Professional Documents

Culture Documents

Smart Earthing Monitoring en

Uploaded by

Reinaldo Sciliano juniorOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Smart Earthing Monitoring en

Uploaded by

Reinaldo Sciliano juniorCopyright:

Available Formats

IoT

SMART EARTHING

MONITORING SYSTEM

Smart system for distributed

processing and centralised

monitoring of earthing systems

IoT

Earthing system is a mirror that reflects

the state of an electrical installation

Earthing system is a fundamental safety element that requires

regular maintenance. An earthing system makes it not only to

observe the electrical dynamics attributable to the abnormal

operation of facility but also of equipment connected to it,

which could be affected by transients, leakage, spurious and

harmonics currents, etc.

SMART EARTHING MONITORING SYSTEM performs

centralised monitoring of earthing systems by means

of smart sensors distributed in selected control

points, evaluating the status of the facility at regular

and programmable intervals, guaranteeing safety and

continuity of the service.

Optimise safety and operational-financial efficiency of your

assets.

RISK MINIMISATION

Prevention of critical situations such as those that can be

generated by step and touch voltages in facilities that are

not continuously supervised or without proper maintenance.

OPERATIONAL EFFICIENCY

Data-driven predictive maintenance that optimises asset

lifetime. Real-time alerts for corrective maintenance. Theft

and vandalism detection.

FINANCIAL EFFICIENCY

Cost savings through logistical simplification of verification

processes and early detection of asset failure situations.

© 2022 Aplicaciones Tecnológicas S.A 2 www.at3w.com · atsa@at3w.com

IoT

SMART EARTHING

MONITORING SYSTEM

Efficient monitoring

of earthing systems

SMART EARTHING MONITORING SYSTEM enables distributed processing and centralised monitoring

of earthing systems as well as interpretation of data, providing useful feedback for decision making.

IoT IA

Data collection Accurate diagnostics Objective multi-channel alerts

Centralised monitoring using Interpretation of data through AI Feedback is received by different

distributed smart sensors allows real- algorithms such as Clustering, departments: asset management,

time status monitoring of the electrical Adaptive Filtering or Deep Learning, operations, maintenance, etc., both

installation and equipment connected provides information for complete in form of alerts and historical

to it in an economically efficient way, characterisation of the monitored measurements. In this way, risks,

ensuring safety and continuity of system. failures and their effects can be

service. minimised, and the useful life of

assets can be optimised through

High-capacity distributed processing predictive maintenance. All this

facilitates the incorporation of new results in cost savings due to

features and/or user requirements and logistical simplification of verification

enables automatic local action. processes and optimisation of

corrective preventive maintenance.

Distributed sensorisation, IoT connectivity and Artificial Intelligence for

the supervision of earthing systems.

© 2022 Aplicaciones Tecnológicas S.A 3 www.at3w.com · atsa@at3w.com

IoT

SMART EARTHING

MONITORING SYSTEM

Applications

Ă Logistical and operational optimisation of periodic regulatory

checks.

Ă Determination of the regulatory resistive value of the monitored

system.

Ă Verification of conductors and connections that form part of the

monitored loop (cable screens, etc.).

Ă Verification of continuity of the earthing conductor (breakage,

vandalism, etc.).

Ă Characterisation of current flow in interconnected earthing

systems.

Ă Evaluation of leakage currents in industrial systems and processes

for optimisation of preventive maintenance of machinery.

Ă Assessment of the level of electrical noise causing interference

associated with equipment malfunctions.

Ă Monitoring of earthing fittings and neutral transformer in

substations.

Ă Optimisation of maintenance associated with cathodic protection.

Ă Power supply quality control.

Main sectors

Ă Transport and energy distribution

Ă Oil&Gas

Ă Telecommunications

Ă Renewable energy

Ă Industry

Ă Mining

Ă Facilities with sensitive equipment

© 2022 Aplicaciones Tecnológicas S.A 4 www.at3w.com · atsa@at3w.com

IoT

SMART EARTHING

MONITORING SYSTEM

System Characteristics

SMART EARTHING MONITORING SYSTEM is a technological solution developed and patented by

Aplicaciones Tecnológicas for efficient supervision of earthing systems, characterised by:

Ă Robustness: the system has a double data storage backup.

