Professional Documents

Culture Documents

Naa347hj (LC-01) Machine Capability

Uploaded by

Jagadesh POriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Naa347hj (LC-01) Machine Capability

Uploaded by

Jagadesh PCopyright:

Available Formats

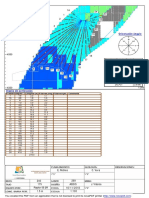

XBar & R chart

PROCESS… PART… GAUGE…

Process BENDING Description NAA347HJ Description VERNIER CALIPER

Work Cell MFG CELL Feature LENGTH Resolution 0.01

Factory STIPL Upper spec 15.20 R&R

Location Bangalore Target 15 U/M mm P/T

Contact 7259029860 Lower spec 14.80 Study month Sep-19

Reference NAA347HJ Calibration due 25.07.2020

Date 03.09.2019 04.09.2019 05.09.2019 06.09.2019 07.09.2019 09.09.2019 10.09.2019

Time

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27

X1 15.05 15.02 15.04 15.03 15.04 14.98 15.02

X2 15.03 14.97 15.02 14.97 15.02 14.99 14.96

X3 14.97 14.96 14.98 15.05 14.99 15.03 14.99

X4

X5

X6

Xbar 15.02 14.98 15.01 15.02 15.02 15.00 14.99

R 0.08 0.06 0.06 0.08 0.05 0.05 0.06

Enter "C" to display calculated limits

Sbgrp size: 3 C Enter "U" to display user-provided limits

Xbar Chart

15.2

15.15

15.1

15.05

15

14.95

14.9

14.85

14.8

R Chart

0.4

0.35

0.3

0.25

0.2

0.15

0.1

0.05

0

Control Chart Constants Calculated Limits User Provided

n d2 A2 D4 Control Limits

IXMR 1 1.128 2.660 3.267 Rbar = 0.062857142857142 RCL 0.15

XbarR 2 1.128 1.880 3.267 UCLR = (Rbar)(D4) = 0.062857142857142 x 2.574 = 0.1617942857143 UCLR 0.2

3 1.693 1.023 2.574 Xdouble bar = 15.0052380952381 XCL 0

4 2.059 0.729 2.282 UCLXbar = Xdbl bar + (A2)(Rbar) = 15.0052380952381 + ( 1.023 x 0.0628571428571 ) = 15.070 UCLX 0.72

? !

I

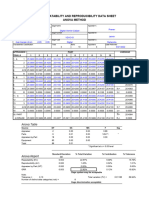

Facility/Location: STIPL

Capability (Cp, Cpk) Calculator Process: MFG

KPI / O: KPI

Key characteristic: HOLE REFERANCE

Month of study: Sept

Study manager: MANAS

Gauge used: VERNIER CALIPER

MEASUREMENT SYSTEM INFORMATION: Gauge resolution: 0.02 mm

GR&R results: 7.50%

Based on an examination of the associated control chart, does

the process appear to be in a state of statistical control (Y/N)? Y

Cp Cpk

Lower Engineering Process Average‡

Specification Limit: LSL = 14.80 * from control chart: Xbar = 15.005 *

Upper Engineering

Specification Limit: USL = 15.20 * Upper Available Tolerance:

UAT = USL - Xbar

UAT = 0.1947619

Engineering Target:

(Used only if spec is two-sided)

T= 15.00 * Lower Available Tolerance:

LAT = Xbar - LSL

LAT = 0.2052381

Upper Process

Specification type Type L --- T --- U

and skewness

Capability Index CpU = 1.77

Skew 0.00 CpU = 2 x UAT / NV

Engineering Lower Process

Tolerance: ET = 0.4 Capability Index CpL = 1.87

ET = USL - LSL CpL = 2 x LAT / NV

Average Range† Process Capability Index:

from control chart:

Rbar = 0.062 * Cpk = min(CpU, CpL)

Cpk = 1.77

Number of measurements Modified Capability Index:

in each sample for which

a range was calculated:

n= 3 * Cpk' = min(Cp, Cpk) Cpk' = -- «

Standard deviation:

(Required if data are not time-ordered,

or if process is not in statistial control.)

s= * Enter "P" for Performance

Indices (Pp& Ppk)

Performance indices require

a standard deviation (s) entry.

Appropriate d2 for

the sample of size n: d2 = 1.693 NOTES:

† Use MRbar if IX-MR control chart was used.

Natural Variation of the process ‡ Use Xdouble bar if Xbar & R control chart was used.

NV = 6 x Rbar / d2

NV = 0.220 * User supplied data.

« Applies only when target is not centered in spec.

