Professional Documents

Culture Documents

TPP1

Uploaded by

Jagadesh PCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TPP1

Uploaded by

Jagadesh PCopyright:

Available Formats

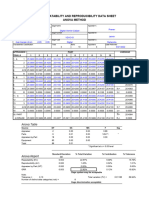

XBar & R chart

PROCESS… PART… GAUGE…

Process PUNCHING TPP 01 Description NAA382AW Description VERNIER CALIPER Me-VC-28

Work Cell MFG CELL Feature REFERNCE Resolution 0.01

Factory MALLIKS Upper spec 0.50 R&R 5.89%

Location Bangalore Target 194 U/M mm P/T

Contact 7259029876 Lower spec -0.50 Study month Sep-22

Reference Upright Calibration due 1/1/2023

Date 05.09.22 08.09.22 12.09.22 15.09.22 18.09.22 20.09.2022 23.09.2022 24.09.2022 30.09.2022

Time

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27

X1 0.07 0.04 0.07 0.08 0.08 0.08 0.10 0.06 0.08

X2 0.09 0.09 0.05 0.10 0.10 0.09 0.07 0.06 0.05

X3 0.05 0.06 0.09 0.05 0.12 0.12 0.05 0.10 0.10

X4

X5

X6

Xbar 0.07 0.06 0.07 0.08 0.10 0.10 0.07 0.07 0.08

R 0.04 0.05 0.04 0.05 0.04 0.04 0.05 0.04 0.05

Enter "C" to display calculated limits

Sbgrp size: 3 C Enter "U" to display user-provided limits

Xbar Chart

0.2

0.15

0.1

0.05

-0.05

-0.1

-0.15

-0.2

R Chart

0.14

0.12

0.1

0.08

0.06

0.04

0.02

Control Chart Constants Calculated Limits User Provided

n d2 A2 D4 Control Limits

IXMR 1 1.128 2.660 3.267 Rbar = 0.0444444444444444 RCL 0.15

XbarR 2 1.128 1.880 3.267 UCLR = (Rbar)(D4) = 0.0444444444444444 x 2.574 = 0.1144 UCLR 0.2

3 1.693 1.023 2.574 Xdouble bar = 0.0777777777777778 XCL 0

4 2.059 0.729 2.282 UCLXbar = Xdbl bar + (A2)(Rbar) = 0.0777777777777778 + ( 1.023 x 0.0444444444444 ) = 0.123 UCLX 0.72

? !

I

Facility/Location: MALLIK

Capability (Cp, Cpk) Calculator Process: MFG

KPI / O: KPI

Key characteristic: Ref.

Month of study: 9/1/2022

Study manager: Muthuraj

Gauge used: VERNIER CALIPER

MEASUREMENT SYSTEM INFORMATION: Gauge resolution: 0.01 mm

GR&R results: 5.89%

Based on an examination of the associated control chart, does

the process appear to be in a state of statistical control (Y/N)? Y

Cp Cpk

Lower Engineering Process Average‡

Specification Limit: LSL = -0.50 * from control chart: Xbar = 0.052 *

Upper Engineering

Specification Limit: USL = 0.50 * Upper Available Tolerance:

UAT = USL - Xbar

UAT = 0.4482

Engineering Target:

(Used only if spec is two-sided)

T= 194.00 * Lower Available Tolerance:

LAT = Xbar - LSL

LAT = 0.5518

Upper Process

Specification type Type -- §

and skewness

Capability Index CpU = 5.75

Skew n/a CpU = 2 x UAT / NV

Engineering Lower Process

Tolerance: ET = -- § Capability Index CpL = 7.08

ET = USL - LSL CpL = 2 x LAT / NV

Average Range† Process Capability Index:

from control chart:

Rbar = 0.044 * Cpk = min(CpU, CpL)

Cpk = 5.75

Number of measurements Modified Capability Index:

in each sample for which

a range was calculated:

n= 3 * Cpk' = min(Cp, Cpk) Cpk' = -- «

Standard deviation:

(Required if data are not time-ordered,

or if process is not in statistial control.)

s= * Enter "P" for Performance

Indices (Pp& Ppk)

Performance indices require

a standard deviation (s) entry.

