Professional Documents

Culture Documents

BT7 Steam Trap Uid91920091059231

Uploaded by

Ramesh-NairOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BT7 Steam Trap Uid91920091059231

Uploaded by

Ramesh-NairCopyright:

Available Formats

Indianapolis ● Chicago ● San Juan

www.hollandapt.com

800-800-8464

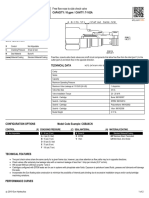

Stainless Steel Balanced Pressure Thermostatic Steam Trap

BTM7/BTS7

The BTM7 (maintainable) and

Model ➪ BTM7 / BTS7

Typical Applications

BTS7 (sealed) are vertical

body thermostatic steam traps, Fermenter sterilization, steam barriers (block &

PMO 102 psig

with all AISI 316L construction bleed systems), sterilizer drainage and air vent-

designed for use in clean Sizes 1/2", 3/4", 1"

ing, CIP/SIP system condensate drainage, and

steam systems. Normal opera- 0.065" O.D. Tube, NPT sterilization of process vessels and pipes.

tion is close to saturated steam Connections

or Tri-Clamp®* compatible (BTM7 only)

temperature, with minimal

back-up of condensate. Construction All 316L Stainless Steel

Other connections are available 1

Options Fixed bleed (BTM7 only)

3.1B available (BTM7 only)

FEP encapsulated silicone ‘O’ ring is

recommended and available. For use on 6

systems where there is, or maybe lactic acid

present BTM7 only.

* A registered trademark of Tri-Clover Inc.

Limiting Operating Conditions

Max. Operating Pressure (PMO) 102 psig (7 barg) 4

2 5

Max. Operating Temperature Saturated Steam Temperature

BTM7

Pressure Shell Design Conditions

PMA 145 psig/0-302˚F 10 barg/0-150˚C

Max. allowable pressure

132 psig/338˚F 9 barg/170˚C

3

TMA 338˚F/0-132 psig 170˚C/0-9 barg

Stainless Steel

Specialties

Max. allowable temperature 5

Capacities

Differential Pressure, bar

0.2 0.5 1 2 3 5 7

4,000

1,500

3,000

2,000 1,000 BTS7

cold

1,000 l 500 Construction Materials

oo ol

bc o No. Part Material

su ubc

BT6, BTM7/BTS7 ˚F s

1 (BTM7) Body (Inlet) Stainless Steel AISI 316L

500 20 0˚F

Condensate, lb/h

1 200

Condensate, kg/h

2 (BTM7) Body w/ Seat (Outlet) Stainless Steel AISI 316L

90 3 (BTS7) Body Stainless Steel AISI 316L

200

4 (BTM7) O-Ring gasket Grey Viton ‘O’ ring complies with

50

(standard) FDA CFR title 21, paragraph 177 section

100

2600 and 3A’s sanitary standards 20-22.

O-Ring gasket Clear Teflon FEP encapsulated

50 20

(optional) silicone compliant to:

15

30 - FDA regulation 21 CFR 177.1550

10 5 - 3A’s sanitary standard 20-22

- USP class VI

5 Element Stainless Steel AISI 316L

1 3 5 10 20 50 100

6 (BTM7) Nuts & Bolts Stainless Steel BS6105 Gr A4 80

Differential Pressure, psi

Local regulation may restrict the use of this product below the conditions quoted. Limiting conditions refer to standard connections only.

In the interests of development and improvement of the product, we reserve the right to change the specification. TI-2-0002-US 11.07

5: 366

Stainless Steel Balanced Pressure Thermostatic Steam Trap

BTM7/BTS7

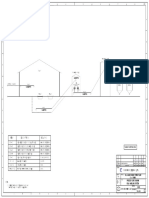

Dimensions

(nominal) in inches and millimeters

BTM7 BTS7

Size A B C D E Weight Size A B C D Weight

Tube Tube Screwed Tri-Clamp* Tube Screwed Tri-Clamp* Tube Tube Screwed Tube Screwed

1/2" 2.8 4.2 1.5 2.9 1.85 .62 lb .66 lb .48 lb 1/2" 1.6 4.2 1.5 2.9 .44 lb .49 lb

70 106 40 74 47 .28 kg .30 kg .22 kg 40 106 4.0 74 .20 kg .22 kg

3/4" 2.8 5.1 1.5 3.2 1.85 .68 lb .77 lb .48 lb 3/4" 1.6 5.1 1.5 3.2 .51 lb .60 lb

