Professional Documents

Culture Documents

86 Qwi Me 611 Leak Test

Uploaded by

Mohamed Reda Hussein SengarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

86 Qwi Me 611 Leak Test

Uploaded by

Mohamed Reda Hussein SengarCopyright:

Available Formats

M.A. AL-KAWARI EST.

TRADING AND GENERAL CONTRACTING

Document# MAK: QWI/ME-611 Revision: 1 Date: December 20, 2012

M.A.

AL-KAWARI EST.

FOR TRADING AND

GENERAL CONTRACTING

Prepared / Compiled by: QA/QC Manager

QUALITY PLAN MUTTHAN KANAGASOORIYAM

Reviewed & Approved by: Officer-In-Charge

RANDELL S. RELLES

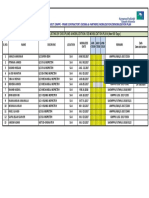

DOCUMENT TITLE: LEAK TEST WORK INSTRUCTIONS

Page 1 of 5

1.0 GENERAL & PREFERENCES:

1.1 Leak/Pneumatic testing will be carried out strictly in accordance

with Saudi Aramco Engineering Standard and Specification.

Leak test conducted using air or other approved gas as the test

medium or in conjunction with liquid.

This test, when conducted, shall be in accordance with GI-2.102

for additional safety requirements.

Pneumatic testing with air for piping systems, which have been

in flammable service shall be concurred by the Manager, Loss

Prevention Department.

Pneumatic/Leak test is applicable for this project on welded

reinforcement pads full encirclement sleeves & Weld Plus-Ends.

1.2 This Leak/Pneumatic test procedure is to be read in conjunction

with the following references:

SAES-A-004 : Gen. Requirements for Pressure Testing

SAES-L-150 : Pressure Testing of Plant Piping &

P/L’s

GI-2-100 : Work Permit

GI-2-102 : Safety Precaution for Pressure

Testing Safety

GI-2-102.1 : Checklist for Pressure Testing Safety

API-1104 : Standard for Welding Pipeline & Related

Facilities

M.A. AL-KAWARI EST.

TRADING AND GENERAL CONTRACTING

Document# MAK: QWI/ME-611 Revision: 1 Date: December 20, 2012

M.A.

AL-KAWARI EST.

FOR TRADING AND

GENERAL CONTRACTING

Prepared / Compiled by: QA/QC Manager

QUALITY PLAN MUTTHAN KANAGASOORIYAM

Reviewed & Approved by: Officer-In-Charge

RANDELL S. RELLES

DOCUMENT TITLE: LEAK TEST WORK INSTRUCTIONS

Page 2 of 5

2.0 TEST EQUIPMENT:

Pressure Gauge.

Pressure Gauge should be of proper range and must be calibrated by a

Saudi Aramco approved Independent Testing Laboratory. Calibration

certificate shall be made available to Inspection personnel prior to the

commencement of the test.

3.0 REFERENCE TEST PROCEDURE:

This Pneumatic/Leak tests shall be carried out in complete

conformance with paragraph 10.2 of Section 10: Pressure Testing of

Miscellaneous Piping Component, of SAES-L-150.

4.0 LEAK TEST:

4.1 Leak testing of Reinforcing Pads and/or Full Encirclement

Sleeves.

4.1.1 Connect the calibrated pressure gauge in the threaded

vent hole thru temporary fittings.

4.1.2 Start pressurizing and raised the pressure up to the

required 25 psig. Hold the pressure, if there is any leak

pressure drop will be observed.

M.A. AL-KAWARI EST.

TRADING AND GENERAL CONTRACTING

Document# MAK: QWI/ME-611 Revision: 1 Date: December 20, 2012

M.A.

AL-KAWARI EST.

FOR TRADING AND

GENERAL CONTRACTING

Prepared / Compiled by: QA/QC Manager

QUALITY PLAN MUTTHAN KANAGASOORIYAM

Reviewed & Approved by: Officer-In-Charge

RANDELL S. RELLES

DOCUMENT TITLE: LEAK TEST WORK INSTRUCTIONS

Page 3 of 5

4.1.3 Stop pressurizing and examined for leaks using soap

solution at a reduced pressure of 3-5 psig.

4.1.4 If there is any leakage/pressure decrease is evident,

depressurized the system to zero (0) pressure, and repair

the leak.

4.1.5 After the leak test is successfully complete and accepted,

depressurize the system to zero (0) psig and disconnect

the pressure indicator and temporary fittings.