Appropriate d2 for

the sample of size n: d2 = 1.693 NOTES:

† Use MRbar if IX-MR control chart was used.

Natural Variation of the process ‡ Use Xdouble bar if Xbar & R control chart was used.

NV = 6 x Rbar / d2

NV = 0.156 * User supplied data.

« Applies only when target is not centered in spec.

Potential § Target is not bracketed by LSL and USL. Be sure LSL < T <

Process Capability Cp = -- USL.

Cp = ET / NV

Table of d2 values:

n d2 Engineering Tolerance (ET) & Process Variation (NT) n

2 1.128

3 1.693

Proc. Var,

4 2.059 NV

5 2.326

6 2.534 Spec, ET Tgt

2.534

7 2.704

8 2.847 2.847

2.847

9 2.970 -50 0 50 100 150 200 250

10 3.078 3.078

3.078

3.078

3.078

3.078

You might also like

- PB04Document2 pagesPB04Jagadesh PNo ratings yet

- Electronics for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionFrom EverandElectronics for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionRating: 5 out of 5 stars5/5 (1)

- TPP2Document2 pagesTPP2Jagadesh PNo ratings yet

- Shearing MachineDocument2 pagesShearing MachineJagadesh PNo ratings yet

- Machine Capability For Welding-Mar-2019Document2 pagesMachine Capability For Welding-Mar-2019Jagadesh PNo ratings yet

- Naa347hj (LC-01) Machine CapabilityDocument2 pagesNaa347hj (LC-01) Machine CapabilityJagadesh PNo ratings yet

- Naa347fy (PP-01) Machine CapabilityDocument2 pagesNaa347fy (PP-01) Machine CapabilityJagadesh PNo ratings yet

- Machine Capability - SPOT Welding - Platform Width (+ - 1.2)Document2 pagesMachine Capability - SPOT Welding - Platform Width (+ - 1.2)Jagadesh PNo ratings yet

- Overlay Determination-231127Document23 pagesOverlay Determination-231127adnan qadirNo ratings yet

- Gage R&R-part To Part-ToleranceDocument5 pagesGage R&R-part To Part-ToleranceTiếnTrầnHồVănNo ratings yet

- A Appearance No Burr, Rust, Crack, Paint Defect Visual: Part No. Part Name ModelDocument24 pagesA Appearance No Burr, Rust, Crack, Paint Defect Visual: Part No. Part Name ModelSanjayNo ratings yet

- PommelDocument3 pagesPommelVilasNo ratings yet

- Customer Pt. Unilever Indon Esia Project Name Spiral Conveyor System Project Number C075. 00131 CommisionDocument14 pagesCustomer Pt. Unilever Indon Esia Project Name Spiral Conveyor System Project Number C075. 00131 CommisionParama Ahmad ParahitaNo ratings yet

- Threaded RodDocument1 pageThreaded RodDhanu goswamiNo ratings yet

- Anexo 4.2. Optimizacion de Una Columna de DestilacionDocument2 pagesAnexo 4.2. Optimizacion de Una Columna de DestilacionDanny GutierrezNo ratings yet

- Bousekaa, Ahmed 10223 Ascan Calc-Report 202211241453Document1 pageBousekaa, Ahmed 10223 Ascan Calc-Report 202211241453Abderrahim Rahim SekakNo ratings yet

- 4-TRUCPHI14x35 05Document1 page4-TRUCPHI14x35 05thuydvNo ratings yet

- Query Print11Document1 pageQuery Print11Julio Cesar Santos de JesusNo ratings yet

- Seccion G2: Orientación ÁnguloDocument21 pagesSeccion G2: Orientación ÁnguloCCL CONSULTORIANo ratings yet

