Professional Documents

Culture Documents

Shearing Machine

Uploaded by

Jagadesh POriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shearing Machine

Uploaded by

Jagadesh PCopyright:

Available Formats

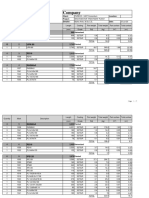

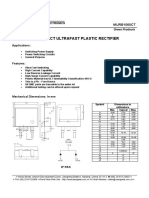

XBar & R chart

PROCESS… PART… GAUGE…

Process SHEARING Description NAA347HC Description VERNIER CALIPER ME-VC-31

Work Cell MFG CELL Feature LENGTH Resolution 0.02

Factory MALLIK Upper spec 2.00 R&R 3.14%

Location Bangalore Target 1296 U/M mm P/T

Contact 7259029860 Lower spec 0.00 Study month Jul-22

Reference NAA347HC Calibration due 2/1/2023

Date 05.07.2022 05.07.2022 08.07.2022 09.07.2022 10.07.2022 12.07.2022 13.07.2022

Time

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27

X1 1.14 1.28 1.24 1.04 1.18 1.06 0.88

X2 0.92 0.90 1.10 1.10 1.26 1.24 1.06

X3 1.24 0.84 1.32 0.92 1.02 0.96 1.02

X4

X5

X6

Xbar 1.10 1.01 1.22 1.02 1.15 1.09 0.99

R 0.32 0.44 0.22 0.18 0.24 0.28 0.18

Enter "C" to display calculated limits

Sbgrp size: 3 C Enter "U" to display user-provided limits

Xbar Chart

2

1.8

1.6

1.4

1.2

0.8

0.6

0.4

0.2

R Chart

1

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

Control Chart Constants Calculated Limits User Provided

n d2 A2 D4 Control Limits

IXMR 1 1.128 2.660 3.267 Rbar = 0.265714285714286 RCL 0.15

XbarR 2 1.128 1.880 3.267 UCLR = (Rbar)(D4) = 0.265714285714286 x 2.574 = 0.6839485714286 UCLR 0.2

3 1.693 1.023 2.574 Xdouble bar = 1.08190476190476 XCL 0

4 2.059 0.729 2.282 UCLXbar = Xdbl bar + (A2)(Rbar) = 1.08190476190476 + ( 1.023 x 0.2657142857143 ) = 1.354 UCLX 0.72

? !

I

Facility/Location: MALLIK

Capability (Cp, Cpk) Calculator Process: MFG

KPI / O: KPI

Key characteristic: Length

Month of study: JULY

Study manager: MUTHU

Gauge used: VERNIER CALIPER

MEASUREMENT SYSTEM INFORMATION: Gauge resolution: 0.02 mm

GR&R results: 3.14%

Based on an examination of the associated control chart, does

the process appear to be in a state of statistical control (Y/N)? Y

Cp Cpk

Lower Engineering Process Average‡

Specification Limit: LSL = 0.00 * from control chart: Xbar = 1.082 *

Upper Engineering

Specification Limit: USL = 2.00 * Upper Available Tolerance:

UAT = USL - Xbar

UAT = 0.9180952

Engineering Target:

(Used only if spec is two-sided)

T= 1296.00 * Lower Available Tolerance:

LAT = Xbar - LSL

LAT = 1.0819048

Upper Process

Specification type Type -- §

and skewness

Capability Index CpU = 1.96

Skew n/a CpU = 2 x UAT / NV

Engineering Lower Process

Tolerance: ET = -- § Capability Index CpL = 2.30

ET = USL - LSL CpL = 2 x LAT / NV

Average Range† Process Capability Index:

from control chart:

Rbar = 0.265 * Cpk = min(CpU, CpL)

Cpk = 1.96

Number of measurements Modified Capability Index:

in each sample for which

a range was calculated:

n= 3 * Cpk' = min(Cp, Cpk) Cpk' = -- «

Standard deviation:

(Required if data are not time-ordered,

or if process is not in statistial control.)

s= * Enter "P" for Performance

Indices (Pp& Ppk)

Performance indices require

a standard deviation (s) entry.