Potential

Process Capability Cp = 1.82

Cp = ET / NV

Table of d2 values:

n d2 Engineering Tolerance (ET) & Process Variation (NT) n

2 1.128

3 1.693

Proc. Var,

4 2.059 NV

5 2.326

6 2.534 Tgt Spec, ET

2.534

7 2.704

8 2.847 2.847

2.847

9 2.970 14.75 14.8 14.85 14.9 14.95 15 15.05 15.1 15.15 15.2 15.25

10 3.078 3.078

3.078

3.078

3.078

3.078

You might also like

- Production and Operations ManagementDocument79 pagesProduction and Operations ManagementKishore Kumar63% (16)

- Six Sigma GB Workshop Assessment QuestionsDocument5 pagesSix Sigma GB Workshop Assessment QuestionsMohamed Asper100% (1)

- Performance Qualification and MaintenanceDocument19 pagesPerformance Qualification and MaintenanceApoloTrevinoNo ratings yet

- TPP1Document2 pagesTPP1Jagadesh PNo ratings yet

- XBar & R chart analysis of shearing process length capabilityDocument2 pagesXBar & R chart analysis of shearing process length capabilityJagadesh PNo ratings yet

- PB04Document2 pagesPB04Jagadesh PNo ratings yet

- TPP2Document2 pagesTPP2Jagadesh PNo ratings yet

- Machine Capability For Welding-Mar-2019Document2 pagesMachine Capability For Welding-Mar-2019Jagadesh PNo ratings yet

- Naa347fy (PP-01) Machine CapabilityDocument2 pagesNaa347fy (PP-01) Machine CapabilityJagadesh PNo ratings yet

- Machine Capability - SPOT Welding - Platform Width (+ - 1.2)Document2 pagesMachine Capability - SPOT Welding - Platform Width (+ - 1.2)Jagadesh PNo ratings yet

- Gage R&R-part To Part-ToleranceDocument5 pagesGage R&R-part To Part-ToleranceTiếnTrầnHồVănNo ratings yet

- XR Industrial - Gage R&RDocument1 pageXR Industrial - Gage R&Rlatasardina09No ratings yet

- Seccion G2: Orientación ÁnguloDocument21 pagesSeccion G2: Orientación ÁnguloCCL CONSULTORIANo ratings yet

- Seccion G2: Orientación ÁnguloDocument21 pagesSeccion G2: Orientación ÁnguloCCL CONSULTORIANo ratings yet

- Voltage Drop Calculation for Bulk CarrierDocument6 pagesVoltage Drop Calculation for Bulk CarrierJagmohan SinghNo ratings yet

- Data Sheet: PQ Cores and AccessoriesDocument6 pagesData Sheet: PQ Cores and AccessoriesLimitedNo ratings yet

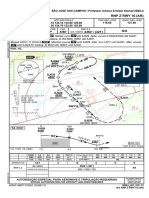

- JeppView - RJBB (26 Charts)Document36 pagesJeppView - RJBB (26 Charts)Seyi WilliamsNo ratings yet

- SBJV - Rnav CTB 1e - Raxit 1e Rwy 15 - Star - 20221006Document1 pageSBJV - Rnav CTB 1e - Raxit 1e Rwy 15 - Star - 20221006gameplayPSNo ratings yet

- SBRJ Rnp-E-Rwy-20l Iac 20221006Document2 pagesSBRJ Rnp-E-Rwy-20l Iac 20221006Luiz SantosNo ratings yet

- Msa (25.40)Document1 pageMsa (25.40)Quality VenusNo ratings yet

- Form / Format Gauge Repeatability & Reproducibility Report: CapacitorDocument4 pagesForm / Format Gauge Repeatability & Reproducibility Report: CapacitorhimanshuNo ratings yet

- (IAC) RNP B Rwy 02R: N/A N/ADocument2 pages(IAC) RNP B Rwy 02R: N/A N/Athiagoteles0No ratings yet

- Demoboard 900 MHZ Lna With The Bga2003: Application InformationDocument8 pagesDemoboard 900 MHZ Lna With The Bga2003: Application InformationnokiadevnservNo ratings yet

- SRA100/166/210/166L/120EL: World Class Speed RobotDocument2 pagesSRA100/166/210/166L/120EL: World Class Speed RobotXanti Zabala Da RosaNo ratings yet

- Gauge R&R (MSA) - GoodDocument1 pageGauge R&R (MSA) - Goodsdaruwale20No ratings yet

- ACGJ4WF-21Document2 pagesACGJ4WF-21Иван КадигробNo ratings yet

- Ash 13.8 em 411B - AsbuiltDocument25 pagesAsh 13.8 em 411B - AsbuiltMr IlchamNo ratings yet