- Seccion G2: Orientación ÁnguloDocument21 pagesSeccion G2: Orientación ÁnguloCCL CONSULTORIANo ratings yet

- Najran Ra.02 P442 PSB Reach TestDocument3 pagesNajran Ra.02 P442 PSB Reach TestkarthikNo ratings yet

- Form / Format Gauge Repeatability & Reproducibility Report: CapacitorDocument4 pagesForm / Format Gauge Repeatability & Reproducibility Report: CapacitorhimanshuNo ratings yet

- Inspection Report: Product: Ball Screw DRG - NO. LP-IM02-001 Material: 17-4P SsDocument1 pageInspection Report: Product: Ball Screw DRG - NO. LP-IM02-001 Material: 17-4P SsYash UpadhyayNo ratings yet

- SMD Power Inductors - SD43 SERIESDocument3 pagesSMD Power Inductors - SD43 SERIESpepe pecasNo ratings yet

- 09-Sep-17 06-Apr-2022 17:52 PLATAFORMAS 0.std: Job No Sheet No RevDocument1 page09-Sep-17 06-Apr-2022 17:52 PLATAFORMAS 0.std: Job No Sheet No RevJulio Cesar Santos de JesusNo ratings yet

- Detail: 76,000 Dwt Bulk Carrier 76,000吨散货轮Document6 pagesDetail: 76,000 Dwt Bulk Carrier 76,000吨散货轮Jagmohan SinghNo ratings yet

- Roughness Conversion Chart RampinelliDocument1 pageRoughness Conversion Chart RampinelliServesh KumarNo ratings yet

- AISC 9th Edition: Non-Standard UnitsDocument7 pagesAISC 9th Edition: Non-Standard UnitsHomer SilvaNo ratings yet

- Axle Push Lever - BK-7Document1 pageAxle Push Lever - BK-7Preetam KumarNo ratings yet

- Cold-Formed Steel Design CheckDocument2 pagesCold-Formed Steel Design CheckLuís OliveiraNo ratings yet

- Pap 6600-20-v08Document3 pagesPap 6600-20-v08marc_lobert4808100% (2)

- Msa (25.40)Document1 pageMsa (25.40)Quality VenusNo ratings yet

- AsdsdsDocument1 pageAsdsdsJulio Cesar Santos de JesusNo ratings yet

- Bodine-Electric Standard Products CatalogDocument44 pagesBodine-Electric Standard Products CatalogAlexanderNaranjoOsorioNo ratings yet

- ET-SGM37FE-1222 (20170810003-H16035) ModelDocument1 pageET-SGM37FE-1222 (20170810003-H16035) Modelruta0405No ratings yet

- RK 370ca PDFDocument1 pageRK 370ca PDFSetiawan Si GethokNo ratings yet

- D10367150a PDFDocument1 pageD10367150a PDFGaurav VashishtNo ratings yet

- Latihan Soal ReksadanaDocument2 pagesLatihan Soal Reksadanairga ayudiasNo ratings yet

- DAIF, AHMED 54123 AScan Calc-Report 2022112154638Document1 pageDAIF, AHMED 54123 AScan Calc-Report 2022112154638Abderrahim Rahim SekakNo ratings yet

- PTR90 777814Document5 pagesPTR90 777814Sgly ZemogNo ratings yet

- Part No. & Name: Gauge Name:/ Micrometer Date 20.1.18 Characteristics: Outside Diameter Specification: SKSDocument11 pagesPart No. & Name: Gauge Name:/ Micrometer Date 20.1.18 Characteristics: Outside Diameter Specification: SKSPraveen kumarNo ratings yet

- Gauge R&R (MSA) - GoodDocument1 pageGauge R&R (MSA) - Goodsdaruwale20No ratings yet

- 3.levelling Elevasi Way Ruguk FinalDocument3 pages3.levelling Elevasi Way Ruguk FinalabdullahmahifalNo ratings yet

