Professional Documents

Culture Documents

YUW 750 XT Unitized Curtain Wall System 4 Side SSG: Installation Manual

Uploaded by

Nguyễn SơnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

YUW 750 XT Unitized Curtain Wall System 4 Side SSG: Installation Manual

Uploaded by

Nguyễn SơnCopyright:

Available Formats

YUW 750 XT Unitized Curtain Wall System

4 Side SSG

Installation Manual

©2020 YKK AP America Inc.

YUW 750 XT Unitized Curtain Wall System

4 Side SSG

TABLE OF CONTENTS

Installation Notes .................................................................................Page ii

Notice for SSG Curtain Wall Installation ............................................Page iii

PARTS DESCRIPTION ............................................................................YUW 750 XT

Framing Members ......................................................................................Page 1 & 2

YUW 750 XT Accessories ..........................................................................Page 2 to 5

FRAME INSTALLATION

Anchor and Mullion Centerlines .........................................................Page 6

Install Sill Starter..................................................................................Page 7 to 12

Install Anchors .....................................................................................Page 13 & 14

Curtain Wall Unit Installation ...............................................................Pages 15 to 26

Effective Date: March 2, 2020 | 04-4023-08 Page-i

YUW 750 XT Unitized Curtain Wall System

4 Side SSG

Installation Notes

1. Do not drop, roll or drag boxes of aluminum framing. Move and stack boxes with proper support

to prevent distortion. If fork lifts are used, be especially careful about striking the boxes when lifting

or moving.

2. Store in a dry, out of the way area. If rain exposure, condensation or any water contact is likely,

then all packaging material should be removed. Wet packaging materials will discolor and may stain

aluminum finishes and paints.

3. All materials should be checked for quality and quantity upon receipt, YKK AP must be notified

immediately of any discrepancies in shipment. Check to make sure that you have the required shims,

sealants, supplies and tools necessary for the installation.

4. Carefully check the openings and surrounding conditions that will receive your material.

Remember, if the construction is not per the construction documents, it is your responsibility to notify

the general contractor in writing. Any discrepancies must be brought to the general contractor’s

attention before you proceed with the installation.

5. Gather your shop drawings, materials, packing list, and this installation manual. Carefully review

parts location, the sequence it goes therein, when you glaze it and how you seal it. Installation

instructions are of a general nature and may not cover every condition you will encounter. The shop

drawings and/or installation manuals were prepared specifically for the product.

6. Any material substitutions must be of equal or greater quality.

7. Make certain that material samples have been sent for compatibility testing for all manufacturer’s

sealants involved. Make certain sealants have been installed in strict accordance with the

manufacturer’s recommendations and specifications.

8. Remember to isolate, in an approved manner, all aluminum from uncured masonry or other

incompatible materials.

9. System-to-structure fasteners are not supplied by YKK AP. Fasteners called out on shop drawings

are to indicate minimum sizes for design loading.

10. If any questions arise concerning YKK AP products or their installation, contact YKK AP for

clarification before proceeding.

11. YKK AP storefront and/or curtain wall framing is typically completed before drywall, flooring and

other products which may still be in process. Take the extra time to wrap and protect the work produced.

12. Cutting tolerances are plus zero, minus one thirty second unless otherwise noted.

13. Check our website, www.ykkap.com, for the latest installation manual update prior to

commencing work.

Page-ii 04-4023-08 | Effective Date: March 2, 2020

YUW 750 XT Unitized Curtain Wall System

4 Side SSG

Important Notice for

SSG Curtain Wall Systems:

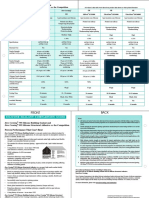

In order to properly perform and to maintain structural integrity, in addition to all other installation

requirements, structurally glazed curtain wall systems rely specifically upon effective and appropriate

structural sealant selection and installation.

It is the responsibility of the glazing contractor to take all steps to ensure the installed structural seal-

ant is capable of meeting all applicable project requirements in accordance with industry standards.

Such steps on each project may include, but are not limited to, design reviews, formal adhesion test-

ing, project specification compliance, validating applications, field testing, auditing, sealant design

strength analysis, and the quality control review of the installation and surrounding conditions.

Subject to project specific design pressures, requirements, and/or specifications, the structural seal-

ant that is used between the glass and framing system must be capable of withstanding tensile and

shear stresses imposed by the curtain wall without failing adhesively or cohesively.

The structural sealant’s capability to withstand these stresses are dependent on several factors

including, but not limited to, type of structural sealant, method of application (i.e. cleaning, primer),

construction of glazing material (i.e. insulating glass unit (IGU), other infill, and finish of framing (i.e.

anodizing, paint).

- Adhesive failure occurs when sealant pulls away from substrate cleanly, leaving no sealant

material behind.

- Cohesive failure occurs when sealant breaks or tears within itself but does not separate from each

substrate because sealant-to-substrate bond strength exceeds sealant’s internal strength.

The IGU and/or other infill must be constructed for installation into structurally sealant glazed cur-

tain walls. Notify the manufacturer or fabricator of the IGU and/or infill and advise of the product’s

application into 2 or 4-sided structurally sealant glazed curtain walls along with the project’s design

requirements so that appropriate fabrication steps are taken.

