Professional Documents

Culture Documents

Work Instruction Fabrication

Uploaded by

Aaron Perez0 ratings0% found this document useful (0 votes)

16 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views1 pageWork Instruction Fabrication

Uploaded by

Aaron PerezCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

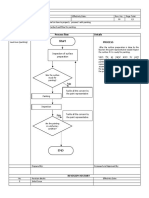

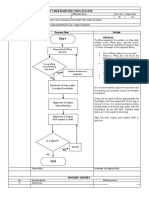

Work Instruction Title:

FABRICATION

WI. Ref NO Effectivity Date: Rev. No.: Page Total:

WI-RAJT-05 09.01.2020 00 1/1

PURPOSE: : To Inform operation personnel on how to properly proceed with frames and bulkhead fabrication.

SCOPE: : This procedure are the standard way of frames & bulkhead fabrication

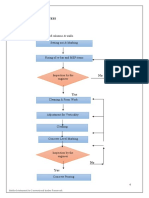

Responsible Process flow Details

Project Engineer

Lofts men PLANS REQUIRED:

Foreman Start midship plan

construction plan

lines plan

PROCESS

Plot the generated lines form at the Upon completion of mold lofting and generation of

lofting area to the fabrication area final lines plan the ship frame and bulkheads are

onsite now ready for fabrication.

Wooden patterns can be produced for complex full

forms such us forward or aft section for section such

us girders longitudinal or transverse bulkheads the

Form the transverse frame section following measurement are marked in Liston wood

for practicality.

using the lines plan as guide Baseline

Main deck Height

Stringer

Longitudinal frame spaces

The offset of the frame

Form the longitudinal sections by

using offsets marked on Liston wood For basic section shapes, t bars and bulkhead plate

to produce complex frame shapes can be fabricated as frames by forming them using

the lines plan as a guide

For longitudinal frame and bulkhead sections with

curved forms, plot the offset marked on Liston wood

directly on the steel plate to be utilized to produce

Fabricate the transverse and the section shape.

longitudinal bulkheads by using offsets Fabricate the transverse bulkhead by fitting up the

marked on Liston wood steel plates required and plot the offsets from Liston

wood to produce the bulkhead shape

END

Prepared by: Reviewed and Approved By:

JOHN ANGELO D. TULIAO ALLEN JAMES C. TULIAO

Operations Head Director

REVISION HISTORY

No. Revision details: Effectivity Date:

0 Initial Issue 09.01.2020

You might also like

- Manual of Engineering Drawing: British and International StandardsFrom EverandManual of Engineering Drawing: British and International StandardsRating: 3.5 out of 5 stars3.5/5 (4)

- Syllabus As Per WeightageDocument1 pageSyllabus As Per WeightageSatish VarakNo ratings yet

- Forming OriginalDocument16 pagesForming OriginalJulio QuitoNo ratings yet

- (En) Design of A Steel Beams and ColumnsDocument110 pages(En) Design of A Steel Beams and ColumnsVirmantas JuoceviciusNo ratings yet

- 400 Cross Sections Chapter: Supplement To Tac Geometric Design GuideDocument18 pages400 Cross Sections Chapter: Supplement To Tac Geometric Design GuideNesreen Ahmed NaoumNo ratings yet

- A Complete Package For Building Analysis, Design & Drawings: Salient FeaturesDocument4 pagesA Complete Package For Building Analysis, Design & Drawings: Salient FeaturesAHSANNo ratings yet

- Frame TypesDocument5 pagesFrame TypesmaheshbandhamNo ratings yet

- Work Instruction - Keel LayingDocument1 pageWork Instruction - Keel LayingAaron PerezNo ratings yet

- 3d Open Source Foam CutterDocument22 pages3d Open Source Foam CutterOtto GonzalezNo ratings yet

- Buckling Restrained Braces Standards Developments and Innovative Applications RobinsonDocument7 pagesBuckling Restrained Braces Standards Developments and Innovative Applications RobinsonAnonymous DwRdnPTXY0No ratings yet

- Effective Span Length: 139 Concrete Deck SlabsDocument5 pagesEffective Span Length: 139 Concrete Deck SlabsJohn Royer Araúz Fuentes100% (1)

- Structural Analysis, Design & Detailing SoftwareDocument6 pagesStructural Analysis, Design & Detailing SoftwareSrajeshK0% (1)

- Structural Steel Design BowlesDocument276 pagesStructural Steel Design BowlesCafeo Wine100% (1)

