993658 2312 9.10

Geotechnical Investigation and Foundation Recommendation Report 1

SABA Engineering Plc.

Addis Ababa City Roads Authority

Bole-Meskel Square Road, Rwanda Embassy Junction

1.3 Regional and Site Geology

1.3.1 Regional Geology

Addis Ababa city is situated in the western margin of the Main Ethiopian Rift and

represents a transition zone between the Ethiopian Plateau and the rift with poorly

defined escarpment.

The geology of Addis Ababa area is represented by four volcanic units dominated in

the lower part by basaltic lava flows (Addis Ababa basalt), followed by a pyroclastic

sequence, mainly formed by ignimbrites (Addis Ababa Ignimbrite), followed by

central composite volcanoes (Central Volcanoes unit), and finally small spatter cones

and lava flows (Akaki unit).

Addis Ababa basalt extensively crops out along Akaki, Kebena, and Dukem rivers at

the east to southeastern part of Addis Ababa, and represents the oldest unit of the

area.

It consists of essentially sub-horizontal lava flows with thickness ranging from few

meters up to 20m. Maximum exposed thickness was found east of Addis Ababa,

along the Kebena River. Addis Ababa basalt is predominantly constituted by alkaline

and olivine basalts with three main textural attributes, that is, porphyritic, aphyric,

and sub-aphyric.

Addis Ababa ignimbrite is exposed close to Addis Ababa along the Akaki and

Kebena rivers. It overlies the Addis Ababa basalt and locally covers the products of

the composite central volcanoes of Wechecha and Furi. The sequence is constituted

by different flow units, consisting of pale-green to pale-yellow welded and crystal

rich ignimbrites.

Central volcanoes unit includes the Yerer volcano and the product of the two

composite volcanoes Wechecha and Furi west and southeast of Addis Ababa,

respectively. Wechecha and Furi volcanoes are two large edifices composed by

predominant trachyte with minor pyroclastics. Yerer represents the largest volcanic

edifice in the region, with a relief of 1000m from the plain and 14km wide along east-

west direction. Products mainly consist of trachytes, even if pyroclastics are

widespread mainly in the central part eastern sector. The highest part of Yerer

volcano was affected by a more recent volcanic activity that produces spatter cones

and associated basalt.

Akaki unit crops out east of Addis Ababa and consists of scoria and spatter cones

with associated tabular lava flows and phreato-magmatic deposits. Alluvial deposits

covering these units consists of regolith, reddish brown soils, talus and alluvium with

maximum thickness of about two meters.

1.3.2 Site Geology

The top most part of the project site is covered by back-fill material having

thicknesses varying from 0.50m to 1.50m. Underlying the back-fill, a residual soil

layer of basalt origin comprising very stiff/hard, dark-grey to yellowish-brown, sandy

clayey silt/silty sand with some gravel-sized basalt fragments was found having an

average thickness of about 4.40m. Below the residual soil, dark-grey, fine grained,

moderately to highly weathered and closely jointed, medium strong basalt was

Geotechnical Investigation and Foundation Recommendation Report 2

SABA Engineering Plc.

Addis Ababa City Roads Authority

Bole-Meskel Square Road, Rwanda Embassy Junction

identified in borehole BH-D, BH-E, BH-H, BH-I, BH-J and BH-K and continued to

the maximum depth where drilling terminated. In borehole BH-G and BH-F, the

residual soil is followed by a contact marking paleosol comprising stiff, reddish silty

clay/clayey silt layer. The paleosol pinches out toward BH-F and grades into highly

weathered and decomposed volcanic Tuff comprising light-yellow to brownish clayey

silt/silty clay and continued to the bottom depth where drilling terminated.

The detailed geological strata encountered are presented in the boreholes log sheets

attached with this report (Appendix 1).

Geotechnical Investigation and Foundation Recommendation Report 3

SABA Engineering Plc.

Addis Ababa City Roads Authority

Bole-Meskel Square Road, Rwanda Embassy Junction

2. METHODOLOGY

Drilling

Rotary core drilling technique has been employed using one Korean made crawler

type drilling rig having the capacity to perform boring operation to the required

standard and quality.

Dry drilling method has been utilized for the top soil formation using inner lining and

double core barrels fitted with appropriate size tungsten carbide bits at the bottom in

order to achieve good quality core recovery. When the formation changed to rock,

water was pumped down to the bit through hollow drill rods, thus, lubricating the bit

and flushing the debris up the borehole.

Telescopic drilling was used whereby the drilling size was reduced progressively

starting from 110 mm hole diameter through 101mm and to 86mm and remained so

till the completion depth.

Ground water was not encountered in all the boreholes till completion depth.

Testing and Sampling

Field Testing

The field testing was conducted in the boreholes starting from a depth of 1.50m

below NGL

Standard penetration tests (SPTs) have been conducted inside boreholes using a

standard hammer, weighting 63.5 kg and falling freely from a height of 760 mm

along a frictionless guide rod in accordance with test procedure mentioned in test No.

19 of BS 1377; 1975. Blow counts for a total penetration depth of 450 mm from the

bottom of a cleaned borehole were recorded and counts for the first 150 mm

penetration were discarded since the ground is considered to be distributed by drilling

activity prior to the test. SPT N-values for the last 300 mm penetration were thus

recorded at the corresponding depths on the borehole log sheets.

Sampling

Two undisturbed soil samples were taken using thin wall Shelby tube from boreholes

BH-G and BH-F at a depth of 3.0m and 9.10m for soil UCS and direct shear tests.

Additionally, ten distributed soil samples were taken for laboratory determinations of

gradation, Atterberg limit and free swell tests. Also six rock samples were collected

for determination of unit weight and rock UCS.

Table (2-1) presents summary of the exploration methods and tests performed for the

project.

Core samples recovered from core barrels were arranged in partitioned wooden core

boxes having 1.0 m length, and are properly labeled indicating project name, client,

borehole designation, depth, etc. The cores inside core boxes were logged and

photographed (colored) as part of the report document.

Geotechnical Investigation and Foundation Recommendation Report 4

SABA Engineering Plc.

Addis Ababa City Roads Authority

Bole-Meskel Square Road, Rwanda Embassy Junction

Table 2.1: Summary of Methods of Exploration and Tests Performed for the

Project

Type of Exploration/Test Qty.