4.1.6 The tapped vent hole shall be packed it heavy grease

after the completion of the test.

4.2 Leak testing on Weld Plus-Ends

For leak testing purposes the uppermost bolt hole on both ends

of the Weld Plus-End Coupling is left open after the W+E

Coupling is welded & all the other bolts cut & sealed welded.

4.2.1 Connect the calibrated pressure gauge in the open bolt

hole at one end of the coupling thru a temporary fittings.

4.2.2 Start pressurizing and raised the pressure up to the

required pressure (35 to 70 kPa) or (5 to 10 psig). Hold

the pressure, if there is any leak pressure drop will be

observed.

4.2.3 Stop pressurizing & examined for leaks using a soap

solution.

M.A. AL-KAWARI EST.

TRADING AND GENERAL CONTRACTING

Document# MAK: QWI/ME-611 Revision: 1 Date: December 20, 2012

M.A.

AL-KAWARI EST.

FOR TRADING AND

GENERAL CONTRACTING

Prepared / Compiled by: QA/QC Manager

QUALITY PLAN MUTTHAN KANAGASOORIYAM

Reviewed & Approved by: Officer-In-Charge

RANDELL S. RELLES

DOCUMENT TITLE: LEAK TEST WORK INSTRUCTIONS

Page 4 of 5

4.2.4 If there is any leakage/pressure decrease is evident,

depressurized the system to zero (0) pressure, and repair

the leak(s).

4.2.5 After the leak test is successfully complete and accepted,

depressurize the system to zero (0) psig and disconnect

the pressure indicator and temporary fittings.

4.2.6 Re-install the pressure indicator in the open both hole at

the other side of the coupling & repeat steps 4.2.2 to

4.2.5.

4.2.7 Install the bolts & tightened to the required torque. Cut

the bolts flush to the surface of the coupling & then seal

weld.

4.2.8 The Weld Plus-End coupling connection is now ready to

receive the required coating.

5.0 QA/QC INSPECTION

The Contractor QA/QC Mechanical Inspector shall ensure the

Pneumatic /Leak testing is carried out in accordance within the

approved Leak Test Procedure.

6.0 QA/QC REPORT/DOCUMENTATION

6.1 All testing shall be witnessed by Saudi Aramco representatives

and Contractor QA/QC Mechanical Inspector.

M.A. AL-KAWARI EST.

TRADING AND GENERAL CONTRACTING

Document# MAK: QWI/ME-611 Revision: 1 Date: December 20, 2012

M.A.

AL-KAWARI EST.

FOR TRADING AND

GENERAL CONTRACTING

Prepared / Compiled by: QA/QC Manager

QUALITY PLAN MUTTHAN KANAGASOORIYAM

Reviewed & Approved by: Officer-In-Charge

RANDELL S. RELLES

DOCUMENT TITLE: LEAK TEST WORK INSTRUCTIONS

Page 5 of 5

6.2 All test results shall be recorded using both Saudi Aramco Test

Report Forms (Saudi Aramco Form 2642-ENG). Document shall

be signed by Saudi Aramco Representative and Contractor

QA/QC Mechanical Inspector.

You might also like

- MST Valve TestingDocument7 pagesMST Valve TestingSiva RamNo ratings yet

- Hydro Test Work ProcedureDocument9 pagesHydro Test Work ProcedureshahidbolarNo ratings yet

- Procedure Welding Part 2Document14 pagesProcedure Welding Part 2mohammadNo ratings yet

- TUV SUD - PT Procedure Rev.05Document13 pagesTUV SUD - PT Procedure Rev.05HassanNo ratings yet

- Fe-Gen-St-Xxxxx-Welder Qualification and Control Procedure-R1Document10 pagesFe-Gen-St-Xxxxx-Welder Qualification and Control Procedure-R1Parag WadekarNo ratings yet

- RP 6.0 2015 Vfinal - 0Document18 pagesRP 6.0 2015 Vfinal - 0Kewell LimNo ratings yet

- Piping Pressure Test, Flushing & Air Blowing ProcedureDocument17 pagesPiping Pressure Test, Flushing & Air Blowing Proceduresoumaya yahyaoui100% (8)

- A-Qac-Pro-730-38930 Rev ADocument10 pagesA-Qac-Pro-730-38930 Rev ARamzi ZoghlamiNo ratings yet