Effective Date: March 2, 2020 | 04-4023-08 Page-iii

YUW 750 XT Unitized Curtain Wall System

4 Side SSG

FRAMING MEMBERS

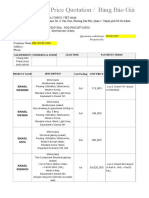

Stacking Tray Jamb Mullion

E9-7027 E9-7098

For 7-1/2” System For 7-1/2” System

Stacking Tray Jamb Mullion

E9-7037 E9-7063

For 6” System For 6” System

90° Outside Corner

Intermediate Horizontal

E9-7097 Male Mullion E9-7045

For 7-1/2” System

For 7-1/2” System

90° Outside Corner

Intermediate Horizontal

E9-7064 Male Mullion E9-7068

For 6” System

For 6” System

90° Outside Corner

Open Back Head/Sill

E9-7099 Female Mullion E9-7046

For 7-1/2” System

For 7-1/2” System

90° Outside Corner

Open Back Head/Sill

E9-7065 Female Mullion E9-7069

For 6” System

For 6” System

90° Inside Corner

SSG Stacking Sill

E9-7023 Male Mullion E9-7047

For 7-1/2” System

For 7-1/2” System

90° Inside Corner

SSG Stacking Sill

E9-7078 Male Mullion E9-7070

For 6” System

For 6” System

90° Inside Corner

Male Mullion

E9-7095 Female Mullion E9-7048

For 7-1/2” System

For 7-1/2” System

90° Inside Corner

Male Mullion

E9-7061 Female Mullion E9-7071

For 6” System

For 6” System

Female Mullion

E9-7002 Starter Sill E9-7094

For 7-1/2” System

Female Mullion SSG Jamb Spacer

E9-7062 E9-4597

For 6” System For 1-5/16” Glazing

Effective Date: March 2, 2020 | 04-4023-08 Page-1

YUW 750 XT Unitized Curtain Wall System

4 Side SSG

FRAMING MEMBERS

Mullion

SSG Jamb Adaptor

E9-7052 Interlocking Clip E9-7072

Base

For 6” System

1/4” Adaptor

SSG Jamb Adaptor E9-7053 E9-7749

For 1-5/16” Glazing

Flush Filler Face Cover

E9-7044 E9-1206

Use with E9-7043 (Optional)

Pressure Plate

Flush Filler

E9-7066 (Optional) AS-7054

Use with E9-7065

For 1” Glazing

Mullion Pressure Plate

Interlocking Clip E9-7003 (Optional) AS-7057

For 7-1/2” System For 1-5/16” Glazing

ACCESSORIES

Mullion Sleeve

Stack Joint Plate E1-7001 Right Hand E1-7021

For 7-1/2” System

Mullion Sleeve

End Dam E1-7002 Left Hand E1-7022

For 7-1/2” System

Mullion Sleeve

Mullion Clip

E1-7003 Right Hand E1-7075

Use with E9-7002

For 6” System

Mullion Sleeve

Mullion Clip

E1-7072 Left Hand E1-7076

Use with E9-7062

For 6” System

Mullion Reinforcement

Mullion Anchor Sleeve E1-7006 Clip E1-7046

For 6” System

Mullion Reinforcement Corner Mullion Sleeve

Clip E1-7007 Right Hand E1-7048

For 7-1/2” System For 7-1/2” System

Page-2 04-4023-08 | Effective Date: March 2, 2020

YUW 750 XT Unitized Curtain Wall System

4 Side SSG

ACCESSORIES

Corner Mullion Sleeve

90º I.S. Corner Leveling

Left Hand E1-7049 E1-7033

Anchor (LH)

For 7-1/2” System

Corner Mullion Clip

90º O.S. Corner Level-

Use with E9-7046 & E1-7050 E1-7032

ing Anchor

E9-7069

Corner Mullion Sleeve

90º I.S. Corner Leveling

Right Hand E1-7079 E1-7034

Anchor (RH)

For 6” System

Corner Mullion Sleeve

Left Hand E1-7080 Bracket Sleeve E1-7092

For 6” System

Corner Mullion Rein-

E1-7051 Bracket Sleeve E1-3906

forcement Clip

Mullion Anchor

E1-7004 L Anchor E1-3907

For 6” System

Jamb Anchor

E1-7005 Lock Washer E1-3908

For 6” System

Mullion Anchor 90° L Anchor

E1-7024 E1-3917

For 7-1/2” System For 90° Outside Corner

SSG Setting Block

Jamb Anchor

E1-7025 Chair E1-7067

For 7-1/2” System

For 1” Glass

SSG Setting Block

90º I.S. Corner Anchor E1-7028 Chair E1-7011

For 1-5/16” Glass

90º Corner Starter Sill

90º O.S. Corner Anchor E1-7029 E1-7027

Splice

Leveling Anchor

E1-7014 Jamb Stack Block E1-7081

Right Hand

Leveling Anchor

E1-7015 Silicone Splice Sleeve E2-0070

Left Hand

Effective Date: March 2, 2020 | 04-4023-08 Page-3

YUW 750 XT Unitized Curtain Wall System

4 Side SSG

ACCESSORIES

Sill Horizontal

3/4” Spacer Sponge E2-0725 E2-7016

Weather Seal

SSG Thermal Barrier

Stacking Tray Spacer E2-3906 E3-7013

For 1” Glazing

SSG Thermal Barrier

Interior Gasket E2-7001 E3-7011

For 1-5/16” Glazing

SSG Corner Thermal

Glazing Spacer Tape E2-0110 Barrier E3-7020

For 1-5/16” Glazing

I.G.U. Cap

SSG Corner Spacer E2-7014 E3-7002

For 1” Glazing

I.G.U. Cap

Air Water Seal Gasket E2-7002 E3-7018

For 1-5/16” Glazing

Stacking Tray

E2-7004 Sill Track Adaptor E3-7023

Gasket

Pocket Filler

Exterior Gasket E2-7005 E3-7008

For 1” Glazing

Pocket Filler

SSG Wiper Gasket E2-7009 E3-7015

For 1-5/16” Glazing

SSG Corner Wiper

E2-7015 Thermal Barrier E3-7017

Gasket

Captured Setting Block Thermal Shield

E2-7011 E3-7003

For 1” Glazing For 1” Glazing

Captured Setting Block Thermal Shield

E2-7018 E3-7016

For 1-5/16” Glazing For 1-5/16” Glazing

Weather Seal Gasket E2-7010 End Cap E3-7024

Page-4 04-4023-08 | Effective Date: March 2, 2020

YUW 750 XT Unitized Curtain Wall System

4 Side SSG

ACCESSORIES

#10 x 5/8” PHSMS

#10 x 5/8” FHSMS Type AB, Stainless Steel PC-1010-

FC-1010

Type AB, Zinc Plated Steel For Attachment of End Dam SS

to Sill Starter

1/2”-13 x 1/2” Set Screw

1/4”–20 x 1-1/4” HWHS HD-

Zinc Plated Steel YM-5008

Type CA, Zinc Plated Steel 2520-W3 For Leveling Bracket

#12 x 1-1/4” HWHS #10-24 x 1/2” FHUCMS

Stainless Steel HC-1220- Stainless Steel, For UF-1008-

For Screw Spline SS Attachment of End Cap to SS

Attachment Vertical Mullion

#12 x 1-3/4” HWHSMS #10 x 1/2” PHSMS

Stainless Steel HC-1228- Type AB, Stainless Steel PC-1008-

For Screw Spline SS For Attachment of Angle to SS

Attachment at Corner Jamb

1/4”-20x2” HHMS

Stainless Steel HM-2532-

For Pressure Plate SS

Attachment

Effective Date: March 2, 2020 | 04-4023-08 Page-5

YUW 750 XT Unitized Curtain Wall System

4 Side SSG

UNIT INSTALLATION

STEP 1

CHECK OPENINGS

Elevations and slabs must be within adjustment of anchoring system. See approved shop drawings

for allowable adjustment.