70 130 40 81 47 .31 kg .35 kg .22 kg 40 130 40 81 .23 kg .27 kg

1" 2.8 5.0 1.5 3.7 1.85 .77 lb .90 lb .78 lb 1" 1.6 5.0 1.5 3.7 .60 lb .73 lb

70 126 40 95 47 .35 kg .41 kg .37 kg 40 126 40 95 .27 kg .33 kg

C C

B B

D E D

A

A

Sample Specification

Steam trap shall be self-adjusting balanced

pressure type capable of operating close to Spare Parts

saturated steam temperature. All wetted

parts shall be manufactured from 316L

stainless steel. Trap shall be maintainable

Stainless Steel

(BTM7), or sealed construction (BTS7), and

Specialties

shall be completely self-draining when

installed in vertical pipeline. Connections

shall be 0.065" extended O.D. tube, Tri-

Clamp® compatible (BTM7 only), or

screwed NPT. All wetted parts of this trap Element Assembly A

are manufactured from FDA/3-A approved Gasket (Pkt of 3) B

materials. Body with Seat C

A

Installation

The traps are designed for installation in ver-

tical lines with the flow downward to ensure Available spare parts are

self-draining. The element may be damaged shown in heavy outline. Parts

if it is exposed to superheated steam. Full- shown in broken lines are B

flow isolating valves, such as Spirax Sarco not available as spares.

Model 70i or 80i Clean Ball Valve, should be

installed so as to permit servicing. C

© Spirax Sarco, Inc. 2007

Maintenance

The BTM7 is a maintainable trap.The BTS7 is

non-maintainable. Maintenance on the BTM7

can be performed once the steam trap is iso-

lated from system and return line pressure.

Complete Installation & Maintenance instruc-

tions are given in IM-2-0002-US, which is

included with the product.

TI-2-0002-US 11.07

Spirax Sarco, Inc., 1150 Northpoint Blvd, Blythewood, SC 29016 Telephone: (803) 714-2000 FAX (803) 714-2222

5: 367

You might also like

- AE36 and AE36A Automatic Air Eliminators/ Air Vents For Liquid SystemsDocument2 pagesAE36 and AE36A Automatic Air Eliminators/ Air Vents For Liquid SystemsjorgeNo ratings yet

- TD62LM & TD62M Thermodynamic Steam Traps With Replaceable Seats ASTM Body (Flanged Connections)Document5 pagesTD62LM & TD62M Thermodynamic Steam Traps With Replaceable Seats ASTM Body (Flanged Connections)Hsalmani1991No ratings yet

- Regulator Vzduchu Wilkerson r30 Katalogove ListyDocument3 pagesRegulator Vzduchu Wilkerson r30 Katalogove ListyStefanny PalomarNo ratings yet

- Series 5100: Texsteam Gas/Pneumatic Driven Injection PumpDocument18 pagesSeries 5100: Texsteam Gas/Pneumatic Driven Injection PumpNajem A. SakorNo ratings yet

- Sr. No. Particulars Value Unit of Measuremen T: MSGL-3KL-R002B/CDocument3 pagesSr. No. Particulars Value Unit of Measuremen T: MSGL-3KL-R002B/CBhaumik BhuvaNo ratings yet

- Spirax Sarco - Pure Steam GeneratorDocument5 pagesSpirax Sarco - Pure Steam GeneratorFelipeTinelNo ratings yet

- Airodyn TI P610 05 ENDocument3 pagesAirodyn TI P610 05 ENEreny AbanobNo ratings yet

- Disk Diffuser - ITA-ENG - Rev1 - MailDocument6 pagesDisk Diffuser - ITA-ENG - Rev1 - MailDaniele BacchiNo ratings yet

- BVW 0 o 8Document24 pagesBVW 0 o 8Nofra HardikoNo ratings yet

- B38 Filter/regulator (Stainless Steel) : Medium: Maximum Inlet Pressure: Port Sizes: Ambient/Media Temperature: MaterialsDocument3 pagesB38 Filter/regulator (Stainless Steel) : Medium: Maximum Inlet Pressure: Port Sizes: Ambient/Media Temperature: Materialsarif fadhillahNo ratings yet

- 3kl R 002ADocument3 pages3kl R 002ABhaumik BhuvaNo ratings yet

- GES EN-PSG-Plus BrochureDocument4 pagesGES EN-PSG-Plus BrochuregarethooanalyticsNo ratings yet