- Benqmon V551 PDFDocument21 pagesBenqmon V551 PDFBhaskaranand LNo ratings yet

- 0 SBAR-SBBR MergedDocument8 pages0 SBAR-SBBR MergedRaphael EduardoNo ratings yet

- Financial Year End Capital and Operating Cost EstimatesDocument15 pagesFinancial Year End Capital and Operating Cost Estimatesmarlina elisabethNo ratings yet

- Measurement System Analysis - Gage R & R Study Data Sheet: AV EVDocument2 pagesMeasurement System Analysis - Gage R & R Study Data Sheet: AV EVKrishnaraj.C (INEL -Materials)No ratings yet

- Tax CalculationDocument6 pagesTax CalculationancillajoyceNo ratings yet

- Load Calculation Sheet: (All Calculations Have Been Taken From The CYCLO® 6000 Catalog (General Engineering Section) )Document3 pagesLoad Calculation Sheet: (All Calculations Have Been Taken From The CYCLO® 6000 Catalog (General Engineering Section) )Muhammad IqbalNo ratings yet

- LBP 1120Document21 pagesLBP 1120bangio77No ratings yet

- (IAC) RNP A Rwy 02R: Ponte Rio - NiteriDocument2 pages(IAC) RNP A Rwy 02R: Ponte Rio - Niterithiagoteles0No ratings yet

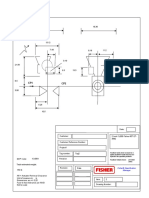

- CP2 CP1: Fisher® Specification ManagerDocument1 pageCP2 CP1: Fisher® Specification ManagerEdison ArotaypeNo ratings yet

- MC E762 SM PanasonicDocument8 pagesMC E762 SM PanasonicMstefNo ratings yet

- Secondary Hot Air (Right Second Bed) PressureDocument1 pageSecondary Hot Air (Right Second Bed) PressureuthaNo ratings yet

- COLUMNASDocument6 pagesCOLUMNASSUSANA DEYANIRA FLORES PEREZNo ratings yet

- CP2 CP1: Fisher® Specification ManagerDocument2 pagesCP2 CP1: Fisher® Specification ManagerPaolo SossiNo ratings yet

- Eggc HonileyDocument1 pageEggc HonileyRabee JibreenNo ratings yet

- LRFD LIVE LOAD DISTRIBUTIONDocument15 pagesLRFD LIVE LOAD DISTRIBUTIONJordy CoolNo ratings yet

- Rear Final Drive: SectionDocument41 pagesRear Final Drive: SectionEduardo ColinNo ratings yet

- Notes:: Drawing For Information Only Not For ConstructionDocument1 pageNotes:: Drawing For Information Only Not For ConstructionPandi KokoyNo ratings yet

- Control Chart (Template)Document7 pagesControl Chart (Template)Rudi PurnamaNo ratings yet

- AK5383Document20 pagesAK5383Louis Richard FerdinandusNo ratings yet

- 1694086646ded Dewa Ruci 36 Rev-1Document13 pages1694086646ded Dewa Ruci 36 Rev-1Yoga PrasytioNo ratings yet

- OQC Inspection Sheet Pulley, Motor, CR: OK OK OK OK OKDocument1 pageOQC Inspection Sheet Pulley, Motor, CR: OK OK OK OK OKadi meliNo ratings yet

- 6490 16R0999Document24 pages6490 16R0999luisroosNo ratings yet

- LGMK MikonosDocument16 pagesLGMK Mikonosm.pilotto71No ratings yet

- Lactate Casein Butyrate Propionate GlucoseDocument9 pagesLactate Casein Butyrate Propionate Glucosed_kuri52No ratings yet

- Overlay Determination-231127Document23 pagesOverlay Determination-231127adnan qadirNo ratings yet

- b9.1Document1 pageb9.1EakJhuanNo ratings yet

- 19 TMEET111L ME12 Torres Chuck-JawDocument1 page19 TMEET111L ME12 Torres Chuck-JawEnyong LumanlanNo ratings yet

- Adobe Scan 01 Aug 2022Document4 pagesAdobe Scan 01 Aug 2022SadhuCharan SahooNo ratings yet

- China AIP ENR 2.2.2.5-1 Zhuhai standard departure routesDocument11 pagesChina AIP ENR 2.2.2.5-1 Zhuhai standard departure routesYui MisakaNo ratings yet

- (IAC) RNP Z Rwy 16 (Ar) : Alt, Elev, HGT: FT Dist: NM BRG: Mag VA/CHG: 05'WDocument1 page(IAC) RNP Z Rwy 16 (Ar) : Alt, Elev, HGT: FT Dist: NM BRG: Mag VA/CHG: 05'WRicardo PalermoNo ratings yet