- Kantas International Nigeria Limited: Generic Hydrotesting ProcedureDocument7 pagesKantas International Nigeria Limited: Generic Hydrotesting ProcedureGbenga MoboladeNo ratings yet

- IQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFDocument15 pagesIQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFAli MajeedNo ratings yet

- Relief Valves ProcedureDocument15 pagesRelief Valves ProcedureNuwan RanaweeraNo ratings yet

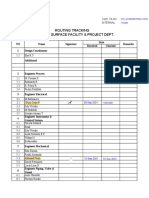

- Routing Tracking Operation Surface Facility & Project Dept.: 015 - JX-200238-PHG-LI-VD-21 TA-026Document8 pagesRouting Tracking Operation Surface Facility & Project Dept.: 015 - JX-200238-PHG-LI-VD-21 TA-026aurinkokelloNo ratings yet

- 002 DPB PT Asme 2012 PT AsmeDocument43 pages002 DPB PT Asme 2012 PT AsmeAozoraLazoraNo ratings yet

- Hidrostatic Test Procedure: Hafizul - HasrolDocument7 pagesHidrostatic Test Procedure: Hafizul - HasrolRafique MunirNo ratings yet

- VINDAIR SOP.01 Duct Pressure TestDocument3 pagesVINDAIR SOP.01 Duct Pressure TestRamakrishna Agumbe100% (1)

- HYDRO TEST PROCEDUREDocument5 pagesHYDRO TEST PROCEDUREBharat BhoirNo ratings yet

- Audit Criteria: AC 7109 REV. DDocument9 pagesAudit Criteria: AC 7109 REV. DsenthilNo ratings yet

- S.A.E.P. - 1145Document20 pagesS.A.E.P. - 1145silvrsurfr637No ratings yet

- Ms For Hyrdo Pneumatic Testing of Spherical TANKS (730-TK-03 A/B & C) A-CON-PRO-730-38939Document15 pagesMs For Hyrdo Pneumatic Testing of Spherical TANKS (730-TK-03 A/B & C) A-CON-PRO-730-38939Ramzi ZoghlamiNo ratings yet

- Inspection and Certification of Blowout Preventers (CAODC)Document18 pagesInspection and Certification of Blowout Preventers (CAODC)Carlos MunizagaNo ratings yet

- 05 Hyd - Test ProcedureDocument3 pages05 Hyd - Test ProcedureirfanNo ratings yet

- Hydro TEST PROCEDURE FOR BELLOWDocument4 pagesHydro TEST PROCEDURE FOR BELLOWselvakumarNo ratings yet

- Contractor QC Supervisor Resume Review ChecklistDocument1 pageContractor QC Supervisor Resume Review ChecklistAdnan ArshidNo ratings yet

- JEL hydrotest procedure EQUATE projectsDocument8 pagesJEL hydrotest procedure EQUATE projectsSaravananRamasamy100% (2)

- Pneumatic Test ProcedureDocument5 pagesPneumatic Test ProcedureBharat BhoirNo ratings yet

- Micro ManualDocument55 pagesMicro ManualNiranjan PradhanNo ratings yet

- 8.2.4 - JSL QMS QP 14 Hydrotest - ProcedureDocument5 pages8.2.4 - JSL QMS QP 14 Hydrotest - ProcedureGbenga MoboladeNo ratings yet

- Nordam Group The: 6911 N. Whirlpool DRDocument3 pagesNordam Group The: 6911 N. Whirlpool DRamirkhakzad498No ratings yet

- Calibration Procedure for Torque WrenchesDocument7 pagesCalibration Procedure for Torque Wrenchesvinsensius rasaNo ratings yet

- 1 SATIP-A-004-02 Hydro Test of Plant Piping-Rev 1Document2 pages1 SATIP-A-004-02 Hydro Test of Plant Piping-Rev 1Ariel Anasco50% (2)

- C22-Yb60-F-4765 - 0 Sa3-Ps2, Butterfly Valve, Test ProceduresDocument8 pagesC22-Yb60-F-4765 - 0 Sa3-Ps2, Butterfly Valve, Test Proceduressartaj100% (1)

- Caodc RP 6.0 Inspection and Certification of BopDocument19 pagesCaodc RP 6.0 Inspection and Certification of BopEDWIN M.P0% (1)

- Vacuum TestDocument3 pagesVacuum TestHarry DobleNo ratings yet

- Method Statement For Installation of Chilled Water Pump & Condenser Water PumpDocument14 pagesMethod Statement For Installation of Chilled Water Pump & Condenser Water Pump721917114 47No ratings yet