− Boreholes to a maximum depth of 15.75 meters 8

− Standard Penetration Tests (SPT) 14

− Undisturbed Soil Sampling 2

− Disturbed Soil Sampling 10

− Laboratory Tests

Gradation 10

Atterberg Limits 10

Free Swell 10

Direct Shear 2

UCS of Soil 2

UCS of rock 6

Geotechnical Investigation and Foundation Recommendation Report 5

SABA Engineering Plc.

Addis Ababa City Roads Authority

Bole-Meskel Square Road, Rwanda Embassy Junction

3. GEOTECHNICAL CHARACTERISTICS

Descriptive analysis was made on the soil and rock samples retrived from the

boreholes. This was used together with the classification tests and relative compactions

as indicated from the SPT tests, and the following generalized geo-technical layers are

identified. Details on type and extent of the geothecnical layers are given in Appendix 1

(Borehole logs).

A. Back-fill material

The top most part of the project site at Rwanda embassy junction is composed of a

back-fill material having thicknesses varying from 0.50m around BH-F to 1.50m

around BH-D.

B. Stiff/hard residual soil layer

Underlying the back-fill material, a residual soil layer of basalt origin comprising very

stiff/hard, dark-grey to yellowish-brown, sandy clayey silt/silty sand with some gravel-

sized basalt fragments was found having an average thickness of about 4.40m. The field

SPT N-values conducted in these layers ranges from 5 to 31 indicating the dense nature

of compaction down deep the layer.

The soil consistency test results for the residual soil layer showed Plasticity Index and

Liquid Limit values varying from 7% to 49% and from 35% to 99% respectively. The

free swell ranges from 30% to 80%.

According to Unified Soil Classification System, the residual soil layer is classified as

low plastic silt. According to Bowles, 1988, soils having a PI values lower than 35%

show a very low potential for volume change.

C. Stiff paleosol layer

The residual soil is followed by a contact marking paleosol comprising stiff, reddish

silty clay/clayey silt layer and it was found in BH-F and BH-G. The field SPT N-values

conducted in these layers ranges from 18 to 20 indicating stiff consistency of the layer.

The soil consistency test results for these soil layers showed Plasticity Index and Liquid

Limit values of 30% and 62% respectively. The free swell is 90%.

D. Weathered and decomposed volcanic Tuff layer

Underlying the paleosol, highly weathered and decomposed volcanic Tuff comprising

light-yellow to brownish clayey silt/silty clay was found in BH-F and BH-G and

continued to the bottom depth where drilling terminated. The field SPT N-values

conducted in these layers ranges from 13 to 30 indicating the very stiff consistency of

the layer.

The soil consistency test results for the weathered and decomposed volcanic Tuff layer

showed Plasticity Index and Liquid Limit values varying from 23% to 33% and from

65% to 80% respectively. The free swell ranges from 20% to 90%.

According to Unified Soil Classification System, the decomposed volcanic Tuff layer is

classified as high plastic silt. According to Bowles, 1988, soils having a PI values lower

than 35% show a very low potential for volume change.

Geotechnical Investigation and Foundation Recommendation Report 6

SABA Engineering Plc.

Addis Ababa City Roads Authority

Bole-Meskel Square Road, Rwanda Embassy Junction

E. Medium strong basalt layer

Dark-grey, fine grained, moderately to highly weathered and closely jointed, medium

strong basalt was identified in boreholes BH-D, BH-E, BH-H, BH-I, BH-J and BH-K

and continued to the bottom depth where drilling terminated. The average R.Q.D values

for the encountered basalt layer vary from 27% to 74%.

Six rock samples were collected from boreholes BH-D, BH-E,BH-H, BH-I, BH-J and

BH-K for unit weight and unconfined compressive strength tests from depths of 6.50m,

6.20m, 4.00m, 6.00m, 4.50m and 3.50m respectively and the UCS values obtained for

the six rock samples are 1008.1 kg/cm2, 687.2 kg/cm2 , 861.3 kg/cm2, 751.3 kg/cm2,

683.7 kg/cm2 and 910.8 kg/cm2 respectively.

Geotechnical Investigation and Foundation Recommendation Report 7

SABA Engineering Plc.

Addis Ababa City Roads Authority

Bole-Meskel Square Road, Rwanda Embassy Junction

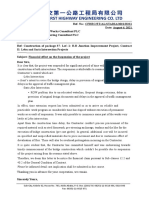

4. FOUNDATION RECOMMENDATION

Foundation recommendation refers to the determination of the bearing layer and depth,

allowable pressure on the bearing layer and type of foundation that could be adopted

safely and economically.

As can be observed from the stratigraphy encountered in all the boreholes, both the

residual soil layer and the underlying medium strong basalt can be considered for

placing foundation footings of the four pier structures of the overpass. The allowable

bearing pressures for the selected foundation layers shall be discussed based on

correlation of the relative compaction of the in-situ ground as indicated from SPT and

laboratory determination of Direct Shear and UCS of soil and rock.

Determination of the allowable bearing pressures and selection of foundation types and

depth is discussed below:

(IA). Isolated Footing Foundation on residual soil layer for the supporting

pier structure around BH-D and BH-F

The very stiff/hard residual soil layer of basalt origin is considered as a competent

foundation bearing layer for the supporting pier structure around boreholes BH-D and

BH-F. Foundation footings shall be placed at a depth of 3.50m below NGL on the very

dense residual soil layer.

Bearing Pressure Based on SPT Values

SPT values were used to calculate the bearing capacity of the residual

soil layers. Representative values are selected from the SPT data. The

boreholes, the depths below NGL at which the selected SPT N- values

are obtained, the SPT N-values and the adjusted N-values (i.e. N’55) are

given below and they are considered for determining the design N-

values.

Boreholes Depth (m) SPT N-value Adjusted SPT N-value

BH-F 1.50 31 37

BH-D 3.00 >50 42

BH-F 9.35 27 16

BH-F 10.20 30 18

BH-F 12.50 16 9

BH-F 14.70 14 7

The N-values are converted to N55 standard energy ratio value according to Bowles

(Bowles, 1988).

N’55 = CN x N x n1 x n2 x n3 x n4

Where

N’55 = adjusted N

CN = adjustment for overburden pressure (p’’o/p’o)1/2

Geotechnical Investigation and Foundation Recommendation Report 8

SABA Engineering Plc.