- Filter Regulator LFR-3/4-D-MAXI-A: Data SheetDocument1 pageFilter Regulator LFR-3/4-D-MAXI-A: Data SheetAnonymous Y2J3QRfdNo ratings yet

- Especificaciones Bomba Graco Modelo 515Document1 pageEspecificaciones Bomba Graco Modelo 515Bryan GuerreroNo ratings yet

- Asco Series 362 562 Ss Spool Valves Non Solenoid CatalogDocument23 pagesAsco Series 362 562 Ss Spool Valves Non Solenoid CatalogGibbe1000No ratings yet

- Technical Sheet A3SDocument4 pagesTechnical Sheet A3SMalik DaniyalNo ratings yet

- Flash Vessel-P404 - 03 PDFDocument3 pagesFlash Vessel-P404 - 03 PDFFrancois HamiauxNo ratings yet

- The Pivotrol Pump Digital Cycle Counter: Specifications DescriptionDocument2 pagesThe Pivotrol Pump Digital Cycle Counter: Specifications DescriptionCarlos MtzNo ratings yet

- (Repairable) : Clean Steam Thermostatic Steam TrapDocument1 page(Repairable) : Clean Steam Thermostatic Steam TrapPaulo CostaNo ratings yet

- Edible Oil Filling Machine 201021Document14 pagesEdible Oil Filling Machine 201021Maryory Ketty Espinoza LunaNo ratings yet

- 1.03.E.DT32 Thermodynamic Steam Traps DN15-25Document1 page1.03.E.DT32 Thermodynamic Steam Traps DN15-25Son Trinh PhuongNo ratings yet

- D-5 30-33 170-173 NewDocument93 pagesD-5 30-33 170-173 NewFadimeNo ratings yet

- Filter Regulator LFR-1/2-D-7-O-MIDI: Data SheetDocument1 pageFilter Regulator LFR-1/2-D-7-O-MIDI: Data SheetRichard Rodriguez GarciaNo ratings yet

- Data Sheet: 35 Frame Plunger PumpsDocument4 pagesData Sheet: 35 Frame Plunger PumpsJordan aguilarNo ratings yet

- Manual DDocument16 pagesManual DMatias OnateNo ratings yet

- Liqui-Cel EXF-10x28 Data Sheet LC-1031Document2 pagesLiqui-Cel EXF-10x28 Data Sheet LC-1031LuisAngelCordovadeSanchezNo ratings yet

- Air Operated Double Diaphragm Pump: Service & Operating ManualDocument12 pagesAir Operated Double Diaphragm Pump: Service & Operating ManualLuiz AraujoNo ratings yet

- AGM Sludge and Bilge Pumps - ENGDocument8 pagesAGM Sludge and Bilge Pumps - ENGAdrianDanNo ratings yet

- AFR Festo LFR 34 Auto DrainDocument1 pageAFR Festo LFR 34 Auto DrainrinaltoNo ratings yet

- 359 Flexpet En-Bi 170209Document2 pages359 Flexpet En-Bi 170209hendra matatiaNo ratings yet

- Series 6000 Brass Super-Rapid Fittings For Plastic TubesDocument22 pagesSeries 6000 Brass Super-Rapid Fittings For Plastic TubesBRUNO CANDIDO DE PAULANo ratings yet

- Technical Sheet BPT13Document2 pagesTechnical Sheet BPT13Malik DaniyalNo ratings yet

- Service Unit FRC-1/2-D-MAXI-A: Data SheetDocument1 pageService Unit FRC-1/2-D-MAXI-A: Data SheetWahyu ArdiansyahNo ratings yet

- FT54 Carbon Steel Ball Float Steam Trap With Flanged ConnectionsDocument7 pagesFT54 Carbon Steel Ball Float Steam Trap With Flanged Connectionsmaryam karimiNo ratings yet

- JCL 301 Compact Gas Conditioning SystemDocument4 pagesJCL 301 Compact Gas Conditioning SystemmateusT850No ratings yet

- Filtro Dúplex de Alta Presión Serie DFHDocument8 pagesFiltro Dúplex de Alta Presión Serie DFHJesus Davila ZarateNo ratings yet