- Ayub Ali Mohammed CVDocument12 pagesAyub Ali Mohammed CVMatías AlonsoNo ratings yet

- NITON - HYDRO TEST PROCEDURE - Rev.0Document6 pagesNITON - HYDRO TEST PROCEDURE - Rev.0PRASHANT100% (2)

- QA/QC Procedure for FabricationDocument7 pagesQA/QC Procedure for FabricationRajesh K Pillai100% (6)

- Pressure TestingDocument9 pagesPressure TestingSanjay SinghNo ratings yet

- Emrsn HTP 001 A1Document7 pagesEmrsn HTP 001 A1Karthik BanariNo ratings yet

- SATIP-N-001-02 Rev. 4Document2 pagesSATIP-N-001-02 Rev. 4Anonymous 4e7GNjzGW100% (1)

- water tanker Front1Document2 pageswater tanker Front1engr.haseebbalochNo ratings yet

- Glf-whp02-Epcic4 Exhibit H App h1Document7 pagesGlf-whp02-Epcic4 Exhibit H App h1Pete RueangchimNo ratings yet

- Construction Instrument Tubing Pressure & Leak Test ProcedureDocument9 pagesConstruction Instrument Tubing Pressure & Leak Test Procedurezack zeeartNo ratings yet

- HVAC Flushing and Cleaning Method StatementDocument3 pagesHVAC Flushing and Cleaning Method StatementMohmed SaydNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 Mechkarthi51289100% (1)

- 1 SATIP-N-001-02 Hot InsulationDocument2 pages1 SATIP-N-001-02 Hot InsulationJithuJohnNo ratings yet

- Saep 1145Document20 pagesSaep 1145Amit shah100% (1)

- Hydrotest Procedure for Reinforced Thermosetting Epoxy-Resin PipesDocument13 pagesHydrotest Procedure for Reinforced Thermosetting Epoxy-Resin PipesMohammad Rizwan0% (1)

- Testing Procedure For Ball Valve MAPDocument16 pagesTesting Procedure For Ball Valve MAPbasuki100% (3)

- Method Statement - Soil InvestigationDocument10 pagesMethod Statement - Soil InvestigationKamal Deo ShahNo ratings yet

- Quality PlanDocument32 pagesQuality PlannayumNo ratings yet

- Iqwq Ce1091 Vphyt D7 9005 - 0Document5 pagesIqwq Ce1091 Vphyt D7 9005 - 0Bello Friday JacksonNo ratings yet

- Hydro Test ProcedureDocument11 pagesHydro Test ProcedureRohit SharmaNo ratings yet

- U Stamp ManualDocument57 pagesU Stamp ManualJayeshNarang100% (4)

- Gi-0002 102Document18 pagesGi-0002 102Md Azizul Mawla100% (2)

- 34 Hardness Tester 034Document2 pages34 Hardness Tester 034ASHOK KUMAR LENKANo ratings yet

- 1 SATIP-A-004-05 Leak Testing Per SAES-A-004 - Rev1Document1 page1 SATIP-A-004-05 Leak Testing Per SAES-A-004 - Rev1j fNo ratings yet

- 215-Operation and Calibration of Dissolution Apparatus (VDA-8D) New NewDocument4 pages215-Operation and Calibration of Dissolution Apparatus (VDA-8D) New NewDeepak ChaudharyNo ratings yet

- SOP QC-101 ASME B31.9 Shop and Field Inspection - Rev.1Document5 pagesSOP QC-101 ASME B31.9 Shop and Field Inspection - Rev.1iplaruffNo ratings yet

- G446-2900-DD-0140-0355 900-Tk-10abcDocument1 pageG446-2900-DD-0140-0355 900-Tk-10abcMohamed Reda Hussein SengarNo ratings yet

- G446-2900-DD-0140-0350-SHT 02 900-Tk-10abcDocument1 pageG446-2900-DD-0140-0350-SHT 02 900-Tk-10abcMohamed Reda Hussein SengarNo ratings yet

- G446-2900-DD-0140-0353 900-Tk-10abcDocument1 pageG446-2900-DD-0140-0353 900-Tk-10abcMohamed Reda Hussein SengarNo ratings yet

- J3868 Ibsf NP T 0092Document2 pagesJ3868 Ibsf NP T 0092Mohamed Reda Hussein SengarNo ratings yet