Addis Ababa City Roads Authority

Bole-Meskel Square Road, Rwanda Embassy Junction

p’o = overburden pressure

p’’o = reference overburden pressure (95.76 kPa or 1.0 kg/cm2)

n1 = Er/Erb (where Er is average energy ratio that depends on the drill system and Erb is

the standard energy ratio). Er is taken as 45 and Erb as 55.

n2 = Rod length correction

Rod length > 10 m = 1,

Rod length 6-10 m = 0.95,

Rod length 4-6 m = 0.85,

Rod length 0-4 m = 0.75

n3 = sampler correction (1.00 in our case)

n4 = borehole diameter correction (1.00 in our case)

After adjusting the N-values based on the above formula and taking corresponding

average values from respective boreholes, a design N-values are chosen from

consecutive depths where the test is performed. The design N-values are taken as the

average of N-values which are found in between ½ B above and 2B below the proposed

footing depths where B is the width of the foundation.

The bearing capacity for the soil layer is calculated from the SPT N- values using

Meyerhof’s equation as follows (Bowles, 1988): -

qa = (N/F2) [(B+F3)/B)]2 kd , B>F4

B = Width of foundation

D = Depth of foundation

qa = Allowable bearing pressure for settlement limited to 25 mm.

Kd = 1+0.33D/B < 1.33

F2 = 0.08

F3 = 0.3

F4 = 1.2

The following allowable bearing pressures are calculated for different foundation

widths at a footing depth of 3.50m below the ground level for settlement limited to 25

mm. Footing width is a significant parameter since a large footing width will affect the

soil to a greater depth and strains integrated over a greater depth will produce a larger

settlement.

Geotechnical Investigation and Foundation Recommendation Report 9

SABA Engineering Plc.

Addis Ababa City Roads Authority

Bole-Meskel Square Road, Rwanda Embassy Junction

Table 4.1 Allowable Bearing Pressures Based on SPT

Width B (m)

Proposed Footing Depth

Below Ground Level 1.5 2.0 2.5 3.0 3.5 4.0

(m)

Allowable Bearing Pressures (KPa)

3.50 m 525 480 470 445 430 410

Usually SPT reflects the actual in-situ condition of the ground and, therefore, we

recommend an allowable bearing values ranging from 410 kPa to 525 kPa based on

footing widths (table 4.1) for foundations around boreholes BH-D and BH-F.

(IB).Isolated Footing Foundation on stiff, reddish clayey soil layer for the

supporting pier structure around BH-G

A. Bearing Pressure Based on UCS

UCS test was conducted on one undisturbed soil sample taken from BH-G from a depth

of 3.00m. The test results are shown below:

Bulk Unit Dry Unit Moisture

BH UCS Cu

Depth (m) Weight Weight Content

No. (kg/cm2) (kg/cm2)

(gm/cc) (gm/cc) (%)

BH-G 3.00-3.50 1.850 1.403 31.88 0.835 0.418

Unconfined compression test was conducted on one soil samples to derive the

undrained shear strength value, Cu of the soil. The Cu value obtained from BH-G is

considered and angle of internal friction, Ø, is taken as zero.

Ø = 0, UCS = 81.8 kPa, Cu = 40.9 kPa (½ UCS)

The net ultimate bearing pressure for vertical loads on clay soils is normally computed

as a simplification of either the Meyerhof or Hansen equations as follows (Bowles,

1984). For cohesive soils, changes in ground water levels do not affect theoretical

ultimate bearing capacity. Presence of ground water has no effect on cohesive soils with

Ø = 0. For the most critical stability state (Ø = 0), which is created when the foundation

load is applied so rapidly, the immediate bearing capacity is independent of the location

of the water table. This is in contrast to the long term stability in which case the value

of the drained shear strength cd, and the bearing capacity factors are obtained

corresponding to a drained friction angle Ød.

qult = CNcScdc + q(Nq – 1)

Geotechnical Investigation and Foundation Recommendation Report 10

SABA Engineering Plc.

Addis Ababa City Roads Authority

Bole-Meskel Square Road, Rwanda Embassy Junction

When C = su, we have Ø = 0 and Nq = 1.0. In this case we have

qult = CNcScdc (when Ø = 0, Nc = 5.14)

qult = CNcScdc = 40.9(5.14)(1.2)(1.2) = 303

When designing a foundation on the basis of ultimate bearing capacity, a suitable factor

of safety should be used to determine the allowable pressure so that the foundation

system may be safe against shear failure. For footing foundations, a factor of safety of 2

to 3 is commonly used under normal loading conditions. Thus, taking a factor of safety

of 3; one obtains:

qallowable = 303/3 = 101 kPa

The allowable bearing pressure obtained from the analysis based on soil UCS test is

very low and unrepresentative for the encountered sub-surface material.

B. Bearing Pressure Based on Direct Shear Test

In order to get the shear strength properties of the reddish clayey soil layer, Direct

Shear test was conducted on undisturbed sample retrieved from borehole BH-G. The

friction angle (φ), cohesion (C) and unit weight (γ) are obtained from the direct shear

test conducted on one Shelby tube sample taken from BH-G. The test results are shown

below:

Bulk Unit Dry Unit Moisture

BH φ

Depth (m) Weight Weight Content C (kN/m2)

No. (degree)

(gm/cc) (gm/cc) (%)

BH-G 3.00-3.50 1.851 1.408 31.4 93.00 19.29

Among the bearing capacity equations we have chosen Meyerhof’s bearing capacity

equation since it can be used in any situation. Terzaghi’s bearing capacity equation is

usually preferred for very cohesive soils where D/B < 1.

Allowable Bearing Capacity for a Square Footing Using Meyerhof’s equation:

qult = CNcscdc + qNqsqdq + 0.5γBNγsγdγ

qult = Ultimate Bearing Capacity

qall = Allowable Bearing Capacity

C= Cohesion (93 kPa),

φ= Friction Angle (19.29°),

γ= Unit Weight (18.2 kN/m3),

B= Width of Footing

D= Depth of Footing

sc, sq, sγ = Shape Factors

dc,dq,dγ = Depth Factors

Nc,Nq,Nγ= Bearing Capacity Factors

J.E.Bowels states that the base width term can be ignored for a conservative solution

since its contribution is not substantial. Thus the base width term has been ignored and

the depth factor dropped since the application of these theoretically based values to a

practical situation has been questionable. (Vesic, 1975).Thus the increased bearing

capacity of shallow footings due to the depth effect has not been taken into account.

Geotechnical Investigation and Foundation Recommendation Report 11

SABA Engineering Plc.