Anchoring surfaces of perimeter construction must be level and plumb within the adjustment limits of

the head, sill and jamb. See approved shop drawings for allowable adjustment.

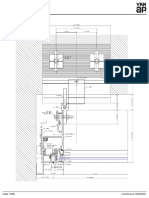

STEP 2

LAY OUT ANCHOR AND MULLION CENTERLINES

-Use wall lines established by the general contractor. On each floor, lay out a reference line to

establish in and out wall locations.

-Use columns center lines established by the general contractor. On each floor, lay out mullion

center lines and anchor center lines.

See Detail 1.

Exterior

face of beam

or floor slab

C/L OF MULLION

± 1/32"

Varies with job

conditions

System Depth 1”

Typical

Mullion E1-3907

Varies

Detail 1

Page-6 04-4023-08 | Effective Date: March 2, 2020

YUW 750 XT Unitized Curtain Wall System

4 Side SSG

UNIT INSTALLATION

STEP 3

INSTALL STARTER SILL

Starter sill pieces can be up to 20’-0” long. Prior to anchoring the starter sill, the stacking tray gasket

(E2-7004) and the stacking tray spacer (E2-3906) should be installed to the starter sill pieces.

-Cut the stacking tray spacer to the length of starter

sill. For starter sill jamb pieces, cut the air water seal

gasket to starter sill length plus (+) 1/8”. For

intermediate starter sill pieces, cut the air water E2-3906

E2-7004

seal gasket to starter sill length (+) 1/4”.

Note: To ensure proper gasket length at corner

starter sill pieces, the length of the starter sill should

be measured at the reglets. Detail 2

-Install the gaskets into the starter sill as shown in Detail 2.

-Apply bond breaker tape to the front of the stack joint plate.

-Slide stack joint plate into starter sill and secure the plate with tape.

-Apply sealant to the starter sill at the jamb where the end dam will be placed.

-Attach end dams at jamb location with (2) PC-1012 screws.

-Locate the back of the curtain wall system (back of the vertical mullions) and mark locations.

Note: the back of the E9-7011 starter sill is to be flush with the back of the mullions for 7-1/2” system.

-Locate the centerline of the vertical mullions from established column lines and mark the locations.

See Detail 3.

Note: Neither outside nor inside corners can utilize the stack joint plate.

E1-7002

End Dam

Sealant

Starter Sill @ E1-7001

O.S. Corner Stack Joint

Plate

Starter

Sill

PC-1012

Detail 3

Effective Date: March 2, 2020 | 04-4023-08 Page-7

YUW 750 XT Unitized Curtain Wall System

4 Side SSG

UNIT INSTALLATION

STEP 3 (Continued)

INSTALL STARTER SILL

-Position sill track and shim as necessary to place it at the proper height. (measured from established

benchmark) the shim stack and perimeter anchors to be located per approved shop drawings. The

sill track must be level and straight. Leave 1/4” space between starter sill ends at the splice.

-Field match and drill building condition for the sill track’s perimeter fasteners. Locate fasteners from

interfering with the unit’s sill horizontal, when unit is installed. Apply fasteners.

-Slide stack joint plate to center across splice joint and align bond breaker tape with 1/4” space.

See Detail 4.

1/4” E1-7001

Stack Joint

Plate

Anchor Fastener per

Engineering Calculations

& Approved Shop Drawings

Shims

Detail 4

Return Backer

Rod & Sealant

at Jambs

-Insert backer rod and apply perimeter primary

sealant including return to back of starter sill

at jambs.

Sealant

See Detail 5.

Detail 5 Backer Rod

Page-8 04-4023-08 | Effective Date: March 2, 2020

YUW 750 XT Unitized Curtain Wall System

4 Side SSG

UNIT INSTALLATION

STEP 3 (Continued)

INSTALL STARTER SILL

-Seal between gasket ends of the air water seal gasket, crowding them together where splices

occur. Miter cut at corners. Tool silicone smooth.

See Detail 6.

Sealant

Splice if

Necessary

Sealant

Sealant

Detail 6

Effective Date: March 2, 2020 | 04-4023-08 Page-9

YUW 750 XT Unitized Curtain Wall System

4 Side SSG

UNIT INSTALLATION

STEP 3 (Continued)

INSTALL STARTER SILL

-Cut the E3-7023 PVC adaptor to fit up to the splice location. Adaptors can be spliced between

starter splices if needed, leaving a 1/4” gap and joined with a E2-0070 silicone sheet.

-Before installing the PVC sill track adaptor, apply a bead of silicone sealanti nto the upper cavity of

the starter sill.

-While the silicone is still wet, insert the PVC sill track adaptor into the cavity starter sill.

With the top leg in place, engage the bottom of the adaptor into the starter sill as shown.

-See splice detail for sealant of the splice, then apply backer rod and apply the secondary seal.

-Seal the top lip continuously as shown.

See Detail 7.

E3-7023 A

Detail 7

Back of Mullion

Reference

Sealant

at Splice

Secondary

Seal E1-7001

Page-10 04-4023-08 | Effective Date: March 2, 2020

YUW 750 XT Unitized Curtain Wall System

4 Side SSG

UNIT INSTALLATION

STEP 3 (Continued)

INSTALL STARTER SILL

-Apply and tool sealant at the gaps between the starter sill members at the PVC adaptors.

See Detail 8.

Sealant

Sealant

Sealant

Detail 8

Prepare the Splices at Corner

-Cut the E2-0070 splices in the middle as shown in Detail 9.

-Do not cut the splices for non-corner joints.