- DatasheetDocument1 pageDatasheetStuxnetNo ratings yet

- LCD DisplayDocument2 pagesLCD Displaydewidewi76No ratings yet

- 2700 0 29 6 137 Rectangular Column (Reinf. On 2 Sides) : Short Column Slender ColumnDocument1 page2700 0 29 6 137 Rectangular Column (Reinf. On 2 Sides) : Short Column Slender Columnmanoj_mousamNo ratings yet

- Beam Design ReportDocument57 pagesBeam Design ReportOkechukwu NwaewoNo ratings yet

- Axle Push Lever - BK - 44Document1 pageAxle Push Lever - BK - 44Preetam KumarNo ratings yet

- Query PrintasdsdDocument1 pageQuery PrintasdsdJulio Cesar Santos de JesusNo ratings yet

- Part Number 2875 - 2820, Tapered Roller Bearings - TS (Tapered Single) ImperialDocument5 pagesPart Number 2875 - 2820, Tapered Roller Bearings - TS (Tapered Single) ImperialGỗ MộcNo ratings yet

- C-Pad 03Document1 pageC-Pad 03wotax31173No ratings yet

- 523-XXX - Coupling Cut SheetDocument1 page523-XXX - Coupling Cut SheetRavishankarNo ratings yet

- SBJV - Rnav CTB 1e - Raxit 1e Rwy 15 - Star - 20221006Document1 pageSBJV - Rnav CTB 1e - Raxit 1e Rwy 15 - Star - 20221006gameplayPSNo ratings yet

- Verificación Col Confinamiento TabiqueríaDocument2 pagesVerificación Col Confinamiento TabiqueríaflorenciaNo ratings yet

- OQC Inspection Sheet Pulley, Motor, CR: OK OK OK OK OKDocument1 pageOQC Inspection Sheet Pulley, Motor, CR: OK OK OK OK OKadi meliNo ratings yet

- Datasheet Nema23Document1 pageDatasheet Nema23Juan De La TorreNo ratings yet

- Axis: 1 Storey: 1: Bending (Top Edge) ..Document22 pagesAxis: 1 Storey: 1: Bending (Top Edge) ..Ong George SammyNo ratings yet

- Protec Date Limited Max Value 0.75 Upper Limit Nature Mean 0.70 Centreline Unit Min Value 0.65 Lower Limit X1 X2 0.6 X3 X4 X5 X XDocument3 pagesProtec Date Limited Max Value 0.75 Upper Limit Nature Mean 0.70 Centreline Unit Min Value 0.65 Lower Limit X1 X2 0.6 X3 X4 X5 X Xngọc hiếu trươngNo ratings yet

- Beam Design ReportDocument57 pagesBeam Design ReportOkechukwu NwaewoNo ratings yet

- Lawyers, Cloud Computing and Innovation (How Cloud Computing Facilitates Innovation in The Delivery of Legal Services)Document19 pagesLawyers, Cloud Computing and Innovation (How Cloud Computing Facilitates Innovation in The Delivery of Legal Services)ainNo ratings yet

- Cô MAI PHƯƠNG (Chủ đề SCIENCE AND TECHNOLOGY)Document2 pagesCô MAI PHƯƠNG (Chủ đề SCIENCE AND TECHNOLOGY)Giang VũNo ratings yet

- Mercedes Wis en - Asra - Data - SpoolerDocument91 pagesMercedes Wis en - Asra - Data - SpoolerrtamercedesNo ratings yet

- NAME: Sai Kumar.p REG - NO:18BCA0079: Assessment 5 Ita1005 - Database Management Systems LabDocument12 pagesNAME: Sai Kumar.p REG - NO:18BCA0079: Assessment 5 Ita1005 - Database Management Systems LabSaikumar P 18BCA0079No ratings yet

- Golden Software Voxler v4 - User's Guide (Voxler4UserGuide-eBook)Document970 pagesGolden Software Voxler v4 - User's Guide (Voxler4UserGuide-eBook)wantssomebook100% (1)

- Astro Smart TV Multiroom TTTDocument29 pagesAstro Smart TV Multiroom TTTSobnavalle KesavanNo ratings yet