Appropriate d2 for

the sample of size n: d2 = 1.693 NOTES:

† Use MRbar if IX-MR control chart was used.

Natural Variation of the process ‡ Use Xdouble bar if Xbar & R control chart was used.

NV = 6 x Rbar / d2

NV = 0.939 * User supplied data.

« Applies only when target is not centered in spec.

Potential § Target is not bracketed by LSL and USL. Be sure LSL < T <

Process Capability Cp = -- USL.

Cp = ET / NV

Table of d2 values:

n d2 Engineering Tolerance (ET) & Process Variation (NT) n

2 1.128

3 1.693

Proc. Var,

4 2.059 NV

5 2.326

6 2.534 Spec, ET Tgt

2.534

7 2.704

8 2.847 2.847

2.847

9 2.970 0 200 400 600 800 1000 1200 1400

10 3.078 3.078

3.078

3.078

3.078

3.078

You might also like

- Chapter 6 Strategy Analysis and Choice: Strategic Management: A Competitive Advantage Approach, 16e (David)Document27 pagesChapter 6 Strategy Analysis and Choice: Strategic Management: A Competitive Advantage Approach, 16e (David)Masum ZamanNo ratings yet

- Prometric Questions-1 AnswersDocument45 pagesPrometric Questions-1 AnswersNina Grace Joy Marayag-Alvarez100% (1)

- Installation of Submarine PE PipesDocument84 pagesInstallation of Submarine PE Pipeswaseemiqbal133100% (2)

- Cummins: ISX15 CM2250Document17 pagesCummins: ISX15 CM2250haroun100% (4)

- Time Box 1 Box 2 Box 3 Box 4 Sample Means Sample RangeDocument7 pagesTime Box 1 Box 2 Box 3 Box 4 Sample Means Sample RangevrankNo ratings yet

- Gracella Irwana - G - Pert 04 - Sia - 1Document35 pagesGracella Irwana - G - Pert 04 - Sia - 1Gracella IrwanaNo ratings yet

- The Limits of The Sectarian Narrative in YemenDocument19 pagesThe Limits of The Sectarian Narrative in Yemenهادي قبيسيNo ratings yet

- Literature Review - Part Time Job Among StudentDocument3 pagesLiterature Review - Part Time Job Among StudentMarria65% (20)

- Machine Capability For Welding-Mar-2019Document2 pagesMachine Capability For Welding-Mar-2019Jagadesh PNo ratings yet

- PB04Document2 pagesPB04Jagadesh PNo ratings yet

- TPP2Document2 pagesTPP2Jagadesh PNo ratings yet

- TPP1Document2 pagesTPP1Jagadesh PNo ratings yet

- Naa347fy (PP-01) Machine CapabilityDocument2 pagesNaa347fy (PP-01) Machine CapabilityJagadesh PNo ratings yet

- Naa347hj (LC-01) Machine CapabilityDocument2 pagesNaa347hj (LC-01) Machine CapabilityJagadesh PNo ratings yet

- Machine Capability - SPOT Welding - Platform Width (+ - 1.2)Document2 pagesMachine Capability - SPOT Welding - Platform Width (+ - 1.2)Jagadesh PNo ratings yet

- Overlay Determination-231127Document23 pagesOverlay Determination-231127adnan qadirNo ratings yet

- Seccion G2: Orientación ÁnguloDocument21 pagesSeccion G2: Orientación ÁnguloCCL CONSULTORIANo ratings yet

- Seccion G2: Orientación ÁnguloDocument21 pagesSeccion G2: Orientación ÁnguloCCL CONSULTORIANo ratings yet