8”

3”

1-1/2”

E2-0070 4”

Detail 9

Effective Date: March 2, 2020 | 04-4023-08 Page-11

YUW 750 XT Unitized Curtain Wall System

4 Side SSG

UNIT INSTALLATION

STEP 3 (Continued)

INSTALL STARTER SILL

-Apply the E2-0070 as shown in Detail 10. Trim off any overhanging portion of the splice at the front

on intermediate mullion locations. Completely seal and adhere the splices to the PVC adaptor with

sealant.

Detail 10

E2-0070

Set in

Sealant

E2-0070

E2-0070 Set in

Set in Sealant

Sealant

-Apply an additional E2-0070 splice to the outside corner as shown in Detail 11. Trim off any

overhanging portion of the splice, and adhere with sealant.

-Fill the gaps at the very top of the starter sill with sealant.

Sealant

Detail 11

Sealant

Sealant

E2-0070

Set in

Sealant

Page-12 04-4023-08 | Effective Date: March 2, 2020

YUW 750 XT Unitized Curtain Wall System

4 Side SSG

UNIT INSTALLATION

STEP 4

INSTALL ANCHORS

-See approved shop drawings for anchor types and locations.

-Locate the centerline of the vertical mullions from established column lines and mark the locations.

Note: Aluminum anchors must be separated from concrete and steel building substrates with a

material to prevent galvanic reaction.

-Locate centerline of aluminum anchor and mark for centerline of mullion. Also locate anchor at in/

out position. Apply aluminum washer and attach to building substrate. Final in/out adjustment can be

made prior to tightening in place.

-Tighten bolts down after final adjustment.

Note:

Anchors and fasteners to be sized per engineering calculations and approved shop drawings.

See Detail 12 on Page 14.

Effective Date: March 2, 2020 | 04-4023-08 Page-13

YUW 750 XT Unitized Curtain Wall System

4 Side SSG

UNIT INSTALLATION

STEP 4 (Continued)

INSTALL ANCHORS

* Note:

Anchor assembly allows ±1” construction tolerance in all three directions.

-Provide anchor fasteners as per approved shop drawings or engineering calculations.

E1-3908

Back of Mullion Aluminum Washer

Reference

TOP VIEW

E1-3907

E1-7014 Aluminum Anchor

Center of Mullion

Reference

E9-3839

E1-7015 Fastener per P.E.

E1-3906 Calculations or Approved

Detail 12 Shop Drawings

YM-5008 E1-3908

E1-3906

±1” Building

Tolerance

F.F. Elevation

Varies

Back of Mullion

Reference Separator

1” 3” Slot for Final

1” In/Out Adjustment

2-1/2” ±1” Building

Tolerance E1-3907

Page-14 04-4023-08 | Effective Date: March 2, 2020

YUW 750 XT Unitized Curtain Wall System

4 Side SSG

UNIT INSTALLATION

STEP 5

CURTAIN WALL UNIT INSTALLATION

Note: All curtain wall installation, per YKK AP fabrication instructions, is shown with the installation

starting from left, and any deviation from left to right may require shop / fabrication drawing modifica-

tion. Reference the key plans shown in approved shop drawings for starting locations.

Clean and prepare all surfaces for sealant application per sealant manufacturer’s recommendations.

Inspect frames prior to hoisting. The hoist spreader beam chains should be spaced apart the length

of the distance between mullion sleeves. The movement of the frame must be controlled as it is being

hoisted. It must not be allowed to swing or spin. Check maximum unit weight to ensure hoisting re-

quirements.

See Detail 13.

EXTERIOR

12”

Detail 13

Effective Date: March 2, 2020 | 04-4023-08 Page-15

YUW 750 XT Unitized Curtain Wall System

4 Side SSG

UNIT INSTALLATION

STEP 5 (Continued)

CURTAIN WALL UNIT INSTALLATION

-Prior to setting the curtain wall units, install E2-0725

spacer sponge. Coat the sponge with a non-hardening

silicone and place on top of the stack joint as shown

in Detail 14.

-Install the first unit (from left to right) by lifting it

over the starter sill of the unit below and engage

bottom of unit until it is resting on temporary

shims at head of unit below.

Note: While setting the unit, take care not to allow

the sill horizontal weather seal to get caught on the

starter sill weather seal below. Engage anchor bolts

at head of unit with anchor pre-installed on site E2-0725

@ Jamb

conditions. & Corner

-Remove temporary shims at expansion horizontal

as well as 4” long reinforcing angle from the right

side of the head horizontal used for hoisting.

-Using an allen wrench, adjust set screws in leveling

bracket to ensure the unit is level and the unit Detail 14

is supported by the aluminum anchor.

See Detail 14.

Page-16 04-4023-08 | Effective Date: March 2, 2020

YUW 750 XT Unitized Curtain Wall System

4 Side SSG

UNIT INSTALLATION

STEP 5 (Continued)

CURTAIN WALL UNIT INSTALLATION

-Block the jamb unit to prevent lateral movement when the adjacent unit is set.

-At the jamb, insert a backer rod at the end dam and apply and tool sealant as shown in Detail 15.

Backer Rod

and Sealant

E2-0725 Backer Rod

and Sealant

Detail 15

Effective Date: March 2, 2020 | 04-4023-08 Page-17

YUW 750 XT Unitized Curtain Wall System

4 Side SSG

UNIT INSTALLATION

STEP 5 (Continued)

CURTAIN WALL UNIT INSTALLATION

-Just prior to installing next unit, apply sealant to the E9-7095 mullion from bottom of mullion to 8”

above horizontal air/water seal gasket. Add sealant to the top of the E9-7095 mullion as shown.

-Install the E2-0725 spacer sponge, thoroughly coated with a non-hardening silicone selant centered,

on top of the stack joint tray (typical at all mullion locations).

See Detail 16.

E9-7095

Sill Track

Below

Mullion Apply a non-skinning silicone grease to the back side

Notch of the mullion at the mullion notch locations.

Sealant on Top

E2-0725 Sealant in Front

(First 8” from bottom of mullion)

Detail 16

Page-18 04-4023-08 | Effective Date: March 2, 2020

YUW 750 XT Unitized Curtain Wall System

4 Side SSG

UNIT INSTALLATION

STEP 5 (Continued)

CURTAIN WALL UNIT INSTALLATION

CL Mullion

-Install the next unit by lifting unit up to clear the leg

at the sill and move to the left to engage the units

together as shown in Detail 17. Squeeze the

mullion halves together until the clips engage.