Ă Highly resilient design: optimised to reduce dependence on the availability of electronic components

on the market, increasing the guarantee of supply and reducing delivery times.

Ă Adaptability: remotely adaptable functionalities and options, either individually (for implementation

and testing of new functions), for groups (for partial pilots, adjustment of local configurations) or

globally.

Ă Independence: local processing independent of communications.

ADAPTABILITY TO ANY SCENARIO

Adapted monitoring of earthing and elements connected to it.

Development of ad-hoc projects according to customer requirements.

© 2022 Aplicaciones Tecnológicas S.A 5 www.at3w.com · atsa@at3w.com

IoT

SMART EARTHING

MONITORING SYSTEM

Results and benefits of the system

OPERATIONAL RISK FINANCIAL

EXCELLENCE MINIMISATION EFFICIENCY

Ă Data-driven predictive Ă Reduction of the risk of step Ă Cost savings due to logistical

maintenance. and touch voltages with the simplification of verification

danger of electric shock for processes.

Ă Real-time alerts for corrective people.

maintenance. Ă Early detection of asset failure

Ă Continuous and remote

verification of assets status. situations.

Ă Prevention of failures and

safety-critical situations. Ă Real-time detection of earthing Ă Optimisation of corrective and

disconnections. preventive maintenance.

Ă Centralised monitoring.

Ă Alerts in the event of theft,

Ă Configurable system adaptable degradation, breakdown or

to user needs. accidental breakage.

Ă Remote updates.

© 2022 Aplicaciones Tecnológicas S.A 6 www.at3w.com · atsa@at3w.com

IoT

SMART EARTHING

MONITORING SYSTEM

SMART EARTHING MONITORING SYSTEM:

system structure

The system consists of a layered structure, each with a specific infrastructure.

The sensing layer contains the sensor elements that

are installed in the assets to be monitored. This layer

SENSING LAYER

communicates with the server layer via a secure channel

(MPLS).

ETL

SERVERS

LAYER

The server layer has physical support of the databases

where the set of data is registered by all the equipment

SQL

in the field. A set of ETL services is in charge of OLAP

LAYER

organising data appropriately in the OLAP layer.

At the algorithm layer, the different AI algorithms

convert raw data into useful information, which is

inserted back into database in the processing layer. ALGORITHM

LAYER

In the target layer, the functions and options required by

AT-CLOUD

user are determined based on collected data.

MIDDLEWARE

SERV PROCESSING

LAYER

SCADA

JSON

MIDDLEWARE

At the user layer, via a web portal, each user profile

can access real-time visualisation of data, access to

historical data, alert management, analysis, data export,

etc.

COR

COA

USER LAYER

The high computational capacity of sensors and WEB PORTAL - APP

CCA

OPERATOR

power provided by the distributed process allow data

integration from the different layers that form the

system.

© 2022 Aplicaciones Tecnológicas S.A 7 www.at3w.com · atsa@at3w.com

IoT

SMART EARTHING

MONITORING SYSTEM

System structure

SMART EARTHING MONITORING SYSTEM uses IoT technology to monitor earthing

systems and elements connected to them at regular and programmable intervals.

The data from the sensors are transferred via a secure protocol to the AT-CLOUD, a redundant

and secure data centre (TIER IV-Gold) where the AI algorithms transform the data into useful

information for the client.

The processed information is sent via M2M communication both to the web portal and other

channels (e-mail, APP, integration with SCADA), where it is available:

Ă Real-time visualisation of earthing status

Ă Alerts via push notification

Ă Historical data for analysis and studies

© 2022 Aplicaciones Tecnológicas S.A 8 www.at3w.com · atsa@at3w.com

IoT

SMART EARTHING

MONITORING SYSTEM

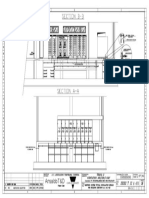

Equipment configuration

Starting from the common base unit and depending on the application, the

configuration of units is completed by selecting characteristics related to:

Power supply Sensor

The equipment can be configured for Choice of an external to the enclosure

mains power supply using a power or integrated with the enclosure sensor

supply unit, direct power supply from (available for weatherproof enclosure).