- Slope Stabliity - Bishop MethodDocument1 pageSlope Stabliity - Bishop MethodPiseyNo ratings yet

- AK5394Document24 pagesAK5394Timuçin İLTERNo ratings yet

- 1.sagging ScheduleDocument1 page1.sagging ScheduleIlham Hussein RasyidNo ratings yet

- MTech Project Management W.E.F. 2015-16Document27 pagesMTech Project Management W.E.F. 2015-16Er Vaibhav NyatiNo ratings yet

- TQM Tools & TechniquesDocument106 pagesTQM Tools & Techniquesvinay tripathiNo ratings yet

- TQM FundamentalsDocument36 pagesTQM FundamentalsECE113 - SURESH KUMAR MNo ratings yet

- Understanding, Evaluating, Defining, and Managing Expectations Are Essential To SatisfyingDocument12 pagesUnderstanding, Evaluating, Defining, and Managing Expectations Are Essential To SatisfyingKubiriba Shaddie AllanNo ratings yet

- Chapter 8-Process Management: Jit & TQM Issues in Supply Chain ManagementDocument31 pagesChapter 8-Process Management: Jit & TQM Issues in Supply Chain ManagementKota MelakaNo ratings yet

- Design of Experiments and Control ChartsDocument4 pagesDesign of Experiments and Control ChartsSudipta SarangiNo ratings yet

- Quality in The Medieval Guilds of EuropeDocument26 pagesQuality in The Medieval Guilds of EuropeFB MemesNo ratings yet

- VvenDocument7 pagesVvenAdvendro Chandra0% (1)

- Assessment of Procurement Demand of Milk Plant Using Quality Control Tools A Case StudyDocument6 pagesAssessment of Procurement Demand of Milk Plant Using Quality Control Tools A Case StudyMohammad JawadNo ratings yet

- 1e1 S4hana2022 BPD en UsDocument60 pages1e1 S4hana2022 BPD en UsprajeethNo ratings yet

- Quality & RiskDocument31 pagesQuality & RisklinaNo ratings yet

- Coca-Cola 1Document66 pagesCoca-Cola 1Jyoti KumariNo ratings yet

- Statistical Quality Control: by 4Th Edition © Wiley 2010 Powerpoint Presentation by R.B. Clough - Unh M. E. Henrie - UaaDocument40 pagesStatistical Quality Control: by 4Th Edition © Wiley 2010 Powerpoint Presentation by R.B. Clough - Unh M. E. Henrie - UaaGazulitaNo ratings yet

- Response Surface Methodology reviewDocument4 pagesResponse Surface Methodology reviewElifNo ratings yet

- Narrative ReportDocument7 pagesNarrative ReportJeLo ReaNdelarNo ratings yet

- Index: Mechanical Engineering Department Sir B.P.I., BhavnagarDocument30 pagesIndex: Mechanical Engineering Department Sir B.P.I., Bhavnagarmer sanjayNo ratings yet

- Statistics and Quality (P Chart)Document21 pagesStatistics and Quality (P Chart)bernie_uyNo ratings yet

- ISYE 530 Spring 2020 SyllabusDocument2 pagesISYE 530 Spring 2020 SyllabusswapnilNo ratings yet

- International Statistical Standards: A Guide For The UninitiatedDocument6 pagesInternational Statistical Standards: A Guide For The UninitiatedfandimokuNo ratings yet

- Black Belt Project Storyboard Template v3.2Document36 pagesBlack Belt Project Storyboard Template v3.2Muhammad Amjad MaroofNo ratings yet

- Measure Phase Quiz - Student December 2017Document8 pagesMeasure Phase Quiz - Student December 2017Mireya RochaNo ratings yet

- 1 Introduction To Statistical Quality ControlDocument20 pages1 Introduction To Statistical Quality Controljher18No ratings yet

- Quality Control: Chapter OutlineDocument40 pagesQuality Control: Chapter OutlineLoreine Jane ClaritoNo ratings yet

- Estimating Measurement-Uncertainty - in Quantitative Chemical AnalysisDocument18 pagesEstimating Measurement-Uncertainty - in Quantitative Chemical AnalysisMohammad Youssefi100% (2)

- Statistical Process Control-BBADocument43 pagesStatistical Process Control-BBAHritik DilawariNo ratings yet

- Work SamplingDocument36 pagesWork SamplingAngelicaAngeloOconNo ratings yet

- GE 8077 - TQM Principles and ToolsDocument36 pagesGE 8077 - TQM Principles and ToolsmenakadevieceNo ratings yet