Slide unit down to engage unit at the sill track.

Check to make sure that the E2-7010 air seal

vertical gaskets have not slid down from the

mullion reglets. When stacking units, align mullions

with unit below. Use temporary shims at sill track to

level unit at nominal position (Approximately 1”).

-Adjust unit height to make sure that it is level,

plumb and at the correct height. Once unit is level,

tighten anchors to secure frame and remove

temporary shims at sill. See Detail 18. Detail 17

YM-5008

Detail 18

Effective Date: March 2, 2020 | 04-4023-08 Page-19

YUW 750 XT Unitized Curtain Wall System

4 Side SSG

UNIT INSTALLATION

STEP 5 (Continued)

CURTAIN WALL UNIT INSTALLATION

-Slide the E1-7001 stainless steel bar w/ bond breaker tape at the left side to engage the adjoining unit

and center it on the mullion centerline. Apply a bead of sealant at both sides of intermediate stainless steel

bars to prevent the bars from walking.

Sealant

See Detail 19. E1-7001

-Join the ends of the stacking tray gasket E2-7004

together with sealant, trimming off excess sealant.

Note: Gasket ends should be square cut & joined

tight.

-Place the E2-0070 silicone sheet centered over

the joint as shown in Detail 20a. Fold down and

cut the sheet at the face of glass. Remove the

silicone sheet for now. Detail 19

Mullion Sleeves

-Fill the joint between the I.G.U. caps with sealant not shown for

as shown in Detail 20b. clarity

CL Joint

6”

I.G.U.

Cap

Sealant Seal Ends

of E2-7004

Together

E2-0070

Detail 20a Detail 20b

Page-20 04-4023-08 | Effective Date: March 2, 2020

YUW 750 XT Unitized Curtain Wall System

4 Side SSG

UNIT INSTALLATION

STEP 5 (Continued)

CURTAIN WALL UNIT INSTALLATION

-Seal the area where the sheet will be located.

Set the silicone sheet back into place as shown Sealant

in Detail 21, tucking it into the slot above. Tool

sealant smooth.

-Fill the gap at the top of the stacking tray with

sealant.

-Inspect the splice joint for any gap where air

or water may penetrate. Seal completely

watertight. E2-0070

Set in

-Continue across elevation in a similar manner. Sealant

Check unit spacing to eliminate dimensional

build-up of the width of the elevation. If necessary,

block and clamp mullion halves together to keep

units in alignment during installation of the next

unit.

-Before proceeding to the next floor, inspect all Detail 21

horizontal joints. All splice sealant must be cured to

avoid sealant tearing.

-Continue to the next floor. Install units using steps

as previously stated.

-Add E2-0725 spacer sponges, coated with non-

curing silicone sealant, above every joint as shown

in Detail 22.

Applying a liberal amount of non-curing silicone E2-0725

sealant at the front of the sponge ensures a water- Non-Cure

tight seal against the interior face of the mullions. Sealant

Detail 22

Effective Date: March 2, 2020 | 04-4023-08 Page-21

YUW 750 XT Unitized Curtain Wall System

4 Side SSG

UNIT INSTALLATION

STEP 6

APPLY PERIMETER SEALANT

-At stack joint jambs, apply an E2-0070 silicone

“A”

sheet across end of stack joint as shown. Set

silicone sheet in sealant and seal over edges.

Tool to maintain a low profile and minimize

excessive sealant build up.

See Detail 23.

E2-0070

“A”

Detail 23

3”

E2-0070

Sealant

8”

Section “A-A”

Page-22 04-4023-08 | Effective Date: March 2, 2020

YUW 750 XT Unitized Curtain Wall System

4 Side SSG

UNIT INSTALLATION

STEP 6 (Continued)

APPLY PERIMETER SEALANT

-Apply backer rod and perimeter seals. See Detail 24.

Backer Rod

Perimeter

Air/Water Seal

Secondary

Sealant

Detail 24

Effective Date: March 2, 2020 | 04-4023-08 Page-23

YUW 750 XT Unitized Curtain Wall System

4 Side SSG

UNIT INSTALLATION

STEP 7

CURTAIN WALL UNIT INSTALLATION @ 90° Outside Corner

Apply sealant to fill the joint between the

mitered track adaptors.

See Detail 25.

Sealant

E2-7015

Detail 25

Cut two silicone splice sleeves (E2-0070) in the

center. See Detail 26.

8”

3”

1-1/2”

E2-0070 4”

Detail 26

Page-24 04-4023-08 | Effective Date: March 2, 2020

YUW 750 XT Unitized Curtain Wall System

4 Side SSG

UNIT INSTALLATION

STEP 7 (Continued)

CURTAIN WALL UNIT INSTALLATION @ 90° Outside Corner

Apply the first silicone splice sleeve as shown in

Detail 27. Set in sealant to adhere to the corner.

E2-0070

Set in sealant

Sealant

Sealant

E2-7015

Detail 27

Apply the second silicone splice sleeve as shown in (2) E2-0725

Detail 28. Set in sealant to adhere to the corner. Miter Cut

Trim off any overhanging silicone splice. Fill gap Sealant

in the top of the head with sealant.

E2-0070

Apply two E2-0725 spacer sponges, coated with Trim to fit

a non-curing silicone sealant, to the top of the

stacking tray at the corner. Miter cut to fit. Sealant

E2-7015

Detail 28

Effective Date: March 2, 2020 | 04-4023-08 Page-25

YUW 750 XT Unitized Curtain Wall System

4 Side SSG

UNIT INSTALLATION

STEP 7A (Continued)

CURTAIN WALL UNIT INSTALLATION @ 90° Intside Corner

Apply sealant to fill the joint between the

mitered track adaptors.

See Detail 29.

Sealant

Sealant

Cut One silicone splice sleeve (E2-0070) in the

center as shown on Detail 9, Page 11.

E2-7009

Detail 29

(2) E2-0725

Miter Cut

Apply the silicone splice sleeve as shown on Sealant

Detail 30. Set in sealant to adhere to the E2-0070

corner. FIll gap in the top of the head with Set in sealant

sealant.

Apply two E2-0725 spacer sponges, coated

with a non-curing silicone sealant, to the top

of the stacking tray at the corner. Miter cut to fit.

Detail 30

E2-7009

Page-26 04-4023-08 | Effective Date: March 2, 2020

YKK AP America Inc.

