Professional Documents

Culture Documents

09-2. Test Report Sikasil WS355N Astm C920-C50

09-2. Test Report Sikasil WS355N Astm C920-C50

Uploaded by

Nguyễn Sơn0 ratings0% found this document useful (0 votes)

28 views8 pagesOriginal Title

09-2. TEST REPORT SIKASIL WS355N ASTM C920-C50

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

28 views8 pages09-2. Test Report Sikasil WS355N Astm C920-C50

09-2. Test Report Sikasil WS355N Astm C920-C50

Uploaded by

Nguyễn SơnCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

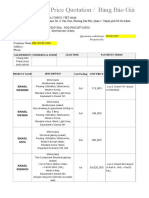

Admatericls —

Technologies

Prous toe pate cement

TEST REPORT

CLIENT NAME 1 SIKA ASIA PACIFIC MANAGEMENT PTE LTD

ADDRESS : 39 ROBINSON ROAD

#17-04

SINGAPORE 068911

ATTENTION TO

TELNO

MR. VINCENT YAN

9692 3119

ACCOUNT 2 SIKA ASIA PACIFIC MANAGEMENT PTE LTD

CHARGEABLE TO

PROJECT CODE : PT02976

PROJECT TITLE : GENERAL TESTING

TEST STANDARDS

STAINING AND COLOR CHANGE (ASTM C510: 2006a(2011))

EXTRUSION RATE (ASTM C1183/ 61183M: 2013)

RHEOLOGICAL (FLOW) PROPERTIES (ASTM C839: 2001(2011))

INDENTATION HARDNESS (ASTM C861: 2006(2011))

TACK-FREE TIME (ASTM C679: 2003 (2009)"")

EFFECTS OF HEAT AGING (ASTM C1246: 2000(2012))

ADHESION-IN-PEEL (ASTM C794:2010)

TEST SPECIFICATION & OBJECTIVE :

ADHESION AND COHESION UNDER CYCLIC MOVEMENT (ASTM C719: 2014)

EFFECTS OF LABORATORY ACCELERATED WEATHERING (ASTM C793: 2005(2010))

1.465 6362 9066

F465 6362 2080

'nfoadmateralsepelementcom

‘wa acmateril cm

LUENVGST No: 200805959¢

‘TEST SEALANT ACCORDING TO STANDARD SPECIFICATION FOR ELASTOMERIC JOINT

‘SEALANTS (ASTM C920: 2014a) FOR CONFORMANCE TO TYPE S, GRADE NS, CLASS 50,

USES NT, G, AAND M

JOB REF. : 719-08409

CLIENT SAMPLE REF. : SIKASILWS-355 N

SAMPLE TYPE ONE PART SILICONE SEALANT

DATE RECEIVED 20-Jun-2019

DATE OF REPORT 2 27-Aug-2019

TOTAL PAGES : 8 (INCLUDING COVER PAGE)

anenceradty Admt edt ea winner th etn eid

‘accredited

{cborstory

‘SAC-SINGLAS

Admaterials

Technolog;

ies

JOBREF: 719-08409

Page 8

Test TeatMethod | Resutts [ASTM C920: 2014a Standard Specification for

parvsenaty astu.crtes | 7o.45mumin [6292 NS (nonog or grade sealant shat

een |Grade NS (nonsag or gunnabie) sealant shall

Properties) pares |displacement and show no deformation in

No deformation |norizontal displacement.

|Test piece 1, average | ASTM C661 26 reading of less than 60.

Tasker ee vine) pS C879) esses: polyethylene film when tested at 72 hours.

efeate of Heat oong |The sealant shalll not lose > 7% of its original

Moreen

yous Noone tate

enacaofacelrted | acy czag | Notte ster UY | ected UV exposure and shal how no cracks

Weathering ee ‘est lafter exposure at cold temperature and the bend

fos

fchosion neal

Ja) Aluminium 107.2Nand0% — |not be < 22.2 N (5 Ibf). In addition, the sealant

ASTM C794 | adhesive bond loss | shail show no > 25% adhesive bond loss for

adhesive bond loss

Admaterials

Technologies

JOBREF: T19-08409

Page 3 of 8

4. STAINING AND COLOR CHANGE (ASTM C510: 2005a(2011}

Weathering machine: QUV Accelerated Weathering Tester

Test cycle 100 hours UV exposure at 60 °C

Lamp designation Fluorescent UVA 340 nm

Exposure duration 100 hours.