- Form / Format Gauge Repeatability & Reproducibility Report: CapacitorDocument4 pagesForm / Format Gauge Repeatability & Reproducibility Report: CapacitorhimanshuNo ratings yet

- Anexo 4.2. Optimizacion de Una Columna de DestilacionDocument2 pagesAnexo 4.2. Optimizacion de Una Columna de DestilacionDanny GutierrezNo ratings yet

- Gage R&R-part To Part-ToleranceDocument5 pagesGage R&R-part To Part-ToleranceTiếnTrầnHồVănNo ratings yet

- SQC Problems1Document35 pagesSQC Problems1Vedank ParasharNo ratings yet

- Ethyl Lysergate-Fumarate HNMRDocument5 pagesEthyl Lysergate-Fumarate HNMRmlphoneuseNo ratings yet

- Mbr1060Ctl Schottky Rectifier: Sangdest Microelectronics Green ProductsDocument6 pagesMbr1060Ctl Schottky Rectifier: Sangdest Microelectronics Green ProductsManos MagicasNo ratings yet

- Page 1 - 10Document8 pagesPage 1 - 10Hoàng Vỹ PhạmNo ratings yet

- Bousekaa, Ahmed 10223 Ascan Calc-Report 202211241453Document1 pageBousekaa, Ahmed 10223 Ascan Calc-Report 202211241453Abderrahim Rahim SekakNo ratings yet

- Part No. & Name: Gauge Name:/ Micrometer Date 20.1.18 Characteristics: Outside Diameter Specification: SKSDocument11 pagesPart No. & Name: Gauge Name:/ Micrometer Date 20.1.18 Characteristics: Outside Diameter Specification: SKSPraveen kumarNo ratings yet

- Assemblies-Blower HouseDocument22 pagesAssemblies-Blower HouseMarko AnticNo ratings yet

- Stock Data AnalysisDocument9 pagesStock Data AnalysisUmaima hafeezNo ratings yet

- 1.6 Q4Document3 pages1.6 Q4Muhuseen ThajudeenNo ratings yet

- Umbilical CalDocument1 pageUmbilical CalThejus PrakashNo ratings yet

- Bodine-Electric Standard Products CatalogDocument44 pagesBodine-Electric Standard Products CatalogAlexanderNaranjoOsorioNo ratings yet

- BCDocument1 pageBCmedtsl.cppNo ratings yet

- Beam Design ReportDocument57 pagesBeam Design ReportOkechukwu NwaewoNo ratings yet

- BC Outdoor AcDocument1 pageBC Outdoor Acmedtsl.cppNo ratings yet

- Customer Pt. Unilever Indon Esia Project Name Spiral Conveyor System Project Number C075. 00131 CommisionDocument14 pagesCustomer Pt. Unilever Indon Esia Project Name Spiral Conveyor System Project Number C075. 00131 CommisionParama Ahmad ParahitaNo ratings yet

- G R&RDocument12 pagesG R&Rpradeep kumarNo ratings yet

- Tax CalculationDocument6 pagesTax CalculationancillajoyceNo ratings yet

- Threaded RodDocument1 pageThreaded RodDhanu goswamiNo ratings yet

- AC Fans Static Calculation Final-1Document20 pagesAC Fans Static Calculation Final-1Hendrias A.SNo ratings yet

- Cold-Formed Steel Design CheckDocument2 pagesCold-Formed Steel Design CheckLuís OliveiraNo ratings yet

- 1H NMR Standard - TriPhenylPhospheneOxideDocument2 pages1H NMR Standard - TriPhenylPhospheneOxidedaniel sihyunNo ratings yet

- Beam Design ReportDocument57 pagesBeam Design ReportOkechukwu NwaewoNo ratings yet

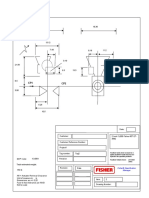

- CP2 CP1: Fisher® Specification ManagerDocument1 pageCP2 CP1: Fisher® Specification ManagerEdison ArotaypeNo ratings yet