270 Riverside Parkway

Suite 100

Austell, Georgia 30168

www.ykkap.com

You might also like

- Unitized Curtain Wall SystemDocument38 pagesUnitized Curtain Wall Systems.senthil nathan100% (1)

- Type 122 8000842-01 - REV-GDocument18 pagesType 122 8000842-01 - REV-GTuvia LeNo ratings yet

- ALU-JET10 DK-Beschlagprogramm 01-18 ENGDocument4 pagesALU-JET10 DK-Beschlagprogramm 01-18 ENGLaomedon KonstaNo ratings yet

- Layher Allround Scaffolding - Technical BrochureDocument48 pagesLayher Allround Scaffolding - Technical BrochureEmaVanni100% (5)

- 75 Point Checklist For Staging and PhotographyDocument2 pages75 Point Checklist For Staging and PhotographyFrank KlesitzNo ratings yet

- Umer Associates Builders, Engineers & Contructors: Abstract of Quantities SR - No Description Unit Earthwork/ExcavationDocument4 pagesUmer Associates Builders, Engineers & Contructors: Abstract of Quantities SR - No Description Unit Earthwork/ExcavationSaqib Ali100% (1)

- Yuw 750 XT 4 Side Captured - Window Wall: Installation ManualDocument14 pagesYuw 750 XT 4 Side Captured - Window Wall: Installation ManualNguyễn SơnNo ratings yet

- YCW 750 XT 2-Sided SSG Structural Silicone Glazed Curtain Wall SystemDocument64 pagesYCW 750 XT 2-Sided SSG Structural Silicone Glazed Curtain Wall SystemU MariappanNo ratings yet

- Clenergy Catalogue 2020Document36 pagesClenergy Catalogue 2020VicArodriguez.No ratings yet

- Type 180 8000352-03 - REV-DDocument17 pagesType 180 8000352-03 - REV-DTuvia LeNo ratings yet

- YCU 750 TU Unitized Curtain Wall System: Installation InstructionsDocument22 pagesYCU 750 TU Unitized Curtain Wall System: Installation InstructionsbaharehNo ratings yet

- PV Ezrack Product Catalogue - enAU - V20150623Document28 pagesPV Ezrack Product Catalogue - enAU - V20150623Panji Joyonegoro RamadhanNo ratings yet

- PDF Alimak sc45 30 Technical Description Construction Hoist - CompressDocument26 pagesPDF Alimak sc45 30 Technical Description Construction Hoist - CompressDiaz ishakNo ratings yet

- Universal Assembly Instructions For Versatube Frontier Garage BuildingsDocument35 pagesUniversal Assembly Instructions For Versatube Frontier Garage BuildingsMatthew BurkhalterNo ratings yet

- Tehnickko Uputstvo Za Montazu SistemaDocument8 pagesTehnickko Uputstvo Za Montazu Sistemao5mal13kNo ratings yet

- 04 4012 00 PDFDocument38 pages04 4012 00 PDFrmdarisaNo ratings yet

- MIDTERM in TECHWRITEDocument17 pagesMIDTERM in TECHWRITEChiyoNo ratings yet

- S-Series Posilok Installation, Removal MaintenanceDocument12 pagesS-Series Posilok Installation, Removal MaintenanceOdrzavanje MPEUNo ratings yet

- Aegi ClampsDocument12 pagesAegi ClampssssydorenkoNo ratings yet

- Yale & Sentry 2010 Closure Catalog - R&MDocument16 pagesYale & Sentry 2010 Closure Catalog - R&MAlfredo OrellanaNo ratings yet

- Solar Mount Installation ManualDocument20 pagesSolar Mount Installation ManualXe CohNo ratings yet

- GU Catalogue - ALU JET - 06 - 06 19 - WP00083 04 1 1Document156 pagesGU Catalogue - ALU JET - 06 - 06 19 - WP00083 04 1 1José Roberto RamosNo ratings yet

- Sterner Infranor Polaris-6 Series Brochure 2006Document20 pagesSterner Infranor Polaris-6 Series Brochure 2006Alan MastersNo ratings yet

- ALIMAK-Scando 650 Tech Desc 9104228-107 USDocument117 pagesALIMAK-Scando 650 Tech Desc 9104228-107 USramtsanNo ratings yet

- Alimak Scando - 650 - SeriesDocument148 pagesAlimak Scando - 650 - SeriesmoiburNo ratings yet

- Instalacion de CanatalDocument36 pagesInstalacion de Canataltecnofresh.serviciosNo ratings yet

- Solar Carport Installation Manual 2019 2.0Document15 pagesSolar Carport Installation Manual 2019 2.0Shankara ArijeyNo ratings yet

- Manual de Zaranda Alta Frecuencia Sds38-6mv-5 (Sr4639)Document15 pagesManual de Zaranda Alta Frecuencia Sds38-6mv-5 (Sr4639)victoranticonajicaro100% (1)

- 5" Multi-Jaw Bench Vise: Operator's ManualDocument6 pages5" Multi-Jaw Bench Vise: Operator's ManualHamid HojatiNo ratings yet

- Modular Steelwork SolutionsDocument132 pagesModular Steelwork SolutionsDanny MatousekNo ratings yet

- Digitilt Horizontal Probe Manual 2006Document17 pagesDigitilt Horizontal Probe Manual 2006Mahesh JalluNo ratings yet

- Catalogue Skylight PDFDocument16 pagesCatalogue Skylight PDFDaniel DediuNo ratings yet

- Centrifugal IOMDocument12 pagesCentrifugal IOMvalentinlupascu33No ratings yet

- InstallationGuide AWS IO 10302023Document45 pagesInstallationGuide AWS IO 10302023Bindanna JoshiNo ratings yet

- Clesta 511, 512, 515, 517N, 518, 530X Light Inst & Operation Manual E120105Document32 pagesClesta 511, 512, 515, 517N, 518, 530X Light Inst & Operation Manual E120105Taha ImamiNo ratings yet

- SoEasy Roof Mounting Solution.Document8 pagesSoEasy Roof Mounting Solution.Irfan FatahilahNo ratings yet

- Installation, Operation & Maintenance Manual - Original VersionDocument11 pagesInstallation, Operation & Maintenance Manual - Original VersionAli AafaaqNo ratings yet