No. of determination: 1 for staining test, 1 for color change, 1 as control

‘SPECIMEN. STAIN DISCOLORATION REQUIREMENT

1 No staining

'No visible staining on white coment mortar base

2 No colour change

“Refer to Figure 2

2, EXTRUSION RATE (ASTM C1183/ C1183M: 2013)

Procedure used A

Type of nozzle Plastic

rest RESULTS

Specific gravity, ot. 431

Intl weight of empty container 9 13.90

NWeioht of container + extruded sealant, g 117.99

Weight of exuded sealant 9 104.09

[Extrusion rate, m/min 7946

RHEOLOGICAL (FLOW) PROPERTIES (ASTM C639: 20012011

“Type of sealant = Type i

Isa Test ‘AMOUNT OF SAG, mm DEFORMATION

Vertical Displacement

omm

Horizontal Displacement

No deformation

Admaterials

Technologies

JOB REF: T19-08409

Page 4 of 8

4, INDENTATION HARDNESS (ASTM C661; 2006/2044,

Type of durometer: Type A-2

Curing conditions: 24°C and 60% RH

‘Curing period 14 days

READING 1 READING 2 READING 3 MEAN

Specimen 1 25 26 26

‘Specimen 2 25 28 27

5. TACK-FREE TIME (ASTM C679: 200:

TIME OF CURE OBSERVATIONS*

Specimen 1 110 mins No transfer of test specimens to the polyethylene film.

‘Specimen 2 110 mins No transfer of test specimens to the polyethylene film

* Whether the film was clean or the film contained a thin layer of plastclers.

8. EFFECTS OF HEAT AGING (ASTM €1246: 2000(2012)

‘SPECIMEN 1 SPECIMEN2 | SPECIMEN 3 (CONTROL)

Percentage of weight loss

Iduring heat aging, % Hai be cea

\Cracking* 0 0 o

IChalking o ° 0

“Number 0 represents no cracking or no chalking,

“Refer to Figure 3

Admaterials

Technologies

JOBREF: T19-08409

DHESION AND COHESION UNDER CYCLIC MOVEMENT (ASTM C719: 2014)

Percentage of cyclic movement: 50.0%

Substrate: a) Aluminium

b) Glass

Dimension in Compression and Extension

Page 5 of 8

aia Dimension E- With of Joint in Extension,

‘Compression, mm mm

30 64 19.1

Curing conditions

a) 23°C and 50% relative humidity for 7 days

b) 87.8 °C and 95% relative humidity for 7 days

©) 29°C and 80% relative humidity for 7 days

4) Immersion in disilled water at 23 °C for 7 days

@), Drying in oven at 70°C for? days

Cyclic Test Conditions:

Stage A - 10 cycles of joint movements

4) The joint wicth was compressed from 12.7 mm to 6.4 mm and extended from 6.4 mm to 19.1 mm at 3.2 mm/h

under standard conditions.

Stage B - 10 cycles of joint movements

4) The joint width was compressed to 6.4 mm and conditioned at 70 °C for 16 to 20 hours,

b) After ageing, the test specimens were cooled to 23 °C for 2 to 3 hours,

¢} The joint width was extended to 19.1 mm at - 26°C.

) Specimens were removed and allowed to condition to room temperature.

Icycuc Test PROCEDURE GBSERVATIONS

Ja) Aluminium substrate SAMPIEA eaaple? ies

1st - 10th cycle (Stage A) No bond failure No bond failure No bond failure

118t- 20th cycle (Stage B) No bond failure No bond failure No bond failure

ICYCLIC TEST PROCEDURE cea

Pl Gass substrate SAMPLE 1 ‘SAMPLE 2 SAMPLE 3

Hist 10th cycle (Stage A) No bond failure No bond failure No bond failure

1st - 20th cycle (Stage B) No bond failure No bond failure No bond failure

Admaterials

Technologies

Prout to be pat at @ cement

JOBREF: T19-08409

Page 6 of 8

EFFECTS OF LABORATORY ACCELERATED WEATHERING (ASTM C7:

a} Accelerated Weathering Test Conditions

Weathering machine Alas UV Test

Lamp designation Fluorescent UVA 340 nm

Typical iradiance 0.89 Wim?inm

Approximate wavelength: 340 nm

Exposure duration 250 hours

Exposure cycle Bh UV at 60 (+ 3) °C; 4 h condensation at 50 (+ 3)“

) Bend Test Conditions

Cold exposure duration: 24 hours

Cold exposure condition : -26+2°C

OBSERVATION

Test

SAMPLE 1 ‘SAMPLE 2 ‘SAMPLE 3

JAfter Accelerated Weathering® 0 0 0

After Bend Test" 0 0 0

“Number 0 represents no cracks

“Refer to Figure 4

9, ADHESION-IN-PEEL (ASTM C794:2010)

Substrate: a) Aluminium

b) Glass

‘Substrate surface preparation & cleaning: Clean throughly with IPA solution and wiped with clean cloth

Type of primer: Sika Aktivator 205

Curing conditions: _23 °C and 50% relative humidity for 21 days

Sameuner.., | AVERAGENEEL | reacronce.n | oteswenowo ss | TYPO SEAL

SESTEIESL | MGR | rearoncen |aovesvegootoen [2

Admateriails

Technologies

Pru tobe pnt at @ clement

JOBREF: 1719-08409

Page 7 of 8

Figure 1: Sample as per received

Figure 2: Staining and Color Change

‘Admaterials

Technologies

Proud tobe pater @ cement

JOBREF: 119-08409

Page 8 of 8

PREPARED BY:

jr

JAMES FONG

Engineer

DID: (65) 6362 9070

Email: James.Fong@element.com

APPROVED BY:

ee

JOUFIN

Business Development Manager

DID: (65) 6362 9739

Email: Juin. H@element.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Assessment of Different Concepts For Prestressing Glass Beams With Iron Based Shape Memory Alloy ElementsDocument27 pagesAssessment of Different Concepts For Prestressing Glass Beams With Iron Based Shape Memory Alloy ElementsNguyễn SơnNo ratings yet