- 1 Check of I Shaped Members and Channels Subject To Combined Axial Compression and FlexureDocument15 pages1 Check of I Shaped Members and Channels Subject To Combined Axial Compression and FlexureMahmoud El-KatebNo ratings yet

- And Vallev Frarmng: Gutter Track Ground Line. LatticeDocument2 pagesAnd Vallev Frarmng: Gutter Track Ground Line. LatticeRobertNo ratings yet

- Resumen de BRB Star Seismic 2 PDFDocument8 pagesResumen de BRB Star Seismic 2 PDFRodrigo SilvaNo ratings yet

- Unit 7 Design of Plate Girders: StructureDocument54 pagesUnit 7 Design of Plate Girders: StructureManinder ChaudharyNo ratings yet

- STRUCTURESDocument48 pagesSTRUCTURESartynskuNo ratings yet

- Amm 215-216 197Document6 pagesAmm 215-216 197james bondNo ratings yet

- Acople ELASTICO1Document6 pagesAcople ELASTICO1Oscar CamposNo ratings yet

- 97 2.0f AboutDocument12 pages97 2.0f AboutAndrea GibsonNo ratings yet

- Rapid Prototype Propeller Manufacturing Tech 2019060803Document4 pagesRapid Prototype Propeller Manufacturing Tech 2019060803장영훈No ratings yet

- Boiler Design AutomationDocument61 pagesBoiler Design Automationsdiaman100% (2)

- Bar Bending Schedule For Tie Beams - Strap Beams - Reinforcement DetailDocument14 pagesBar Bending Schedule For Tie Beams - Strap Beams - Reinforcement DetailAman JhaNo ratings yet

- Introduction of E TabsDocument18 pagesIntroduction of E TabsneerajNo ratings yet

- A Finite Element Method Based Process Model For Prediction of Spring Back During Forming of PFBR VesselsDocument2 pagesA Finite Element Method Based Process Model For Prediction of Spring Back During Forming of PFBR VesselssreeshpsomarajanNo ratings yet

- Autoplotter With Road Estimator Software PDFDocument4 pagesAutoplotter With Road Estimator Software PDFpediredlakumar50% (2)

- ETABS Presentation 1Document56 pagesETABS Presentation 1V.m. Rajan100% (9)

- Plate Girder and Its ComponentsDocument6 pagesPlate Girder and Its Componentsing_fernandogalvez2015100% (2)

- RAPT - PT Slab and Beam Design Procedure Rev01Document17 pagesRAPT - PT Slab and Beam Design Procedure Rev01AlirezaNo ratings yet

- Integrated Hull Construction Outfitting and Painting (IHOP) - 2.dioDocument33 pagesIntegrated Hull Construction Outfitting and Painting (IHOP) - 2.diocappoxNo ratings yet

- PLMCC, Jssate-Step, Noida 1 of 7Document7 pagesPLMCC, Jssate-Step, Noida 1 of 7Đình Tước VũNo ratings yet

- Designflex Shapes - Lyra, Calla, Optima, Ultima, Metalworks PanelsDocument3 pagesDesignflex Shapes - Lyra, Calla, Optima, Ultima, Metalworks PanelsRaluca VlNo ratings yet

- Design of Deep Beams and JointsDocument92 pagesDesign of Deep Beams and JointsChakraphan Wuttimuagkwan0% (1)

- Conventional Timber FormworksDocument6 pagesConventional Timber FormworksLasantha WeerasekaraNo ratings yet

- Applied Sciences: Flexural and Shear Performance of Prestressed Composite Slabs With Inverted Multi-RibsDocument19 pagesApplied Sciences: Flexural and Shear Performance of Prestressed Composite Slabs With Inverted Multi-Ribsسجى وليدNo ratings yet

- Design Aspects of Column BasesDocument22 pagesDesign Aspects of Column BasesDhananjay DesaleNo ratings yet

- Erection ManualDocument20 pagesErection ManualJose Arthur AbellaNo ratings yet

- Evo Design Structural Design: Calculation SheetDocument5 pagesEvo Design Structural Design: Calculation SheetBhavishya LahariNo ratings yet

- 5 Design of Steel Truss FootbridgeDocument106 pages5 Design of Steel Truss FootbridgePAYANGDO100% (2)

- Design of Continuity Slabs and The Metro Viaduct Designs PDFDocument6 pagesDesign of Continuity Slabs and The Metro Viaduct Designs PDFraviNo ratings yet

- ObjectivesDocument17 pagesObjectivesChimchim MorgensternNo ratings yet

- Computation: Reinforced Concrete Rectangular Pad Footing DesignDocument5 pagesComputation: Reinforced Concrete Rectangular Pad Footing DesignJamil AlhamatyNo ratings yet