- AJ KV 2016 GreenDocument36 pagesAJ KV 2016 GreenskodgeNo ratings yet

- The Pivotrol Pump PTC & PTF Pressure Powered Pump: Accessories DescriptionDocument2 pagesThe Pivotrol Pump PTC & PTF Pressure Powered Pump: Accessories DescriptionCarlos MtzNo ratings yet

- Model Free Flow Nose To Side Check Valve With Bypass OrificeDocument2 pagesModel Free Flow Nose To Side Check Valve With Bypass OrificeRenjithSivaNo ratings yet

- HF TETPOR HT-Rev 3ADocument2 pagesHF TETPOR HT-Rev 3AbuattugasmetlitNo ratings yet

- Gauge Cock ValveDocument6 pagesGauge Cock ValveGarry Bernard NelsonNo ratings yet

- EagleBurgmann - CobaDGS - Zero Emission Solution - ENDocument2 pagesEagleBurgmann - CobaDGS - Zero Emission Solution - ENUday GokhaleNo ratings yet

- PUSH-IN TconDocument1 pagePUSH-IN TconvniranjanNo ratings yet

- Taborex-Ta 2124 HD Catalyst Masterbatch: Product DescriptionDocument1 pageTaborex-Ta 2124 HD Catalyst Masterbatch: Product DescriptionJaime222No ratings yet

- Indium10.8hf Pbfree Solder Paste 99040 A4 r9Document2 pagesIndium10.8hf Pbfree Solder Paste 99040 A4 r9rigoberto solNo ratings yet

- Model Free Flow Nose To Side Check Valve: CAPACITY: 10 GPM / CAVITY: T-162ADocument2 pagesModel Free Flow Nose To Side Check Valve: CAPACITY: 10 GPM / CAVITY: T-162AsnsnagarajanNo ratings yet

- Seal Supply Systems - Thermosiphon Systems: Rely On ExcellenceDocument5 pagesSeal Supply Systems - Thermosiphon Systems: Rely On ExcellenceDikaAnindyajatiNo ratings yet

- EagleBurgmann - TSA6 Barrier - Buffer Fluid System - ENDocument5 pagesEagleBurgmann - TSA6 Barrier - Buffer Fluid System - ENJavier PerezNo ratings yet

- JCM-310 and JCMF-310: Peltier Sample Gas CoolersDocument4 pagesJCM-310 and JCMF-310: Peltier Sample Gas CoolersAnish KarthikeyanNo ratings yet

- Model 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValvemateusT850No ratings yet

- Leaftlet OneStop+ 2022Document3 pagesLeaftlet OneStop+ 2022smenamorado27No ratings yet

- Wika Type M93X.D1 Pressure Gauge Data SheetDocument5 pagesWika Type M93X.D1 Pressure Gauge Data SheetTrEnD SeT vicky rioNo ratings yet

- Serie Ifr StucchiDocument4 pagesSerie Ifr StucchiHIDRAFLUIDNo ratings yet

- Catalogo Tecnico Valvula y Actuador GEMU 656Document6 pagesCatalogo Tecnico Valvula y Actuador GEMU 656Ronulfo GutierrezNo ratings yet

- 5CP2120W KDocument4 pages5CP2120W KDaniel SaucedaNo ratings yet

- Diaphragm Valve, Metal: ConstructionDocument10 pagesDiaphragm Valve, Metal: ConstructionChemikal EngineerNo ratings yet

- KPP 000 Xa96 702 ADocument39 pagesKPP 000 Xa96 702 ARamesh-NairNo ratings yet

- HRSG Forum Presentation LCRI 9 24 21 1Document12 pagesHRSG Forum Presentation LCRI 9 24 21 1Ramesh-NairNo ratings yet

- Annexure 4Document1 pageAnnexure 4Ramesh-NairNo ratings yet

- JusMundi PDF Heirs To The Sultanate of Sulu V Malaysia Final AwardDocument124 pagesJusMundi PDF Heirs To The Sultanate of Sulu V Malaysia Final AwardRamesh-NairNo ratings yet

- 2023-10-Elder-Manual-sfl - E - Shepherd The Flock of GodDocument290 pages2023-10-Elder-Manual-sfl - E - Shepherd The Flock of GodRamesh-NairNo ratings yet

- GB Electricity Market Implementation PlanDocument39 pagesGB Electricity Market Implementation PlanRamesh-NairNo ratings yet

- KPP 000 Xa96 700 ADocument246 pagesKPP 000 Xa96 700 ARamesh-NairNo ratings yet

- Advert - Assistant Project ManagerDocument2 pagesAdvert - Assistant Project ManagerRamesh-NairNo ratings yet