48V batteries or autonomous power

supply via solar panel.

Battery

It can be selected a 5Ah battery for

Communication

equipment power backup or 10Ah for solar

Communications can be carried out power applications or for supplying power

via the 2G/3G network or over the 4G to small site equipment.

network bands for IoT (LTE-M, NBIoT).

Communication is also possible via

Visualisation

LAN port.

The indoor enclosure allows a 2.4”

TFT screen for visualisation and local

Enclosure

operation of equipment.

It is possible to select a suitable for

indoor use, prepared for wall and

DIN rail mounting enclosure, or the

IP 65 weatherproof enclosure for

environments exposed to inclement

weather.

© 2022 Aplicaciones Tecnológicas S.A 9 www.at3w.com · atsa@at3w.com

IoT

SMART EARTHING

MONITORING SYSTEM

Functional options

Configuration of equipment is completed by a selection of functional

options, which can be activated remotely, even with the equipment already

installed in different locations.

Real-time continuity Potential-free outputs

The equipment monitors status of This function allows configurable local

earthing conductor in real-time and actuation.

generates an immediate warning when

a lack of continuity is detected. GPIO

Puertos analógicos y digitales para

Leakage current detection

centralizar la sensorización del entorno

It detects and measures the leakage mediante el equipo.

current of equipment connected to

the earthing network, e.g. autovalves, Touch voltage

transformers, etc.

Measurement of touch voltage

generated in the event of an earthing

Node evaluation

leakage or a failure.

It allows evaluation of status of

interconnection between different

Expansion port

earthing systems, generating a signal

at one point and evaluating the signal Port intended to communicate the

received in the different nodes of the equipment with other elements of the

network. site.

Autocalibration

It allows unattended calibration of

equipment for regulatory verifications.

© 2022 Aplicaciones Tecnológicas S.A 10 www.at3w.com · atsa@at3w.com

IoT

SMART EARTHING

MONITORING SYSTEM

Platform options

The user platform can be defined according to

management and integration capabilities required:

COA platform APP management for

Alert management associated equipment activation/

with status of the measurement deactivation:

equipment. Mobile APP for management

of activation/deactivation of

CCA platform installed equipment.

Alert management associated with

earthing resistance and continuity SCADA

measurements. Integration of data processed in

client’s system.

COR Platform

Alert management associated

with leakage current, failure

location, etc.

© 2022 Aplicaciones Tecnológicas S.A 11 www.at3w.com · atsa@at3w.com

IoT

SMART EARTHING

MONITORING SYSTEM

Additional services

caret-right Application Maintenance Services:

Remote updating of the application

24x7 Technical Service at3w-connect.com

Data backup

caret-right Equipment Maintenance Services:

Remote equipment updates

Remote equipment diagnostics

24x7 Technical Service

Local data recovery

Autocalibration

© 2022 Aplicaciones Tecnológicas S.A 12 www.at3w.com · atsa@at3w.com

IoT

Other recommended services

and products

Services

Ă Advanced geoelectrical studies.

Ă Earthing systems 4.0 projects.

Ă Smart storm detection projects.

Ă Lightningand overvoltage

protection projects.

Products

Ă ATSTORM®

Smart early warning system for thunderstorm

risk.

Ă DATCONTROLER® REMOTE

Smart air terminals with IoT technology.

Ă OVERVOLTAGES

Transient and permanent.

© 2022 Aplicaciones Tecnológicas S.A 13 www.at3w.com · atsa@at3w.com

Contact

Name:

Company:

email:

Country:

Message:

I accept the terms and conditions. Read terms and conditions.

SEND

APLICACIONES TECNOLÓGICAS S.A.