- Hotel BookingDocument2 pagesHotel BookingMohamed Reda Hussein SengarNo ratings yet

- Site Query: Tanmia For Oil and Construction LimitedDocument3 pagesSite Query: Tanmia For Oil and Construction LimitedMohamed Reda Hussein SengarNo ratings yet

- Gosp.12 PWS (26-April-2018 To 02-May-2018)Document2 pagesGosp.12 PWS (26-April-2018 To 02-May-2018)Mohamed Reda Hussein SengarNo ratings yet

- G446 2999 Itp 0140 002Document9 pagesG446 2999 Itp 0140 002Mohamed Reda Hussein SengarNo ratings yet

- Site Query: Tanmia For Oil and Construction LimitedDocument3 pagesSite Query: Tanmia For Oil and Construction LimitedMohamed Reda Hussein SengarNo ratings yet

- Onshore Maintain Potenstial Project (Ompp) - Prime Contractor'S (Nesma & Partners) Mobilization/Demobilization PlanDocument1 pageOnshore Maintain Potenstial Project (Ompp) - Prime Contractor'S (Nesma & Partners) Mobilization/Demobilization PlanMohamed Reda Hussein SengarNo ratings yet

- Site Query: Tanmia For Oil and Construction LimitedDocument3 pagesSite Query: Tanmia For Oil and Construction LimitedMohamed Reda Hussein SengarNo ratings yet

- Astm D698Document11 pagesAstm D698Mohamed Reda Hussein SengarNo ratings yet

- Welder Job Clearance Card Saudi AramcoDocument3 pagesWelder Job Clearance Card Saudi AramcoMohamed Reda Hussein SengarNo ratings yet

- SOP Galvanized Repair ProcessDocument4 pagesSOP Galvanized Repair ProcessMohamed Reda Hussein SengarNo ratings yet

- Straightening Procedure: (IBSF-J3868-STP-001-REV.A)Document3 pagesStraightening Procedure: (IBSF-J3868-STP-001-REV.A)Mohamed Reda Hussein SengarNo ratings yet

- Weld Mapping - Wellhead - Rev0Document13 pagesWeld Mapping - Wellhead - Rev0Mohamed Reda Hussein SengarNo ratings yet

- Welder Job Clearance Card: Nesma/TanmiaDocument8 pagesWelder Job Clearance Card: Nesma/TanmiaMohamed Reda Hussein SengarNo ratings yet

- Acrylonitrile-Butadiene-Styrene (ABS) Plastic Pipe, Schedules 40 and 80Document8 pagesAcrylonitrile-Butadiene-Styrene (ABS) Plastic Pipe, Schedules 40 and 80AndresBenitezNo ratings yet

- Astm D2241 (2000)Document8 pagesAstm D2241 (2000)Mohamed Reda Hussein SengarNo ratings yet

- Qdoc - Tips - Identification and TraceabilityDocument6 pagesQdoc - Tips - Identification and TraceabilityMohamed Reda Hussein SengarNo ratings yet

- Sample WPS Format PDFDocument1 pageSample WPS Format PDFait.koufiNo ratings yet

- Astm D1418Document3 pagesAstm D1418Mohamed Reda Hussein Sengar100% (2)

- Astm D2239 (2001)Document8 pagesAstm D2239 (2001)Mohamed Reda Hussein SengarNo ratings yet

- Weld Mapping - Tie-In - Rev0Document1 pageWeld Mapping - Tie-In - Rev0Mohamed Reda Hussein SengarNo ratings yet

- Quality Standard For Steel Castings For Valves, Flanges, and Fittings and Other Piping ComponentsDocument9 pagesQuality Standard For Steel Castings For Valves, Flanges, and Fittings and Other Piping ComponentsMohamed Reda Hussein SengarNo ratings yet

- RENDORC FC (FOSAM) Method Statement - CompressedDocument27 pagesRENDORC FC (FOSAM) Method Statement - CompressedMohamed Reda Hussein SengarNo ratings yet

- Item No. Location /section Comments 1: Special Process Procedure For Concrete Repair - MIP14Document2 pagesItem No. Location /section Comments 1: Special Process Procedure For Concrete Repair - MIP14Mohamed Reda Hussein SengarNo ratings yet

- Nematc22003 Electrical Polyvinyl Chloride PVC ConduitpdfDocument26 pagesNematc22003 Electrical Polyvinyl Chloride PVC ConduitpdfMohamed Reda Hussein SengarNo ratings yet