- K Series: User ManualDocument105 pagesK Series: User ManualCraig AdamsNo ratings yet

- Kinetix 5700 Passive Shunt Modules: Installation InstructionsDocument8 pagesKinetix 5700 Passive Shunt Modules: Installation InstructionssenthilNo ratings yet

- SUCOOT Access Facade ScaffoldDocument24 pagesSUCOOT Access Facade ScaffoldhadipurnomoputraNo ratings yet

- Ejot Solar Full enDocument24 pagesEjot Solar Full enJie RongNo ratings yet

- XSGlobe On Double Fold Seam En-Product DataDocument3 pagesXSGlobe On Double Fold Seam En-Product DataAdefisayo HaastrupNo ratings yet

- Pennbarry Fumex IOM v6Document22 pagesPennbarry Fumex IOM v6RanielNo ratings yet

- Sliding Window Lock InstallationDocument2 pagesSliding Window Lock InstallationMathan JeyaramanNo ratings yet

- Masco - Cooper - Medc - BG - Ul (TM110) enDocument4 pagesMasco - Cooper - Medc - BG - Ul (TM110) enparallax1957No ratings yet

- Sliding Window DetailsDocument18 pagesSliding Window DetailsArif NadafNo ratings yet

- For Flexibolts: DSI-Mining Australia Products Drilling Products For FlexiboltsDocument2 pagesFor Flexibolts: DSI-Mining Australia Products Drilling Products For Flexiboltspradhith kattaNo ratings yet

- 772 - Wall Penstock - MIDocument15 pages772 - Wall Penstock - MIJohn KurongNo ratings yet

- Form C 1608 AnchorLoc3 Install GuideDocument4 pagesForm C 1608 AnchorLoc3 Install GuideKelvin JinNo ratings yet

- General Electronics RacksDocument20 pagesGeneral Electronics RacksAbhijith S. MenonNo ratings yet

- DormaKaba Lagard 3000 Series ManualDocument13 pagesDormaKaba Lagard 3000 Series ManualWilliam TerryNo ratings yet

- Threaded Fasteners SGDocument97 pagesThreaded Fasteners SGSyahri TamaNo ratings yet

- EN - Allround Technical BrochureDocument48 pagesEN - Allround Technical BrochuresivanaNo ratings yet

- Interchangeable Spindle Users Guide 4C v0311 WebDocument21 pagesInterchangeable Spindle Users Guide 4C v0311 WebMynor SGNo ratings yet

- 2900SF Asy 660005033 Rev2Document44 pages2900SF Asy 660005033 Rev2Иван Сергеевич ЛатошаNo ratings yet

- Capping Manual Rev001Document54 pagesCapping Manual Rev001Gabriel AmorimNo ratings yet

- Dumbwaiter Installation ManualDocument26 pagesDumbwaiter Installation Manualmozhi selvamNo ratings yet

- Alpine CDA 7990 Installation Manual.Document64 pagesAlpine CDA 7990 Installation Manual.Jason BrownNo ratings yet

- spr2-135 841 01 01 02Document8 pagesspr2-135 841 01 01 02vlad69.vl77No ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Why Industrial Bearings Fail: Analysis, Maintenance, and PreventionFrom EverandWhy Industrial Bearings Fail: Analysis, Maintenance, and PreventionNo ratings yet

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

- Imperial Avenue Dubai, United Arab Emirates: Structural Calculation For Add On Façade at Level 26 & 27Document125 pagesImperial Avenue Dubai, United Arab Emirates: Structural Calculation For Add On Façade at Level 26 & 27Nguyễn Sơn100% (1)

- DOWSIL™ 791 Silicone Weatherproofing Sealant: Features & BenefitsDocument6 pagesDOWSIL™ 791 Silicone Weatherproofing Sealant: Features & BenefitsNguyễn SơnNo ratings yet

- S A T - S: Ilicone Sealant Pplication Raining Ite TeamDocument74 pagesS A T - S: Ilicone Sealant Pplication Raining Ite TeamNguyễn SơnNo ratings yet

- Glasscorners - English Version - 15062007 PDFDocument10 pagesGlasscorners - English Version - 15062007 PDFNguyễn SơnNo ratings yet

- 2021-007 - Lancaster Luminare - Structural Silicone Sealant Design For Glass Corner PDFDocument1 page2021-007 - Lancaster Luminare - Structural Silicone Sealant Design For Glass Corner PDFNguyễn SơnNo ratings yet

- BM Window LTD Co, Whom It May Concern: Dow Chemical Vietnam LLCDocument1 pageBM Window LTD Co, Whom It May Concern: Dow Chemical Vietnam LLCNguyễn SơnNo ratings yet

- Dow High Performance Building Americas Asia Emeai: Imagine The PossibilitiesDocument3 pagesDow High Performance Building Americas Asia Emeai: Imagine The PossibilitiesNguyễn SơnNo ratings yet

- Sika Silicone Sealant của công ty Topco - Bảng báo giá - BM WINDOWS - 20191107Document2 pagesSika Silicone Sealant của công ty Topco - Bảng báo giá - BM WINDOWS - 20191107Nguyễn SơnNo ratings yet

- Thuan Thanh Glass Corporation 18 - 20 LE QUY DON ST., 6 WARD, 3 Dist., HO CHI MINH City Hochiminh City, Viet Nam Ho Chi Minh 70000Document4 pagesThuan Thanh Glass Corporation 18 - 20 LE QUY DON ST., 6 WARD, 3 Dist., HO CHI MINH City Hochiminh City, Viet Nam Ho Chi Minh 70000Nguyễn SơnNo ratings yet

- Dow High Performance Building Americas Asia Emeai: Imagine The PossibilitiesDocument3 pagesDow High Performance Building Americas Asia Emeai: Imagine The PossibilitiesNguyễn SơnNo ratings yet

- Part 1 - Silicone Technology &Document22 pagesPart 1 - Silicone Technology &Nguyễn SơnNo ratings yet

- GE - SSG4600 Performance & Behavior r.081516Document4 pagesGE - SSG4600 Performance & Behavior r.081516Nguyễn SơnNo ratings yet

- 21-009832 TIEN GIANG GENERAL HOSPITAL Adhesion 582913Document3 pages21-009832 TIEN GIANG GENERAL HOSPITAL Adhesion 582913Nguyễn SơnNo ratings yet