Addis Ababa City Roads Authority

Bole-Meskel Square Road, Rwanda Embassy Junction

Substituting the relevant values in the equation we obtain:

qult = CNcsc + qNqsq

= 93 X 14.2X1.4+ (18.2-9.81) X 5.97 X 1.2 = 1909kPa

qult = 1849 + 60 = 1909 kPa

When designing a foundation on the basis of ultimate bearing capacity, a suitable factor

of safety should be used to determine the allowable pressure so that the foundation

system may be safe against shear failure. For footing foundations, a factor of safety of 2

to 3 is commonly used under normal loading conditions. Thus, taking a factor of safety

of 2.5; one obtains:

qallowable = 1909/3 = 636 kPa

C. Bearing Pressure Based on SPT Values

SPT values were used to calculate the bearing capacity of the residual soil layers.

Representative values are selected from the SPT data. The boreholes, the depths below

NGL at which the selected SPT N- values are obtained, the SPT N-values and the

adjusted N-values (i.e. N’55) are given below and they are considered for determining

the design N-values.

Boreholes Depth (m) SPT N-value Adjusted SPT N-value

BH-G 3.50 20 17

BH-G 4.50 19 16

BH-G 6.10 18 14

The N-values are converted to N55 standard energy ratio value according to Bowles

(Bowles, 1988).

N’55 = CN x N x n1 x n2 x n3 x n4

Where

N’55 = adjusted N

CN = adjustment for overburden pressure (p’’o/p’o)1/2

p’o = overburden pressure

p’’o = reference overburden pressure (95.76 kPa or 1.0 kg/cm2)

n1 = Er/Erb (where Er is average energy ratio that depends on the drill system and Erb is

the standard energy ratio). Er is taken as 45 and Erb as 55.

n2 = Rod length correction

Rod length > 10 m = 1,

Geotechnical Investigation and Foundation Recommendation Report 12

SABA Engineering Plc.

Addis Ababa City Roads Authority

Bole-Meskel Square Road, Rwanda Embassy Junction

Rod length 6-10 m = 0.95,

Rod length 4-6 m = 0.85,

Rod length 0-4 m = 0.75

n3 = sampler correction (1.00 in our case)

n4 = borehole diameter correction (1.00 in our case)

After adjusting the N-values based on the above formula and taking corresponding

average values from respective boreholes, a design N-values are chosen from

consecutive depths where the test is performed. The design N-values are taken as the

average of N-values which are found in between ½ B above and 2B below the proposed

footing depths where B is the width of the foundation.

The bearing capacity for the soil layer is calculated from the SPT N- values using

Meyerhof’s equation as follows (Bowles, 1988): -

qa = (N/F2) [(B+F3)/B)]2 kd , B>F4

B = Width of foundation

D = Depth of foundation

qa = Allowable bearing pressure for settlement limited to 25 mm.

Kd = 1+0.33D/B < 1.33

F2 = 0.08

F3 = 0.3

F4 = 1.2

The following allowable bearing pressures are calculated for different foundation

widths at a footing depth of 4.0m below the ground level for settlement limited to 25

mm. Footing width is a significant parameter since a large footing width will affect the

soil to a greater depth and strains integrated over a greater depth will produce a larger

settlement.

Table 4.1 Allowable Bearing Pressures Based on SPT

Width B (m)

Proposed Footing Depth

Below Ground Level 1.5 2.0 2.5 3.0 3.5 4.0

(m)

Allowable Bearing Pressures (KPa)

4.0 m 360 330 320 300 295 290

From the above analysis, one can see that allowable bearing pressure obtained using

bearing capacity equations from UCS tests is 101 kPa which is a very low value and do

not represent the engineering behavior for the encountered sub-surface foundation

Geotechnical Investigation and Foundation Recommendation Report 13

SABA Engineering Plc.

Addis Ababa City Roads Authority

Bole-Meskel Square Road, Rwanda Embassy Junction

material of the project site. The allowable bearing pressure obtained from Direct Shear

test is 636 kPa which is highly exaggerated values for the stiff reddish clayey soil.

Usually SPT reflects the actual in-situ condition of the ground and, therefore, we

recommend an allowable bearing values ranging from 290 kPa to 360 kPa based on

footing widths (table 4.1) for foundations around borehole BH-G.

(II). Foundation on rock layer for the supporting pier structures around BH-E,

BH-H, BH-I, BH-J and BH-K

Since basalt rock was encountered at a relatively shallower depths in boreholes BH-E,

BH-H, BH-I, BH-J and BH-K starting from 1.50m, 2.20m,4.10m, 2.0m and 4.60m

respectively and continued to the bottom depth where drilling terminated, it is

recommended to place foundation footings for pier structures around BH-E, BH-H, BH-

I, BH-J and BH-K at a depth where rock is encountered and footings shall be imbedded

at least 0.50m with in the rock layer. Footings shall be placed at a depth of 3.0m around

BH-E, BH-H and BH-J and at 5.0m around BH-I and BH-K below NGL within the

rock layer.

Six rock samples were collected from BH-D, BH-E, BH-H,BH-I, BH-J and BH-K for

unit weight and unconfined compressive strength tests from depths of 6.50m, 6.20m,

4.0m, 6.0m, 3.50m and 4.50m respectively and the UCS values obtained for the six

samples are 1008.1 kg/cm2, 687.2 kg/cm2 , 861.3 kg/cm2, 751.3 kg/cm2, 910.8 kg/cm2

and 683.7 kg/cm2 respectively. According to Bowles, 1988, the allowable rock bearing

pressure is taken in the range of 1/10 to 1/3 the unconfined compression strength. For

safety reasons, we have taken 1/10 of the unconfined compression strength of the

average of the results for the samples and we obtain an allowable rock bearing pressure

of 81.7 kg/cm2 (8200 kPa).

Geotechnical Investigation and Foundation Recommendation Report 14

SABA Engineering Plc.

Addis Ababa City Roads Authority

Bole-Meskel Square Road, Rwanda Embassy Junction

Table 4.2 Summary of Bearing Parameters

Alternative (1A): Isolated Footing Foundation on Residual Soil Layer for

supporting pier structure around BH-D and BH-F

Stiff, light yellowish brown, clayey sandy silt mixed with silty

Bearing Layer

sandy gravel (Residual soil of basalt origin).

3.50 meter below NGL for the supporting pier structure around

Bearing Depth

BH-D and BH-F.

Vary from 410 kPa to 525kPa based on footing widths (See

Allowable bearing pressure

table 4.1).