- (GUIDE) Unbrick A Hard Bricked L90 All Varia - LG Optimus L90 PDFDocument1 page(GUIDE) Unbrick A Hard Bricked L90 All Varia - LG Optimus L90 PDFpartidasluisNo ratings yet

- CAT6 EN OptimiertDocument332 pagesCAT6 EN OptimiertGoran MladenovicNo ratings yet

- Inside The Young People'S Attitude Toward Virtual Traveling Agencies: Case in VietnamDocument8 pagesInside The Young People'S Attitude Toward Virtual Traveling Agencies: Case in VietnamNhi Trương BảoNo ratings yet

- Test Inheritance PDFDocument9 pagesTest Inheritance PDFAyushi Sharma60% (5)

- What Is SAP BTP?Document5 pagesWhat Is SAP BTP?PALURU GIRIDHARNo ratings yet

- 2323 EXT HD50C Product SheetDocument2 pages2323 EXT HD50C Product SheetGayane KhachatryanNo ratings yet

- The Operations FunctionDocument35 pagesThe Operations FunctionrajNo ratings yet

- Cloudwater: A Web and Mobile Based Software-As-A-Service For Water Refilling BusinessesDocument11 pagesCloudwater: A Web and Mobile Based Software-As-A-Service For Water Refilling Businessesdionisio balbabocoNo ratings yet

- Implementationof Fuzzy Tsukamoto Algorithmin Determining Work FeasibilityDocument5 pagesImplementationof Fuzzy Tsukamoto Algorithmin Determining Work Feasibilitydikson piterNo ratings yet

- Talk Homework Cards WordDocument6 pagesTalk Homework Cards Wordafmtbbasx100% (1)

- Zippo Manufacturing Co. v. Zippo Dot Com, IncDocument2 pagesZippo Manufacturing Co. v. Zippo Dot Com, Incron22No ratings yet

- Integrating With HCMDocument588 pagesIntegrating With HCMbalabalabala123No ratings yet

- Code (Edited)Document8 pagesCode (Edited)Khương MaiNo ratings yet

- Opening Case How Starbucks Is Changing To A Digital and Social EnterpriseDocument3 pagesOpening Case How Starbucks Is Changing To A Digital and Social Enterpriseleeyaa aNo ratings yet

- Dockerfile Reference Docker DocsDocument68 pagesDockerfile Reference Docker DocsRamaroson JosoaNo ratings yet

- DS-400 Semi-Auto Chemistry Analyzer CatalogDocument1 pageDS-400 Semi-Auto Chemistry Analyzer CatalogJason WangNo ratings yet

- CNT 100 - Introduction To Windows Networking Syllabus: Instructor: Email: Phone: Office: Office Hours: Course OverviewDocument5 pagesCNT 100 - Introduction To Windows Networking Syllabus: Instructor: Email: Phone: Office: Office Hours: Course OverviewColleen VenderNo ratings yet

- M BusDocument91 pagesM BusZoran MilicNo ratings yet

- Lead2Pass Latest Free Oracle 1Z0 060 Dumps (81 90) Download!Document5 pagesLead2Pass Latest Free Oracle 1Z0 060 Dumps (81 90) Download!aaNo ratings yet

- Information Technology in Civil Engineering: Introduction - Ceng 116B Database Management in ConstructionDocument26 pagesInformation Technology in Civil Engineering: Introduction - Ceng 116B Database Management in ConstructionRalph CrucilloNo ratings yet

- RAB Recording & Multimedia StreamingDocument2 pagesRAB Recording & Multimedia StreamingTRB RecordNo ratings yet

- VSR PotterDocument5 pagesVSR PotterAhlan kpNo ratings yet

- Tugas Gui Lanjutan Dan SPLDocument8 pagesTugas Gui Lanjutan Dan SPLDewi KurniaNo ratings yet

- Checklist For School ProgramDocument1 pageChecklist For School ProgramHans Jhayson CuadraNo ratings yet