- Brochure AVEVA InitialDesign PDFDocument4 pagesBrochure AVEVA InitialDesign PDFRoni VincentNo ratings yet

- Brochure AVEVA Initial DesignDocument4 pagesBrochure AVEVA Initial DesignJonathen HormenNo ratings yet

- Evo Design - Structural Design: Calculation SheetDocument4 pagesEvo Design - Structural Design: Calculation SheetVij Vaibhav VermaNo ratings yet

- Design of Combined FootingsDocument7 pagesDesign of Combined FootingsFrank StephensNo ratings yet

- Optimum Design of Reinforced Concrete Flat Slab With Drop PanelDocument3 pagesOptimum Design of Reinforced Concrete Flat Slab With Drop PanelAmit HSNo ratings yet

- Forming Operations Performed On Presses and HammersDocument11 pagesForming Operations Performed On Presses and HammerssachinkashidNo ratings yet

- Why Build MasterDocument2 pagesWhy Build MasterAHSANNo ratings yet

- Building ConstDocument38 pagesBuilding ConstRoyal BlueNo ratings yet

- 1 Building Const 1Document38 pages1 Building Const 1ashleyane garlanNo ratings yet

- 03 01 - Sup BD PDFDocument66 pages03 01 - Sup BD PDFجميل عبد الله الحماطيNo ratings yet

- Joints in Steel Construction - Simple Connections - Part 07 PDFDocument56 pagesJoints in Steel Construction - Simple Connections - Part 07 PDFkakem61No ratings yet

- Bolt Design For Repeated LoadingDocument13 pagesBolt Design For Repeated LoadingConradodaMattaNo ratings yet

- LVTSL004 Grundfos - Peerless VT Pump BrochureDocument5 pagesLVTSL004 Grundfos - Peerless VT Pump BrochuredanilobossuNo ratings yet

- Cross-Section Property Calculator: New DXF Link With 3D Visualization, Layer Control and FilDocument2 pagesCross-Section Property Calculator: New DXF Link With 3D Visualization, Layer Control and Filrutgers_vNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Po403 - FSC - Eco Ii Drydocking WorksDocument1 pagePo403 - FSC - Eco Ii Drydocking WorksAaron PerezNo ratings yet

- Astm19 0101Document4 pagesAstm19 0101Aaron PerezNo ratings yet

- Qf-Fsc-Le-002 - Ship Repair AgreementDocument2 pagesQf-Fsc-Le-002 - Ship Repair AgreementAaron PerezNo ratings yet

- PG70ABDLDocument30 pagesPG70ABDLAaron PerezNo ratings yet

- Astm Volume 01 02Document8 pagesAstm Volume 01 02Aaron PerezNo ratings yet

- Work Instruction - Keel LayingDocument1 pageWork Instruction - Keel LayingAaron PerezNo ratings yet

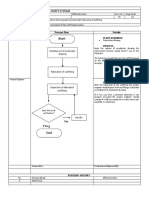

- Work Instruction - PaintingDocument1 pageWork Instruction - PaintingAaron PerezNo ratings yet

- Work Instruction - Installation of Machineries - Main EngineDocument1 pageWork Instruction - Installation of Machineries - Main EngineAaron PerezNo ratings yet

- Work Instruction - Installation of Underwater - Tailshaft and PropellerDocument2 pagesWork Instruction - Installation of Underwater - Tailshaft and PropellerAaron PerezNo ratings yet

- Work Instruction - Fabrication of OutfittingsDocument1 pageWork Instruction - Fabrication of OutfittingsAaron PerezNo ratings yet

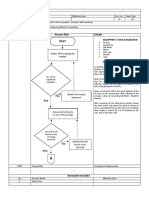

- Work Instruction - Mold LoftingDocument2 pagesWork Instruction - Mold LoftingAaron PerezNo ratings yet

- Work Instruction LaunchingDocument3 pagesWork Instruction LaunchingAaron PerezNo ratings yet

- Astm21 0303Document12 pagesAstm21 0303Aaron PerezNo ratings yet

- TDS-Flaw Crack Detector SystemDocument2 pagesTDS-Flaw Crack Detector SystemAaron PerezNo ratings yet

- Work Instruction - WeldingDocument1 pageWork Instruction - WeldingAaron PerezNo ratings yet

- Church Program 1Document2 pagesChurch Program 1Aaron PerezNo ratings yet

- Ardrox 970P25E 6.5.15Document2 pagesArdrox 970P25E 6.5.15Aaron PerezNo ratings yet