Parque Tecnológico de Valencia

C/Nicolás Copérnico, 4 - 46980 Paterna (Valencia), SPAIN

(+34) 961 318 250 atsa@at3w.com at3w.com

AT-V02-EN

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 11 - PDFsam - E) Employer - S Requirements - B01. Project Description and Procedures - r1Document1 page11 - PDFsam - E) Employer - S Requirements - B01. Project Description and Procedures - r1Reinaldo Sciliano juniorNo ratings yet

- 15 - PDFsam - E) Employer - S Requirements - B01. Project Description and Procedures - r1Document1 page15 - PDFsam - E) Employer - S Requirements - B01. Project Description and Procedures - r1Reinaldo Sciliano juniorNo ratings yet

- 14 - PDFsam - E) Employer - S Requirements - B01. Project Description and Procedures - r1Document1 page14 - PDFsam - E) Employer - S Requirements - B01. Project Description and Procedures - r1Reinaldo Sciliano juniorNo ratings yet

- 10 - PDFsam - E) Employer - S Requirements - B01. Project Description and Procedures - r1Document1 page10 - PDFsam - E) Employer - S Requirements - B01. Project Description and Procedures - r1Reinaldo Sciliano juniorNo ratings yet

- 12 - PDFsam - E) Employer - S Requirements - B01. Project Description and Procedures - r1Document1 page12 - PDFsam - E) Employer - S Requirements - B01. Project Description and Procedures - r1Reinaldo Sciliano juniorNo ratings yet

- 4 - PDFsam - E) Employer - S Requirements - B01. Project Description and Procedures - r1Document1 page4 - PDFsam - E) Employer - S Requirements - B01. Project Description and Procedures - r1Reinaldo Sciliano juniorNo ratings yet

- 13 - PDFsam - E) Employer - S Requirements - B01. Project Description and Procedures - r1Document1 page13 - PDFsam - E) Employer - S Requirements - B01. Project Description and Procedures - r1Reinaldo Sciliano juniorNo ratings yet

- 3 - PDFsam - E) Employer - S Requirements - B01. Project Description and Procedures - r1Document1 page3 - PDFsam - E) Employer - S Requirements - B01. Project Description and Procedures - r1Reinaldo Sciliano juniorNo ratings yet

- 2 - PDFsam - E) Employer - S Requirements - B01. Project Description and Procedures - r1Document1 page2 - PDFsam - E) Employer - S Requirements - B01. Project Description and Procedures - r1Reinaldo Sciliano juniorNo ratings yet

- 1 - PDFsam - E) Employer - S Requirements - B01. Project Description and Procedures - r1Document1 page1 - PDFsam - E) Employer - S Requirements - B01. Project Description and Procedures - r1Reinaldo Sciliano juniorNo ratings yet

- 5 - PDFsam - E) Employer - S Requirements - B01. Project Description and Procedures - r1Document1 page5 - PDFsam - E) Employer - S Requirements - B01. Project Description and Procedures - r1Reinaldo Sciliano juniorNo ratings yet

- FO UndergroundDocument2 pagesFO UndergroundReinaldo Sciliano juniorNo ratings yet

- Datasheet Air 3,5kWDocument1 pageDatasheet Air 3,5kWReinaldo Sciliano juniorNo ratings yet

- Ansaldot&D: Power CareDocument1 pageAnsaldot&D: Power CareReinaldo Sciliano juniorNo ratings yet

- Ansaldot&D: Power CareDocument3 pagesAnsaldot&D: Power CareReinaldo Sciliano juniorNo ratings yet

- FO - Technical ParametersDocument3 pagesFO - Technical ParametersReinaldo Sciliano juniorNo ratings yet

- Ansaldot&D: Power CareDocument1 pageAnsaldot&D: Power CareReinaldo Sciliano juniorNo ratings yet

- Ansaldot&D: Power CareDocument1 pageAnsaldot&D: Power CareReinaldo Sciliano juniorNo ratings yet

- Zelio Logic SR2 - SR3 - SR3B261BDocument6 pagesZelio Logic SR2 - SR3 - SR3B261BReinaldo Sciliano juniorNo ratings yet

- Cidadania Italiana JudicialDocument1 pageCidadania Italiana JudicialReinaldo Sciliano juniorNo ratings yet

- Corporate Presentation At3wDocument19 pagesCorporate Presentation At3wReinaldo Sciliano juniorNo ratings yet

- TN1Ue Reference Manual Issue 9.0Document144 pagesTN1Ue Reference Manual Issue 9.0Reinaldo Sciliano juniorNo ratings yet