- Quality Standard For Steel Castings and Forgings For Valves, Flanges, and Fittings and Other Piping ComponentsDocument9 pagesQuality Standard For Steel Castings and Forgings For Valves, Flanges, and Fittings and Other Piping ComponentsMohamed Reda Hussein SengarNo ratings yet

- Sweeney in MaDocument21 pagesSweeney in Maashes_xNo ratings yet

- Scratch TutorialDocument9 pagesScratch TutorialRamirez CisnerosNo ratings yet

- Resume Audit InternalDocument6 pagesResume Audit InternalPatricia Alvani GultomNo ratings yet

- 5 DB Arithmetic PDFDocument85 pages5 DB Arithmetic PDFnadia_naaz90No ratings yet

- Steam Flow Through Safety Valve Vent PipesDocument11 pagesSteam Flow Through Safety Valve Vent PipesminhphuongphamNo ratings yet

- Audi RS4 Avant quattro technical documentationDocument62 pagesAudi RS4 Avant quattro technical documentationJustin Sandifer100% (1)

- Carbozinc 11.Document2 pagesCarbozinc 11.Jairo Gómez SánchezNo ratings yet

- Python The Complete Course For Beginners by TELCOMADocument177 pagesPython The Complete Course For Beginners by TELCOMARahul Kolambkar100% (1)

- US Army - Improvised Explosive Device (IED) Awareness Guide - Iraq and Afghanistan (2004) TC 9-21-01Document40 pagesUS Army - Improvised Explosive Device (IED) Awareness Guide - Iraq and Afghanistan (2004) TC 9-21-01Siniša Antunović MedoNo ratings yet

- 5G Small Cell Optimized Radio DesignDocument6 pages5G Small Cell Optimized Radio DesignOmar EscurraNo ratings yet

- NavigatorDocument40 pagesNavigatorCRIS SEDANTO100% (1)

- ! BOP Failure Presentation - 1473859760 - 2Document23 pages! BOP Failure Presentation - 1473859760 - 2toxa0707No ratings yet

- Red Taction PPTDocument21 pagesRed Taction PPTRam VBIT100% (3)

- Connect FourDocument12 pagesConnect FourtrollbaitNo ratings yet

- NHAI Quality Assurance ManualDocument308 pagesNHAI Quality Assurance Manualapi-374134093% (27)

- Selecion de Fusibles para Proteccion de TransformadoresDocument14 pagesSelecion de Fusibles para Proteccion de TransformadoresfreddyriveraNo ratings yet

- 2614Document24 pages2614ARULKUMARSUBRAMANIANNo ratings yet

- GEARBOXDocument16 pagesGEARBOXhyundai31050% (2)

- Est 1Document1 pageEst 1kanak2No ratings yet

- CTPAT Job Aid - 7-Point Container Inspection ChecklistDocument2 pagesCTPAT Job Aid - 7-Point Container Inspection ChecklistWilliam “Alex” OrozcoNo ratings yet

- CP4 Mycom ManualDocument246 pagesCP4 Mycom ManualJJG50% (2)

- CR M4SSDocument6 pagesCR M4SSTrần Khắc ĐộNo ratings yet

- AFS DLL For Maintain Estimated MaterialsDocument13 pagesAFS DLL For Maintain Estimated MaterialsIslam WayNo ratings yet

- Sultan Saed Al - Zahrani Est ProfileDocument60 pagesSultan Saed Al - Zahrani Est ProfileaayasirNo ratings yet

- Valve Body and Disc Test PlanDocument4 pagesValve Body and Disc Test PlanJuan GaunaNo ratings yet

- Collins WAAS FMS Quick Reference GuideDocument15 pagesCollins WAAS FMS Quick Reference GuideRaoul Penent d'Izarn100% (2)

- B0400EF - FoxboroDocument240 pagesB0400EF - FoxboroagapitolopesNo ratings yet

- ISO13849-1 Cat Je PDFDocument24 pagesISO13849-1 Cat Je PDFDan001500No ratings yet

- Transformer BIL and Surge Arrester Coordination StudyDocument15 pagesTransformer BIL and Surge Arrester Coordination Studyrajfab100% (1)

- Instalacion y Operacion Tablero Mando VariadorDocument95 pagesInstalacion y Operacion Tablero Mando VariadorGustavo HuertasNo ratings yet