- EDF Will Indeed Buy The Nuclear Activity of GE (Ex-Alstom)Document3 pagesEDF Will Indeed Buy The Nuclear Activity of GE (Ex-Alstom)Ramesh-NairNo ratings yet

- MOLYKOTE - P 3700 - Anti Seize - Paste - 03 1106 01 AGP1022Document2 pagesMOLYKOTE - P 3700 - Anti Seize - Paste - 03 1106 01 AGP1022Ramesh-NairNo ratings yet

- Ash Handling System - Spec - Rev0Document13 pagesAsh Handling System - Spec - Rev0Ramesh-NairNo ratings yet

- Attachment 4 - Sketch For New Plant and Shared Facilities - CEL FinalDocument1 pageAttachment 4 - Sketch For New Plant and Shared Facilities - CEL FinalRamesh-NairNo ratings yet

- Annexure 2Document27 pagesAnnexure 2Ramesh-NairNo ratings yet

- Attachment 4 - PFD Coal Handling SystemDocument1 pageAttachment 4 - PFD Coal Handling SystemRamesh-NairNo ratings yet

- Annexure 10Document10 pagesAnnexure 10Ramesh-NairNo ratings yet

- Fire Fighting System - Spec - Rev0Document14 pagesFire Fighting System - Spec - Rev0Ramesh-NairNo ratings yet

- Workplace Safety and Health (General Provisions) RDocument76 pagesWorkplace Safety and Health (General Provisions) RRamesh-NairNo ratings yet

- Workplace Safety and Health (General Provisions) RDocument11 pagesWorkplace Safety and Health (General Provisions) RRamesh-NairNo ratings yet

- An Introduction To CEEQUAL May 2018Document16 pagesAn Introduction To CEEQUAL May 2018Ramesh-NairNo ratings yet

- Workplace Safety and Health (General Provisions) RDocument65 pagesWorkplace Safety and Health (General Provisions) RRamesh-NairNo ratings yet

- Cambodian Energy Employers RequirementsDocument62 pagesCambodian Energy Employers RequirementsRamesh-NairNo ratings yet

- Workplace Safety and Health (General Provisions) RDocument5 pagesWorkplace Safety and Health (General Provisions) RRamesh-NairNo ratings yet

- Routine Performance Test Guidelines For Steam TurbinesDocument40 pagesRoutine Performance Test Guidelines For Steam TurbinesRamesh-Nair100% (1)

- Ine96pma08-Sa 234WP22Document1 pageIne96pma08-Sa 234WP22Ramesh-NairNo ratings yet

- Steam Turbine Performance Engineers GuideDocument142 pagesSteam Turbine Performance Engineers GuideRamesh-Nair100% (1)

- Executive Summary - Hydrogen Cofiring Demonstration at New York Power Authority - S Brentwood Site - GE LM6000 Gas TurbineDocument8 pagesExecutive Summary - Hydrogen Cofiring Demonstration at New York Power Authority - S Brentwood Site - GE LM6000 Gas TurbineRamesh-NairNo ratings yet

- Newspaper Article - MALACCA BABAS TO TELL THE QUEEN - WE ARE SO WORRIEDDocument2 pagesNewspaper Article - MALACCA BABAS TO TELL THE QUEEN - WE ARE SO WORRIEDRamesh-NairNo ratings yet

- Newspaper Article - STRAITS SETTLEMENTS CIVIL SERVICEDocument5 pagesNewspaper Article - STRAITS SETTLEMENTS CIVIL SERVICERamesh-NairNo ratings yet

- Newspaper Article - No More Having Best of 2 WorldsDocument8 pagesNewspaper Article - No More Having Best of 2 WorldsRamesh-NairNo ratings yet

- Newspaper Article - NO COMPROMISE ON DUAL CITIZENSHIPDocument2 pagesNewspaper Article - NO COMPROMISE ON DUAL CITIZENSHIPRamesh-NairNo ratings yet

- Applied Partial Differential Equations - J. David Logan-1998Document2 pagesApplied Partial Differential Equations - J. David Logan-1998Jeremy Mac LeanNo ratings yet

- Hartnell Governor Isochronous Speed Equations - Engineers EdgeDocument1 pageHartnell Governor Isochronous Speed Equations - Engineers Edgestallone21No ratings yet