Foundation Type Isolated Footing

Alternative (1B): Isolated Footing Foundation on stiff, reddish clayey soil layer for

supporting pier structure around BH-G

Bearing Layer Stiff, reddish silty clay/ clayey silt (paleosol).

4.00 meter below NGL for the supporting pier structure around

Bearing Depth

BH-G

Vary from 290 kPa to 360 kPa based on footing widths (See

Allowable bearing pressure

table 4.1).

Foundation Type Isolated Footing

Alternative 2: Foundation on Rock Layer for Pier structures around BH-E, BH-H,

BH-I, BH-J and BH-K

Dark-grey, fine-grained, moderately weathered and jointed

Bearing Layer

medium strong basalt.

3.00m below NGL for the supporting pier structure around BH-

E, BH-H and BH-J and;

Average Bearing Depth

5.00M below NGL for the supporting pier structure around BH-I

and BH-K with in the rock layer.

Allowable bearing pressure 8200 kPa.

Foundation Type Isolated Footing

Since SABA Engineering is involved in supervision of the bridge construction it shall

carryout confirmation test/investigations during foundation construction works. SABA

Engineering shall conduct supervision of the foundation excavation works during

construction to verify/check the actual subsurface conditions, and will make

adjustments to the foundation recommendation as given in this report, where actual site

conditions warrant such changes.

Geotechnical Investigation and Foundation Recommendation Report 15

SABA Engineering Plc.

Addis Ababa City Roads Authority

Bole-Meskel Square Road, Rwanda Embassy Junction

5. CONCLUSION

Bearing capacities are calculated for shallow foundation systems for two alternative

bearing layers at different depths.

Isolated Footing Foundation on Residual Soil Layer for supporting pier structure around

BH-D and BH-F shall be placed at a depth of 3.50m below NGL. An allowable

bearing pressure varying from 410 kPa to 525 kPa is recommended based on footing

widths for this option (see table 4.1).

Isolated Footing Foundation on stiff, reddish silty clayey/ clayey silt (paleosol) soil

layer for supporting pier structure around BH-G shall be placed at a depth of 4.00m

below NGL. An allowable bearing pressure varying from 290 kPa to 360 kPa is

recommended based on footing widths for this option (see table 4.2).

For the supporting Pier structures around BH-E, BH-H, BH-I, BH-J and BH-K,

foundation footings shall be placed on dark-grey, fine-grained, moderately weathered

and jointed medium strong basalt. Footings shall be placed at a depth of 3.00m around

BH-E, BH-H and BH-J and at a depth of 5.00m around BH-I and BH-K below NGL

within the rock layer. An allowable rock bearing pressure of about 8200 kPa is

recommended for this option.

Geotechnical Investigation and Foundation Recommendation Report 16

SABA Engineering Plc.

Addis Ababa City Roads Authority

Bole-Meskel Square Road, Rwanda Embassy Junction

APPENDICES

Geotechnical Investigation and Foundation Recommendation Report

SABA Engineering Plc.

Addis Ababa City Roads Authority

Bole-Meskel Square Road, Rwanda Embassy Junction

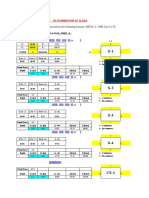

Appendix 1

Borehole Logs

Geotechnical Investigation and Foundation Recommendation Report

SABA Engineering Plc.

Addis Ababa City Roads Authority

Bole-Meskel Square Road, Rwanda Embassy Junction

Appendix 2

Borehole Locations

Geotechnical Investigation and Foundation Recommendation Report

SABA Engineering Plc.

Addis Ababa City Roads Authority

Bole-Meskel Square Road, Rwanda Embassy Junction

Appendix 3

Geological Cross Section

Geotechnical Investigation and Foundation Recommendation Report

SABA Engineering Plc.

Addis Ababa City Roads Authority

Bole-Meskel Square Road, Rwanda Embassy Junction

Appendix 4

Laboratory Test Results

Geotechnical Investigation and Foundation Recommendation Report

SABA Engineering Plc.

Addis Ababa City Roads Authority

Bole-Meskel Square Road, Rwanda Embassy Junction

Appendix 5

Core Boxes Photograph

Geotechnical Investigation and Foundation Recommendation Report

SABA Engineering Plc.