- Product Comparison - GE SSG4400 UltraGlaze Vs SSG4600 UltraGlaze Vs DC98...Document8 pagesProduct Comparison - GE SSG4400 UltraGlaze Vs SSG4600 UltraGlaze Vs DC98...Nguyễn SơnNo ratings yet

- GE UltraGlaze SSG4600 Strucutral Bite Calculation (SDS 138psi & SDS 210p...Document2 pagesGE UltraGlaze SSG4600 Strucutral Bite Calculation (SDS 138psi & SDS 210p...Nguyễn SơnNo ratings yet

- 21 - 1575 - Sika Corner BondingDocument4 pages21 - 1575 - Sika Corner BondingNguyễn SơnNo ratings yet

- Spec CRL995Document3 pagesSpec CRL995Nguyễn SơnNo ratings yet

- Confirmation Laminated Glass 2020-06-02Document3 pagesConfirmation Laminated Glass 2020-06-02Nguyễn SơnNo ratings yet

- 31295007040800Document152 pages31295007040800Nguyễn SơnNo ratings yet

- Facade Systems Specification GuideDocument48 pagesFacade Systems Specification GuideEvgeny Shavelzon100% (2)

- 795 & 995 Silicone Coparison ChartDocument2 pages795 & 995 Silicone Coparison ChartNguyễn SơnNo ratings yet

- 21 1575 StatementDocument4 pages21 1575 StatementNguyễn SơnNo ratings yet

- 09-3. Test Report Sikasil WS355N Astm C1248Document2 pages09-3. Test Report Sikasil WS355N Astm C1248Nguyễn SơnNo ratings yet

- Ycu750tu Monoanchorvertd2Document1 pageYcu750tu Monoanchorvertd2Nguyễn SơnNo ratings yet

- Ycu750tu Monoanchorljd2Document1 pageYcu750tu Monoanchorljd2Nguyễn SơnNo ratings yet

- Capacity P500 Node Curtain WallDocument212 pagesCapacity P500 Node Curtain WallNguyễn SơnNo ratings yet

- Design For Snapfit Revi-10 PDFDocument26 pagesDesign For Snapfit Revi-10 PDFDmitry ShelestNo ratings yet

- AD391 LTB of Rectangular Plate PDFDocument1 pageAD391 LTB of Rectangular Plate PDFFrankie ChanNo ratings yet

- Example 2.4Document3 pagesExample 2.4Nebiyu solomonNo ratings yet

- Swisspearl 16 150Document68 pagesSwisspearl 16 150santhoshNo ratings yet

- Group 3 Abalorio, Daan, Daculara Worksheet 5 EE-PC 4113Document8 pagesGroup 3 Abalorio, Daan, Daculara Worksheet 5 EE-PC 4113Joshua CarlNo ratings yet

- Wood - Materials For Furniture PDFDocument5 pagesWood - Materials For Furniture PDFseba82820% (1)

- Element Warren A2LA 0038 01 MechanicalDocument21 pagesElement Warren A2LA 0038 01 MechanicalBau2NineNo ratings yet

- Properties of MatterDocument117 pagesProperties of MatterKarren Ferrer-Mora Handayan100% (1)

- R & AcDocument6 pagesR & AcM.ThirunavukkarasuNo ratings yet

- VRV Heat Recovery Hot Water System - PCVMT1536 PDFDocument12 pagesVRV Heat Recovery Hot Water System - PCVMT1536 PDFAhmed NabilNo ratings yet

- Fired Heater Specification PDFDocument5 pagesFired Heater Specification PDFsvnaik14100% (1)

- Awwa C905 (2010) PDFDocument40 pagesAwwa C905 (2010) PDFceleste576012No ratings yet

- BIS - CementDocument12 pagesBIS - CementSuvendu DeyNo ratings yet

- InRoom Tech Data 31010 ApcDocument92 pagesInRoom Tech Data 31010 ApcRolandoNo ratings yet

- Industrial and Genset Cooling System Issue 11Document49 pagesIndustrial and Genset Cooling System Issue 11khoirulfeb.rizmarosNo ratings yet

- 1492Document15 pages1492_Anggyaa_No ratings yet

- B - Tech Civil Batch 2011 PTU SyllabusDocument12 pagesB - Tech Civil Batch 2011 PTU SyllabusMohit Dev100% (1)

- Car ShowroomDocument1 pageCar ShowroomRAHUL RATHODNo ratings yet

- Metallurgical Engineering (MT) : GATE 2019Document1 pageMetallurgical Engineering (MT) : GATE 2019Samarjeet Kumar SinghNo ratings yet

- Review of Related LiteratureDocument6 pagesReview of Related LiteratureMontzo Diana BaltonadoNo ratings yet

- Prestress LossesDocument29 pagesPrestress LossesMuhammad FaheemNo ratings yet

- Edc - Piping StandardsDocument11 pagesEdc - Piping StandardsSrikrishnan KrishNo ratings yet

- Portal FramesDocument13 pagesPortal FramesArun Sahani100% (2)

- Aimur Tarifa PVP Magic Christmas 19-20Document50 pagesAimur Tarifa PVP Magic Christmas 19-20VEMATELNo ratings yet

- Doors and Windows Details PDFDocument1 pageDoors and Windows Details PDFMark Anthony Capito AñosNo ratings yet

- Technical Bulletin 4Document8 pagesTechnical Bulletin 4RANAIVOARIMANANANo ratings yet

- Water Source Heat Pump Axiom Horizontal Vertical EXH EXV, DXH DXV PDFDocument228 pagesWater Source Heat Pump Axiom Horizontal Vertical EXH EXV, DXH DXV PDFVirgilio Jr ArtajoNo ratings yet

- Abstract of Retaining Wall & Bathing Ghat To Protect Ramraja Temple From Flood Protection of Angori River at Bhagor VillageDocument4 pagesAbstract of Retaining Wall & Bathing Ghat To Protect Ramraja Temple From Flood Protection of Angori River at Bhagor VillageankitNo ratings yet

- Spreadsheet Esp Calculation FansDocument36 pagesSpreadsheet Esp Calculation Fansjomy_pj81060% (1)

- Flupec - Catalog-Garnituri PDFDocument928 pagesFlupec - Catalog-Garnituri PDFRadu VasileNo ratings yet