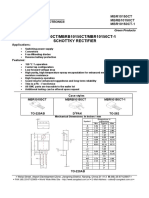

- MBR10150CT/MBRB10150CT/MBR10150CT-1 Schottky Rectifier: Sangdest MicroelectronicsDocument6 pagesMBR10150CT/MBRB10150CT/MBR10150CT-1 Schottky Rectifier: Sangdest MicroelectronicsJOHN BRICCO A. MATACSILNo ratings yet

- Molding Power Inductors: FeaturesDocument5 pagesMolding Power Inductors: FeaturesPușcă MartinNo ratings yet

- General Information: Location A Location BDocument3 pagesGeneral Information: Location A Location BZayed SyedNo ratings yet

- Bu 9348 KDocument3 pagesBu 9348 KbinkyfishNo ratings yet

- Hybrid Stepper Motors 24HS SeriesDocument4 pagesHybrid Stepper Motors 24HS SeriesMike ChanNo ratings yet

- Part Inspection Report: 458519100 Cover Plate 4/12/2021 NILDocument3 pagesPart Inspection Report: 458519100 Cover Plate 4/12/2021 NILRohit QualityNo ratings yet

- Control Chart Constants and FormulaeDocument3 pagesControl Chart Constants and FormulaeBen DesireNo ratings yet

- DAIF, AHMED 54123 AScan Calc-Report 2022112154638Document1 pageDAIF, AHMED 54123 AScan Calc-Report 2022112154638Abderrahim Rahim SekakNo ratings yet

- CNC Final Project-Ramiro AcostaDocument7 pagesCNC Final Project-Ramiro AcostaRamiro Acosta CepedaNo ratings yet

- SBCW 12311Document5 pagesSBCW 12311Johnrenald SuelloNo ratings yet

- Maryke - Detail Summary Estimate 2021-2022Document15 pagesMaryke - Detail Summary Estimate 2021-2022marlina elisabethNo ratings yet

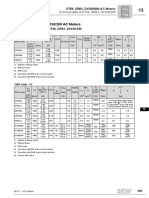

- 13 DT56, DR63, DV250/280 AC MotorsDocument36 pages13 DT56, DR63, DV250/280 AC MotorsSaim PAKERNo ratings yet

- 110minh LC03 13CDocument3 pages110minh LC03 13CThe vinh BuiNo ratings yet

- Murb1060Ct Ultrafast Plastic Rectifier: Sangdest Microelectronics Green ProductsDocument5 pagesMurb1060Ct Ultrafast Plastic Rectifier: Sangdest Microelectronics Green ProductsJOHN BRICCO A. MATACSILNo ratings yet

- Najran Ra.02 P442 PSB Reach TestDocument3 pagesNajran Ra.02 P442 PSB Reach TestkarthikNo ratings yet

- FWD Analysis Using Aashto Equation Anad Calaculation of Overlay Thickness071223Document69 pagesFWD Analysis Using Aashto Equation Anad Calaculation of Overlay Thickness071223adnan qadirNo ratings yet

- One Kstepped ATTDocument3 pagesOne Kstepped ATTasdNo ratings yet

- Detail: 76,000 Dwt Bulk Carrier 76,000吨散货轮Document6 pagesDetail: 76,000 Dwt Bulk Carrier 76,000吨散货轮Jagmohan SinghNo ratings yet

- Bi C012 E-Side FullDocument9 pagesBi C012 E-Side FullChe Amar Shafiq Che BaharumNo ratings yet

- General Information: Location A Location BDocument3 pagesGeneral Information: Location A Location BAsrafur RahmanNo ratings yet

- Report Vibrasi Plant CP-2Document13 pagesReport Vibrasi Plant CP-2hafiz_hayat_44190215No ratings yet

- REPORTDocument8 pagesREPORThabib azka ramaNo ratings yet

- Materials Management - 1 - Dr. VP - 2017-18Document33 pagesMaterials Management - 1 - Dr. VP - 2017-18Vrushabh ShelkarNo ratings yet