Bole-Meskel Square Road, Rwanda Embassy Junction Eng. Zewdie Eskinder & Co.plc

Addis Ababa City Roads Authority

Photo No:1, BH-D

Box 1of2

Depth 0.00 – 4.30m

Photo No:2, BH-D

Box 2of2

Depth 4.30 – 9.00m

Geotechnical Investigation and Foundation Recommendation Report

SABA Engineering plc

Bole-Meskel Square Road, Rwanda Embassy Junction Eng. Zewdie Eskinder & Co.plc

Addis Ababa City Roads Authority

Photo No:3, BH-E

Box 1of2

Depth 0.00 – 5.00m

Photo No:4, BH-E

Box 2of2

Depth 5.00 – 7.00m

Geotechnical Investigation and Foundation Recommendation Report

SABA Engineering plc

Bole-Meskel Square Road, Rwanda Embassy Junction Eng. Zewdie Eskinder & Co.plc

Addis Ababa City Roads Authority

Photo No:5, BH-F

Box 1of3

Depth 0.00 – 5.50m

Photo No:6, BH-F

Box 2of3

Depth 5.50 – 12.00m

Geotechnical Investigation and Foundation Recommendation Report

SABA Engineering plc

Bole-Meskel Square Road, Rwanda Embassy Junction Eng. Zewdie Eskinder & Co.plc

Addis Ababa City Roads Authority

Photo No:7, BH-F

Box 3of3

Depth 12.00 – 15.15m

Photo No:8, BH-G

Box 1of3

Depth 0.00 – 5.10m

Geotechnical Investigation and Foundation Recommendation Report

SABA Engineering plc

Bole-Meskel Square Road, Rwanda Embassy Junction Eng. Zewdie Eskinder & Co.plc

Addis Ababa City Roads Authority

Photo No:9, BH-G

Box 2of3

Depth 5.10 – 10.00m

Photo No:10, BH-G

Box 3of3

Depth 10.00 – 12.00m

Geotechnical Investigation and Foundation Recommendation Report

SABA Engineering plc

Bole-Meskel Square Road, Rwanda Embassy Junction Eng. Zewdie Eskinder & Co.plc

Addis Ababa City Roads Authority

Photo No:11, BH-H

Box 1of2

Depth 0.00 – 4.60m

Photo No:12, BH-H

Box 2of2

Depth 4.60 – 8.60m

Geotechnical Investigation and Foundation Recommendation Report

SABA Engineering plc

Bole-Meskel Square Road, Rwanda Embassy Junction Eng. Zewdie Eskinder & Co.plc

Addis Ababa City Roads Authority

Photo No:13, BH-I

Box 1of2

Depth 0.00 – 3.90m

Photo No:14, BH-I

Box 2of2

Depth 3.90 – 9.00m

Geotechnical Investigation and Foundation Recommendation Report

SABA Engineering plc

Bole-Meskel Square Road, Rwanda Embassy Junction Eng. Zewdie Eskinder & Co.plc

Addis Ababa City Roads Authority

Photo No:15, BH-J

Box 1of2

Depth 0.00 – 4.80m

Photo No:16, BH-J

Box 2of2

Depth 4.80 – 9.10m

Geotechnical Investigation and Foundation Recommendation Report

SABA Engineering plc

Bole-Meskel Square Road, Rwanda Embassy Junction Eng. Zewdie Eskinder & Co.plc

Addis Ababa City Roads Authority

Photo No:17, BH-K

Box 1of2

Depth 0.00 – 5.20m

Photo No:18, BH-K

Box 2of2

Depth 5.20 – 9.10m

Geotechnical Investigation and Foundation Recommendation Report

SABA Engineering plc

You might also like

- Foundation Investigaton Report For Tinishu Akaki BridgeDocument23 pagesFoundation Investigaton Report For Tinishu Akaki BridgeEngineeri TadiyosNo ratings yet

- Voided Slab MopaDocument14 pagesVoided Slab MopaSreekanth SattirajuNo ratings yet

- Khalanga Darchula New Vol 1 20200425 PDFDocument80 pagesKhalanga Darchula New Vol 1 20200425 PDFAmul ShresthaNo ratings yet

- Bukasa Port ProjectDocument24 pagesBukasa Port ProjectAkankwasa RonaldNo ratings yet

- ECG Vol 1 - 2002 PDFDocument368 pagesECG Vol 1 - 2002 PDFBrhane W YgzawNo ratings yet

- DRGS 0401 0201Document1 pageDRGS 0401 0201AJAY SHINDENo ratings yet

- Alignment Report (Peresandra-Gudibande)Document30 pagesAlignment Report (Peresandra-Gudibande)Kiran R GowdaNo ratings yet

- State Dearptment of Housing & Urban Development PDFDocument81 pagesState Dearptment of Housing & Urban Development PDFly0039No ratings yet

- Plan Koordinat Dinding Abt 01 Section Abutmen 01: Shop DrawingDocument1 pagePlan Koordinat Dinding Abt 01 Section Abutmen 01: Shop Drawingimmanuel lumbantobingNo ratings yet

- Auburn Storm WaterDocument52 pagesAuburn Storm WaterJay Ryan SantosNo ratings yet

- Engineering Report AKS FinalDocument215 pagesEngineering Report AKS FinalTolossa Abete100% (1)

- Sub Structure SummaryDocument6 pagesSub Structure SummaryeyuelNo ratings yet

- Musli-Bada QA Final-1Document85 pagesMusli-Bada QA Final-1Daric TesfayeNo ratings yet

- National Roads Authority: Project Appraisal GuidelinesDocument38 pagesNational Roads Authority: Project Appraisal GuidelinesPratish BalaNo ratings yet

- Guidelines For Estimation of Construction Time For Road and Bridge Works 2021Document11 pagesGuidelines For Estimation of Construction Time For Road and Bridge Works 2021Sang Rawal100% (1)

- RFP Gohpur NumaligarhDocument147 pagesRFP Gohpur NumaligarhNallabalu Naadi MalkajgiriNo ratings yet

- CA-33 Part - 1 (Section 1 To 5) PDFDocument205 pagesCA-33 Part - 1 (Section 1 To 5) PDFSumit ShekhawatNo ratings yet

- Chapter 1 Rail PWay ManualDocument20 pagesChapter 1 Rail PWay ManualibnesafiNo ratings yet

- Appendix E Culvert Substructure Design 4 (3.2 To 7.2) ) SubmDocument15 pagesAppendix E Culvert Substructure Design 4 (3.2 To 7.2) ) SubmteweldeNo ratings yet

- Final Design Review Report (Sept 2023)Document195 pagesFinal Design Review Report (Sept 2023)AshebirNo ratings yet

- Technical Schedule NH-148NA - Pkg1Document107 pagesTechnical Schedule NH-148NA - Pkg1dheeraj sehgalNo ratings yet

- Provide of Masonry Open DitchDocument1 pageProvide of Masonry Open DitchEngineeri TadiyosNo ratings yet

- Underpass Top Down PaperDocument17 pagesUnderpass Top Down PaperAlok MehtaNo ratings yet

- Engineering Procurement DirectorateDocument8 pagesEngineering Procurement DirectorateFetene50% (2)

- King Abdullah Road - West Section Part A Bill No. Description Amount (S.R) General Summary of Part ADocument17 pagesKing Abdullah Road - West Section Part A Bill No. Description Amount (S.R) General Summary of Part AenesNo ratings yet

- Final Design Report: Package-III (Malekhu - Mugling) Ch. 43+542 To Ch. 82+403Document55 pagesFinal Design Report: Package-III (Malekhu - Mugling) Ch. 43+542 To Ch. 82+403Santosh AryalNo ratings yet

- P FD FileDocument74 pagesP FD Filesunita guptaNo ratings yet

- Response To Comments Draft Structural Section ReportDocument2 pagesResponse To Comments Draft Structural Section ReportZerihun mulugetaNo ratings yet

- Ethiopia - Butajira-Hossaina-Sodo Road Project - Appraisal ReportDocument63 pagesEthiopia - Butajira-Hossaina-Sodo Road Project - Appraisal ReportTewodros AbateNo ratings yet

- Nepal Urban Road Standard 2076Document48 pagesNepal Urban Road Standard 2076Annya BodhNo ratings yet

- Imp Design of Rail Over BridgeDocument5 pagesImp Design of Rail Over BridgeShivangi MishraNo ratings yet

- Inception Report Kartarpur CorridiorDocument78 pagesInception Report Kartarpur CorridiorGaurav GhaiNo ratings yet