- SSTMZG528: Assignment 1Document4 pagesSSTMZG528: Assignment 1D V BHASKARNo ratings yet

- Ken Auletta: Media MaximsDocument32 pagesKen Auletta: Media MaximsMattDellingerNo ratings yet

- Unit 8Document16 pagesUnit 8luuthuctrinh3204No ratings yet

- Industrial Gases - PPTDocument48 pagesIndustrial Gases - PPTParul Saxena100% (2)

- Ella Brown - Video Questions - Electric Charge Crash Course Physics #25Document4 pagesElla Brown - Video Questions - Electric Charge Crash Course Physics #25Ella BrownNo ratings yet

- 1234 Sasdfasdf 12341234Document20 pages1234 Sasdfasdf 12341234NysekNo ratings yet

- Iap Feb IssueDocument86 pagesIap Feb IssueDhanya PillaiNo ratings yet

- ScienceDocument18 pagesScienceapi-295677008No ratings yet

- National Harmonized Nursing Curriculum February 2013Document476 pagesNational Harmonized Nursing Curriculum February 2013Yakob TadeseNo ratings yet

- Simplified Modified Compression Field Theory For Calculating Shear Strength of Reinforced Concrete ElementsDocument11 pagesSimplified Modified Compression Field Theory For Calculating Shear Strength of Reinforced Concrete ElementsTooma David100% (1)

- Mindfulness in Primary School Children ADocument15 pagesMindfulness in Primary School Children AMuhammad Irfan AneesNo ratings yet

- Advanced Cardiovascular Life Support (Acls)Document45 pagesAdvanced Cardiovascular Life Support (Acls)Erinne DefrianiNo ratings yet

- SPE-195122-MS Smart Dual ESP Completion To Develop Stacked ReservoirsDocument13 pagesSPE-195122-MS Smart Dual ESP Completion To Develop Stacked Reservoirsosama aldresyNo ratings yet

- Lecture HW 5 ProbText Moran2003 Chp11 FluidStaticsDocument2 pagesLecture HW 5 ProbText Moran2003 Chp11 FluidStaticsPanawit HanpinitsakNo ratings yet

- Army Tech Instructions TI 809 - 04Document803 pagesArmy Tech Instructions TI 809 - 04karuna3460% (1)

- 3a. CONOPS Vigilancia ADS-B Base Terrestre COCESNADocument37 pages3a. CONOPS Vigilancia ADS-B Base Terrestre COCESNADairo FerrerNo ratings yet

- Pete Gunter Bergson and JungDocument19 pagesPete Gunter Bergson and JungrottateixeiraNo ratings yet

- Europump Atex Guide - II-rev2019 1.0Document14 pagesEuropump Atex Guide - II-rev2019 1.0Antonio MakkarovNo ratings yet

- Netnumen™ U31 R06: Hardware Installation GuideDocument128 pagesNetnumen™ U31 R06: Hardware Installation GuideRidfa MilisNo ratings yet

- West Bengal TourismDocument6 pagesWest Bengal TourismJoseph Subham MondalNo ratings yet

- Natural Selection Lab ReportDocument6 pagesNatural Selection Lab Reportapi-272576393No ratings yet

- Location: Today Igbo-Speaking Individuals Live All Over Nigeria and in DiverseDocument26 pagesLocation: Today Igbo-Speaking Individuals Live All Over Nigeria and in DiverseStan CNo ratings yet

- Advances in Scanning Force Microscopy For Dimensional MetrologyDocument38 pagesAdvances in Scanning Force Microscopy For Dimensional MetrologyDiana Alejandra Bermudez FajardoNo ratings yet

- Xlathlete Wingate Pro Hockey Combine Prep WorkoutDocument5 pagesXlathlete Wingate Pro Hockey Combine Prep WorkoutNigel MH Adrian ManobandaNo ratings yet

- Xerox Wc423 SMDocument600 pagesXerox Wc423 SMkerintNo ratings yet

- A Crisis Intervention Model For Child Protective S PDFDocument22 pagesA Crisis Intervention Model For Child Protective S PDFKali HartvigsenNo ratings yet

- RCI Root Cause InvestigationDocument24 pagesRCI Root Cause InvestigationCarlos Jose Sibaja CardozoNo ratings yet

- Learning Pentaho Data Integration 8 CE - Third EditionDocument827 pagesLearning Pentaho Data Integration 8 CE - Third EditionRobson Cardoso100% (4)