- Imperial Avenue Dubai, United Arab Emirates: Structural Calculation For Add On Façade at Level 26 & 27Document125 pagesImperial Avenue Dubai, United Arab Emirates: Structural Calculation For Add On Façade at Level 26 & 27Nguyễn Sơn100% (1)

- BM Window LTD Co, Whom It May Concern: Dow Chemical Vietnam LLCDocument1 pageBM Window LTD Co, Whom It May Concern: Dow Chemical Vietnam LLCNguyễn SơnNo ratings yet

- 25mx2.55m Structural Glass CanopyDocument65 pages25mx2.55m Structural Glass CanopyNguyễn SơnNo ratings yet

- UntitledDocument1 pageUntitledNguyễn SơnNo ratings yet

- Thuan Thanh Glass Corporation 18 - 20 LE QUY DON ST., 6 WARD, 3 Dist., HO CHI MINH City Hochiminh City, Viet Nam Ho Chi Minh 70000Document4 pagesThuan Thanh Glass Corporation 18 - 20 LE QUY DON ST., 6 WARD, 3 Dist., HO CHI MINH City Hochiminh City, Viet Nam Ho Chi Minh 70000Nguyễn SơnNo ratings yet

- Analytical Solution and Exact Effective Thickness For Multi Layered Laminated Glass Beams of Arbitrary CompositionDocument23 pagesAnalytical Solution and Exact Effective Thickness For Multi Layered Laminated Glass Beams of Arbitrary CompositionNguyễn SơnNo ratings yet

- Dow High Performance Building Americas Asia Emeai: Imagine The PossibilitiesDocument3 pagesDow High Performance Building Americas Asia Emeai: Imagine The PossibilitiesNguyễn SơnNo ratings yet

- 2021-007 - Lancaster Luminare - Structural Silicone Sealant Design For Glass Corner PDFDocument1 page2021-007 - Lancaster Luminare - Structural Silicone Sealant Design For Glass Corner PDFNguyễn SơnNo ratings yet

- Sika Silicone Sealant của công ty Topco - Bảng báo giá - BM WINDOWS - 20191107Document2 pagesSika Silicone Sealant của công ty Topco - Bảng báo giá - BM WINDOWS - 20191107Nguyễn SơnNo ratings yet

- Dow High Performance Building Americas Asia Emeai: Imagine The PossibilitiesDocument3 pagesDow High Performance Building Americas Asia Emeai: Imagine The PossibilitiesNguyễn SơnNo ratings yet

- GE - SSG4600 Performance & Behavior r.081516Document4 pagesGE - SSG4600 Performance & Behavior r.081516Nguyễn SơnNo ratings yet

- Spec CRL995Document3 pagesSpec CRL995Nguyễn SơnNo ratings yet

- 31295007040800Document152 pages31295007040800Nguyễn SơnNo ratings yet

- Product Comparison - GE SSG4400 UltraGlaze Vs SSG4600 UltraGlaze Vs DC98...Document8 pagesProduct Comparison - GE SSG4400 UltraGlaze Vs SSG4600 UltraGlaze Vs DC98...Nguyễn SơnNo ratings yet

- Confirmation Laminated Glass 2020-06-02Document3 pagesConfirmation Laminated Glass 2020-06-02Nguyễn SơnNo ratings yet

- 21 1575 StatementDocument4 pages21 1575 StatementNguyễn SơnNo ratings yet

- Buckling Behavior of Split MullionDocument41 pagesBuckling Behavior of Split MullionNguyễn SơnNo ratings yet

- 21 - 1575 - Sika Corner BondingDocument4 pages21 - 1575 - Sika Corner BondingNguyễn SơnNo ratings yet

- 09-3. Test Report Sikasil WS355N Astm C1248Document2 pages09-3. Test Report Sikasil WS355N Astm C1248Nguyễn SơnNo ratings yet

- Yuw 750 XT 4 Side Captured - Window Wall: Installation ManualDocument14 pagesYuw 750 XT 4 Side Captured - Window Wall: Installation ManualNguyễn SơnNo ratings yet

- YUW 750 XT Unitized Curtain Wall System 4 Side SSG: Installation ManualDocument34 pagesYUW 750 XT Unitized Curtain Wall System 4 Side SSG: Installation ManualNguyễn SơnNo ratings yet

- MS of Tower Facade - 2016-05-30Document126 pagesMS of Tower Facade - 2016-05-30Nguyễn SơnNo ratings yet

- Accommodation Ofstructuralmovement in Glass-Aluminium Curtain WallsDocument9 pagesAccommodation Ofstructuralmovement in Glass-Aluminium Curtain WallsNguyễn SơnNo ratings yet