- MMSP-DD DFR enDocument317 pagesMMSP-DD DFR enCielo SerranaNo ratings yet

- Final TEFR - Sirkazhi by AecomDocument139 pagesFinal TEFR - Sirkazhi by AecommahakNo ratings yet

- Dabena River BridgeDocument14 pagesDabena River BridgeYared SolomonNo ratings yet

- Ofr2014 1167 - Carrell Tools and Techniques PDFDocument12 pagesOfr2014 1167 - Carrell Tools and Techniques PDFT RNo ratings yet

- Request For Proposal (RFP) For PPP Projects: TemplateDocument13 pagesRequest For Proposal (RFP) For PPP Projects: TemplateAgi BekeNo ratings yet

- UnderpassesDocument36 pagesUnderpassesbryantNo ratings yet

- Tender Documentation - PresentationDocument34 pagesTender Documentation - PresentationmusthaqhassanNo ratings yet

- Assessment 2 - Case StudyDocument5 pagesAssessment 2 - Case StudykhadijjatariqNo ratings yet

- 2012 KPDP Draft Final ReportDocument583 pages2012 KPDP Draft Final ReportboutueilNo ratings yet

- Daily Record For Lideta ProjectDocument3 pagesDaily Record For Lideta ProjectEngineeri TadiyosNo ratings yet

- Revise - Final Inception Report - PK-14 - 076-77Document59 pagesRevise - Final Inception Report - PK-14 - 076-77Ranjit Kumar ShahNo ratings yet

- Vol 2. Autp - Draft Final Report - Design Drawings - Sept 15Document200 pagesVol 2. Autp - Draft Final Report - Design Drawings - Sept 15Bernard OwusuNo ratings yet

- Procedure To Issue Building Completion Certificate From DMDocument1 pageProcedure To Issue Building Completion Certificate From DMHoussamNo ratings yet

- 4 Highway DrainageDocument58 pages4 Highway DrainageAbraham yudhaNo ratings yet

- 2011 Pacific Ottal Seal Monitoring PDFDocument25 pages2011 Pacific Ottal Seal Monitoring PDFLuis PilaresNo ratings yet

- Detailed Project Report: Sunkhani - Kanpa Section of Sunkhani - Sangwa - Jiri RoadDocument66 pagesDetailed Project Report: Sunkhani - Kanpa Section of Sunkhani - Sangwa - Jiri RoadMishal LimbuNo ratings yet

- Feasibility Study Report - Upgrading of Birgunj-Narayanghat SectionDocument120 pagesFeasibility Study Report - Upgrading of Birgunj-Narayanghat SectionBikesh Manandhar100% (1)

- Abu Dhabi Walking and Cycling Master PlanDocument297 pagesAbu Dhabi Walking and Cycling Master PlanYASSER AboughazalaNo ratings yet

- HP Spectre x360 Maintenance and Service GuideDocument100 pagesHP Spectre x360 Maintenance and Service GuideHidariMigiNo ratings yet

- Eldoret-Kapsabet June 2019 ReportDocument16 pagesEldoret-Kapsabet June 2019 ReportCarolNo ratings yet

- 5.2. Desain Drawing Asimetris Ganda 84,96,120 MDocument8 pages5.2. Desain Drawing Asimetris Ganda 84,96,120 MIsti HaryantoNo ratings yet

- Instructions Section 03100 Concrete FormworkDocument38 pagesInstructions Section 03100 Concrete FormworkAlpin MaulidinNo ratings yet

- Design Box Culvert For Shawee River RoadDocument14 pagesDesign Box Culvert For Shawee River RoadABAMELANo ratings yet

- Appendix RW - Design of R.C. Cantilever Retaining Wall: Louis Berger in Association With SABA Engineering PLCDocument12 pagesAppendix RW - Design of R.C. Cantilever Retaining Wall: Louis Berger in Association With SABA Engineering PLCHundeejireenyaNo ratings yet

- Structural ReportDocument10 pagesStructural ReportDawit SolomonNo ratings yet

- Tunnelconsult Job List PDFDocument68 pagesTunnelconsult Job List PDFarslanpasaNo ratings yet

- Lvl. - 0.181 Lvl. - 0.031 Lvl. - 0.00 Lvl. - 0.031 Lvl. - 0.00 Lvl. - 0.031Document10 pagesLvl. - 0.181 Lvl. - 0.031 Lvl. - 0.00 Lvl. - 0.031 Lvl. - 0.00 Lvl. - 0.031Vinay RajNo ratings yet

- Olompia UnderpassDocument60 pagesOlompia UnderpassEngineeri TadiyosNo ratings yet

- Slabs AauDocument26 pagesSlabs AauEngineeri TadiyosNo ratings yet

- Soiltest OrderDocument1 pageSoiltest OrderEngineeri TadiyosNo ratings yet

- Table 6.3 Presumed Design Bearing Resistances Under Vertical LoadingDocument1 pageTable 6.3 Presumed Design Bearing Resistances Under Vertical LoadingesmailNo ratings yet

- Depth Detemination2Document2 pagesDepth Detemination2Engineeri TadiyosNo ratings yet

- Electrical InstalationDocument11 pagesElectrical InstalationEngineeri TadiyosNo ratings yet

- Slab Design2Document5 pagesSlab Design2Engineeri TadiyosNo ratings yet

- Column DesignAAUDocument5 pagesColumn DesignAAUEngineeri TadiyosNo ratings yet

- Combined Footing Design (Strap Final)Document22 pagesCombined Footing Design (Strap Final)Engineeri TadiyosNo ratings yet

- Monopitch Roof Steel Truss (Ware House) 12345Document5 pagesMonopitch Roof Steel Truss (Ware House) 12345FatihNo ratings yet

- Wind Pressure (Duopitch) Elini Work ShopDocument8 pagesWind Pressure (Duopitch) Elini Work ShopFatihNo ratings yet

- Lateral Ebcs 8Document3 pagesLateral Ebcs 8Engineeri TadiyosNo ratings yet

- Staircase Design (With Out Cantilever)Document3 pagesStaircase Design (With Out Cantilever)ABAMELANo ratings yet

- Masonary Retaing Wall DesignDocument1 pageMasonary Retaing Wall DesigntarikuNo ratings yet

- Reynold's MethodDocument3 pagesReynold's MethodEngineeri TadiyosNo ratings yet

- Footing Design, Revised & ProtectedDocument21 pagesFooting Design, Revised & ProtectedEngineeri TadiyosNo ratings yet