- Sistemas de Mando CST Cat (Ing)Document12 pagesSistemas de Mando CST Cat (Ing)Carlos Alfredo LauraNo ratings yet

- Krishna TejaDocument71 pagesKrishna TejaHimanshu GaurNo ratings yet

- Te-Chemical Sem5 CPNM-CBCGS Dec19Document2 pagesTe-Chemical Sem5 CPNM-CBCGS Dec19Mayank ShelarNo ratings yet

- Student Research Project Science ReportDocument8 pagesStudent Research Project Science Reportapi-617553177No ratings yet

- Defining The Standards For Medical Grade Honey PDFDocument12 pagesDefining The Standards For Medical Grade Honey PDFLuis Alberto GarcíaNo ratings yet

- 3DS 2017 GEO GEMS Brochure A4 WEBDocument4 pages3DS 2017 GEO GEMS Brochure A4 WEBlazarpaladinNo ratings yet

- Teamcenter 10.1: Publication Number PLM00015 JDocument122 pagesTeamcenter 10.1: Publication Number PLM00015 JmohanNo ratings yet

- (Ebook - Antroposofia - EnG) - Rudolf Steiner - Fundamentals of TheraphyDocument58 pages(Ebook - Antroposofia - EnG) - Rudolf Steiner - Fundamentals of Theraphyblueyes247No ratings yet

- The Teacher Research Movement: A Decade Later: Cite This PaperDocument13 pagesThe Teacher Research Movement: A Decade Later: Cite This PaperAlexandre NecromanteionNo ratings yet

- What Is The Difference Between Newtonian and Non-Newtonian Fluid and Give Example For Each Case?Document11 pagesWhat Is The Difference Between Newtonian and Non-Newtonian Fluid and Give Example For Each Case?MOHAMED ABD ELGHANYNo ratings yet

- NauseaDocument12 pagesNauseakazakom100% (2)

- DOT RequirementsDocument372 pagesDOT RequirementsMuhammadShabbirNo ratings yet

- Amerex Ansul Badger Ul Catalogo Por PartesDocument37 pagesAmerex Ansul Badger Ul Catalogo Por PartesPuma De La Torre ExtintoresNo ratings yet

- Debate Brochure PDFDocument2 pagesDebate Brochure PDFShehzada FarhaanNo ratings yet

- Lesson Plan Letter SDocument4 pagesLesson Plan Letter Sapi-317303624100% (1)

- Level I 2018 2019 Program Changes PDFDocument2 pagesLevel I 2018 2019 Program Changes PDFMuhammad BurairNo ratings yet

- Lord of The Flies - Chapter Comprehension QuestionsDocument19 pagesLord of The Flies - Chapter Comprehension Questionsjosh johnsyNo ratings yet

- Solid Waste Management in The World's Cities, UN-HABITAT: January 2010Document17 pagesSolid Waste Management in The World's Cities, UN-HABITAT: January 2010Rajasri SNo ratings yet

- 03 IGT-Influence of Codes Guidelines and Other Regulations On The Tunnel Design in AustriaDocument48 pages03 IGT-Influence of Codes Guidelines and Other Regulations On The Tunnel Design in AustriaSudarshan GadalkarNo ratings yet

- New Microsoft Word DocumentDocument3 pagesNew Microsoft Word DocumentAditya ShanbhagNo ratings yet

- C103 - General Checklist - ISO-IEC 17025:2017 Accreditation of Field Testing and Field Calibration LaboratoriesDocument19 pagesC103 - General Checklist - ISO-IEC 17025:2017 Accreditation of Field Testing and Field Calibration LaboratorieshuidhyiuodghNo ratings yet

- Derivation Bragg's Snell Law PDFDocument4 pagesDerivation Bragg's Snell Law PDFVaswati BiswasNo ratings yet