- 218CH047Document6 pages218CH047Aaron PerezNo ratings yet

- 216 NR - 2022 07Document363 pages216 NR - 2022 07Aaron PerezNo ratings yet

- Mitsubishi 4g13 Engine ManualDocument6 pagesMitsubishi 4g13 Engine ManualJose Luis Caceres Severino100% (1)

- Java SampleExamQuestionsDocument18 pagesJava SampleExamQuestionshmasryNo ratings yet

- Astm A769 PDFDocument5 pagesAstm A769 PDFCristian OtivoNo ratings yet

- Chapter.8: Oscillators: ObjectivesDocument13 pagesChapter.8: Oscillators: ObjectivessivasankarnaiduNo ratings yet

- Factors That Affect The Quality of CommunicationDocument9 pagesFactors That Affect The Quality of CommunicationWilliam Paras Inte100% (3)

- 3500 91 Egd Communication Gateway Module Datasheet 0Document6 pages3500 91 Egd Communication Gateway Module Datasheet 0dikastaloneNo ratings yet

- GeomediaDocument37 pagesGeomediaEdilson MahumaneNo ratings yet

- Revised Malaysian Code of Practice For Structural Use of TimberDocument6 pagesRevised Malaysian Code of Practice For Structural Use of Timbermcwong_98No ratings yet

- Investigate The Natural Time Period, Base Shear, Displacement, Story Drift, Story Stiffness by Etabs and Staad ProDocument4 pagesInvestigate The Natural Time Period, Base Shear, Displacement, Story Drift, Story Stiffness by Etabs and Staad ProEditor IJTSRDNo ratings yet

- PSC Girder MethodologyDocument12 pagesPSC Girder MethodologySaurabh KumarNo ratings yet

- Debug 1214Document3 pagesDebug 1214Anonymous B4WiRjNo ratings yet

- Variable Displacements Axial Piston Pumps: Edition: 06/06.2020 Replaces: MVP 05 T ADocument72 pagesVariable Displacements Axial Piston Pumps: Edition: 06/06.2020 Replaces: MVP 05 T ARidha AbbassiNo ratings yet

- SYNC2000 - 4.00.022014 Protocol ConverterDocument2 pagesSYNC2000 - 4.00.022014 Protocol ConverterAnasSalemNo ratings yet

- 4 Contamination Control 2Document61 pages4 Contamination Control 2Vijay RajaindranNo ratings yet

- Method Statement of Pipeline WorksDocument13 pagesMethod Statement of Pipeline Worksमनिसभेटुवाल86% (21)

- Dataproducts - LZR 1260 Laser Printer (1989)Document6 pagesDataproducts - LZR 1260 Laser Printer (1989)Bobby ChippingNo ratings yet

- Physical Pharmacy Answer Key BLUE PACOPDocument34 pagesPhysical Pharmacy Answer Key BLUE PACOPprincessrhenetteNo ratings yet

- ARSTRUCTS Chapter1Document15 pagesARSTRUCTS Chapter1Aila MaeNo ratings yet

- Unit 5 GeosyntheticsDocument315 pagesUnit 5 Geosyntheticskowshik1737551No ratings yet

- Ehe 07Document286 pagesEhe 07api-348272721No ratings yet

- IMDSDocument13 pagesIMDSJohn OoNo ratings yet

- db2v9 EsqlDocument419 pagesdb2v9 EsqlRaphael PugliesiNo ratings yet

- Engineering Department ProcedureDocument29 pagesEngineering Department ProcedureOmar Ahmed Elkhalil100% (1)

- Karcher K - 791 - MDocument12 pagesKarcher K - 791 - MJoão Paulo FernandesNo ratings yet

- CP R70 Smart View Monitor Admin GuideDocument106 pagesCP R70 Smart View Monitor Admin Guideoorhan41No ratings yet

- Customizing The ADFS Sign-In PagesDocument4 pagesCustomizing The ADFS Sign-In Pagesmicu0% (1)

- All Over India Company DataDocument32 pagesAll Over India Company DataViren PatelNo ratings yet

- UntitledDocument34 pagesUntitledRayudu VVSNo ratings yet

- Invalid Keyword Argument Python - December 25 2017Document3 pagesInvalid Keyword Argument Python - December 25 2017Kaleab TekleNo ratings yet

- Master Antenna Television System and Satellite SystemDocument6 pagesMaster Antenna Television System and Satellite SystemMHEP_DANIELNo ratings yet