- Combined Footing Design 1Document2 pagesCombined Footing Design 1Engineeri TadiyosNo ratings yet

- StaticaculationrDocument8 pagesStaticaculationrEngineeri TadiyosNo ratings yet

- Design of Cantilever Slab (Balconey)Document11 pagesDesign of Cantilever Slab (Balconey)Engineeri TadiyosNo ratings yet

- Combined Footing Design (Strap Final)Document22 pagesCombined Footing Design (Strap Final)Engineeri TadiyosNo ratings yet

- Monopitch Roof Steel Truss (Ware House) 12345Document5 pagesMonopitch Roof Steel Truss (Ware House) 12345FatihNo ratings yet

- Design of One Way SlabsDocument5 pagesDesign of One Way SlabsEngineeri TadiyosNo ratings yet

- Staticaculationr ModDocument8 pagesStaticaculationr ModEngineeri TadiyosNo ratings yet

- Reynold's MethodDocument3 pagesReynold's MethodEngineeri TadiyosNo ratings yet

- (L&S) Financial Claim Notice For Delay of Bridge Works at Lebu and Saris-AboDocument2 pages(L&S) Financial Claim Notice For Delay of Bridge Works at Lebu and Saris-AboEngineeri Tadiyos100% (1)

- Further Details For Interim Financial Claim No-1Document1 pageFurther Details For Interim Financial Claim No-1Engineeri TadiyosNo ratings yet

- Right of Way ClaimDocument1 pageRight of Way ClaimEngineeri TadiyosNo ratings yet

- Design of One Way SlabsDocument5 pagesDesign of One Way SlabsEngineeri TadiyosNo ratings yet

- Depth DeteminationDocument6 pagesDepth DeteminationEngineeri TadiyosNo ratings yet

- Further Clarification and Supporting Documents For FinancialDocument4 pagesFurther Clarification and Supporting Documents For FinancialEngineeri TadiyosNo ratings yet

- Interim Financial Claim No-1 Due To Project SuspensionDocument2 pagesInterim Financial Claim No-1 Due To Project SuspensionEngineeri TadiyosNo ratings yet

- WarYoga Tool ManualDocument10 pagesWarYoga Tool ManualJulius AdamsNo ratings yet

- CENTAC Bill of Materials This Data Has Been Tabulated For Serial Number C12629Document15 pagesCENTAC Bill of Materials This Data Has Been Tabulated For Serial Number C12629diego fernando salgado devia100% (1)

- A Primer On Rectangular TanksDocument7 pagesA Primer On Rectangular Tanksfawmer61No ratings yet

- Ijebu Mushin Capital Projects 2022 - UnpricedDocument68 pagesIjebu Mushin Capital Projects 2022 - Unpricedoseni momoduNo ratings yet

- Buckling C ChannelDocument2 pagesBuckling C ChannelНемања КараклајићNo ratings yet

- Article CIGRE 22 - 206E PDFDocument6 pagesArticle CIGRE 22 - 206E PDFIsaac DiazNo ratings yet

- Ficha Sistema de Tuberia Multicapa Pex Al Pe InglesDocument3 pagesFicha Sistema de Tuberia Multicapa Pex Al Pe InglesP.M.No ratings yet

- E272 PDFDocument4 pagesE272 PDFsreemoy123100% (1)

- 3 EVER Panelboard PDFDocument1 page3 EVER Panelboard PDFGLITZ ELEKTRO BUILDERS CDO BRANCHNo ratings yet

- Wis 4 34 04 PDFDocument16 pagesWis 4 34 04 PDFNitinNo ratings yet

- Method Statement Demolition & Removal of Courtyard Flooring, Asphalt, Curb Stones, Block Wall & SeatsDocument26 pagesMethod Statement Demolition & Removal of Courtyard Flooring, Asphalt, Curb Stones, Block Wall & SeatsIrfan AliNo ratings yet

- Typical Joint Box With U-Ditch: Weephole DetailDocument1 pageTypical Joint Box With U-Ditch: Weephole DetailAbid AyubNo ratings yet

- LED LINEAR PROFILE LIGHTING CATALOGUE 18 19 Edited EditedDocument42 pagesLED LINEAR PROFILE LIGHTING CATALOGUE 18 19 Edited EditedKeshav SinghNo ratings yet

- Valvulas de Bola PDFDocument9 pagesValvulas de Bola PDFChristian VegaNo ratings yet

- Mobile Flare StackDocument4 pagesMobile Flare StackMurat KalfaNo ratings yet

- Damp ProofingDocument23 pagesDamp ProofingyaredNo ratings yet

- Casing & Tubing HangerDocument4 pagesCasing & Tubing Hangerandreinicusor1958-1No ratings yet

- Sewerage SystemDocument11 pagesSewerage Systemhajjiyare2016100% (1)

- Design Recommendations For Precast Concrete Structures: Reported by ACI-ASCE Committee 550Document8 pagesDesign Recommendations For Precast Concrete Structures: Reported by ACI-ASCE Committee 550nathanNo ratings yet

- Post Concreting ChecklistDocument1 pagePost Concreting ChecklistJeman Nawi71% (7)

- 01 The Law and Practice of Delay Claims A Practical Introduction TrainorDocument19 pages01 The Law and Practice of Delay Claims A Practical Introduction TrainorMOHNo ratings yet

- Pipeline PiggingDocument28 pagesPipeline PiggingDeny Arief Rusamsi100% (1)

- Schieber EN2008 PDFDocument144 pagesSchieber EN2008 PDFperfilma2013No ratings yet

- Circularity in The Built Environment: Case StudiesDocument72 pagesCircularity in The Built Environment: Case StudiesMargarita KianidouNo ratings yet

- Ca Intermediate Study MaterialsDocument23 pagesCa Intermediate Study MaterialsjshashimohanNo ratings yet

- BoQ Extend Ramp Door Pontoon-Blank (1) HindoliDocument3 pagesBoQ Extend Ramp Door Pontoon-Blank (1) HindoliandhyirawanNo ratings yet

- City Development Plan As A Strategic Tool For City Development: MaheshwarDocument16 pagesCity Development Plan As A Strategic Tool For City Development: MaheshwarAmiteshAwasthi0% (1)

- Criterios de Falla Vesic (1975)Document13 pagesCriterios de Falla Vesic (1975)ira0218No ratings yet

- Concrete Insulated PanelsDocument12 pagesConcrete Insulated Panelssabid100% (1)